01.23.18

Global aerosol packaging technology provider Lindal Group has opened a new application laboratory dedicated to bag-on-valve (BOV) technologies. The new application laboratory, located in Briey, France, offers “high-level expertise from all corners of the packaging and formulation industry,” and will allow Lindal customers to see the latest brand-building BOV solutions “brought to life.” At this new hub, customers launching new BOV products can obtain product samples, develop product specifications and test protocols, conduct compatibility studies and learn more about the advantages of barrier packaging systems.

The facility is designed to further elevate Lindal’s BOV strategy and industry position in this technology. The laboratory team is led by Ünal Varol, Lindal global BOV business manager, and includes aerosol industry experts from chemical engineering, cosmetic, formulation and packaging backgrounds. The conception and implementation of the new laboratory has been overseen by BOV industry expert, Georges Bouille, who has supported this new development with Lindal for the past two years.

“What makes our new lab so special is the combination of industry leading in-depth knowledge and insight into the packaging industry, coupled with technicians with best-in-class technical expertise in packaging, formulation and engineering,” said Varol.

Kashif Choudhry, Lindal product marketing manager, commented: “Our new laboratory is a key part of our overall strategy to allow our customers to recognize how they can gain a competitive advantage with bag-on-valve technology. It is a tangible resource to demonstrate our new product concepts and help our customers bring them to market faster and more reliably.”

“We believe we have achieved our aims and, in addition, we can also demonstrate new market opportunities and provide access to new developments we are working on,” Choudhry added.

The new laboratory is situated alongside Lindal’s Global Innovation Centre (GIC) in Briey. The GIC is home to what the company calls “a formidable arsenal of expertise and capability in aerosol dispensing solutions.” It opened in 2013 and was designed as an R&D hub to further improve time-to-market, speed commercialization of new products and enhance overall quality.

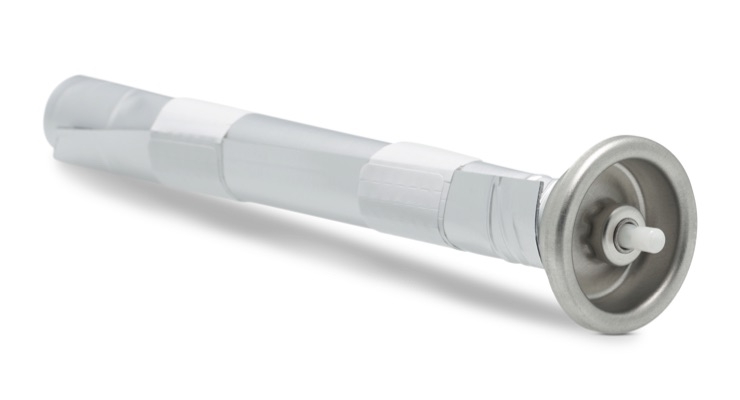

The Bag-on-Valve (BOV) aerosol system is a barrier package that protects the formulation from the propellant and other outside influences. Thus, shelf life is prolonged, with reduced dependence on preservatives, and the end-user experience optimized. It is convenient and user friendly as it can be sprayed evenly at all angles and delivers superior product evacuation particularly with viscous products, minimizing waste and maximizing consumer value.

BOV consists of an aerosol valve with a welded bag. The product is placed inside the bag while the propellant is filled in the space between bag and can. The product is dispensed by the propellant simply squeezing the bag when the actuator is depressed. Product is squeezed out of the bag by the compressed gas (no need for hydrocarbon propellants), which creates the dispensing as a spray, foam, cream or gel.

Lindal Group’s BOV solutions are compatible with a wide range of the company’s standard actuators and standard can sizes, and available with male and female valves.

The facility is designed to further elevate Lindal’s BOV strategy and industry position in this technology. The laboratory team is led by Ünal Varol, Lindal global BOV business manager, and includes aerosol industry experts from chemical engineering, cosmetic, formulation and packaging backgrounds. The conception and implementation of the new laboratory has been overseen by BOV industry expert, Georges Bouille, who has supported this new development with Lindal for the past two years.

“What makes our new lab so special is the combination of industry leading in-depth knowledge and insight into the packaging industry, coupled with technicians with best-in-class technical expertise in packaging, formulation and engineering,” said Varol.

Kashif Choudhry, Lindal product marketing manager, commented: “Our new laboratory is a key part of our overall strategy to allow our customers to recognize how they can gain a competitive advantage with bag-on-valve technology. It is a tangible resource to demonstrate our new product concepts and help our customers bring them to market faster and more reliably.”

“We believe we have achieved our aims and, in addition, we can also demonstrate new market opportunities and provide access to new developments we are working on,” Choudhry added.

The new laboratory is situated alongside Lindal’s Global Innovation Centre (GIC) in Briey. The GIC is home to what the company calls “a formidable arsenal of expertise and capability in aerosol dispensing solutions.” It opened in 2013 and was designed as an R&D hub to further improve time-to-market, speed commercialization of new products and enhance overall quality.

The Bag-on-Valve (BOV) aerosol system is a barrier package that protects the formulation from the propellant and other outside influences. Thus, shelf life is prolonged, with reduced dependence on preservatives, and the end-user experience optimized. It is convenient and user friendly as it can be sprayed evenly at all angles and delivers superior product evacuation particularly with viscous products, minimizing waste and maximizing consumer value.

BOV consists of an aerosol valve with a welded bag. The product is placed inside the bag while the propellant is filled in the space between bag and can. The product is dispensed by the propellant simply squeezing the bag when the actuator is depressed. Product is squeezed out of the bag by the compressed gas (no need for hydrocarbon propellants), which creates the dispensing as a spray, foam, cream or gel.

Lindal Group’s BOV solutions are compatible with a wide range of the company’s standard actuators and standard can sizes, and available with male and female valves.