Jamie Matusow, Editor-in-Chief12.04.17

Ask those in the beauty community what the word “Innovation” means, and you’re likely to get a diverse range of responses, broader than ever before. But with the word holding the cachet that everyone’s looking for, its use continues to captivate. And indeed, there are many valid developments in the beauty world—packaging, products and services—that deserve this crowning descriptor.

Indie brands have taken the concept further, adding distinct stories embodied, envisioned and formulated by their founders. Many of these products, which also appeal to Millennials’ values, tell a sustainability tale and often, an ethically and/or socially charged one as well.

Ultimately, “innovation” in the beauty sector comes down to how suppliers, brands and consumers interpret and broadcast “newness” in everything from formulations to applicators to presentations. While “true innovation” may be difficult to achieve, examples of “creative differentiation” abound.

Innovation’s Interpretations

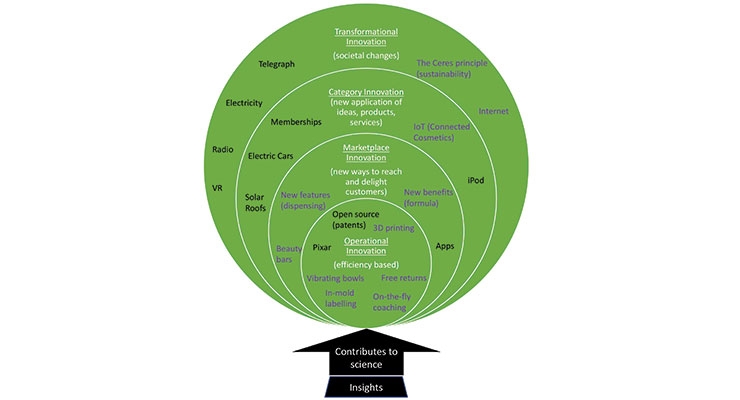

From a “true innovation” perspective, Marisol Simard, president, dandelion clocks, a consulting firm focused on business growth through innovation strategies and creative team dynamics for the beauty industry, tells Beauty Packaging: “Unfortunately for many companies today, the word ‘innovation’ seems to have lost its meaning.” She believes that to deliver strategic growth, it is critical for the beauty community and its brands to deeply understand both innovation (sustainable growth) and “creative differentiation” (short-lived growth) solutions. (Please refer to Simard’s diagram)

“To be considered an innovation,” explains Simard, “a solution must not only be unique, valuable and worthy of exchange, it must also contribute to science, and comprise patentable concepts. The latter is the main distinction with ‘creative differentiation’ which consists of clever and new ways to use available technologies in more trendy, irresistible, sensorial configurations.”

Simard says, “While our industry is strongly influenced by Transformational (e.g, Sustainability) and Category (e.g, IoT) Innovations, most of the time these societal changes and new application ideas originate outside of our category.” She notes that the most visible beauty brands’ innovation contributions fall into the third Innovation tier, Marketplace Innovation, related to reaching and delighting consumers via formula, dispensing systems, applicator breakthroughs and more. Less visible, but also vital, says Simard, is the efficiency-based contributions to science devised in the fourth innovation tier, the Operational Innovation.

Changing the Consumer Experience

Philip Tarrant, leader, Packaging Concept Development, Coty, has a wider view. “To me,” says Tarrant, “innovation can be as simple as changing the consumer experience.” For example, he cites Coty’s new Covergirl mascara (produced by Albéa) that was designed with the ergonomics of the user in mind. He says, “It features a bi-injected soft touch cap for precision and control, along with edge-to-edge hot stamping on the bottle and cap to complete the look.”

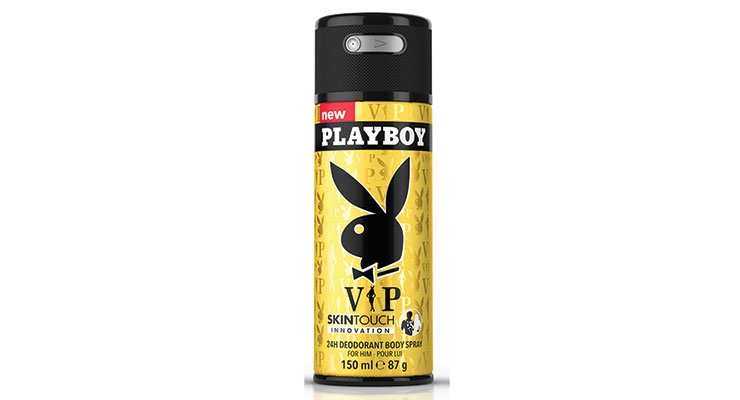

Another example is Coty’s Playboy Skin Touch deodorant that was redesigned from a traditional aerosol valve and over cap, to a premium looking, lockable spray-through cap. “Not only did this redesign change the consumer experience, it also was a significant reduction in plastic,” says Tarant.

Ethical Positioning: A New Way to Evaluate Purchases

More than ever, packaging has become a billboard for messaging the consumer through creative words as well as through distinct features.

Dr. Benjamin Punchard, global packaging insights director, Mintel, tells Beauty Packaging, innovation continues to be product led, “but the important role for packaging in both delivery and information/support hasn’t been forgotten.” He says, “Packaging gives the brand the vehicle it needs to provide claims and ingredient information, but more importantly it is finding its role in providing an opportunity to tell a broader story.” For example, says Punchard, soft-touch packing can relieve stress, colors can be mood-enhancing and smart technologies can provide a multi-layered product experience. “Increasingly, he says, “we are seeing smarter use of these packaging structural elements to support brand positioning.”

Punchard explains, “This is important when you consider that within Beauty, the story of the product is becoming the star feature.” One trend Mintel has observed, according to Punchard, is the growing importance of ethical positioning, particularly social ethics, focusing on people, aligning a brand with both those who work for it and who buy it. This, he says, is about empowerment of suppliers, employees, local communities, etc. He explains, “This sits well with consumers; for example, 49% of UK consumers consider how ethical a personal care and beauty company is before they buy its products.”

Punchard points to The Soap Co., as a good example of this trend. Describing itself as “an ethical luxury brand that makes products that are good and do good,” The Soap Co. is committed to employing blind, disabled and disadvantaged people, who represent 80% of its workforce. However, supporting the vision-impaired is its primary aim. “To clearly communicate this positioning, underline its empathy and create great in-store stand out, the front of pack features labels printed in braille,” explains Punchard.

Another example cited by Punchard is Thankyou. This brand uses 100% of profits to help get safe water, hygiene and sanitation services to people in need. Again, the packaging has a clear and important role, says Punchard, “firstly to communicate this positioning in store with bold simple packs that put the Thankyou message front and center.” He says this provides the user with a “virtue signaling opportunity” (e.g, ensuring this clear thank you message is seen by friends and family who use the guest bathroom). Also, each pack is printed with a unique code to enable the shopper to see where their money is being spent, and the specific projects they are supporting.

No surprise, another Mintel observation, according to Punchard: “We’ve seen brands waking up to the power of social media. Every brand wants to replicate what Starbucks did with the Unicorn Frappuccino, which became a sensation on Twitter, Instagram, etc. For brands, many are realizing that providing interactive and engaging packaging is a route to creating a ‘shareable’ or ‘Instagram ready’ moment.”

According to Anna Lombardi, director of marketing, Lombardi Design & Manufacturing, innovation comes into play with “a growing emphasis on customizable beauty items.” She says consumers are looking to invest in products that are not only good for their personal regime, but from a packaging perspective, they want to feel that it is all their own. From a development standpoint, says Lombardi, “The lines between a brand’s marketing strategy and product design are beginning to merge. This is something we have started implementing through emerging brands and turnkey opportunities. It is a very exciting time in the industry and it will be interesting to witness how this trend continues to evolve.”

As marketing strategy and design merge, “thinking outside the components” on the operational level, has also become a must for suppliers as they innovate in areas of quality, customer service and speed to market.

At Decotech, Richard Engel, Jr., president/COO, says flexibility is critical in offering customers creative solutions—especially with the growing emphasis on speed to market. He says the trend has been for smaller launch quantities and shorter lead times. Because of the direction the consumer market has taken, he says brands are more risk averse and massive launches planned 18 months out are becoming a thing of the past. Brands are also launching regionally rather than globally. “It is not uncommon to see multi-billion dollar companies start with a 25,000-piece launch and chase into a good sell-through with rapid, short lead-time reorders,” says Engel, adding “the complexity of the decoration has not changed, so now you have difficult decoration that has to be delivered with less lead time.”

Engel says flexibility has been the key to their success as a supplier in this environment. “At Decotech,” says Engel, “we can run large-scale launches when they do occur, and we are also able to run smaller launches and reorders quickly and efficiently. Brands need to identify local suppliers with all types of equipment that can handle fast-turnaround orders from large to small quantities. That’s what Decotech does best.”

With customer service key to success, IBC Shell Packaging has introduced VIVALDI (www.ibcshell.com/vivaldi). Norman Kay, CEO, IBC Shell Packaging, says “The Global Enterprise Client Packaging Portal delivers strategic, innovative, equity-building design, development and project management for packaging, products, and branded giftware—on schedule, on budget, and with maximum impact at market.” What’s more,” says Kay, “VIVALDI Progressive Development is the neoteric path to optimal accelerated packaging execution, and it’s provided at no additional cost to IBC Shell clients.”

Kay explains: “The VIVALDI portal is an elegant, radically novel approach to design, development, and management of luxury packaging initiatives. Its comprehensive scope and detail eliminates the complexity that erodes the vitality of projects.”

Across the Board Creativity

The suppliers and brands Beauty Packaging spoke with for this article illustrate many of the issues and trends which Simard and Punchard have addressed. Following are innovative cosmetic industry packaging examples ranging from revelations to revolutions, new gestures to new concepts—and creativity throughout.

Brainstorming Cosmetic Solutions

Makeup, from eye products to foundation, has continued to grow at astronomical levels over the last several years, with numerous innovations ranging from formulations to applicators to packaging.

At HCT Group, Denis Maurin, VP of sales and industrial innovation, speaks to the trends, saying, “These days, we’re seeing cosmetics becoming more skincare enhanced, creating an excitingly new hybrid range between the two categories of makeup and skincare. What that means for us in terms of packaging is the need to create sophisticated concepts that are highly protective of sensitive formulas without driving up the cost of these goods.”

That being said, Maurin explains, “Our main inspiration is coming from high-end skincare packaging, as we develop ways to simplify these designs and create a more ergonomic package that can be easily incorporated into anyone’s daily makeup routine.”

While brands want products launched quicker and more efficiently, Maurin says, “It’s our job to keep up with their needs without losing any steam when it comes to innovation and creativity. Luckily for us we are able to adapt by evolving our engineering/construction skills to develop a faster producing product. Another key focus for us in producing creative products quickly is decoration, and we continue to find new, innovatively efficient processes to create some of our most challenging decorations. Also, we find it productive to always keep a close eye on what’s going on outside our own four walls, finding new technologies used among different industries and adapting them to the world of cosmetics.”

One of HCT Group’s recent branded innovations was for Hourglass. “We are very excited this year about having launched the Hourglass Confession Ultra Slim High Intensity Refillable Lipstick,” says Maurin. “This component mixes an aluminum cap with a zamac base, delivering a beautifully luxurious finish. As “an innovative bonus to the consumer,”

Maurin explains that the lipstick was made to be refillable to aid in its affordability.

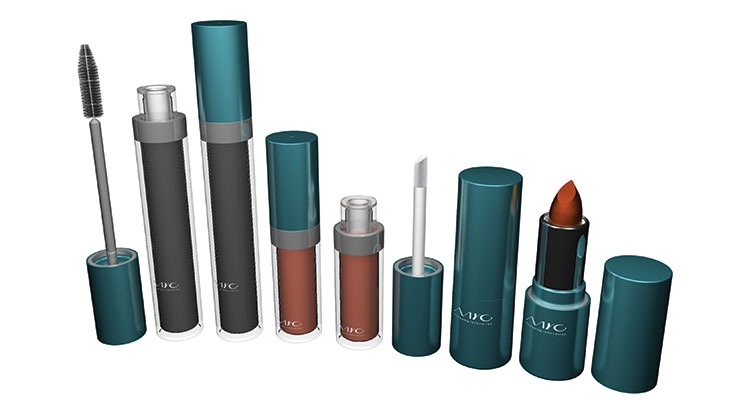

Speed to market is an essential element in product innovation at MYC Packaging, where Andrea Perego, director of innovation, says, “The simplified digital world has changed the way we live, communicate, inform and consume.”

She tells Beauty Packaging: “The consumers ask their brands for new ideas and products with a dynamic that significantly reduces the time-to-market. The new lifestyle requires packaging that is able to communicate values of user-friendly experience and quality of the product itself.” Perego says customization is a strategic element to stand out from the market and the formulations are more and more sophisticated and require a package that guarantees their integrity. The key elements of innovation trends, she says, are personalization, design, new delivery systems and new materials.

Perego says MYC works to anticipate their customers’ needs, exploring new technical and industrial opportunities, “conceiving the perfect package in line with the upcoming marketing strategies affecting the final consumers.”

MYC offers solutions for both solvent and water-based products with “demanding” formulas, including standard airtight products. The supplier is also now launching its patented Airtight & Magnetic line, with mascara and lipgloss packaging. Also new is the Performing System Collection, packaging that MYC Innovation created based on the needs of consumers who are looking for an HD makeup experience. Perego says, “We believe the Performing Collection, with its fully customizable shape, with different combinations of heads and applicators, will meet more demanding customers’ expectations.”

At World Wide Packaging (WWP), Jim Farley, EVP global business development, tells Beauty Packaging they’re seeing “continued demand for unique delivery systems and product application, in compacts and lipsticks—and a growing demand for various eye applications.” He explains that eye stamps, cat eye shapes and newly configured eye liners are very popular.”

WWP recently debuted Lash 180°, an ergonomic patented brush, that Farley says “challenges the ordinary and creates an innovative solution to wide eye and messy mascara application.” Shaped like a triangle and designed to be held vertically, the brush styles eyelashes 180° making it simple to lengthen, curl, define and volumize with one swipe.

Unique Packaging for Competitive Skincare

With brands eager to launch new and numerous standout products quickly, economically and efficiently, Farley says, “Clients are more apt to modify a stock package with a modestly unique twist in light of timing and speed to market as opposed to greenfield designs.”

For instance, WWP was challenged with providing a unique delivery system for StriVectin’s Advanced Acid. The supplier utilized a standard offering that was customized with specialty graphics and metallization. Farley says, “Our dual chamber pumps allow for the precise mixture of two serums to be dispensed as one, for maximum performance.”

Englewood Lab, known for their innovative skincare formulations, has entered the Color Cosmetics category—and is merging the two into striking new products. For ease of launch and speed to market—and to maintain the quality—the supplier is providing more turnkey solutions than in the past.

David Chung, founder and CEO, Englewood Lab, tells Beauty Packaging: “There is definitely a trend for brands to want turnkey capabilities when it comes to creating a product. From choosing the right ingredients and creating an innovative formula, to determining the ideal packaging that will provide the best efficacy and stand out on the shelf, brands want to work with one company to make the process quick, seamless and integrated.”

He says other trends include the drive for packaging innovation to blend seamlessly with new formulation concepts including multi-sensorial formulations that transform, new anti-pollution/blue light protection ingredients, and probiotics. “Englewood Lab is also seeing packaging trends that involve dual-action elements and digital interplay,” says Chung.

Most important, Chung says, “is for all teams to work together to make sure each element fits within the puzzle. It’s important to consider the packaging as part of the overall product development process and think ahead about the product’s method of dispensing and how that can help overcome potential compatibility issues.”

Chung says Farmacy’s Honey Potion Mask (developed by Englewood Lab) is a great example that speaks to formulation and packing working together for a great product experience.

“Farmacy’s Honey Potion Mask ash wood magnetic cap helps the metal spatula used to apply the luxurious self-warming mask to stay in place, keeping it always at hand and never lost,” explains Chung. “The spatula is essential in the application process due to the unique anhydrous formulation and can easily get lost in traditional packaging. We needed to develop a unique, thoughtful way to combine the two elements in a design that was beautiful, luxurious and functional.”

One of La Prairie’s latest sensational skincare products features packaging to match. Greg Prodromides, the luxury brand’s chief marketing officer, says, “Skin Caviar Absolute Filler was designed to answer women’s most demanding needs. Inside the beautiful object, La Prairie has developed an innovative airless pump system that preserves the formula from the environment.”

A simple press of the sleek inverted button releases the perfect dose of cream for a complete face and neck application.” The lid opens to reveal the inverted button. At MakeUp in NewYork, Hana Packaging displayed the beautiful jar, saying they had designed, developed and produced the complete package. They added that it was “a new, very different technology” that they could not yet reveal.

Clarins continues to evolve its high-end skincare products and packaging. The brand’s new anti-aging Double Serum features a unique Hydric + Lipidic System—two separate phases—which mix together upon application. The unique pushbutton system automatically delivers just the right amount of each phase (2/3 water-based ingredients and 1/3 oil-based ones), and lets the user customize the amount of product according to her skin’s needs, the climate or season.

Antoine de Beaumesnil, packaging development manager, Clarins, tells Beauty Packaging, “For the next generation of Double Serum, we were really committed to developing an exclusive futurist-shaped bottle, loyal to Clarins’ core value—innovation. This high-tech packaging perfectly embodies Clarins’ philosophy and allows the brand to continue being a leader in the beauty industry.”

de Beaumesnil says after four years of work, they are proud to introduce the “innovative and exclusive packaging.” It is also an overall eco-responsible product, he says, using recycled material for 10% of the packaging, reducing the outer packaging, and optimizing supply chain steps.

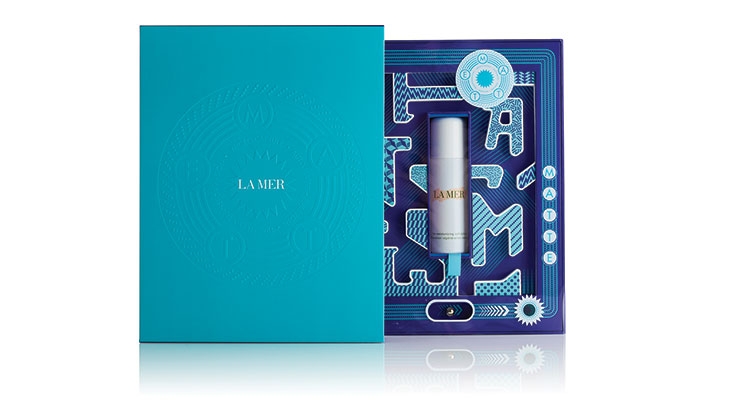

For the world’s dedicated La Mer fans, there’s something particularly special—and playful—about the brand’s recently released Moisturizing Matte Lotion. Not only does this lotion promise to “intensely nourish and smooth skin,” it comes housed in a limited edition, strikingly different, interactive box, designed by the La Mer team and manufactured by MW Packaging.

Inspired by vintage pinball machines and Chinese puzzle boxes, this innovative pack is comprised of a rigid board outer sleeve wrapped in matte paper, and a main box which, when slid out, reveals a playable labyrinth. The labyrinth walls were constructed from EVA foam in the shape of the letters M, A, T, T and E. Printed card stock was used to top the lettering, and a small recess was included to hold the ball bearing used to navigate the maze.

Delicate detailing can be found everywhere: in the blind embossed “M.A.T.T.E.” acronym on the outer sleeve, the color-matched ribbon attachment which allows the user to remove the lotion, and the concealed magnet holding the ball bearing in place. For ultimate peace of mind, the entire pack is also wrapped in a clear acetate security sleeve.

Dustin Wills, managing director of the Americas, MW Luxury Packaging, tells Beauty Packaging: “The intent was to get this package into the hands of ‘influencers’ across the globe who can promote this new brand launch either by word of mouth, Instagram, Snapchat, Facebook, blogs or any of the multiple ways that influencers are changing the way brands advertise and reach consumers, especially Millennials.”

He says, “In the last year, La Mer has gone from ‘dipping a toe’ into influencer packaging to diving in head first and leading the industry in innovation, design and budgets allocated to influencer packaging.”

What started out as a pinball machine evolved into “a much more fun, interactive package.” Wills says there were many challenging aspects and timing associated with the package. He says the most challenging is “the highly aggressive magnet that holds the metal ball suspended in the middle of the die cut cavity at the bottom. The other major challenge was the registration of the large and intricate die cut EVA foam and the printed, die cut top card on top of the EVA foam.”

Why does this stand out among other packages in the beauty arena? Wills says, “It’s never been done before like this. The reveal of the high-quality yet standard slipcase on the outside of the pack reveals a surprise to the customer when they open it up to a fully functioning maze and metal ball.”

Skincare-Smart Packaging

Lumson is introducing another way to delight customers via packaging. Matteo Moretti, Lumson’s CEO tells Beauty Packaging: “We are experiencing an increasingly higher demand for packaging featuring shoplifting protection and anti-counterfeiting technology, to deal with one of the most common problems in the cosmetic market.”

To meet these market needs, Lumson now offers a patent-pending solution, thanks to the cutting-edge MET, which stands for Microchip Embedded Technology for its Airless System packaging.

Moretti explains that the NFC system (Near Field Communication) makes it possible to develop a chip that can communicate with a smartphone and tablet. The technology supplies wireless connectivity at short range, to provide the final customer with all the customizable info she or he expects about the product, not only as far as anti-counterfeiting, but also as a complete overview of its production chain, recyclability and more—all with the simple touch of a Smartphone. Everything is communicated, without space limitations or burdensome labels.

A Twist on Caps & Closures

Magnets have been a growing attraction for cosmetic packages such as lipsticks and compacts, but Virospack has now taken their ease of use and satisfying click to new heights—and a never-before-use and new gesture for luxury skincare packaging and application. It’s a new concept of dropper, according to Vicenç Rodriguez, Virospack’s CEO: an innovative dispenser dropper pack with a magnetic sealing system.

Rodriguez says the breakthrough came via a commitment to service and innovation and a strong investment in R&D. He explains: “The development was fully realized by the technical team of Virospack, and offers innovation and technology, accompanied as always with quality, functionality and personalization.”

He describes the patented dropper, with an exclusive closing system, as a “trendsetter in cosmetic packaging,” due to its technology, expertise, engineering, development, sealing, attraction, power, waterproofness, safety, usability, image and magnetism.

The bulb dropper with magnetic closure system and “perfect sealing feel” is comprised of two pieces that contain “a multitude of components for an innovative, functional, safe and of course, customizable final result.”

Gustavo Bay, Virospack’s development leader, technical department, describes the unique closure system as “an exclusive and patented system of magnetic attraction of two poles, without the need to twist for opening and closing the pack, avoiding screw necks.” He says the innovative packaging development—from technical, marketing and usage points of view—consists of a dropper and a clip-on bezel that fits all FEA15 vials, one of the most common bottlenecks in cosmetics.

Both components can be decorated with different techniques for a personalized magnetic dropper. The dropper has two components that are both provided with one magnet of four poles, which produce an attraction with each other to achieve the closing of the dropper with the vial, and in the case of the opening, with a simple rotation of the dropper with respect to the vial, the poles with the same magnetic charge are found, and cause the dropper to separate from the vial without applying a great effort.

The two standard components are the dropper (visible by a cap that can be painted or metallized, plus a pipette and rubber bulb); and the neck cover (which is beveled and separate from its “shoulder-cover” function of the vial, and also acts as a wiper for the dropper pipette). It is customizable, since the visible part consists of two pieces, the aluminum cover and the plastic collar-drainer, and can be metallized or injected in any color. Available in two cover designs, this magnetic dropper also adapts to bottles of various designs such as squares or cylinders.

Lombardi Design & Manufacturing also created a unique closure—a “pull-cap” that is an applicator and closure in one assembled part. The supplier was challenged by Clinique to engineer their rendering of what was to become Clinique’s Pep-Start Eye Cream. Married to a tube provided by Albéa, Lombardi’s Pull-Cap, combined as an applicator and closure, seals when closed, and becomes an applicator when open.

According to Anna Lombardi, the Pep-Start Eye Cream applicator/closure was an example of the supplier’s engineering expertise in part design and “our knowledge of maximizing the characteristics of advanced resins.” The ball and outer cap parts were a specially designated co-polyester for clarity and structure.

There seems to always be an exciting edge to packaging from TNT Global Manufacturing, and their latest cap for Jean Paul Gaultier’s Scandal fragrance, from Puig, illustrates the supplier’s technical know-how in product development and quality.

“It was a real technical challenge that TNT Global Manufacturing took up to meet Puig’s requirements to make this zamac cap in one piece,” says Toby Cattermole, CEO, TNT Global Manufacturing Hong Kong, “and we were the ones to meet this challenge.” The beautiful electroplated champagne gold cap—two legs in the air—is the result of a complex production process in zamac die casting, according to Cattermole. He says it “took no less than three slide-cams to unmold the raw piece, followed by a complicated polishing process to erase all parting lines, including areas difficult to access.” He says TNT Global Manufacturing did not hesitate to invest heavily in a dedicated auto-polishing line to achieve an output of 80,000 units per week. Inside the cap too, “the quest for perfection was met.” Cattermole says the PP liner “is clipped inside a groove avoiding any visible crimping pin, while ensuring a mechanical fitting, preferred to glue.”

“We have a principle which is ‘best-perceived value/price ratio, and delivered on time,” says Xavier Leboucher, development packaging Prestige/Premium and innovation director at Puig. “For this great cap produced by TNT Global Manufacturing, we wanted it to be authentic and qualitative, so we went for zamac. Our engineers worked in co-development with TNT Global Manufacturing to fine tune the process and achieve a very special request: to make the die-casted piece in one metal component, despite the complicated legs design with many undercuts.” He adds: “This was important for two reasons: First to lower the price (less assembly) but also to ensure perfect color matching.”

Dispensing That Makes Sense

After years of what Aveda describes as “innovation in the polypropylene recycling arena,” the environmentally responsible brand that espouses Planet-Respecting Packaging, says it has reached “a milestone in sustainable packaging.” The longtime pioneer of utilizing post-consumer recycled (PCR) content, recently introduced a polypropylene dispensing tube closure with PCR content. It will make its debut in early 2018, phasing in as a new package for Enlightener Creme Booster, part of Aveda’s hair color category.

Following two years of trials and testing, the Enlightener Creme Booster tube will utilize a dispensing closure with 25% PCR content. After a successful rollout of this closure in early 2018, Aveda will pursue a closure with higher PCR content, in an effort to “never stop taking things to the next level.”

According to Deb Darling, director Packaging Materials & Innovations Initiatives at Aveda, “Determining the appropriate percentage of PCR content to integrate into a dispensing, hinged closure, or any packaging component for that matter, requires time intensive resources, molding trials and testing.” She says, “Aveda took on this concentrated goal 100 percent because the result aligns with the Aveda Mission of caring for the world we live in. We aim to commercialize packaging innovations that reflect our high-quality standards as we strive to set an example for environmental leadership and responsibility.”

This current achievement is the latest milestone in Aveda’s many years of dedication in the polypropylene recycling arena. In 2011, following the momentum of its successful “Recycle Caps with Aveda” program, Aveda and their partners, KW Plastics, Montebello Packaging and CCL Industries tube division, began to include PCR content in non-dispensing, hair color and sampling tube closures. The desire to reach beyond non-dispensing caps took hold, and shortly thereafter, Aveda began development work on a dispensing closure that would utilize PCR content.

Yonwoo/PKG saw a need for a new type of dispenser and created one. According to Curt Altmann, marketing director, loose powder dispensing is a big trend in the Korean and Asian markets. He says, “Innovation is essential in the Asian markets because the consumer is more conditioned to seek newness in these markets than the western markets. So marketers have to learn to do custom innovation in a development time as quick as seven months.”

An example of one of these innovations is one that Yonwoo/PKG launched this year: a powder spray which gives the consumer ease of application for SPF powder and dry shampoo. Altmann says this innovation can also be adapted to face color applications.

When Size, Cost and Impact Matter

In 2017, Blisspack, a Seoul, South Korea-based supplier of packaging and equipment—and a leading supplier of blister packaging, filling and OEM products to the Chinese, Korean and Japanese health & beauty markets—began to introduce its unique product line to the U.S. market by working with the En Vogue Consulting Group. Jonathan Needham, president of En Vogue, says, “Blisspack is the innovative future of blister packaging.”

Needham tells Beauty Packaging, “The health and beauty industry appears to be moving in two marketing directions. First, to minimize packaging materials to reduce cost and create more sustainable packaging; second, to introduce smaller sizes (unit and multi dose) of more innovative packages to support sustainable packaging efforts, reduce manufacturing costs and most important, to provide more affordable entry level products to consumers.”

Along these lines, Needham says Blisspack has developed the “next” generation of blister-formed packaging, which allows multiple uses of complex products such as mascara, lipgloss and eyeliners. These products can now be produced in a low-cost package using the latest in barrier materials and utilizing the customer’s unique brush/applicator and wiper system. It adds up to “a unique blend of blister packaging, injection molding and customer designed components.”

Blisspack is unique, says Needham, because it is a packaging supplier but also an equipment manufacturer (creating all its own proprietary equipment and molds), a manufacturer of OEM/turnkey products and product innovator with extensive R&D resources. One example of its innovative capabilities is a “3D filling” process (full-size packages, including jars), which allows the creation of complex shapes using products. Another example is the patented process of “freeze dried” products and raw materials. The freeze-dried technology allows the creation of very unique products such as eye shadows and lipgloss, with the advantage of being preservative-free formulas.

Looking Ahead

Moving forward, what will the descriptor “innovative packaging” come to define?

Mintel’s Punchard predicts, “Technology is going to have an increasing impact on beauty packaging.” He explains that this will be due to a number of consumer needs and desires.

“For example,” says Punchard, “sustainable energy is an important topic that will extend into beauty packaging with sensorial benefits, to impact on wellbeing or even absorb energy from the environment and enhance the consumer experience.” He explains that while electronic circuits used to be big, bulky and expensive to produce, the advent of “printed electronics” has been a game-changer, allowing electronic circuits to be added to products that are slim and flexible. Even inkjet printers are now capable of producing electronic circuits. According to Punchard, the applications for this technology include flexible screens, smart labels and packaging—and even textiles. “The market is yet to catch up with the abundance of practical applications for printed electronic circuits,” says Punchard, “but there are plenty of opportunities for new skincare devices and wearables that can link to packaging to ensure the best use of a product and provide reassurance on product use and efficacy.”

Another innovative packaging driver, says Punchard, is the need to provide experiential marketing. Traditional marketing isn’t cutting it anymore. He says consumers are seeking out new and unique brand experiences—many want to be impressed and surprised by brands.

According to Mintel’s report American Lifestyles: Finding Common Ground – US, April 2017, 57% of consumers say they want brands to surprise them by offering unexpected goods/services.

Punchard says experiential marketing is bringing consumers campaigns and initiatives that are sparking emotions and engaging their senses on a deeper level. “Many brands are using VR and AR to offer an interactive sensory experience that makes consumers feel like they’re transported to and exploring a new place.” He cites Burt’s Bees, which launched a 360-degree experience called Burt’s Nature, which takes customers through the brand founder’s cabin in rural Maine. “Packaging has an important role in being either the platform for virtual reality content, or the signpost to direct the user to such content,” says Punchard. “These unique and immersive experiences are helping brands boost engagement and strengthen customer relationships. These experiences are serving as a way to create ongoing experiences with target audiences, which is helping build customer loyalty. It’s also boosting brand visibility, widening customer reach, and increasing sales.”

Finally, Punchard says the environment “is as important as ever but consumer attention is turning to the sea.” He points to the Ellen MacArthur foundation research, which estimates that by 2050 the amount of plastic in the sea will be the same as the amount of fish. As such, Punchard says we’re seeing ocean plastic (material recovered from the marine environment and made back into packaging) going from a niche area to mainstream adoption (such as with P&G’s Head & Shoulders bottles).

“Going forward,” predicts Punchard, “consumers’ interest in the circular economy as a way of keeping plastics out of the sea will drive a renewed interest in recycling. Much of the beauty packaging focus on protecting contents through airless packaging and innovative dispensing will now need to be supported by novel packaging technologies that keep these product protection levels (as consumers will not countenance a return to the days of using preservatives), but enable simple and efficient recycling.

Written by Steve Corsi, director of design development & innovation, Roberts Beauty

Roberts Beauty was recently recognized by students at the Fashion Institute of Technology for “Best Packaging Innovation” at MakeUp in NewYork. Our winning Spring Eyeliner Pen is a result of our open collaboration innovation program which constantly seeks to reinvent the cosmetic packaging experience.

While traditional flow-through eyeliner pens can be made to work very well with formulas that have little variance in capillary action, when it comes to formulas with particulates, flow is often sporadic, leading to a disappointing end user experience.

We wanted to provide the usability experience of our flow-through pens while delivering the exciting formulas offered by inkwell bottles. Our solution was to start with a bottle and simulate the pen-like application by incorporating a sleeve that auto-slides to cover the wand, allowing it to be gripped like a pen for precise line work. The auto-sliding sleeve is housed within an enlarged cap and drops as the cap is removed from the bottle.

The key idea came in a brainstorming session, from Jacky Gunter our VP of operations, and went through three design iterations and two focus group sessions before we finally found the perfect balance of proportion, ergonomics and fill.

Once we shared the innovation with key accounts, more feedback led us to refine further; for example, in one meeting we learned that we needed to control removal of the bottle so that it cannot suddenly eject when opening the package. Working in collaboration with our world class manufacturing partner Ying Shuo in Shanghai, we solved this issue by developing a clutching function engineered into the wiper to ensure a slow release.

This year’s Pentawards’ ‘Best of Show’ recognition was given to Philippe Starck Perfumes for a range of three very distinctive, artfully designed and produced flacons colored in pink, green and gray tones. With the collection of three perfumes—feminine, masculine and neutral—the concept was to create three distinct and independent designs that when together, both as bottles and in packaging, would interlink to form one sculpture. Speaking about the products, the world-renowned designer said: “I have tried to make the minimum around, trying to make the bottles like a clue, to make people understand that something is hidden inside, that there is a mystery.”

The glass supplier is Bormioli Luigi. Olga Bursac, VP sales, Bormioli Luigi, says what’s unique and innovative about these, is “the pristine glass quality, attention to glass tolerances as well as those in the particular decoration, since the line-up of the three bottles had to have perfect symmetry between the glass and the decoration, in order to have the seamless flow of the three separate flavors ending in one perfectly formed Starck wrench, when the three bottles are lined up together.”

Indie brands have taken the concept further, adding distinct stories embodied, envisioned and formulated by their founders. Many of these products, which also appeal to Millennials’ values, tell a sustainability tale and often, an ethically and/or socially charged one as well.

Ultimately, “innovation” in the beauty sector comes down to how suppliers, brands and consumers interpret and broadcast “newness” in everything from formulations to applicators to presentations. While “true innovation” may be difficult to achieve, examples of “creative differentiation” abound.

Innovation’s Interpretations

From a “true innovation” perspective, Marisol Simard, president, dandelion clocks, a consulting firm focused on business growth through innovation strategies and creative team dynamics for the beauty industry, tells Beauty Packaging: “Unfortunately for many companies today, the word ‘innovation’ seems to have lost its meaning.” She believes that to deliver strategic growth, it is critical for the beauty community and its brands to deeply understand both innovation (sustainable growth) and “creative differentiation” (short-lived growth) solutions. (Please refer to Simard’s diagram)

“To be considered an innovation,” explains Simard, “a solution must not only be unique, valuable and worthy of exchange, it must also contribute to science, and comprise patentable concepts. The latter is the main distinction with ‘creative differentiation’ which consists of clever and new ways to use available technologies in more trendy, irresistible, sensorial configurations.”

Simard says, “While our industry is strongly influenced by Transformational (e.g, Sustainability) and Category (e.g, IoT) Innovations, most of the time these societal changes and new application ideas originate outside of our category.” She notes that the most visible beauty brands’ innovation contributions fall into the third Innovation tier, Marketplace Innovation, related to reaching and delighting consumers via formula, dispensing systems, applicator breakthroughs and more. Less visible, but also vital, says Simard, is the efficiency-based contributions to science devised in the fourth innovation tier, the Operational Innovation.

Changing the Consumer Experience

Philip Tarrant, leader, Packaging Concept Development, Coty, has a wider view. “To me,” says Tarrant, “innovation can be as simple as changing the consumer experience.” For example, he cites Coty’s new Covergirl mascara (produced by Albéa) that was designed with the ergonomics of the user in mind. He says, “It features a bi-injected soft touch cap for precision and control, along with edge-to-edge hot stamping on the bottle and cap to complete the look.”

Another example is Coty’s Playboy Skin Touch deodorant that was redesigned from a traditional aerosol valve and over cap, to a premium looking, lockable spray-through cap. “Not only did this redesign change the consumer experience, it also was a significant reduction in plastic,” says Tarant.

Ethical Positioning: A New Way to Evaluate Purchases

More than ever, packaging has become a billboard for messaging the consumer through creative words as well as through distinct features.

Dr. Benjamin Punchard, global packaging insights director, Mintel, tells Beauty Packaging, innovation continues to be product led, “but the important role for packaging in both delivery and information/support hasn’t been forgotten.” He says, “Packaging gives the brand the vehicle it needs to provide claims and ingredient information, but more importantly it is finding its role in providing an opportunity to tell a broader story.” For example, says Punchard, soft-touch packing can relieve stress, colors can be mood-enhancing and smart technologies can provide a multi-layered product experience. “Increasingly, he says, “we are seeing smarter use of these packaging structural elements to support brand positioning.”

Punchard explains, “This is important when you consider that within Beauty, the story of the product is becoming the star feature.” One trend Mintel has observed, according to Punchard, is the growing importance of ethical positioning, particularly social ethics, focusing on people, aligning a brand with both those who work for it and who buy it. This, he says, is about empowerment of suppliers, employees, local communities, etc. He explains, “This sits well with consumers; for example, 49% of UK consumers consider how ethical a personal care and beauty company is before they buy its products.”

Punchard points to The Soap Co., as a good example of this trend. Describing itself as “an ethical luxury brand that makes products that are good and do good,” The Soap Co. is committed to employing blind, disabled and disadvantaged people, who represent 80% of its workforce. However, supporting the vision-impaired is its primary aim. “To clearly communicate this positioning, underline its empathy and create great in-store stand out, the front of pack features labels printed in braille,” explains Punchard.

Another example cited by Punchard is Thankyou. This brand uses 100% of profits to help get safe water, hygiene and sanitation services to people in need. Again, the packaging has a clear and important role, says Punchard, “firstly to communicate this positioning in store with bold simple packs that put the Thankyou message front and center.” He says this provides the user with a “virtue signaling opportunity” (e.g, ensuring this clear thank you message is seen by friends and family who use the guest bathroom). Also, each pack is printed with a unique code to enable the shopper to see where their money is being spent, and the specific projects they are supporting.

No surprise, another Mintel observation, according to Punchard: “We’ve seen brands waking up to the power of social media. Every brand wants to replicate what Starbucks did with the Unicorn Frappuccino, which became a sensation on Twitter, Instagram, etc. For brands, many are realizing that providing interactive and engaging packaging is a route to creating a ‘shareable’ or ‘Instagram ready’ moment.”

According to Anna Lombardi, director of marketing, Lombardi Design & Manufacturing, innovation comes into play with “a growing emphasis on customizable beauty items.” She says consumers are looking to invest in products that are not only good for their personal regime, but from a packaging perspective, they want to feel that it is all their own. From a development standpoint, says Lombardi, “The lines between a brand’s marketing strategy and product design are beginning to merge. This is something we have started implementing through emerging brands and turnkey opportunities. It is a very exciting time in the industry and it will be interesting to witness how this trend continues to evolve.”

As marketing strategy and design merge, “thinking outside the components” on the operational level, has also become a must for suppliers as they innovate in areas of quality, customer service and speed to market.

At Decotech, Richard Engel, Jr., president/COO, says flexibility is critical in offering customers creative solutions—especially with the growing emphasis on speed to market. He says the trend has been for smaller launch quantities and shorter lead times. Because of the direction the consumer market has taken, he says brands are more risk averse and massive launches planned 18 months out are becoming a thing of the past. Brands are also launching regionally rather than globally. “It is not uncommon to see multi-billion dollar companies start with a 25,000-piece launch and chase into a good sell-through with rapid, short lead-time reorders,” says Engel, adding “the complexity of the decoration has not changed, so now you have difficult decoration that has to be delivered with less lead time.”

Engel says flexibility has been the key to their success as a supplier in this environment. “At Decotech,” says Engel, “we can run large-scale launches when they do occur, and we are also able to run smaller launches and reorders quickly and efficiently. Brands need to identify local suppliers with all types of equipment that can handle fast-turnaround orders from large to small quantities. That’s what Decotech does best.”

With customer service key to success, IBC Shell Packaging has introduced VIVALDI (www.ibcshell.com/vivaldi). Norman Kay, CEO, IBC Shell Packaging, says “The Global Enterprise Client Packaging Portal delivers strategic, innovative, equity-building design, development and project management for packaging, products, and branded giftware—on schedule, on budget, and with maximum impact at market.” What’s more,” says Kay, “VIVALDI Progressive Development is the neoteric path to optimal accelerated packaging execution, and it’s provided at no additional cost to IBC Shell clients.”

Kay explains: “The VIVALDI portal is an elegant, radically novel approach to design, development, and management of luxury packaging initiatives. Its comprehensive scope and detail eliminates the complexity that erodes the vitality of projects.”

Across the Board Creativity

The suppliers and brands Beauty Packaging spoke with for this article illustrate many of the issues and trends which Simard and Punchard have addressed. Following are innovative cosmetic industry packaging examples ranging from revelations to revolutions, new gestures to new concepts—and creativity throughout.

Brainstorming Cosmetic Solutions

Makeup, from eye products to foundation, has continued to grow at astronomical levels over the last several years, with numerous innovations ranging from formulations to applicators to packaging.

At HCT Group, Denis Maurin, VP of sales and industrial innovation, speaks to the trends, saying, “These days, we’re seeing cosmetics becoming more skincare enhanced, creating an excitingly new hybrid range between the two categories of makeup and skincare. What that means for us in terms of packaging is the need to create sophisticated concepts that are highly protective of sensitive formulas without driving up the cost of these goods.”

That being said, Maurin explains, “Our main inspiration is coming from high-end skincare packaging, as we develop ways to simplify these designs and create a more ergonomic package that can be easily incorporated into anyone’s daily makeup routine.”

While brands want products launched quicker and more efficiently, Maurin says, “It’s our job to keep up with their needs without losing any steam when it comes to innovation and creativity. Luckily for us we are able to adapt by evolving our engineering/construction skills to develop a faster producing product. Another key focus for us in producing creative products quickly is decoration, and we continue to find new, innovatively efficient processes to create some of our most challenging decorations. Also, we find it productive to always keep a close eye on what’s going on outside our own four walls, finding new technologies used among different industries and adapting them to the world of cosmetics.”

One of HCT Group’s recent branded innovations was for Hourglass. “We are very excited this year about having launched the Hourglass Confession Ultra Slim High Intensity Refillable Lipstick,” says Maurin. “This component mixes an aluminum cap with a zamac base, delivering a beautifully luxurious finish. As “an innovative bonus to the consumer,”

Maurin explains that the lipstick was made to be refillable to aid in its affordability.

Speed to market is an essential element in product innovation at MYC Packaging, where Andrea Perego, director of innovation, says, “The simplified digital world has changed the way we live, communicate, inform and consume.”

She tells Beauty Packaging: “The consumers ask their brands for new ideas and products with a dynamic that significantly reduces the time-to-market. The new lifestyle requires packaging that is able to communicate values of user-friendly experience and quality of the product itself.” Perego says customization is a strategic element to stand out from the market and the formulations are more and more sophisticated and require a package that guarantees their integrity. The key elements of innovation trends, she says, are personalization, design, new delivery systems and new materials.

Perego says MYC works to anticipate their customers’ needs, exploring new technical and industrial opportunities, “conceiving the perfect package in line with the upcoming marketing strategies affecting the final consumers.”

MYC offers solutions for both solvent and water-based products with “demanding” formulas, including standard airtight products. The supplier is also now launching its patented Airtight & Magnetic line, with mascara and lipgloss packaging. Also new is the Performing System Collection, packaging that MYC Innovation created based on the needs of consumers who are looking for an HD makeup experience. Perego says, “We believe the Performing Collection, with its fully customizable shape, with different combinations of heads and applicators, will meet more demanding customers’ expectations.”

At World Wide Packaging (WWP), Jim Farley, EVP global business development, tells Beauty Packaging they’re seeing “continued demand for unique delivery systems and product application, in compacts and lipsticks—and a growing demand for various eye applications.” He explains that eye stamps, cat eye shapes and newly configured eye liners are very popular.”

WWP recently debuted Lash 180°, an ergonomic patented brush, that Farley says “challenges the ordinary and creates an innovative solution to wide eye and messy mascara application.” Shaped like a triangle and designed to be held vertically, the brush styles eyelashes 180° making it simple to lengthen, curl, define and volumize with one swipe.

Unique Packaging for Competitive Skincare

With brands eager to launch new and numerous standout products quickly, economically and efficiently, Farley says, “Clients are more apt to modify a stock package with a modestly unique twist in light of timing and speed to market as opposed to greenfield designs.”

For instance, WWP was challenged with providing a unique delivery system for StriVectin’s Advanced Acid. The supplier utilized a standard offering that was customized with specialty graphics and metallization. Farley says, “Our dual chamber pumps allow for the precise mixture of two serums to be dispensed as one, for maximum performance.”

Englewood Lab, known for their innovative skincare formulations, has entered the Color Cosmetics category—and is merging the two into striking new products. For ease of launch and speed to market—and to maintain the quality—the supplier is providing more turnkey solutions than in the past.

David Chung, founder and CEO, Englewood Lab, tells Beauty Packaging: “There is definitely a trend for brands to want turnkey capabilities when it comes to creating a product. From choosing the right ingredients and creating an innovative formula, to determining the ideal packaging that will provide the best efficacy and stand out on the shelf, brands want to work with one company to make the process quick, seamless and integrated.”

He says other trends include the drive for packaging innovation to blend seamlessly with new formulation concepts including multi-sensorial formulations that transform, new anti-pollution/blue light protection ingredients, and probiotics. “Englewood Lab is also seeing packaging trends that involve dual-action elements and digital interplay,” says Chung.

Most important, Chung says, “is for all teams to work together to make sure each element fits within the puzzle. It’s important to consider the packaging as part of the overall product development process and think ahead about the product’s method of dispensing and how that can help overcome potential compatibility issues.”

Chung says Farmacy’s Honey Potion Mask (developed by Englewood Lab) is a great example that speaks to formulation and packing working together for a great product experience.

“Farmacy’s Honey Potion Mask ash wood magnetic cap helps the metal spatula used to apply the luxurious self-warming mask to stay in place, keeping it always at hand and never lost,” explains Chung. “The spatula is essential in the application process due to the unique anhydrous formulation and can easily get lost in traditional packaging. We needed to develop a unique, thoughtful way to combine the two elements in a design that was beautiful, luxurious and functional.”

One of La Prairie’s latest sensational skincare products features packaging to match. Greg Prodromides, the luxury brand’s chief marketing officer, says, “Skin Caviar Absolute Filler was designed to answer women’s most demanding needs. Inside the beautiful object, La Prairie has developed an innovative airless pump system that preserves the formula from the environment.”

A simple press of the sleek inverted button releases the perfect dose of cream for a complete face and neck application.” The lid opens to reveal the inverted button. At MakeUp in NewYork, Hana Packaging displayed the beautiful jar, saying they had designed, developed and produced the complete package. They added that it was “a new, very different technology” that they could not yet reveal.

Clarins continues to evolve its high-end skincare products and packaging. The brand’s new anti-aging Double Serum features a unique Hydric + Lipidic System—two separate phases—which mix together upon application. The unique pushbutton system automatically delivers just the right amount of each phase (2/3 water-based ingredients and 1/3 oil-based ones), and lets the user customize the amount of product according to her skin’s needs, the climate or season.

Antoine de Beaumesnil, packaging development manager, Clarins, tells Beauty Packaging, “For the next generation of Double Serum, we were really committed to developing an exclusive futurist-shaped bottle, loyal to Clarins’ core value—innovation. This high-tech packaging perfectly embodies Clarins’ philosophy and allows the brand to continue being a leader in the beauty industry.”

de Beaumesnil says after four years of work, they are proud to introduce the “innovative and exclusive packaging.” It is also an overall eco-responsible product, he says, using recycled material for 10% of the packaging, reducing the outer packaging, and optimizing supply chain steps.

For the world’s dedicated La Mer fans, there’s something particularly special—and playful—about the brand’s recently released Moisturizing Matte Lotion. Not only does this lotion promise to “intensely nourish and smooth skin,” it comes housed in a limited edition, strikingly different, interactive box, designed by the La Mer team and manufactured by MW Packaging.

Inspired by vintage pinball machines and Chinese puzzle boxes, this innovative pack is comprised of a rigid board outer sleeve wrapped in matte paper, and a main box which, when slid out, reveals a playable labyrinth. The labyrinth walls were constructed from EVA foam in the shape of the letters M, A, T, T and E. Printed card stock was used to top the lettering, and a small recess was included to hold the ball bearing used to navigate the maze.

Delicate detailing can be found everywhere: in the blind embossed “M.A.T.T.E.” acronym on the outer sleeve, the color-matched ribbon attachment which allows the user to remove the lotion, and the concealed magnet holding the ball bearing in place. For ultimate peace of mind, the entire pack is also wrapped in a clear acetate security sleeve.

Dustin Wills, managing director of the Americas, MW Luxury Packaging, tells Beauty Packaging: “The intent was to get this package into the hands of ‘influencers’ across the globe who can promote this new brand launch either by word of mouth, Instagram, Snapchat, Facebook, blogs or any of the multiple ways that influencers are changing the way brands advertise and reach consumers, especially Millennials.”

He says, “In the last year, La Mer has gone from ‘dipping a toe’ into influencer packaging to diving in head first and leading the industry in innovation, design and budgets allocated to influencer packaging.”

What started out as a pinball machine evolved into “a much more fun, interactive package.” Wills says there were many challenging aspects and timing associated with the package. He says the most challenging is “the highly aggressive magnet that holds the metal ball suspended in the middle of the die cut cavity at the bottom. The other major challenge was the registration of the large and intricate die cut EVA foam and the printed, die cut top card on top of the EVA foam.”

Why does this stand out among other packages in the beauty arena? Wills says, “It’s never been done before like this. The reveal of the high-quality yet standard slipcase on the outside of the pack reveals a surprise to the customer when they open it up to a fully functioning maze and metal ball.”

Skincare-Smart Packaging

Lumson is introducing another way to delight customers via packaging. Matteo Moretti, Lumson’s CEO tells Beauty Packaging: “We are experiencing an increasingly higher demand for packaging featuring shoplifting protection and anti-counterfeiting technology, to deal with one of the most common problems in the cosmetic market.”

To meet these market needs, Lumson now offers a patent-pending solution, thanks to the cutting-edge MET, which stands for Microchip Embedded Technology for its Airless System packaging.

Moretti explains that the NFC system (Near Field Communication) makes it possible to develop a chip that can communicate with a smartphone and tablet. The technology supplies wireless connectivity at short range, to provide the final customer with all the customizable info she or he expects about the product, not only as far as anti-counterfeiting, but also as a complete overview of its production chain, recyclability and more—all with the simple touch of a Smartphone. Everything is communicated, without space limitations or burdensome labels.

A Twist on Caps & Closures

Magnets have been a growing attraction for cosmetic packages such as lipsticks and compacts, but Virospack has now taken their ease of use and satisfying click to new heights—and a never-before-use and new gesture for luxury skincare packaging and application. It’s a new concept of dropper, according to Vicenç Rodriguez, Virospack’s CEO: an innovative dispenser dropper pack with a magnetic sealing system.

Rodriguez says the breakthrough came via a commitment to service and innovation and a strong investment in R&D. He explains: “The development was fully realized by the technical team of Virospack, and offers innovation and technology, accompanied as always with quality, functionality and personalization.”

He describes the patented dropper, with an exclusive closing system, as a “trendsetter in cosmetic packaging,” due to its technology, expertise, engineering, development, sealing, attraction, power, waterproofness, safety, usability, image and magnetism.

The bulb dropper with magnetic closure system and “perfect sealing feel” is comprised of two pieces that contain “a multitude of components for an innovative, functional, safe and of course, customizable final result.”

Gustavo Bay, Virospack’s development leader, technical department, describes the unique closure system as “an exclusive and patented system of magnetic attraction of two poles, without the need to twist for opening and closing the pack, avoiding screw necks.” He says the innovative packaging development—from technical, marketing and usage points of view—consists of a dropper and a clip-on bezel that fits all FEA15 vials, one of the most common bottlenecks in cosmetics.

Both components can be decorated with different techniques for a personalized magnetic dropper. The dropper has two components that are both provided with one magnet of four poles, which produce an attraction with each other to achieve the closing of the dropper with the vial, and in the case of the opening, with a simple rotation of the dropper with respect to the vial, the poles with the same magnetic charge are found, and cause the dropper to separate from the vial without applying a great effort.

The two standard components are the dropper (visible by a cap that can be painted or metallized, plus a pipette and rubber bulb); and the neck cover (which is beveled and separate from its “shoulder-cover” function of the vial, and also acts as a wiper for the dropper pipette). It is customizable, since the visible part consists of two pieces, the aluminum cover and the plastic collar-drainer, and can be metallized or injected in any color. Available in two cover designs, this magnetic dropper also adapts to bottles of various designs such as squares or cylinders.

Lombardi Design & Manufacturing also created a unique closure—a “pull-cap” that is an applicator and closure in one assembled part. The supplier was challenged by Clinique to engineer their rendering of what was to become Clinique’s Pep-Start Eye Cream. Married to a tube provided by Albéa, Lombardi’s Pull-Cap, combined as an applicator and closure, seals when closed, and becomes an applicator when open.

According to Anna Lombardi, the Pep-Start Eye Cream applicator/closure was an example of the supplier’s engineering expertise in part design and “our knowledge of maximizing the characteristics of advanced resins.” The ball and outer cap parts were a specially designated co-polyester for clarity and structure.

There seems to always be an exciting edge to packaging from TNT Global Manufacturing, and their latest cap for Jean Paul Gaultier’s Scandal fragrance, from Puig, illustrates the supplier’s technical know-how in product development and quality.

“It was a real technical challenge that TNT Global Manufacturing took up to meet Puig’s requirements to make this zamac cap in one piece,” says Toby Cattermole, CEO, TNT Global Manufacturing Hong Kong, “and we were the ones to meet this challenge.” The beautiful electroplated champagne gold cap—two legs in the air—is the result of a complex production process in zamac die casting, according to Cattermole. He says it “took no less than three slide-cams to unmold the raw piece, followed by a complicated polishing process to erase all parting lines, including areas difficult to access.” He says TNT Global Manufacturing did not hesitate to invest heavily in a dedicated auto-polishing line to achieve an output of 80,000 units per week. Inside the cap too, “the quest for perfection was met.” Cattermole says the PP liner “is clipped inside a groove avoiding any visible crimping pin, while ensuring a mechanical fitting, preferred to glue.”

“We have a principle which is ‘best-perceived value/price ratio, and delivered on time,” says Xavier Leboucher, development packaging Prestige/Premium and innovation director at Puig. “For this great cap produced by TNT Global Manufacturing, we wanted it to be authentic and qualitative, so we went for zamac. Our engineers worked in co-development with TNT Global Manufacturing to fine tune the process and achieve a very special request: to make the die-casted piece in one metal component, despite the complicated legs design with many undercuts.” He adds: “This was important for two reasons: First to lower the price (less assembly) but also to ensure perfect color matching.”

Dispensing That Makes Sense

After years of what Aveda describes as “innovation in the polypropylene recycling arena,” the environmentally responsible brand that espouses Planet-Respecting Packaging, says it has reached “a milestone in sustainable packaging.” The longtime pioneer of utilizing post-consumer recycled (PCR) content, recently introduced a polypropylene dispensing tube closure with PCR content. It will make its debut in early 2018, phasing in as a new package for Enlightener Creme Booster, part of Aveda’s hair color category.

Following two years of trials and testing, the Enlightener Creme Booster tube will utilize a dispensing closure with 25% PCR content. After a successful rollout of this closure in early 2018, Aveda will pursue a closure with higher PCR content, in an effort to “never stop taking things to the next level.”

According to Deb Darling, director Packaging Materials & Innovations Initiatives at Aveda, “Determining the appropriate percentage of PCR content to integrate into a dispensing, hinged closure, or any packaging component for that matter, requires time intensive resources, molding trials and testing.” She says, “Aveda took on this concentrated goal 100 percent because the result aligns with the Aveda Mission of caring for the world we live in. We aim to commercialize packaging innovations that reflect our high-quality standards as we strive to set an example for environmental leadership and responsibility.”

This current achievement is the latest milestone in Aveda’s many years of dedication in the polypropylene recycling arena. In 2011, following the momentum of its successful “Recycle Caps with Aveda” program, Aveda and their partners, KW Plastics, Montebello Packaging and CCL Industries tube division, began to include PCR content in non-dispensing, hair color and sampling tube closures. The desire to reach beyond non-dispensing caps took hold, and shortly thereafter, Aveda began development work on a dispensing closure that would utilize PCR content.

Yonwoo/PKG saw a need for a new type of dispenser and created one. According to Curt Altmann, marketing director, loose powder dispensing is a big trend in the Korean and Asian markets. He says, “Innovation is essential in the Asian markets because the consumer is more conditioned to seek newness in these markets than the western markets. So marketers have to learn to do custom innovation in a development time as quick as seven months.”

An example of one of these innovations is one that Yonwoo/PKG launched this year: a powder spray which gives the consumer ease of application for SPF powder and dry shampoo. Altmann says this innovation can also be adapted to face color applications.

When Size, Cost and Impact Matter

In 2017, Blisspack, a Seoul, South Korea-based supplier of packaging and equipment—and a leading supplier of blister packaging, filling and OEM products to the Chinese, Korean and Japanese health & beauty markets—began to introduce its unique product line to the U.S. market by working with the En Vogue Consulting Group. Jonathan Needham, president of En Vogue, says, “Blisspack is the innovative future of blister packaging.”

Needham tells Beauty Packaging, “The health and beauty industry appears to be moving in two marketing directions. First, to minimize packaging materials to reduce cost and create more sustainable packaging; second, to introduce smaller sizes (unit and multi dose) of more innovative packages to support sustainable packaging efforts, reduce manufacturing costs and most important, to provide more affordable entry level products to consumers.”

Along these lines, Needham says Blisspack has developed the “next” generation of blister-formed packaging, which allows multiple uses of complex products such as mascara, lipgloss and eyeliners. These products can now be produced in a low-cost package using the latest in barrier materials and utilizing the customer’s unique brush/applicator and wiper system. It adds up to “a unique blend of blister packaging, injection molding and customer designed components.”

Blisspack is unique, says Needham, because it is a packaging supplier but also an equipment manufacturer (creating all its own proprietary equipment and molds), a manufacturer of OEM/turnkey products and product innovator with extensive R&D resources. One example of its innovative capabilities is a “3D filling” process (full-size packages, including jars), which allows the creation of complex shapes using products. Another example is the patented process of “freeze dried” products and raw materials. The freeze-dried technology allows the creation of very unique products such as eye shadows and lipgloss, with the advantage of being preservative-free formulas.

Looking Ahead

Moving forward, what will the descriptor “innovative packaging” come to define?

Mintel’s Punchard predicts, “Technology is going to have an increasing impact on beauty packaging.” He explains that this will be due to a number of consumer needs and desires.

“For example,” says Punchard, “sustainable energy is an important topic that will extend into beauty packaging with sensorial benefits, to impact on wellbeing or even absorb energy from the environment and enhance the consumer experience.” He explains that while electronic circuits used to be big, bulky and expensive to produce, the advent of “printed electronics” has been a game-changer, allowing electronic circuits to be added to products that are slim and flexible. Even inkjet printers are now capable of producing electronic circuits. According to Punchard, the applications for this technology include flexible screens, smart labels and packaging—and even textiles. “The market is yet to catch up with the abundance of practical applications for printed electronic circuits,” says Punchard, “but there are plenty of opportunities for new skincare devices and wearables that can link to packaging to ensure the best use of a product and provide reassurance on product use and efficacy.”

Another innovative packaging driver, says Punchard, is the need to provide experiential marketing. Traditional marketing isn’t cutting it anymore. He says consumers are seeking out new and unique brand experiences—many want to be impressed and surprised by brands.

According to Mintel’s report American Lifestyles: Finding Common Ground – US, April 2017, 57% of consumers say they want brands to surprise them by offering unexpected goods/services.

Punchard says experiential marketing is bringing consumers campaigns and initiatives that are sparking emotions and engaging their senses on a deeper level. “Many brands are using VR and AR to offer an interactive sensory experience that makes consumers feel like they’re transported to and exploring a new place.” He cites Burt’s Bees, which launched a 360-degree experience called Burt’s Nature, which takes customers through the brand founder’s cabin in rural Maine. “Packaging has an important role in being either the platform for virtual reality content, or the signpost to direct the user to such content,” says Punchard. “These unique and immersive experiences are helping brands boost engagement and strengthen customer relationships. These experiences are serving as a way to create ongoing experiences with target audiences, which is helping build customer loyalty. It’s also boosting brand visibility, widening customer reach, and increasing sales.”

Finally, Punchard says the environment “is as important as ever but consumer attention is turning to the sea.” He points to the Ellen MacArthur foundation research, which estimates that by 2050 the amount of plastic in the sea will be the same as the amount of fish. As such, Punchard says we’re seeing ocean plastic (material recovered from the marine environment and made back into packaging) going from a niche area to mainstream adoption (such as with P&G’s Head & Shoulders bottles).

“Going forward,” predicts Punchard, “consumers’ interest in the circular economy as a way of keeping plastics out of the sea will drive a renewed interest in recycling. Much of the beauty packaging focus on protecting contents through airless packaging and innovative dispensing will now need to be supported by novel packaging technologies that keep these product protection levels (as consumers will not countenance a return to the days of using preservatives), but enable simple and efficient recycling.

Written by Steve Corsi, director of design development & innovation, Roberts Beauty

Roberts Beauty was recently recognized by students at the Fashion Institute of Technology for “Best Packaging Innovation” at MakeUp in NewYork. Our winning Spring Eyeliner Pen is a result of our open collaboration innovation program which constantly seeks to reinvent the cosmetic packaging experience.

While traditional flow-through eyeliner pens can be made to work very well with formulas that have little variance in capillary action, when it comes to formulas with particulates, flow is often sporadic, leading to a disappointing end user experience.

We wanted to provide the usability experience of our flow-through pens while delivering the exciting formulas offered by inkwell bottles. Our solution was to start with a bottle and simulate the pen-like application by incorporating a sleeve that auto-slides to cover the wand, allowing it to be gripped like a pen for precise line work. The auto-sliding sleeve is housed within an enlarged cap and drops as the cap is removed from the bottle.

The key idea came in a brainstorming session, from Jacky Gunter our VP of operations, and went through three design iterations and two focus group sessions before we finally found the perfect balance of proportion, ergonomics and fill.

Once we shared the innovation with key accounts, more feedback led us to refine further; for example, in one meeting we learned that we needed to control removal of the bottle so that it cannot suddenly eject when opening the package. Working in collaboration with our world class manufacturing partner Ying Shuo in Shanghai, we solved this issue by developing a clutching function engineered into the wiper to ensure a slow release.

This year’s Pentawards’ ‘Best of Show’ recognition was given to Philippe Starck Perfumes for a range of three very distinctive, artfully designed and produced flacons colored in pink, green and gray tones. With the collection of three perfumes—feminine, masculine and neutral—the concept was to create three distinct and independent designs that when together, both as bottles and in packaging, would interlink to form one sculpture. Speaking about the products, the world-renowned designer said: “I have tried to make the minimum around, trying to make the bottles like a clue, to make people understand that something is hidden inside, that there is a mystery.”

The glass supplier is Bormioli Luigi. Olga Bursac, VP sales, Bormioli Luigi, says what’s unique and innovative about these, is “the pristine glass quality, attention to glass tolerances as well as those in the particular decoration, since the line-up of the three bottles had to have perfect symmetry between the glass and the decoration, in order to have the seamless flow of the three separate flavors ending in one perfectly formed Starck wrench, when the three bottles are lined up together.”