07.13.18

BillerudKorsnäs and researchers at Uppsala University have announced that they have jointly made an important step toward paper batteries. They have taken basic research based on pure cellulose from algae and developed it to work with the same type of fiber that BillerudKorsnäs usually uses to manufacture packaging material. This development opens the way for both inexpensive and eco-friendly batteries. The long-term aim is to enable large-scale production and the future use of paper batteries for applications in areas such as smart packaging.

Technology for large-scale production processes

The development work is being carried out by one of Sweden’s foremost research teams under Maria Strömme, collaborating with BillerudKorsnäs, as a leading company in the development of sustainable packaging technology, in a completely new form.

“What’s special in this case is the model for collaboration between BillerudKorsnäs and Uppsala University that has resulted in technology adapted to large-scale production processes. We’re combining the deep theoretical expertise of the researchers with our understanding of innovation and production technology. By successfully creating a joint platform, we can focus our work on the future, on creating an advanced product that can still be produced in an effective way,” says Lars Sandberg, project manager for innovation at BillerudKorsnäs.

Smart, connected packaging

In the long term, the paper battery opens up possibilities for developing packaging that is both smart and more sustainable. Small paper batteries with sensors can lead to packaging that can be traced through the entire transport chain. This includes, for example, packaging that measures temperature or position in real time and provides information on what is happening with an item during transport.

A paper battery entails many new ways of using packaging and can thus offer exciting opportunities for the packaging industry and BillerudKorsnäs customers that wish to establish systems that safeguard quality and delivery reliability. For example, a light sensor along with a BillerudKorsnäs paper battery could provide information on where in the transport chain a product disappeared from its packaging.

With electrodes based on cellulose from wood fiber, the ambition is that in the future, it will be possible to recycle batteries along with their boxes and make them into new boxes or paper batteries.

“The paper battery is a key piece of the puzzle in efforts to produce smart packaging that requires small, sustainable power sources. By enabling this type of sustainable packaging, the work on the paper battery is fully in line with BillerudKorsnäs’ vision of challenging conventional packaging for a sustainable future. Storing energy in paper instead of in lithium batteries, for example, allows for bio-based batteries that can form part of a circular system, which provides major sustainability benefits,” says Magnus Wikström, technical director at BillerudKorsnäs.

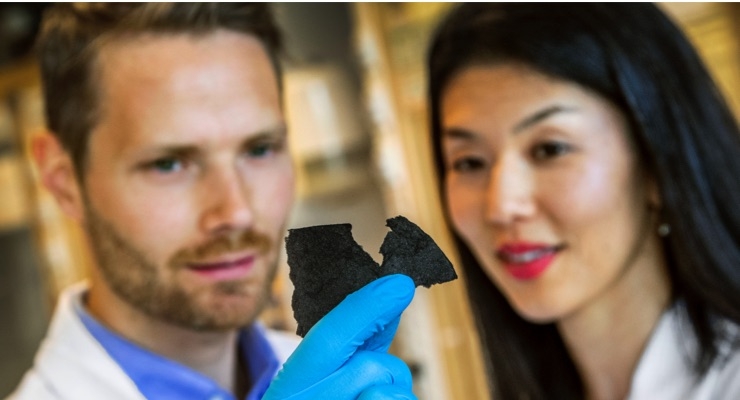

PHOTO: Petter Tammela from Ångström Laboratory and Shoko Yamada from BillerudKorsnäs study the material that becomes the paper battery. (Photo: BillerudKorsnäs)

Technology for large-scale production processes

The development work is being carried out by one of Sweden’s foremost research teams under Maria Strömme, collaborating with BillerudKorsnäs, as a leading company in the development of sustainable packaging technology, in a completely new form.

“What’s special in this case is the model for collaboration between BillerudKorsnäs and Uppsala University that has resulted in technology adapted to large-scale production processes. We’re combining the deep theoretical expertise of the researchers with our understanding of innovation and production technology. By successfully creating a joint platform, we can focus our work on the future, on creating an advanced product that can still be produced in an effective way,” says Lars Sandberg, project manager for innovation at BillerudKorsnäs.

Smart, connected packaging

In the long term, the paper battery opens up possibilities for developing packaging that is both smart and more sustainable. Small paper batteries with sensors can lead to packaging that can be traced through the entire transport chain. This includes, for example, packaging that measures temperature or position in real time and provides information on what is happening with an item during transport.

A paper battery entails many new ways of using packaging and can thus offer exciting opportunities for the packaging industry and BillerudKorsnäs customers that wish to establish systems that safeguard quality and delivery reliability. For example, a light sensor along with a BillerudKorsnäs paper battery could provide information on where in the transport chain a product disappeared from its packaging.

With electrodes based on cellulose from wood fiber, the ambition is that in the future, it will be possible to recycle batteries along with their boxes and make them into new boxes or paper batteries.

“The paper battery is a key piece of the puzzle in efforts to produce smart packaging that requires small, sustainable power sources. By enabling this type of sustainable packaging, the work on the paper battery is fully in line with BillerudKorsnäs’ vision of challenging conventional packaging for a sustainable future. Storing energy in paper instead of in lithium batteries, for example, allows for bio-based batteries that can form part of a circular system, which provides major sustainability benefits,” says Magnus Wikström, technical director at BillerudKorsnäs.

PHOTO: Petter Tammela from Ångström Laboratory and Shoko Yamada from BillerudKorsnäs study the material that becomes the paper battery. (Photo: BillerudKorsnäs)