Joanna Cosgrove, Contributing Editor08.23.21

COVID has brought about a hygienic reckoning for traditional sampling methods and the days of trying a swatch of lipstick, eyeshadow or foundation from community testers are behind us. As brands and retailers go back to the drawing board for ways to encourage trial among prospective customers, mono- and multi-dose packaging suppliers are exploring new frontiers in sample packaging innovation, developing newer cleaner and more eco-responsible ways for consumers to try products before they buy.

The evolving sampling environment has become one of Arcade Beauty’s major business focuses, according to Larry Berman, the company’s senior vice president of sales. Arcade is courting e-sales and contactless sampling by leveraging its digital print capabilities to produce samples of every shade of a brand’s foundation at an “economical price” (set to launch at a major beauty retailer this September), as well as allowing brands to target “high value” customers via its Abeo business.

Berman says his company has seen growth in its single-use, hermetically sealed samples, which are able to be distributed contact-free. “The demand for spray vials has increased exponentially, and as we manufacture our own glass and fill in house, we are able to meet our clients’ needs,” he says. “Additionally, our LiquaTouch technology, which offers a lower cost option to vials, but still the actual fragrance, has also seen a large increase.

“We are [also] partnering with a large beauty retailer to produce our custom BeautiPod, which will be the exclusive way to sample foundation in the store.”

Consumers have spent an inordinate amount of time at home in the last year, sending the home fragrance market for scented candles and diffusers soaring. To that end, Arcade Beauty recently introduced DiscCover with Candle Wax, a re-sealable, home fragrance sampling solution that locks scented candle wax in between two layers of protective film and offers several olfactive trials per sample. “When opened, the fragrance is released into the air,” notes Berman. “It is highly customizable, it comes in a wide range of standard sizes, a dual version, as well as custom die-cuts and wax shapes. The film can be either opaque or transparent to optimize creative design.”

The company also recently worked with Nest New York to formulate, blend and fill a “high percentage fragrance concentration formula” for the brand’s latest 5-fragrance collection. Nest New York opted for 3ml rollerball configurations for their formulas, which are less sticky than traditional perfume oils and meet the Sephora Clean beauty standards. Presented in a beautiful floral coffret, the rollerballs are accented with poly labels and matte finish four-color printing.

Sven Dobler, president and CEO, Orlandi, says that safe, hygienic direct-to-consumer (DCT) and in-store sampling is picking up. “DTC sampling campaigns are relatively small and cautious—and brand budgets are still constrained by the downturn and increasing postage costs for direct-to-home sampling from social media platforms is a challenge even for larger brand companies,” he says. “Much of this activity is still designed for test and learn initiatives, measuring ROIs and consumer engagement.

“Cost-effective, mailable samples will play a role in this new channel,” he continues. “Also, brands exploring their own e-commerce and co-ship sampling will continue as traditional retail is no longer the exclusive way to sell.”

Orlandi’s newest innovation is the MultiScent20 digital scent diffuser (MS20), which samples 20 fragrances in a tablet-sized device with recyclable scent cartridges. Designed for direct sellers and for use in displays, it’s especially helpful for points of sale without beauty advisors and/or easy consumer access to product trial. The diffuser connects wirelessly for digital catalog downloads and can be “no touch” when controlled by consumers’ mobile devices.

Pouches & Sachets

Jones Healthcare Group recently celebrated its centennial year by committing to invest $20 million into its business from 2020-2022, earmarking the funds for multiple new packaging technologies that not only enhance speed to market, but also augment its capabilities for international business partners in the beauty, drug and medical device industries.

“We invested in a state-of-the-art integrated Uhlmann bottle packaging line for solid-dose nutraceutical and cosmeceutical products to complement our travel-sized vial packaging line, [and] acquired a Koenig & Bauer Rapida eight-color folding carton press, which offers unparalleled quality control and enhanced blister card backer printing capabilities for travel-sized products,” says Marta Moniz, business development manager, packaging services.

Demand for pouch packaging at the contract packaging company has also expanded significantly in response to increased, on-the-go market demands, Moniz says. The company recently worked with luxury haircare brand Raincry to package 10ml dual sachet samples of its Shine Polishing Wash and Radiance Rinse products. The sachets were enclosed in upscale coated folders that also helped cross-market additional products in the brand’s portfolio.

Jones Healthcare Group designed the folder to incorporate visuals that accented the presentation of the sachets, using lithographic printing with high-definition screening plates and a shiny, water-based gloss coating for a bold visual appeal.

Sachets are also at the forefront for JP Packaging LLC. The company’s Packet Express program allows new and emerging brands to expedite their sampling program with a 10,000-piece minimum run. “This allows these brands to launch sampling and trial their products without being handcuffed with much larger minimums,” says the company’s Doug Rofheart, senior sales executive. “We are seeing interest from established larger brands taking advantage of this program when launching new and unique products as well as multiple products to target specific demographics versus the masses.”

In addition to its sachets, JP Packaging has also developed a peel and reseal 10 count Saturated Pad package for sampling and travel, as well as single saturated pads in sachets.

“As brands continue to be concerned about the environment and the impact of single-use packaging, our flexible packaging options such as sachets actually fit the bill,” Rofheart says. “They have a better package to product ratio, transportation benefits as sachet film ships to us in roll form, and finished sachets are flat allowing for more inbound and outbound pieces per pallet thus less per truck.

“Couple all of this with our 100% recycled paper outer layer film structure, this makes the configuration a 42% PCR contact,” he continues. “It’s a win-win for the brand and consumer.”

Full-Sized Experience in a Mini

One of the best ways to ensure the success of a trial product is to create a sample that mirrors the user experience of its parent-sized product.

“Brands are demanding the same level of quality, functionality and customization as in the larger packages,” says Rosa Porras Mansilla, marketing and communications manager at Virospack, a specialist in custom dropper package solutions.

One of Virospack’s recent creations was a secure dropper configuration for BIODERMA Laboratorie’s vitamin C-rich, PigmentBio C-Concentrate formula, which requires its mix of liquid and powder at the moment of application. The brand customized Virospack’s Duomix 1 dropper and a 15ml tubular glass bottle with a white injected metal shell cap, white spray painting and custom grey screen printing.

Mansilla says the product is activated with a firm press on the lid to release the vitamin C. The package is shaken for 10 seconds prior to application.

Premi SpA is also maximizing the mini experience with the launch of its Pocket Airless Collection, a slim sized collection of 10-, 15- and 30ml sized airless bottles. Made for portability and precision dosing, these round-shaped PP bottles are suitable for low and high-viscosity formulas and can be customized and decorated with a variety of finishing options.

SamHwa USA Inc. has also increased its focus on the function of trial and sample size products, having produced a 10ml rolling serum and ampoule dropper for deluxe sampling, as well as smaller size airless pumps in all PCR PP, and which use the PP metal free pump, allowing for recycling without the need to separate the parts.

For consumers that enjoy the benefits of aromatherapy, ADORAtherapy debuted its Moodzee collection of 12 single note essential oils, packaged in colorful and adorably portable, pill-shaped bottles.

The 10ml painted glass vessels have a matching electroplated cap and ADORAtherapy markets the bottles in holographic zipper bags that transparently let the bottle colors shine through.

“I found samples of a pill-shaped bottle when traveling in China and fell in love with the shape,” says Laura McCann, founder and CEO, ADORAtherapy. She then worked with her glassware provider, Hangzhou Mig Packaging Co. Ltd., to create chunkier, opaque versions of the bottle that would fit in the hand and protect the sensitive oils from sunlight.

“Aromatherapy is about health and wellness and the shape of this bottle reminded me of supplements and pills,” she says noting the line’s vivid colors. “Plants and flowers are colorful, so I wanted each bottle to tell the story of the plant.”

The packages come with a roller ball dispenser for direct dermal application, or consumers can opt for a dropper for easy blending or use with a diffuser.

Strides in Eco Responsibility

Single-use products are under increased scrutiny and providers are working hard to ensure their sampling solutions are effective, inventive, and environmentally responsible.

“Our planet is suffering, and we need to make a concerted effort to provide products that are not harmful to the environment,” says Sari Sternschein, vice president of marketing and product development, Qosmedix.

Having earned an EcoVadis Bronze Certification, Qosmedix has been sourcing sustainable products like sugarcane bowls, FSC Certified paper, bamboo applicators and PCR plastic packaging for the past two years. A few months ago, the company launched plastic-free, FSC Certified Paper Handled Applicators.

“[This] is a huge step forward considering the millions of applicators that are used by consumers every year,” comments Sternschein. “These applicators are also available with FSC Certified Bamboo handles.”

As a provider of over 150 standard blister shapes, Livcer is well-versed in offering safe, hygienic, thermoformed options for cosmetic sampling and has been hard at work developing solutions that strike the balance of innovative and eco-friendly, according to the company’s Aude De Livonniere, president.

“We can provide an environmentally-friendly single-dose and sample product by eliminating aluminum, using recycled materials and using single-material laminates (recyclable),” she says, adding that the company is currently testing multiple formula-specific options and investigating the potential of alternative materials such as coconut and hemp fibers.”

One of Livcer’s most recent sampling solutions is The Livstick, which consists of a paper applicator stick that’s pre-loaded with a sample-ready lipstick formula. The stick and formula are housed in an eco-designed blister pack made of over 60% recycled material.

“The stick is always 100% secured and clean, ensuring a sanitary sampling experience,” De Livonniere says. “It is also a pleasant experience to open the blister and apply the stick. The contact of the formula on the lips is soft and its fragrance is preserved.”

The Livstick comes in single blister packs or strips of 6 pre-cut blisters and is suitable for all hot-pour formulas.

Thierry Bitout, CEO, Tubex, says improved recyclability is an important component of sample package innovation. “We see a big trend which is aiming at diminishing the number of components/materials in a pack,” he comments. “Companies are looking for alternatives to non-recyclable single use packaging (eg. non-recyclable sachets).”

He says that developing sustainable solutions is also a way to strengthen the partnership between suppliers and brands. “The need for more sustainable single-use packs is increasing and suppliers of packaging need to react with innovation.”

Tubex’s latest sampling solution—the Monotube—is made of a specially developed aluminum alloy consisting of 100% used tubes and recycled aluminum with 95% PCR content. Combined with a highly carbon-sensitive production across Tubex’s supply chain, it’s helping the company minimize emissions and score high on circularity. It features a break-off nozzle that acts as a smart closing system to reseal the tube for later re-use.

“Because every part of the tube is produced from a single material, it is manufactured in just one production step that includes the closure—there is no need to separately manufacture and screw on a plastic cap,” explains Bitout. “The tube’s clever design gives consumers the option of using all the product in one go or resealing it temporarily.”

The Monotube is available in a range of sizes (sample-size, travel-size, single- or multi-use), making it a versatile aluminum solution that provides reliable protection for a wide range of products.

“Aluminum has excellent barrier properties and is a valuable and durable material that can be infinitely recycled,” Bitout says. “[Aluminum] can be melted down and re-formed time and again without losing its premium quality—an impressive 75% of all aluminum ever produced is still in use, and the recycling rate of aluminum packaging in Europe is 69%, which already exceeds the EU’s recycling targets for 2025.”

Having recently made a Zero Waste pledge, REN Clean Skincare, a luxury Unilever brand, chose the Monotube for its eco-smart samples. Arnaud Meysselle, REN Clean Skincare’s CEO, acknowledged that while a metal sample pack is not a cheap manufacturing option, it’s a price worth paying. “There is no silver bullet with recycling, so we have implemented various solutions to meet our Zero Waste pledge,” he says. “While more costly, we are committed to using these new tubes to reduce plastic waste and hope to encourage other beauty brands to rethink their sample packaging with the planet in mind.”

The evolving sampling environment has become one of Arcade Beauty’s major business focuses, according to Larry Berman, the company’s senior vice president of sales. Arcade is courting e-sales and contactless sampling by leveraging its digital print capabilities to produce samples of every shade of a brand’s foundation at an “economical price” (set to launch at a major beauty retailer this September), as well as allowing brands to target “high value” customers via its Abeo business.

Berman says his company has seen growth in its single-use, hermetically sealed samples, which are able to be distributed contact-free. “The demand for spray vials has increased exponentially, and as we manufacture our own glass and fill in house, we are able to meet our clients’ needs,” he says. “Additionally, our LiquaTouch technology, which offers a lower cost option to vials, but still the actual fragrance, has also seen a large increase.

“We are [also] partnering with a large beauty retailer to produce our custom BeautiPod, which will be the exclusive way to sample foundation in the store.”

Consumers have spent an inordinate amount of time at home in the last year, sending the home fragrance market for scented candles and diffusers soaring. To that end, Arcade Beauty recently introduced DiscCover with Candle Wax, a re-sealable, home fragrance sampling solution that locks scented candle wax in between two layers of protective film and offers several olfactive trials per sample. “When opened, the fragrance is released into the air,” notes Berman. “It is highly customizable, it comes in a wide range of standard sizes, a dual version, as well as custom die-cuts and wax shapes. The film can be either opaque or transparent to optimize creative design.”

The company also recently worked with Nest New York to formulate, blend and fill a “high percentage fragrance concentration formula” for the brand’s latest 5-fragrance collection. Nest New York opted for 3ml rollerball configurations for their formulas, which are less sticky than traditional perfume oils and meet the Sephora Clean beauty standards. Presented in a beautiful floral coffret, the rollerballs are accented with poly labels and matte finish four-color printing.

Sven Dobler, president and CEO, Orlandi, says that safe, hygienic direct-to-consumer (DCT) and in-store sampling is picking up. “DTC sampling campaigns are relatively small and cautious—and brand budgets are still constrained by the downturn and increasing postage costs for direct-to-home sampling from social media platforms is a challenge even for larger brand companies,” he says. “Much of this activity is still designed for test and learn initiatives, measuring ROIs and consumer engagement.

“Cost-effective, mailable samples will play a role in this new channel,” he continues. “Also, brands exploring their own e-commerce and co-ship sampling will continue as traditional retail is no longer the exclusive way to sell.”

Orlandi’s newest innovation is the MultiScent20 digital scent diffuser (MS20), which samples 20 fragrances in a tablet-sized device with recyclable scent cartridges. Designed for direct sellers and for use in displays, it’s especially helpful for points of sale without beauty advisors and/or easy consumer access to product trial. The diffuser connects wirelessly for digital catalog downloads and can be “no touch” when controlled by consumers’ mobile devices.

Pouches & Sachets

Jones Healthcare Group recently celebrated its centennial year by committing to invest $20 million into its business from 2020-2022, earmarking the funds for multiple new packaging technologies that not only enhance speed to market, but also augment its capabilities for international business partners in the beauty, drug and medical device industries.

“We invested in a state-of-the-art integrated Uhlmann bottle packaging line for solid-dose nutraceutical and cosmeceutical products to complement our travel-sized vial packaging line, [and] acquired a Koenig & Bauer Rapida eight-color folding carton press, which offers unparalleled quality control and enhanced blister card backer printing capabilities for travel-sized products,” says Marta Moniz, business development manager, packaging services.

Demand for pouch packaging at the contract packaging company has also expanded significantly in response to increased, on-the-go market demands, Moniz says. The company recently worked with luxury haircare brand Raincry to package 10ml dual sachet samples of its Shine Polishing Wash and Radiance Rinse products. The sachets were enclosed in upscale coated folders that also helped cross-market additional products in the brand’s portfolio.

Jones Healthcare Group designed the folder to incorporate visuals that accented the presentation of the sachets, using lithographic printing with high-definition screening plates and a shiny, water-based gloss coating for a bold visual appeal.

Sachets are also at the forefront for JP Packaging LLC. The company’s Packet Express program allows new and emerging brands to expedite their sampling program with a 10,000-piece minimum run. “This allows these brands to launch sampling and trial their products without being handcuffed with much larger minimums,” says the company’s Doug Rofheart, senior sales executive. “We are seeing interest from established larger brands taking advantage of this program when launching new and unique products as well as multiple products to target specific demographics versus the masses.”

In addition to its sachets, JP Packaging has also developed a peel and reseal 10 count Saturated Pad package for sampling and travel, as well as single saturated pads in sachets.

“As brands continue to be concerned about the environment and the impact of single-use packaging, our flexible packaging options such as sachets actually fit the bill,” Rofheart says. “They have a better package to product ratio, transportation benefits as sachet film ships to us in roll form, and finished sachets are flat allowing for more inbound and outbound pieces per pallet thus less per truck.

“Couple all of this with our 100% recycled paper outer layer film structure, this makes the configuration a 42% PCR contact,” he continues. “It’s a win-win for the brand and consumer.”

Full-Sized Experience in a Mini

One of the best ways to ensure the success of a trial product is to create a sample that mirrors the user experience of its parent-sized product.

“Brands are demanding the same level of quality, functionality and customization as in the larger packages,” says Rosa Porras Mansilla, marketing and communications manager at Virospack, a specialist in custom dropper package solutions.

One of Virospack’s recent creations was a secure dropper configuration for BIODERMA Laboratorie’s vitamin C-rich, PigmentBio C-Concentrate formula, which requires its mix of liquid and powder at the moment of application. The brand customized Virospack’s Duomix 1 dropper and a 15ml tubular glass bottle with a white injected metal shell cap, white spray painting and custom grey screen printing.

Mansilla says the product is activated with a firm press on the lid to release the vitamin C. The package is shaken for 10 seconds prior to application.

Premi SpA is also maximizing the mini experience with the launch of its Pocket Airless Collection, a slim sized collection of 10-, 15- and 30ml sized airless bottles. Made for portability and precision dosing, these round-shaped PP bottles are suitable for low and high-viscosity formulas and can be customized and decorated with a variety of finishing options.

SamHwa USA Inc. has also increased its focus on the function of trial and sample size products, having produced a 10ml rolling serum and ampoule dropper for deluxe sampling, as well as smaller size airless pumps in all PCR PP, and which use the PP metal free pump, allowing for recycling without the need to separate the parts.

For consumers that enjoy the benefits of aromatherapy, ADORAtherapy debuted its Moodzee collection of 12 single note essential oils, packaged in colorful and adorably portable, pill-shaped bottles.

The 10ml painted glass vessels have a matching electroplated cap and ADORAtherapy markets the bottles in holographic zipper bags that transparently let the bottle colors shine through.

“I found samples of a pill-shaped bottle when traveling in China and fell in love with the shape,” says Laura McCann, founder and CEO, ADORAtherapy. She then worked with her glassware provider, Hangzhou Mig Packaging Co. Ltd., to create chunkier, opaque versions of the bottle that would fit in the hand and protect the sensitive oils from sunlight.

“Aromatherapy is about health and wellness and the shape of this bottle reminded me of supplements and pills,” she says noting the line’s vivid colors. “Plants and flowers are colorful, so I wanted each bottle to tell the story of the plant.”

The packages come with a roller ball dispenser for direct dermal application, or consumers can opt for a dropper for easy blending or use with a diffuser.

Strides in Eco Responsibility

Single-use products are under increased scrutiny and providers are working hard to ensure their sampling solutions are effective, inventive, and environmentally responsible.

“Our planet is suffering, and we need to make a concerted effort to provide products that are not harmful to the environment,” says Sari Sternschein, vice president of marketing and product development, Qosmedix.

Having earned an EcoVadis Bronze Certification, Qosmedix has been sourcing sustainable products like sugarcane bowls, FSC Certified paper, bamboo applicators and PCR plastic packaging for the past two years. A few months ago, the company launched plastic-free, FSC Certified Paper Handled Applicators.

“[This] is a huge step forward considering the millions of applicators that are used by consumers every year,” comments Sternschein. “These applicators are also available with FSC Certified Bamboo handles.”

As a provider of over 150 standard blister shapes, Livcer is well-versed in offering safe, hygienic, thermoformed options for cosmetic sampling and has been hard at work developing solutions that strike the balance of innovative and eco-friendly, according to the company’s Aude De Livonniere, president.

“We can provide an environmentally-friendly single-dose and sample product by eliminating aluminum, using recycled materials and using single-material laminates (recyclable),” she says, adding that the company is currently testing multiple formula-specific options and investigating the potential of alternative materials such as coconut and hemp fibers.”

One of Livcer’s most recent sampling solutions is The Livstick, which consists of a paper applicator stick that’s pre-loaded with a sample-ready lipstick formula. The stick and formula are housed in an eco-designed blister pack made of over 60% recycled material.

“The stick is always 100% secured and clean, ensuring a sanitary sampling experience,” De Livonniere says. “It is also a pleasant experience to open the blister and apply the stick. The contact of the formula on the lips is soft and its fragrance is preserved.”

The Livstick comes in single blister packs or strips of 6 pre-cut blisters and is suitable for all hot-pour formulas.

Thierry Bitout, CEO, Tubex, says improved recyclability is an important component of sample package innovation. “We see a big trend which is aiming at diminishing the number of components/materials in a pack,” he comments. “Companies are looking for alternatives to non-recyclable single use packaging (eg. non-recyclable sachets).”

He says that developing sustainable solutions is also a way to strengthen the partnership between suppliers and brands. “The need for more sustainable single-use packs is increasing and suppliers of packaging need to react with innovation.”

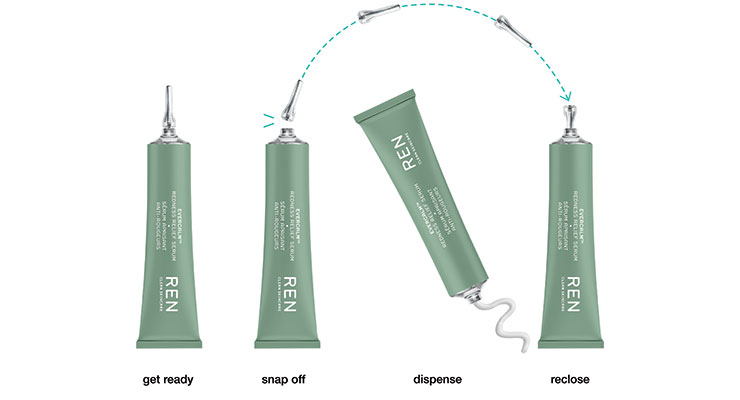

Tubex’s latest sampling solution—the Monotube—is made of a specially developed aluminum alloy consisting of 100% used tubes and recycled aluminum with 95% PCR content. Combined with a highly carbon-sensitive production across Tubex’s supply chain, it’s helping the company minimize emissions and score high on circularity. It features a break-off nozzle that acts as a smart closing system to reseal the tube for later re-use.

“Because every part of the tube is produced from a single material, it is manufactured in just one production step that includes the closure—there is no need to separately manufacture and screw on a plastic cap,” explains Bitout. “The tube’s clever design gives consumers the option of using all the product in one go or resealing it temporarily.”

The Monotube is available in a range of sizes (sample-size, travel-size, single- or multi-use), making it a versatile aluminum solution that provides reliable protection for a wide range of products.

“Aluminum has excellent barrier properties and is a valuable and durable material that can be infinitely recycled,” Bitout says. “[Aluminum] can be melted down and re-formed time and again without losing its premium quality—an impressive 75% of all aluminum ever produced is still in use, and the recycling rate of aluminum packaging in Europe is 69%, which already exceeds the EU’s recycling targets for 2025.”

Having recently made a Zero Waste pledge, REN Clean Skincare, a luxury Unilever brand, chose the Monotube for its eco-smart samples. Arnaud Meysselle, REN Clean Skincare’s CEO, acknowledged that while a metal sample pack is not a cheap manufacturing option, it’s a price worth paying. “There is no silver bullet with recycling, so we have implemented various solutions to meet our Zero Waste pledge,” he says. “While more costly, we are committed to using these new tubes to reduce plastic waste and hope to encourage other beauty brands to rethink their sample packaging with the planet in mind.”