“Direct ownership is immeasurable,” says Jeff Besnick, McLean’s vice president. “Our ownership is part of the problem-solving process and available to make timely decisions without red tape, which encourages customers to look to us for the most innovative solutions.”

A Bright Future

A big part of McLean’s flexible, customer-focused business model is investing in the latest technology and facility enhancements aimed to reduce customer costs, enhance turnaround times, and give customers a better foothold on success in a challenging and demanding marketplace.“Our investments allow us to be a problem-solver for the industry” says Besnick.

For instance, on the folding carton and printing side of its business, McLean’s focus has been “more capability in-line”. With strategic equipment investments, the company has expanded its press and print configurations, giving customers the best possible graphics that require less compromise.

“For each color we add, our customers are requesting more,” he explains. “Today, we have nine- and ten-color Heidelberg presses on the floor with multiple coaters and both equipped with cold foil. These state-of-the-art machines give us every possibility to create shelf presence in a single pass.”

The company has also made investments to broaden its finishing capabilities via new Bobst folder-gluers and a new die cutter/blanker added to its fleet that delivers new technology and improved efficiency in die cutting and gluing.

When it comes to rigid set boxes, McLean Packaging is the only manufacturer in the US with the ability to control and convert every aspect of a rigid set box in-house, meaning the company can quickly present new ideas, react to customer demands, and deliver high-quality packaging with competitive pricing.

The company’s rigid set box division has made the leap into digital technologies with the ultimate goal of advancing to automation. “We have partnered with Emmeci to bring the most accurate equipment with new box-making technology to our floor,” Besnick says. “We have also purchased several robots for inserting product, lidding boxes, etc.”

The company’s corrugated facility has focused its recent efforts on multi-sided, high-value printing produced on machines made by Gopfert. “This technology allows us to focus on e-commerce packaging, as well as very high-quality, direct print for display packaging as a solution to save cost as compared to litho-lamination,” notes Stuart Fenkel, president of McLean’s corrugated division. “McLean also has tremendous capacity for multi-piece gluing where we can assist in inventory and labor savings within the walls of our customers.”

The company’s future-forward approach to delivering the finest quality packaging while helping its customers streamline their supply chains is in constant motion toward progress. However, Besnick says three things will always remain constant. “We’ll continually reinvest in the most technologically advanced equipment and industry leading personnel; communicate product quality through design and production; create innovative, problem-solving designs and market solutions while we work to exceed the expectations of our customers.”

Responsible Environmental Stewardship

Sustainability, along with social and corporate responsibility, are at the forefront of McLean Packaging’s efforts. The company prides itself on its progressive dedication to addressing the environmental impact of the packaging it creates.McLean Packaging currently holds a Forest Stewardship Council (FSC), Sustainable Forest Initiative (SFI) certifications and Programme for the Endorsement of Forest Certification (PEFC).

The company was also recently recognized with a gold EcoVadis certification. EcoVadis reviews companies all over the world by evaluating their corporate, social, and environmental standards in efforts, awarding clear sustainability ratings that can be referenced and analyzed by other companies or organizations. This third-party review helps distinguish and promote businesses that are doing their part to create better resources in their sectors.

“As we continue to monitor our KPIs, we will be able to determine the next best steps in minimizing our effect on the environment and improving the sustainability of our company,” Besnick says. “The EcoVadis rating and participation in CDP not only supplies us with a guideline on areas to improve, but it also provides an objective viewpoint for our customers and potential clients to refer to.”

McLean CARES

The company has recently established the McLean CARES, a program rooted in Community, Academics, Responsibility, Employee education and Sustainability which is designed to create positive impacts on the community, employees, and customers.The community arm of the program contributes to local organizations while supporting the educational efforts of those in need. On the academic side, McLean has established a scholarship fund to assist the children of McLean employees with the cost of higher education.

The company has also established employee safety programs along with social responsibility efforts to ensure a safe work environment and supportive social policies. On the sustainability front, McLean has adopted a continuous improvement approach towards refining its overall sustainability and environmental impact.

Environmental responsibility is a top priority to McLean because the products the company makes today affect the future. “We are maintaining a sustainable business for the future and want to ensure the quality of the environment around us by making efforts to evaluate and reduce our carbon footprint, recycle as much as possible, and continue to participate in programs that support sustainability goals,” comments Besnick. “We also know the efforts we make reflect on our clients and customers. We strive to be a partner in their environmental efforts, as well as our own, to help them achieve their various sustainability goals.”

Diverse Packaging Solutions Designed and Manufactured In-House

McLean Packaging provides a broad range of paperboard, rigid set boxes and corrugated packaging options for both the shelf-/retail-ready and e-commerce goods segments. McLean specializes in crafting tested, validated, retail-compliant specifications with an experienced understanding of what it takes for optimum shelf performance and engagement. The company’s seasoned team of packaging professionals also understands what it takes to fulfill the demands of fast-paced, omni-channel marketing.McLean Packaging can help brands develop the right packaging that will promote and protect products throughout the new supply chain of today.

Corrugated Packaging and Displays: McLean keeps costs in-check with an enhanced, multi-sided, flexo-direct print process that offers a high-resolution, multi-color option for corrugated graphic packaging.

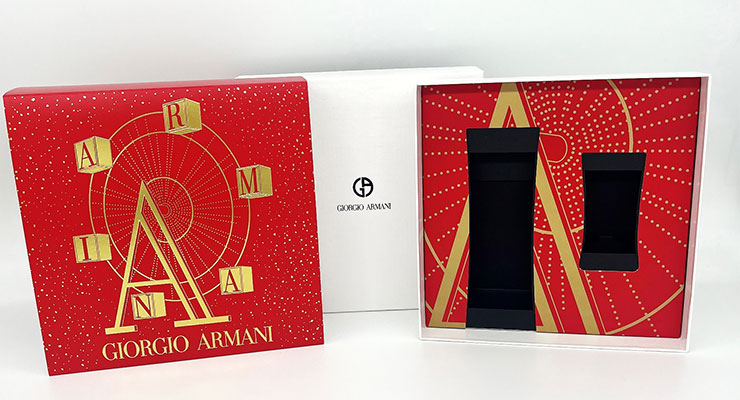

Rigid Set Boxes: Custom gift set packaging enhanced by McLean’s wrapping lines with the in-house ability to line board, print wraps, make vacuum forms, insert trays, produce lids, apply masks, and provide in-line pack-outs.

Folding Cartons: Value-added versatility in plastic, paperboard or a combination of both, executed with on-site, G7-certifed printing presses (color, cold foil, metallic inks and specialty coatings like soft touch, high raised gloss, and pearlescent), embossing, hot stamping, die-cutting and gluing.

Thermoforming: From trays and inserts to media-filled trays and RF sealing, McLean ensures that each component of a brand’s displays, blister packs, pack out and more are produced efficiently and on time. Options include color-matched, media-filled and post-consumer recycled vacuum forms, as well as masking thermoformed trays with decorated board to help create stunning in-box visuals.

www.mcleanpackaging.com