Stratasys, a global leader in additive manufacturing has introduced a full-color 3D printing solution that allows packaging designers to create their visual samples in-house with an industry-first streamlined software workflow producing colorful, high transparency, sharp graphic prototypes in a single print.

Stratasys innovations help the world’s leading packaging companies gain business agility, competitive advantage and faster time to market. Here, Beauty Packaging speaks with Lior Elgali, the product manager of Stratasys’ design business unit. Elgali is Stratasys’ undisputed expert on the full-color 3D printing workflow and CMF domain. He has a rich, diverse industrial design and 3D printing application engineering background.

Jamie Matusow: Can you please give us the top 5 reasons why companies should 3D print their prototypes?

Lior Elgali: To truly understand the design of a package, a person needs to hold it in their hand, see it in a real-world environment with room lighting or in a store, and understand the true size and form of the shape and legibility of the text. Since 3D renders and visualizations aren’t enough, physical appearance models need to be made. With traditional methods, product designers need to either outsource and wait for long periods, which can be expensive, or complete multiple manual steps to reach the end result for each model, whereas digital printing methodology, supports a simplified workflow.

The Top 5 Reasons to 3D print your designs, are:

JM: Why is this prototyping efficiency so important to brands?

LE: To sell more products, a brand can do many things such as lower prices, change shelf location and spend more on marketing; all of these practices are valid but expensive and ongoing. The one-time solution for improving product sales is better design, which sells itself. Appearance is everything – this is what gets attention through social media. It is the design model on the billboards, and the ‘emotion’ that triggers the customer’s passion to reach for the product on the shelf, when they have thousands of others to choose from.

Refined design that the customer cares about is reached as a result of more ideas and more visual sample tests, with quick iterations streamlining creativity and attention to detail, that raise confidence in the decision making and stakeholder approval processes. Attractiveness, brand fit, distinction from competitors, ideal shelf placement and more can all be increased when samples are created on-site and when designers do not need to worry about manually gluing on the graphics or have their traditional outsource misinterpret their design intent.

JM: This appears to be unlike anything we’ve seen. What’s the benefit to packaging designers?

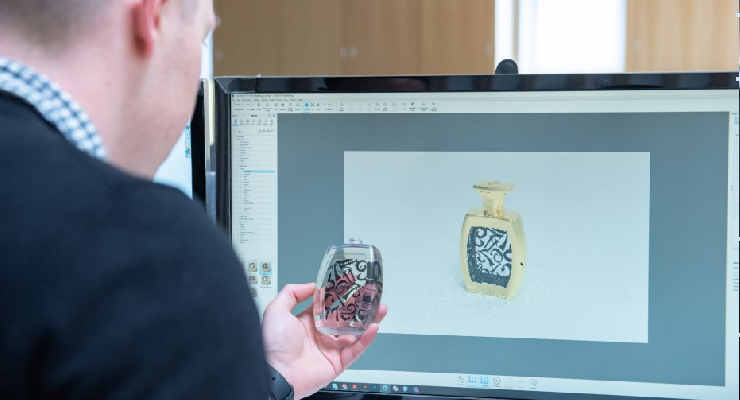

LE: 3D printing has been around for a while. It’s only recently that a combination of advanced chemistry, engineering and groundbreaking software development has enabled us to create a solution to transform the way packaging design is being prototyped. In order to make graphics bright and text sharp, we have created new materials with the highest opacity yet in PolyJet technology. To simulate a glass-like transparency, we created the clearest and most transparent resin we ever had. On the software side, we had to rethink how we apply opaque and transparent color graphics while making the process simpler so that designers can focus their efforts solely on design. We believe they shouldn’t have to compromise on time or color and should have the ability to create both rapid and full color prototypes in-house for quick visual samples. Iterate more creative designs faster for smarter decision making with less manual labor.

JM: What are the benefits of Stratasys over your competitors?

LE: There are numerous benefits, including:

JM: What is the streamlined new process for the designers to create these prototypes?

LE: Designers today are creating 3D files to soft-proof their ideas as part of the design process. This is all done on screen. Behind these renders there is a model that already has features such as labels, graphics, materials and more. The next step would be exporting this 3D file – but this time not for rendering – for printing! Our J series 3D printers can produce many of these features at once, and thanks to our GrabCAD Print software that supports many native file types including the latest 3MF format, the designer can easily load their model and send to print.

Depending on each user’s specific workflow, this can take anywhere from minutes to a couple of hours, at the end of which they can send a file and continue with their day job while the printer does all the hard work.

After the print is finished, the prototype can be polished or sandblasted to achieve the final appearance. Hear more about it directly from our customers here.

Stratasys innovations help the world’s leading packaging companies gain business agility, competitive advantage and faster time to market. Here, Beauty Packaging speaks with Lior Elgali, the product manager of Stratasys’ design business unit. Elgali is Stratasys’ undisputed expert on the full-color 3D printing workflow and CMF domain. He has a rich, diverse industrial design and 3D printing application engineering background.

Jamie Matusow: Can you please give us the top 5 reasons why companies should 3D print their prototypes?

Lior Elgali: To truly understand the design of a package, a person needs to hold it in their hand, see it in a real-world environment with room lighting or in a store, and understand the true size and form of the shape and legibility of the text. Since 3D renders and visualizations aren’t enough, physical appearance models need to be made. With traditional methods, product designers need to either outsource and wait for long periods, which can be expensive, or complete multiple manual steps to reach the end result for each model, whereas digital printing methodology, supports a simplified workflow.

The Top 5 Reasons to 3D print your designs, are:

- Simple digital workflow

- 1-2 days lead time with an in-house printer

- Cost efficiency

- Reduced miscommunication caused by multi-processing

- Realistic, high-quality models

JM: Why is this prototyping efficiency so important to brands?

LE: To sell more products, a brand can do many things such as lower prices, change shelf location and spend more on marketing; all of these practices are valid but expensive and ongoing. The one-time solution for improving product sales is better design, which sells itself. Appearance is everything – this is what gets attention through social media. It is the design model on the billboards, and the ‘emotion’ that triggers the customer’s passion to reach for the product on the shelf, when they have thousands of others to choose from.

Refined design that the customer cares about is reached as a result of more ideas and more visual sample tests, with quick iterations streamlining creativity and attention to detail, that raise confidence in the decision making and stakeholder approval processes. Attractiveness, brand fit, distinction from competitors, ideal shelf placement and more can all be increased when samples are created on-site and when designers do not need to worry about manually gluing on the graphics or have their traditional outsource misinterpret their design intent.

JM: This appears to be unlike anything we’ve seen. What’s the benefit to packaging designers?

LE: 3D printing has been around for a while. It’s only recently that a combination of advanced chemistry, engineering and groundbreaking software development has enabled us to create a solution to transform the way packaging design is being prototyped. In order to make graphics bright and text sharp, we have created new materials with the highest opacity yet in PolyJet technology. To simulate a glass-like transparency, we created the clearest and most transparent resin we ever had. On the software side, we had to rethink how we apply opaque and transparent color graphics while making the process simpler so that designers can focus their efforts solely on design. We believe they shouldn’t have to compromise on time or color and should have the ability to create both rapid and full color prototypes in-house for quick visual samples. Iterate more creative designs faster for smarter decision making with less manual labor.

JM: What are the benefits of Stratasys over your competitors?

LE: There are numerous benefits, including:

- In-house design visual prototypes: Protect your design and IP and get your parts in days instead of weeks.

- Cost savings from about $40-60K per annum: Our customers tell us their yearly saving on models is big and that’s even without counting the shorter projects made possible through quick iterations.

- Avoid miscommunication: Through streamlined workflows, designers can simply use their 3D render files from render software like Keyshot, which already holds geometry, transparency, graphics, and more. Designers can print as-is, eliminating the need to use multiple decoration processes that require separate files and knowledge.

- Most affordable full-color CMF 3D printer: The J55 Prime provides the best-in-class combination of colors (over 500,000 unique colors, almost twice as traditional 2D printing) including validated Pantone swatches, transparency, great surface finish, and a large build tray for many parts in one print.

- High-end, high versatility: The J8 Prime series supports up to 7 materials at once—meaning you can combine full color with transparency and rubber-like materials – all in one part.

- One or many models: With the simplicity of the model preparation, and size of the tray, the designer can test a number of iterations all at once.

- Simple workflow: GrabCAD Print, the print preparation software for PolyJet technology allows loading 3MF files – the most advanced 3D printing file available, which is constantly being updated with new features. One of our partners for exporting rich 3MF files is the industry-leading Keyshot render software, which natively exports colors, opacities, labels, and more. GrabCAD Print also supports full color .obj and .wrl files, as well as a large number of native CAD formats. And it’s free!

- High accuracy and surface finish: PolyJet technology enables up to ±100µ accuracy, and a consistent solid surface that can be polished to a mirror finish, or sand-blasted to a great silky finish.

- Big build volume: Stratasys’ full color 3D printers come in 3 tray sizes, large enough to hold multiple packages on one build.

- Best-in-class transparency: Great glass simulation through high transparency, low yellow index.

- High contrast, sharp, bright graphics: Our high opacity white and black resins allow for high contrast and readability of text, barcodes and more. Combined with our Vivid CMY resins, they create smooth bright gradients and graphics, or even simulate the liquid inside the bottle.

JM: What is the streamlined new process for the designers to create these prototypes?

LE: Designers today are creating 3D files to soft-proof their ideas as part of the design process. This is all done on screen. Behind these renders there is a model that already has features such as labels, graphics, materials and more. The next step would be exporting this 3D file – but this time not for rendering – for printing! Our J series 3D printers can produce many of these features at once, and thanks to our GrabCAD Print software that supports many native file types including the latest 3MF format, the designer can easily load their model and send to print.

Depending on each user’s specific workflow, this can take anywhere from minutes to a couple of hours, at the end of which they can send a file and continue with their day job while the printer does all the hard work.

After the print is finished, the prototype can be polished or sandblasted to achieve the final appearance. Hear more about it directly from our customers here.