Joanna Cosgrove, Contributing Editor04.28.16

Simplicity may be a predominant packaging trend but there’s no denying the timeless appeal of metal packaging and metallized accents. The most obvious quality of metal packaging is its gleam, but there’s also a tangibility factor that makes it uniquely engaging with consumers. Its weight in the hand conveys an ultra-high-end sensibility, and it’s initially cool but warms to the touch. Whether used as classic refined accents or show-stopping focal pieces, metal and metallized packaging componentry exudes a chic allure and an instant sense of luxury—for both prestige and mass brands.

A touch of metal was the solution for Tatcha, a premium “modern-day Geisha”—inspired skin care brand. Last year, founder Victoria Tsai decided to add the first of two lipsticks to the line. She sought a package that emulated the beauty, craftsmanship and heritage associated with Japanese culture.

Tatcha’s Kyoto Red Silk Lipstick is housed in a subtly elegant zamac lipstick case designed by Tatcha and executed by HCT Group. “The Tatcha shiny gold logo plaques on the cover and base were created by embossing electroplated zamac, which created a luxurious contrast with the deep, rich black e-coating of the body,” says Jackie Paterno, HCT Group’s director of sales.

This spring, Tatcha tweaked the lipstick case to launch a second, limited edition color, Plum Blossom. “For this edition, Tatcha went with a white e-coating which gave a polished, porcelain appearance and a soothing cool feel to the touch,” Paterno says, adding that the shade paired beautifully with the light and airy pink plum blossom lip color. “Choosing zamac over plastic gave the package such a luxurious feel. The weight, cool touch and porcelain appearance really provided this package with its own unique charm.”

Based in France, Pochet is renowned for its packaging work with iconic French brands. Mathieu Pivaudran, director of communications for the Pochet Goup and director of marketing and creation for Solev and Pochet du Courval, explains that the company utilizes a variety of techniques to execute the prestige look of metal on a package. Its methods range from traditional yet innovatively executed gold leaf metallizing, which was used to accent a recent Nina Ricci fragrance, to a new robotized vacuum metallization line for “big market” glass and plastic packaging.

The Pochet Group recently worked in concert to produce the packaging for two additional fragrances. For Christian Dior’s Sauvage de Dior fragrance, Pochet used a liquid metallization technique to control transparency and gradation on a glass bottle produced by Pochet du Courval that features metallic, steel blue shaded lacquering, implemented by Solev.

The bottle base is subtly engraved with the CD logo, which is also echoed on the cap. “Executed by Qualipac, the cap is made of aluminum with a magnetic closing system, automatically repositioning the logo to line up with the CD logo on the base and the screen printing on the front and back of the bottle,” says Pivaudran. “The luxurious detail that completes the ensemble is the emblematic “CD” that can be deciphered in both directions on the glass as well as on the metal.”

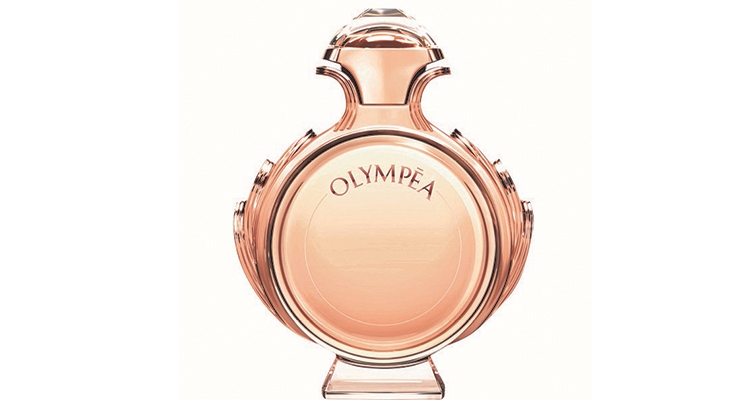

For Olympea by Paco Rabanne, the Pochet Group began with a technically complex bottle shape from Pochet du Courval and turned it over to Solev, which embellished the bottle with smooth, rose gold-embossed laurel leaves. “[This] metallization technique [was] achieved by hiding the sides and base of the bottle,” he says.

The rose gold shade is also featured on the bottle’s collar and cap (produced by Qualipac). “The cap boasts a cast-molded zamac base with a Surlyn resin dome resting on top of it, giving a harmonious finish to the ensemble,” he says.

The Estée Lauder brand turned to Badalona, Spain-based Virospack when it sought a special dropper for its Re-Nutriv Ultimate Lift skin care product. “Ultimate Lift is an excellent cosmetic presented in a premium dropper that transmits the selective image of the brand,” says Rosa Porras, Virospack’s marketing and communication manager. “It’s a push button dropper with an innovative actuator shape like a ‘syringe dropper’ that transmits to the customer the effect of Botox, but without the injection.

“In this case, both elements—the shell and also the button—are metallized,” she continues, noting both pieces were metallized in different colors, increasing the difficulty to get the premium result requested by Estée Lauder. “The shape is metallized in gold and the button in onyx, [while] the bottle has a metal shell too, but in this element, in silver aluminum.”

Virospack recently debuted a new process of metallizing the rubber bulb of droppers without sacrificing the elasticity of the bulb material. “With this finish, brands get a premium presentation [and] a high visual impact resulting from subtle shines, light reflections and the mirror effect that the metallization offers,” she says. “Metallized bulbs could be colored in the always elegant gold or silver, or in quartz pink, or in red, green or fuchsia, to match partner components.”

Metal for the Masses

Metal may look pricey–and some treatments are–but the truth is, metal isn’t just for prestige brands anymore. Mass brands are incorporating other types of metal detailing to add high-end appeal to their packaging. Some of the greatest advancements among metallized packaging suppliers have been related to the increased ease in making metal accessible to mass brands.

For instance, Coverpla USA, Long Island City, NY, offers a wide variety of stock metal caps in stock to give both niche and mass brands more budget-friendly options and shorter lead-times. “Most of these caps are available in shiny gold and shiny silver but we also have some in matte and glossy black, gunmetal, matte silver or gold,” says the company’s Gilda Cutri, national sales manager. She continues that Coverpla just added the new ‘Edge’ cap to its popular zamac options and launched a new, patterned aluminum cap at the end of March as well.

Metal tubes and tins are another great way for brands to add sparkle to their product lineup. Not only are finishes, designs and deco options practically unlimited, metal tubes and tins also offer the added bonus of protecting sensitive ingredients—a plus for delicate formulations.

“Our airless tube deluxe in Polyfoil is all about shiny brightness, stunning tactiles and hot stamping,” says Monika Rüegg, strategic market projects leader for Switzerland-based Hoffman Neopac. The tube is accented with “Polyfoil fascinating gloss” and uses Aptar metal pumps.

In addition to its tube lineup, Hoffman Neopac additionally launched customized TinCaps earlier this year. The metallized caps are fully decorated, including embossing/debossing options for tubes, jars and bottles.

The company also debuted a metal tin with soft-touch coating for the wound-care brand Hansaplast. “Its look and touch is much more individual and luxurious than a standard carton or plastic box,” Rüegg explains. “The refill box is highly resistant, and easy to open and carry around. It protects the plasters (or bandages) from humidity and builds a nice ‘accessory’ for travels.”

Metallized Papers and Foiling

The use of metallized paper and paperboard can do a lot for a standard beauty or personal care packaging design. For starters, it lends an air of premiumization. “Metallized silver and holographic papers and paperboards allow beauty and personal care packaging to stand out on the shelf as a premium high value product,” says Wendy Cross, national accounts manager, AR Metallizing Ltd., Franklin, MA. “Metallized packaging in many independent tests repeatedly demonstrates consumer’s perception of high-end luxury which gets noticed first and holds attention longer.”

Metallized papers and paperboards also enable brands to communicate about sustainability. “It is plastic-free; in other words, it is a compostable and recyclable alternative to films and plastics in packaging,” she says. “Companies can utilize or continue to utilize metallized and holographic luxury packaging, but now have the benefit of a package that helps improve their stewardship to the environment and any commitments they may have to lower their landfill waste.”

A unique feature to metallized paper-based products is the stiffness and strength provided to laminated board, allowing brands to opt for lighter weight and alternative boards. Another advantage is its ability to fold and adhere with less glue and memory. Both features deliver cost-efficiency without sacrificing design aesthetic, according to Cross.

AR Metallizing is prepping the launch of a new line of metallized silver and holographic paperboard products called “SilberBoard,” with two options specifically developed for the beauty and cosmetics market: SilberBoard UltraShine and SilberBoard Whiteback.

“SilberBoard UltraShine is a high-gloss packaging solution,” Cross explains. “SilberBoard WhiteBack enables brands in the beauty segment to optimize branding and communication strategies. Due to the printable backside, this packaging solution offers brands extensive design and marketing possibilities.”

John Rebecchi, senior vice president, marketing and business development, DISC, Hauppauge, NY, asserts there have been significant advances in foil decorating techniques for folding cartons over the past several years. Leading the field is cold foil, an in-line process of applying foil during the printing operation, a process he breaks down into stages. “In the first unit of the printing press, a UV curable adhesive is applied with a printing plate in the areas we want to foil,” he says. “In the second print unit, a specialized device is mounted to the press with a foil delivery reel and takeaway reels for the unused foil and carrier.

“The foil is pressed against the sheet in this unit and sticks only to the adhesive; the rest is pulled away for recycling,” he explains. “The adhesive and foil combination passes under UV lights to instantly cure it to the paper. The result is a precise application of foil that is in register to the adjacent printed areas, or can be printed over to create any number of colors.”

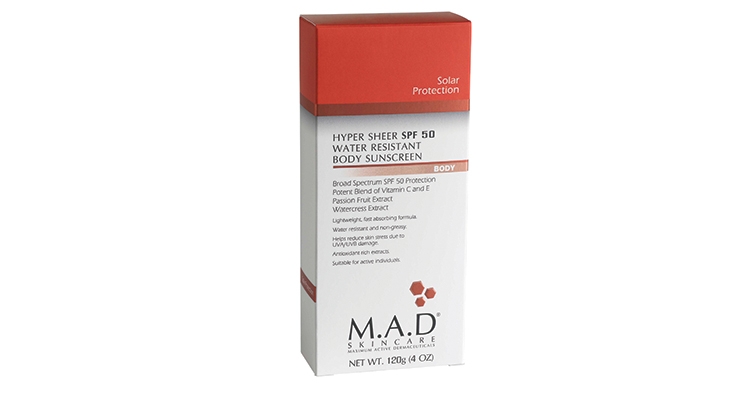

Cold foiling can be worked in solid, gradients, half tones, fine reverse copy or fine type. “The results of this application are virtually impossible to achieve with hot stamping or using metallized laminated paperboard without the addition of an opaque white to cover up unwanted foil,” Rebecci says. “We are seeing it used in a variety of personal care products including the M.A.D. Skincare and eclipse solar moisturizer body lotion with sunscreen.”

Conversely, he adds, hot foil stamping remains a staple of carton decorating because it provides an exceptionally smooth surface and can be combined with embossing in a single operation. Pigment foils can be used, which can’t be done in the cold foil process.

April Lytle, marketing coordinator, Kurz Transfer Products, L.P., Charlotte, NC, agrees and asserts that as technology emerges, foil decoration is also a great option for brand authentication and communication. “A decorated logo, QR code, serial code or authenticating hologram (OVD) can be scanned and linked to a customized smart phone application, enabling the brand owner to benefit from a wide variety of functional and marketing objectives,” she says, noting that one of the most successful strategies high-end brands are using to add appeal is to coordinate their primary and secondary packaging through decorative and visually engaging foil usage.

As an example, Lytle points to Kurz’s Deep Lens makeup box, featuring the Kurz Deep Lens registered single image OVD. Compared to laminates, she says, Deep Lens designs offer more flexibility in the selection of substrates and in design, and can be directly linked to Kurz’s Brand Enhancement program. “The designs are applied separately and emphasize selective penetrating features,” she says. “This box was printed in four-color offset and was hot stamped with the Deep Lens and Alufin Satingloss foils.”

Kurz’s offers a handful of foil options germane to cosmetic and personal care brands. Digital Metal enables brands to marry foil with digital printing for secondary packaging in much the same way as they would design with cold foil, but at a fraction of the cost. Additionally, the company’s digital heat transfer process eliminates the ceiling of design possibilities because designs can include fine lines, gradients, endless color possibilities as well as customized variable data for large or small volumes. And finally Kurz’s new in-line foiling process, designed specifically for bottles and tubes, features advanced edge definition not previously found, along with surface quality and over-printability with over-varnish capabilities for achieving custom color.

“Rarely has a brand owner remained unconvinced of the very effective cost/value ratio in foil decoration,” Lytle concludes. “Quite simply, foil ‘sells’ and when viewed from the perspective of increased sales and market share, the incremental cost of foil decoration is really quite reasonable.”

There’s a metallizing movement afoot that involves brands taking control and bringing the process under their own roof.

“Many companies source their metallizing overseas, primarily in China,” says Tony Denning, president, Tapematic USA Inc., Orlando, FL. “Combined with the production runs and shipping costs etc., companies are realizing that taking full control of their metallizing in-house is economical, environmental and making turnaround times an advantage.”

Denning says there are some general considerations that companies should consider before selecting metallizing equipment. “To produce a metallized effect on an object is not as simple as selecting a company that manufacturers metallizers as a lot of other factors/equipment is required,” he stresses. Tapematic offers a complete production line for metallizing which consists of an auto-loading, pre-treatment station, base coating, metallizing, top coat, Hi-Dev quality inspection, and auto off load, all in a single continuously running line that is fully enclosed in a HEPA system.

The PST Line is positioned as a way for brands to improve their idea-to-marketplace time and is hallmarked by its user-friendly controls and full, in-line automation. This cost-effective equipment offers full process control of the complete system), less waste and with minimum VOCs. It can also flexibly use many metals or metal alloys (e.g. aluminum, chromium, titanium, stainless steel) as sputtering materials.

A touch of metal was the solution for Tatcha, a premium “modern-day Geisha”—inspired skin care brand. Last year, founder Victoria Tsai decided to add the first of two lipsticks to the line. She sought a package that emulated the beauty, craftsmanship and heritage associated with Japanese culture.

Tatcha’s Kyoto Red Silk Lipstick is housed in a subtly elegant zamac lipstick case designed by Tatcha and executed by HCT Group. “The Tatcha shiny gold logo plaques on the cover and base were created by embossing electroplated zamac, which created a luxurious contrast with the deep, rich black e-coating of the body,” says Jackie Paterno, HCT Group’s director of sales.

This spring, Tatcha tweaked the lipstick case to launch a second, limited edition color, Plum Blossom. “For this edition, Tatcha went with a white e-coating which gave a polished, porcelain appearance and a soothing cool feel to the touch,” Paterno says, adding that the shade paired beautifully with the light and airy pink plum blossom lip color. “Choosing zamac over plastic gave the package such a luxurious feel. The weight, cool touch and porcelain appearance really provided this package with its own unique charm.”

Based in France, Pochet is renowned for its packaging work with iconic French brands. Mathieu Pivaudran, director of communications for the Pochet Goup and director of marketing and creation for Solev and Pochet du Courval, explains that the company utilizes a variety of techniques to execute the prestige look of metal on a package. Its methods range from traditional yet innovatively executed gold leaf metallizing, which was used to accent a recent Nina Ricci fragrance, to a new robotized vacuum metallization line for “big market” glass and plastic packaging.

The Pochet Group recently worked in concert to produce the packaging for two additional fragrances. For Christian Dior’s Sauvage de Dior fragrance, Pochet used a liquid metallization technique to control transparency and gradation on a glass bottle produced by Pochet du Courval that features metallic, steel blue shaded lacquering, implemented by Solev.

The bottle base is subtly engraved with the CD logo, which is also echoed on the cap. “Executed by Qualipac, the cap is made of aluminum with a magnetic closing system, automatically repositioning the logo to line up with the CD logo on the base and the screen printing on the front and back of the bottle,” says Pivaudran. “The luxurious detail that completes the ensemble is the emblematic “CD” that can be deciphered in both directions on the glass as well as on the metal.”

For Olympea by Paco Rabanne, the Pochet Group began with a technically complex bottle shape from Pochet du Courval and turned it over to Solev, which embellished the bottle with smooth, rose gold-embossed laurel leaves. “[This] metallization technique [was] achieved by hiding the sides and base of the bottle,” he says.

The rose gold shade is also featured on the bottle’s collar and cap (produced by Qualipac). “The cap boasts a cast-molded zamac base with a Surlyn resin dome resting on top of it, giving a harmonious finish to the ensemble,” he says.

The Estée Lauder brand turned to Badalona, Spain-based Virospack when it sought a special dropper for its Re-Nutriv Ultimate Lift skin care product. “Ultimate Lift is an excellent cosmetic presented in a premium dropper that transmits the selective image of the brand,” says Rosa Porras, Virospack’s marketing and communication manager. “It’s a push button dropper with an innovative actuator shape like a ‘syringe dropper’ that transmits to the customer the effect of Botox, but without the injection.

“In this case, both elements—the shell and also the button—are metallized,” she continues, noting both pieces were metallized in different colors, increasing the difficulty to get the premium result requested by Estée Lauder. “The shape is metallized in gold and the button in onyx, [while] the bottle has a metal shell too, but in this element, in silver aluminum.”

Virospack recently debuted a new process of metallizing the rubber bulb of droppers without sacrificing the elasticity of the bulb material. “With this finish, brands get a premium presentation [and] a high visual impact resulting from subtle shines, light reflections and the mirror effect that the metallization offers,” she says. “Metallized bulbs could be colored in the always elegant gold or silver, or in quartz pink, or in red, green or fuchsia, to match partner components.”

Metal for the Masses

Metal may look pricey–and some treatments are–but the truth is, metal isn’t just for prestige brands anymore. Mass brands are incorporating other types of metal detailing to add high-end appeal to their packaging. Some of the greatest advancements among metallized packaging suppliers have been related to the increased ease in making metal accessible to mass brands.

For instance, Coverpla USA, Long Island City, NY, offers a wide variety of stock metal caps in stock to give both niche and mass brands more budget-friendly options and shorter lead-times. “Most of these caps are available in shiny gold and shiny silver but we also have some in matte and glossy black, gunmetal, matte silver or gold,” says the company’s Gilda Cutri, national sales manager. She continues that Coverpla just added the new ‘Edge’ cap to its popular zamac options and launched a new, patterned aluminum cap at the end of March as well.

Metal tubes and tins are another great way for brands to add sparkle to their product lineup. Not only are finishes, designs and deco options practically unlimited, metal tubes and tins also offer the added bonus of protecting sensitive ingredients—a plus for delicate formulations.

“Our airless tube deluxe in Polyfoil is all about shiny brightness, stunning tactiles and hot stamping,” says Monika Rüegg, strategic market projects leader for Switzerland-based Hoffman Neopac. The tube is accented with “Polyfoil fascinating gloss” and uses Aptar metal pumps.

In addition to its tube lineup, Hoffman Neopac additionally launched customized TinCaps earlier this year. The metallized caps are fully decorated, including embossing/debossing options for tubes, jars and bottles.

The company also debuted a metal tin with soft-touch coating for the wound-care brand Hansaplast. “Its look and touch is much more individual and luxurious than a standard carton or plastic box,” Rüegg explains. “The refill box is highly resistant, and easy to open and carry around. It protects the plasters (or bandages) from humidity and builds a nice ‘accessory’ for travels.”

Metallized Papers and Foiling

The use of metallized paper and paperboard can do a lot for a standard beauty or personal care packaging design. For starters, it lends an air of premiumization. “Metallized silver and holographic papers and paperboards allow beauty and personal care packaging to stand out on the shelf as a premium high value product,” says Wendy Cross, national accounts manager, AR Metallizing Ltd., Franklin, MA. “Metallized packaging in many independent tests repeatedly demonstrates consumer’s perception of high-end luxury which gets noticed first and holds attention longer.”

Metallized papers and paperboards also enable brands to communicate about sustainability. “It is plastic-free; in other words, it is a compostable and recyclable alternative to films and plastics in packaging,” she says. “Companies can utilize or continue to utilize metallized and holographic luxury packaging, but now have the benefit of a package that helps improve their stewardship to the environment and any commitments they may have to lower their landfill waste.”

A unique feature to metallized paper-based products is the stiffness and strength provided to laminated board, allowing brands to opt for lighter weight and alternative boards. Another advantage is its ability to fold and adhere with less glue and memory. Both features deliver cost-efficiency without sacrificing design aesthetic, according to Cross.

AR Metallizing is prepping the launch of a new line of metallized silver and holographic paperboard products called “SilberBoard,” with two options specifically developed for the beauty and cosmetics market: SilberBoard UltraShine and SilberBoard Whiteback.

“SilberBoard UltraShine is a high-gloss packaging solution,” Cross explains. “SilberBoard WhiteBack enables brands in the beauty segment to optimize branding and communication strategies. Due to the printable backside, this packaging solution offers brands extensive design and marketing possibilities.”

John Rebecchi, senior vice president, marketing and business development, DISC, Hauppauge, NY, asserts there have been significant advances in foil decorating techniques for folding cartons over the past several years. Leading the field is cold foil, an in-line process of applying foil during the printing operation, a process he breaks down into stages. “In the first unit of the printing press, a UV curable adhesive is applied with a printing plate in the areas we want to foil,” he says. “In the second print unit, a specialized device is mounted to the press with a foil delivery reel and takeaway reels for the unused foil and carrier.

“The foil is pressed against the sheet in this unit and sticks only to the adhesive; the rest is pulled away for recycling,” he explains. “The adhesive and foil combination passes under UV lights to instantly cure it to the paper. The result is a precise application of foil that is in register to the adjacent printed areas, or can be printed over to create any number of colors.”

Cold foiling can be worked in solid, gradients, half tones, fine reverse copy or fine type. “The results of this application are virtually impossible to achieve with hot stamping or using metallized laminated paperboard without the addition of an opaque white to cover up unwanted foil,” Rebecci says. “We are seeing it used in a variety of personal care products including the M.A.D. Skincare and eclipse solar moisturizer body lotion with sunscreen.”

Conversely, he adds, hot foil stamping remains a staple of carton decorating because it provides an exceptionally smooth surface and can be combined with embossing in a single operation. Pigment foils can be used, which can’t be done in the cold foil process.

April Lytle, marketing coordinator, Kurz Transfer Products, L.P., Charlotte, NC, agrees and asserts that as technology emerges, foil decoration is also a great option for brand authentication and communication. “A decorated logo, QR code, serial code or authenticating hologram (OVD) can be scanned and linked to a customized smart phone application, enabling the brand owner to benefit from a wide variety of functional and marketing objectives,” she says, noting that one of the most successful strategies high-end brands are using to add appeal is to coordinate their primary and secondary packaging through decorative and visually engaging foil usage.

As an example, Lytle points to Kurz’s Deep Lens makeup box, featuring the Kurz Deep Lens registered single image OVD. Compared to laminates, she says, Deep Lens designs offer more flexibility in the selection of substrates and in design, and can be directly linked to Kurz’s Brand Enhancement program. “The designs are applied separately and emphasize selective penetrating features,” she says. “This box was printed in four-color offset and was hot stamped with the Deep Lens and Alufin Satingloss foils.”

Kurz’s offers a handful of foil options germane to cosmetic and personal care brands. Digital Metal enables brands to marry foil with digital printing for secondary packaging in much the same way as they would design with cold foil, but at a fraction of the cost. Additionally, the company’s digital heat transfer process eliminates the ceiling of design possibilities because designs can include fine lines, gradients, endless color possibilities as well as customized variable data for large or small volumes. And finally Kurz’s new in-line foiling process, designed specifically for bottles and tubes, features advanced edge definition not previously found, along with surface quality and over-printability with over-varnish capabilities for achieving custom color.

“Rarely has a brand owner remained unconvinced of the very effective cost/value ratio in foil decoration,” Lytle concludes. “Quite simply, foil ‘sells’ and when viewed from the perspective of increased sales and market share, the incremental cost of foil decoration is really quite reasonable.”

There’s a metallizing movement afoot that involves brands taking control and bringing the process under their own roof.

“Many companies source their metallizing overseas, primarily in China,” says Tony Denning, president, Tapematic USA Inc., Orlando, FL. “Combined with the production runs and shipping costs etc., companies are realizing that taking full control of their metallizing in-house is economical, environmental and making turnaround times an advantage.”

Denning says there are some general considerations that companies should consider before selecting metallizing equipment. “To produce a metallized effect on an object is not as simple as selecting a company that manufacturers metallizers as a lot of other factors/equipment is required,” he stresses. Tapematic offers a complete production line for metallizing which consists of an auto-loading, pre-treatment station, base coating, metallizing, top coat, Hi-Dev quality inspection, and auto off load, all in a single continuously running line that is fully enclosed in a HEPA system.

The PST Line is positioned as a way for brands to improve their idea-to-marketplace time and is hallmarked by its user-friendly controls and full, in-line automation. This cost-effective equipment offers full process control of the complete system), less waste and with minimum VOCs. It can also flexibly use many metals or metal alloys (e.g. aluminum, chromium, titanium, stainless steel) as sputtering materials.