Joanna Cosgrove, Contributing Editor11.02.15

Ponce de León’s fabled quest for the fountain of youth continues to resonate with modern day women and men who are on the hunt for skin care products that will help turn back the hands of time and protect the health of their complexions as they age. Today’s skin care market is on a steady trajectory toward a staggering $148.32 billion global worth by 2020 (+5.0% CAGR from 2014), according to Transparency Market Research. Product formulations span both high-tech formulas and those marked by their ingredient simplicity, with a similar theme connecting both ends of the spectrum: Products that promise flawless complexions deserve flawless packaging.

“A popular trend we have seen among many skin care consumers is that they want products that offer a new experience,” says Denis Maurin, vice president of sales and industrial innovation, HCT Group, Santa Monica, CA. “If a product feels good when applied to the skin, it leaves the consumer with a positive experience to associate with that product.”

To that end, HCT Group has been innovative with applicators, first creating its globally patented Cooling Tip Technology ZAMAC and ceramic applicators and, more recently, its new patent-pending Gel Tip applicators. “We believe that the gel tips are going to be a huge success among both the skin care and color cosmetic industries,” Maurin says. “They offer a ‘skin to skin’ experience that is ultra-soft and unlike any of the other materials currently being used on the market.”

Approaching skin care packaging with a creative mindset is a necessity for skin care packaging providers. Carrollton, TX-based East Hill Industries Inc. acted quickly and creatively to accommodate a request from Image Skincare, which needed an upscale container for its finely milled Intense Brightness Exfoliating Powder.

“The customer wanted a custom/unique package that did not look like a standard powder bottle, but didn’t have the time and budget for a 100% custom-tooled bottle, dispenser and cap,” recalls East Hill’s Chris James, vice president.

Using an existing airless bottle mold and cap, East Hill custom tooled a new powder sifter dispenser to fit the bottle and cap in three weeks, which slashed the tooling cost from roughly $22,000 to just under $5,000. The resulting pearlized polystyrene bottle, cap and sifter are accented with custom color metallization to help achieve the upscale look.

The company then ran the bottles and caps ahead of time to accommodate the production of the new powder sifters. “This allowed us to run the custom production in four weeks,” says James. “We were able to have the first production run finished and delivered in time for the scheduled product launch.”

To Protect and Serve

For certain skin care products with sensitive active ingredients and preservative-free formulas, conveying the benefits to the consumer requires packaging that protects and preserves delicate ingredients from degradation when exposed to light and air. Some also require point-of-use blending and/or precision dosing for best results.

Earl Trout, vice president, global sales and marketing for Airopack of The Netherlands, says consumers love products with packaging that functionally displays a product’s “visible transformation” as it happens. “Consumers want to see the creams or sprays at work, and formulators are creating exciting new blends to make that happen,” he says. “The difficult part for packaging is that most of these transformative experiences require the formulation to be protected so that the transformation does not happen until she dispenses the product.”

Trout says that depending on the formulation, this means packaging must be airtight or held under constant pressure. “Airopack does both—our system is airtight and pressurized, allowing for truly transformative formulations like the Elizabeth Arden Ceramide Self-Foaming Mask that was launched in Airopack earlier this year.”

An airtight system is also critical for the trend in preservative-free formulations. “With new ingredients being introduced, and certain ingredients/preservatives becoming less accepted, the only option is typically an airtight packaging solution,” says Trout. “Most airless packages are not airtight; there is still exposure to air in the system. Traditional packaging solutions typically expose the product to air at first use.”

He explains that airtight options give formulators the opportunity to bring new formulations to market. “Since gas is not in contact with the formulation, this may inspire formulators to think differently and develop products that have greater intensity, integrity or efficacy,” he says, adding that even though the company’s Airopack technology is powered by air, the air drives the system without touching the product, even for highly viscous formulas that might ordinarily be packaged in jars and tubes.

Hand Chemistry Hyaluronic Body Mist, from DECIEM, selected Airopack’s airtight pressurized system, along with a specifically selected spray performance to deliver a consistent hydrating mist. Trout says the product has enjoyed considerable market success and recently won “Best Body Hydrator” at the Cosmopolitan Beauty Lab Awards 2015.

VPI Packaging, Lyndhurst, NJ, recently teamed with MediCell Technologies to create an airless package for its high-end and highly delicate stem cell cosmeceutical formulation. According to VPI’s Paul Donahie, West Coast sales, the package is square-shaped and made of ABS. It is topped off with a standard pump with a metallized collar.

“The formula has no preservatives and needs as little contact from the outside environment as possible,” he says, adding that the silk screened and hot stamped square-shaped bottle, gives the package a luxurious feel. “Round is a common shape for bottles; the square package gives an upgraded look…and conveys [that] the consumer is buying something that is not only expensive, but works.”

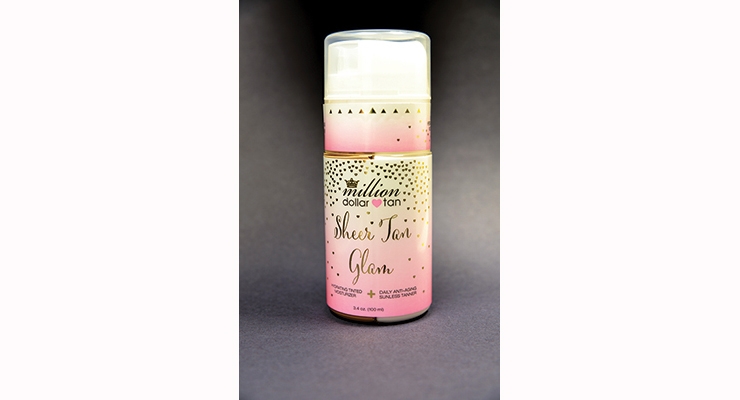

California-based Million Dollar Tan, turned to the expertise of VariBlend Dual Dispensing Systems, Greenville, SC, when it sought a specialized airless package for its hybrid skin care and sun care product that would allow consumers to flexibly customize the amount of active product they dispensed.

The solution was the VariBlend dual chamber packaging, which allows for the custom blending of two elements at the moment of use. “The variable, dual-outlet dispenser blends two separate formulas—a tinted hydrating moisturizer and an anti-aging sunless tanner—smoothly, evenly and cleanly, with no streaking, dripping or mess, which is important to today’s end-users,” says Robert Brands, CEO and president of VariBlend. “By easily rotating the dispenser head, multiple formula strengths can be selected.”

Taking the “two-become-one” concept a step further, VariBlend most recently added a dual-chambered, propellant-free, one-touch foamer to its range. “We teamed with the global tube-maker Viva Healthcare Packaging to offer fully recyclable, customizable dual-chamber tubes with an easy-to-use flip top,” Brands says. “The length of each chamber within the single tube package can be adjusted to hold up to four ounces of formula, ideal for brands owners in a wide range of consumer product categories, including skin care.

“From this, we plan to combine our patented custom-blending, dual-dispensing technology and Viva’s 100% polypropylene dual-chamber tubes,” he continues. “This configuration will appeal to brand owners in a variety of ‘regimen-based’ product categories that deliver a different multi-element formula over time.”

Emphasizing Natural Attributes

The interest in more holistically branded products featuring natural/organic ingredients is also driving demand for packaging that echoes that natural theme.

In that vein, UA Packaging, headquartered in China with offices in Shanghai and Guangzhou, has fielded an increased demand for packaging components incorporating bamboo into packaging covers and shells. However, bamboo has inherent caveats when it comes to its use in packaging. “With bamboo or other processed natural materials, there are often issues in regard to contamination, complicating import, storage and usage of the product,” comments Steven Peters, the company’s sales manager.

In order to achieve a natural-looking package that circumvents the complications, UA’s solutions innovatively revolve around decoration techniques such as water transfer printing, fiber-plastic hybrid material and epoxy technology.

Peters explains that water transfer printing offers the natural essence of real wood, but with all the practicalities and conveniences of plastic. “Originally used as camouflage patterns, or automotive decoration, we’ve invested in bringing the look of natural wood to rigid plastic materials,” he says, adding that fiber-plastic hybrid material features real wood pulp mixed with a PP plastic resin to deliver a natural look and feel. “It reaches closer in terms of the look and feel to any purely natural material than anything else on the market.”

UA’s epoxy technology, though originally used for button pins, is another exciting decorative trend. It already has been proven to be a popular application for makeup packaging, such as compacts, in the past. “The gel drop simulates the effect of water for a clear and soft surface, enhancing the decoration beneath,” Peters explains, noting that the company has already applied the technique to closures for skin care packaging, too. “It offers a big advantage in the ability to use detailed art on a label and enhance the look with the epoxy technology. Traditional printing decoration wouldn’t be able to achieve the same detail and glamour.”

Hand in hand with the holistic product and packaging trend is the effort for more environmental responsibility. Yoolie Park, director of sales and marketing, Nest-Filler USA, Buena Park, CA, says her company has seen an increase in inquiries pertaining to packaging featuring recyclable materials, such as polypropylene and glass.

One of these inquiries resulted in beautiful packaging for Purorganic’s organic skin care line, which required packaging that was in line with the concept. The company ultimately selected skin care components that were recyclable and simple in design and concept. Nest-Filler provided a complete package—bottles, dispensers, caps and the frosted, spray coated decoration—which consisted of polypropylene and glass in conjunction with the theme of recyclable materials in organic skin care. “The package was designed with simplicity in mind, in keeping with their organic skin care products,” Park says.

Packaging suppliers like Epopack Co. Ltd. of Taiwan, are also working to make sure skin care packaging made with eco-friendly materials can still convey a high-end, luxury look. And according to the company’s Amy Pan, business manager, the answer is PET heavy wall bottles. “Eco-friendly concepts have been a trend for many years and will continue to grow in the near future. PET holds international recycled code number 1; therefore, this material has a very strong voice of eco-friendly,” she says. “But we are in a ‘beautiful industry [and] everything has to be eye-catching.

Packaging has to be able to speak for itself, therefore a glass look of heavy wall style becomes the solution.”

Epopack recently supplied its TR-30 30ml PET heavy wall bottle with dropper for Youth Forever’s Anti-Spot Whitening Essence. Pan says the bottle was produced in all white to help block light and prevent the degradation of the product’s sensitive formula. “The white bottle has a very smooth and shiny surface; therefore just one-pass silk screen printing can really give the products a clean, professional look,” she says.

Epopack is currently focusing on larger sized PET bottles to capitalize on the value-size trend. They are often used in promotions and appeal to value-conscious consumers. “This value-size trade started last year, and will continue in 2016,” Pan comments. “We are going to launch four different designs of 150ml stylish PET heavy wall bottles with larger output pumps for this value-size project.”

Inspiration from Abroad

Europe and, more recently Korea, are hotbeds of skin care innovation so it’s no surprise that packaging suppliers stateside are looking to those locales for new inspiration.

“The Korean market is certainly having a big impact on the way our industry is strategizing the future of the global skin care market,” says Curt Altmann, marketing director, Yonwoo/PKG, New York.

“With so much segmentation in the market in the extremely competitive Korean market, there is a big focus on new formula and new package dispensing, including targeted application.”

Yonwoo/PKG recently produced a 15ml dropper tube for the Mamonde division of Korean skin care giant, Amore Pacific. The tube houses Mamonde Age Control Camellia Oil, a multi-purpose essential oil for the face, hands and feet that contains antioxidants extracted from the camellia flower’s leaf and seed. “The package functions like a dropper, but is made with a tube to be very economical,” Altmann says.

Baldwin Park, CA-based Pacific Packaging Components Inc. keeps a keen eye on packaging systems hailing from Europe and Korea, especially those that feature measured-dosage configurations.

“This is especially important for [the skin care] field, where avoiding waste of product during the application and evacuation process is essential,” says the company’s Rod Vilencia, vice president of sales and marketing.

At this year’s 2015 National Association of Container Distributors’ (NACD) Packaging Awards, PPC won the Gold Award in the Beauty and Personal Care Packaging Category for its 15ml Airless Eye Serum package, which was produced by Aptar in France for Drunk Elephant Skin Care’s Shaba Complex Eye Serum.

This package features a dispensing stem that delivers a .078ml dosage with each depression of the actuator button that’s located on the bottom of the package. “It offers optimum protection of the serum which includes the elimination of degradation to the formulation,” Vilencia says.

The package’s inner unit is polypropylene and the outer barrel is PET featuring a custom matte white color and two-color deco. The actuator button and over cap were also run in a custom color and are matte-coated as well.

“Packaging that has efficacy, looks good, keeps the products from degrading, and allows for maximum application efficiency can help a brand to secure clients that will buy the product again and again and become loyal to the formula as well as the packaging,” Vilencia concludes.

“A popular trend we have seen among many skin care consumers is that they want products that offer a new experience,” says Denis Maurin, vice president of sales and industrial innovation, HCT Group, Santa Monica, CA. “If a product feels good when applied to the skin, it leaves the consumer with a positive experience to associate with that product.”

To that end, HCT Group has been innovative with applicators, first creating its globally patented Cooling Tip Technology ZAMAC and ceramic applicators and, more recently, its new patent-pending Gel Tip applicators. “We believe that the gel tips are going to be a huge success among both the skin care and color cosmetic industries,” Maurin says. “They offer a ‘skin to skin’ experience that is ultra-soft and unlike any of the other materials currently being used on the market.”

Approaching skin care packaging with a creative mindset is a necessity for skin care packaging providers. Carrollton, TX-based East Hill Industries Inc. acted quickly and creatively to accommodate a request from Image Skincare, which needed an upscale container for its finely milled Intense Brightness Exfoliating Powder.

“The customer wanted a custom/unique package that did not look like a standard powder bottle, but didn’t have the time and budget for a 100% custom-tooled bottle, dispenser and cap,” recalls East Hill’s Chris James, vice president.

Using an existing airless bottle mold and cap, East Hill custom tooled a new powder sifter dispenser to fit the bottle and cap in three weeks, which slashed the tooling cost from roughly $22,000 to just under $5,000. The resulting pearlized polystyrene bottle, cap and sifter are accented with custom color metallization to help achieve the upscale look.

The company then ran the bottles and caps ahead of time to accommodate the production of the new powder sifters. “This allowed us to run the custom production in four weeks,” says James. “We were able to have the first production run finished and delivered in time for the scheduled product launch.”

To Protect and Serve

For certain skin care products with sensitive active ingredients and preservative-free formulas, conveying the benefits to the consumer requires packaging that protects and preserves delicate ingredients from degradation when exposed to light and air. Some also require point-of-use blending and/or precision dosing for best results.

Earl Trout, vice president, global sales and marketing for Airopack of The Netherlands, says consumers love products with packaging that functionally displays a product’s “visible transformation” as it happens. “Consumers want to see the creams or sprays at work, and formulators are creating exciting new blends to make that happen,” he says. “The difficult part for packaging is that most of these transformative experiences require the formulation to be protected so that the transformation does not happen until she dispenses the product.”

Trout says that depending on the formulation, this means packaging must be airtight or held under constant pressure. “Airopack does both—our system is airtight and pressurized, allowing for truly transformative formulations like the Elizabeth Arden Ceramide Self-Foaming Mask that was launched in Airopack earlier this year.”

An airtight system is also critical for the trend in preservative-free formulations. “With new ingredients being introduced, and certain ingredients/preservatives becoming less accepted, the only option is typically an airtight packaging solution,” says Trout. “Most airless packages are not airtight; there is still exposure to air in the system. Traditional packaging solutions typically expose the product to air at first use.”

He explains that airtight options give formulators the opportunity to bring new formulations to market. “Since gas is not in contact with the formulation, this may inspire formulators to think differently and develop products that have greater intensity, integrity or efficacy,” he says, adding that even though the company’s Airopack technology is powered by air, the air drives the system without touching the product, even for highly viscous formulas that might ordinarily be packaged in jars and tubes.

Hand Chemistry Hyaluronic Body Mist, from DECIEM, selected Airopack’s airtight pressurized system, along with a specifically selected spray performance to deliver a consistent hydrating mist. Trout says the product has enjoyed considerable market success and recently won “Best Body Hydrator” at the Cosmopolitan Beauty Lab Awards 2015.

VPI Packaging, Lyndhurst, NJ, recently teamed with MediCell Technologies to create an airless package for its high-end and highly delicate stem cell cosmeceutical formulation. According to VPI’s Paul Donahie, West Coast sales, the package is square-shaped and made of ABS. It is topped off with a standard pump with a metallized collar.

“The formula has no preservatives and needs as little contact from the outside environment as possible,” he says, adding that the silk screened and hot stamped square-shaped bottle, gives the package a luxurious feel. “Round is a common shape for bottles; the square package gives an upgraded look…and conveys [that] the consumer is buying something that is not only expensive, but works.”

California-based Million Dollar Tan, turned to the expertise of VariBlend Dual Dispensing Systems, Greenville, SC, when it sought a specialized airless package for its hybrid skin care and sun care product that would allow consumers to flexibly customize the amount of active product they dispensed.

The solution was the VariBlend dual chamber packaging, which allows for the custom blending of two elements at the moment of use. “The variable, dual-outlet dispenser blends two separate formulas—a tinted hydrating moisturizer and an anti-aging sunless tanner—smoothly, evenly and cleanly, with no streaking, dripping or mess, which is important to today’s end-users,” says Robert Brands, CEO and president of VariBlend. “By easily rotating the dispenser head, multiple formula strengths can be selected.”

Taking the “two-become-one” concept a step further, VariBlend most recently added a dual-chambered, propellant-free, one-touch foamer to its range. “We teamed with the global tube-maker Viva Healthcare Packaging to offer fully recyclable, customizable dual-chamber tubes with an easy-to-use flip top,” Brands says. “The length of each chamber within the single tube package can be adjusted to hold up to four ounces of formula, ideal for brands owners in a wide range of consumer product categories, including skin care.

“From this, we plan to combine our patented custom-blending, dual-dispensing technology and Viva’s 100% polypropylene dual-chamber tubes,” he continues. “This configuration will appeal to brand owners in a variety of ‘regimen-based’ product categories that deliver a different multi-element formula over time.”

Emphasizing Natural Attributes

The interest in more holistically branded products featuring natural/organic ingredients is also driving demand for packaging that echoes that natural theme.

In that vein, UA Packaging, headquartered in China with offices in Shanghai and Guangzhou, has fielded an increased demand for packaging components incorporating bamboo into packaging covers and shells. However, bamboo has inherent caveats when it comes to its use in packaging. “With bamboo or other processed natural materials, there are often issues in regard to contamination, complicating import, storage and usage of the product,” comments Steven Peters, the company’s sales manager.

In order to achieve a natural-looking package that circumvents the complications, UA’s solutions innovatively revolve around decoration techniques such as water transfer printing, fiber-plastic hybrid material and epoxy technology.

Peters explains that water transfer printing offers the natural essence of real wood, but with all the practicalities and conveniences of plastic. “Originally used as camouflage patterns, or automotive decoration, we’ve invested in bringing the look of natural wood to rigid plastic materials,” he says, adding that fiber-plastic hybrid material features real wood pulp mixed with a PP plastic resin to deliver a natural look and feel. “It reaches closer in terms of the look and feel to any purely natural material than anything else on the market.”

UA’s epoxy technology, though originally used for button pins, is another exciting decorative trend. It already has been proven to be a popular application for makeup packaging, such as compacts, in the past. “The gel drop simulates the effect of water for a clear and soft surface, enhancing the decoration beneath,” Peters explains, noting that the company has already applied the technique to closures for skin care packaging, too. “It offers a big advantage in the ability to use detailed art on a label and enhance the look with the epoxy technology. Traditional printing decoration wouldn’t be able to achieve the same detail and glamour.”

Hand in hand with the holistic product and packaging trend is the effort for more environmental responsibility. Yoolie Park, director of sales and marketing, Nest-Filler USA, Buena Park, CA, says her company has seen an increase in inquiries pertaining to packaging featuring recyclable materials, such as polypropylene and glass.

One of these inquiries resulted in beautiful packaging for Purorganic’s organic skin care line, which required packaging that was in line with the concept. The company ultimately selected skin care components that were recyclable and simple in design and concept. Nest-Filler provided a complete package—bottles, dispensers, caps and the frosted, spray coated decoration—which consisted of polypropylene and glass in conjunction with the theme of recyclable materials in organic skin care. “The package was designed with simplicity in mind, in keeping with their organic skin care products,” Park says.

Packaging suppliers like Epopack Co. Ltd. of Taiwan, are also working to make sure skin care packaging made with eco-friendly materials can still convey a high-end, luxury look. And according to the company’s Amy Pan, business manager, the answer is PET heavy wall bottles. “Eco-friendly concepts have been a trend for many years and will continue to grow in the near future. PET holds international recycled code number 1; therefore, this material has a very strong voice of eco-friendly,” she says. “But we are in a ‘beautiful industry [and] everything has to be eye-catching.

Packaging has to be able to speak for itself, therefore a glass look of heavy wall style becomes the solution.”

Epopack recently supplied its TR-30 30ml PET heavy wall bottle with dropper for Youth Forever’s Anti-Spot Whitening Essence. Pan says the bottle was produced in all white to help block light and prevent the degradation of the product’s sensitive formula. “The white bottle has a very smooth and shiny surface; therefore just one-pass silk screen printing can really give the products a clean, professional look,” she says.

Epopack is currently focusing on larger sized PET bottles to capitalize on the value-size trend. They are often used in promotions and appeal to value-conscious consumers. “This value-size trade started last year, and will continue in 2016,” Pan comments. “We are going to launch four different designs of 150ml stylish PET heavy wall bottles with larger output pumps for this value-size project.”

Inspiration from Abroad

Europe and, more recently Korea, are hotbeds of skin care innovation so it’s no surprise that packaging suppliers stateside are looking to those locales for new inspiration.

“The Korean market is certainly having a big impact on the way our industry is strategizing the future of the global skin care market,” says Curt Altmann, marketing director, Yonwoo/PKG, New York.

“With so much segmentation in the market in the extremely competitive Korean market, there is a big focus on new formula and new package dispensing, including targeted application.”

Yonwoo/PKG recently produced a 15ml dropper tube for the Mamonde division of Korean skin care giant, Amore Pacific. The tube houses Mamonde Age Control Camellia Oil, a multi-purpose essential oil for the face, hands and feet that contains antioxidants extracted from the camellia flower’s leaf and seed. “The package functions like a dropper, but is made with a tube to be very economical,” Altmann says.

Baldwin Park, CA-based Pacific Packaging Components Inc. keeps a keen eye on packaging systems hailing from Europe and Korea, especially those that feature measured-dosage configurations.

“This is especially important for [the skin care] field, where avoiding waste of product during the application and evacuation process is essential,” says the company’s Rod Vilencia, vice president of sales and marketing.

At this year’s 2015 National Association of Container Distributors’ (NACD) Packaging Awards, PPC won the Gold Award in the Beauty and Personal Care Packaging Category for its 15ml Airless Eye Serum package, which was produced by Aptar in France for Drunk Elephant Skin Care’s Shaba Complex Eye Serum.

This package features a dispensing stem that delivers a .078ml dosage with each depression of the actuator button that’s located on the bottom of the package. “It offers optimum protection of the serum which includes the elimination of degradation to the formulation,” Vilencia says.

The package’s inner unit is polypropylene and the outer barrel is PET featuring a custom matte white color and two-color deco. The actuator button and over cap were also run in a custom color and are matte-coated as well.

“Packaging that has efficacy, looks good, keeps the products from degrading, and allows for maximum application efficiency can help a brand to secure clients that will buy the product again and again and become loyal to the formula as well as the packaging,” Vilencia concludes.