11.02.20

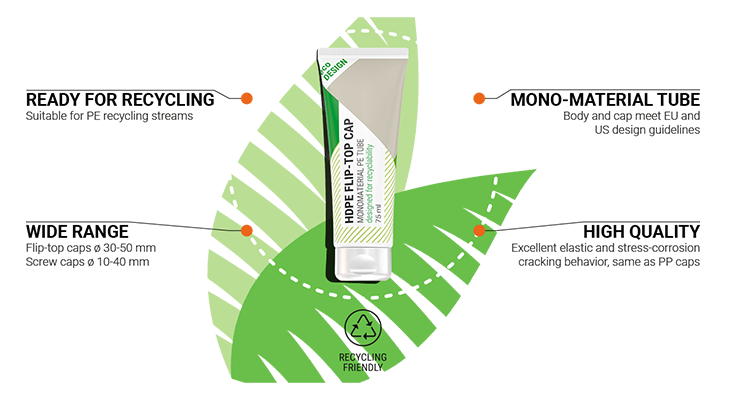

Hoffmann Neopac has introduced what they say is “the market’s first fully recyclable polyethylene-based tubes with high-density polyethylene (HDPE) flip-top caps.” The supplier calls this “a breakthrough in the worldwide push for packaging sustainability, as the mono-material tube + cap combination overcomes a longstanding functionality hurdle for hinged caps, which were previously made predominantly from less recyclable polypropylene (PP) materials.”

The new tube solutions are a packaging first, according to Neopac. They are fully recyclable tube solutions whose body, shoulder and caps are composed of a single-material family. Also available in screw-top formats, the new tubes are ideal for health & beauty, food and pharma packaging applications.

In existing recycling streams, mono-material plastic packaging is said to be more preferable than combination plastics, as its comparable simplicity is considered fully recyclable in mechanical recycling plants and therefore a key factor in moving toward a truly circular packaging landscape.

In addition to the new HDPE flip-top caps, Neopac also is launching a comprehensive portfolio of PE screw caps.

The new tube solutions are a packaging first, according to Neopac. They are fully recyclable tube solutions whose body, shoulder and caps are composed of a single-material family. Also available in screw-top formats, the new tubes are ideal for health & beauty, food and pharma packaging applications.

In existing recycling streams, mono-material plastic packaging is said to be more preferable than combination plastics, as its comparable simplicity is considered fully recyclable in mechanical recycling plants and therefore a key factor in moving toward a truly circular packaging landscape.

In addition to the new HDPE flip-top caps, Neopac also is launching a comprehensive portfolio of PE screw caps.