Marie Redding, Associate Editor12.07.15

Colored glass and metallized looks are some of the decorative effects that always attract attention, but many brands, especially fragrances, are opting for a more elegant and understated look this year.

“This was a year marked with customers’ desires to see really beautiful flint glass with minimal or no deco—the glass purity, shape and heavy weight were at the forefront,” says Olga Bursac, vice president of sales & marketing, Bormioli Luigi. “Every other year the push is back for simply elegant glass, with very little distraction through complex decorating processes,” she adds.

While fragrance bottles often trend toward minimalist looks, cartons often require a decoration that’s a bit flashier, since the outer packaging bears the burden of getting a product noticed on store shelves.

“One of the challenges we keep hearing is how can a brand stand out, especially in duty free stores, for instance, when shoppers have limited time to browse,” says Leif Dahlberg, vice president sales North America, Papierfabrik Scheufelen.

“The outer packaging has to have that ‘wow’ factor on shelf—but it has become challenging to differentiate, as printers and converters are consistently delivering imaginative designs, with higher levels of quality,” he explains.

Hand Crafted Techniques

The new fragrance, Norell New York, is a modern updated version of the 1968 iconic Norell, and the new bottle was designed with the original in mind, according to the team at Parlux.

Norell partnered with Baccarat to produce a limited edition Norell New York Parfum that pays homage to traditional glass-making techniques. Baccarat only produced 500 bottles handmade at their factory in France, and the uber-exclusive fragrance retails for $1,500. Each bottle is numbered, and hand-sealed with gold thread.

“A flat cut was decided upon for the bottle’s design, which is featured in Baccarat’s oldest and most iconic collection to date, the Harcourt collection, which dates back to 1941,” a spokesperson for the brand stated, continuing to explain, “Each bottle was individually hand crafted, much like the bespoke garments of Norman Norell.”

The bottle was designed by the team at Norell in an effort to highlight Baccarat’s exceptional know-how in technical craftsmanship and artistry. A Baccarat creation involves the best blowers, cutters, engravers and guilders—some of them fifth generation craftspersons who have a required minimum of 15 years training in their fields before they are allowed to create a Baccarat piece.

Hand-Engraved Caps From a Jeweler

Sometimes all it takes is a standout cap to transform a simple bottle shape into a luxuriously elegant package that makes a statement. This is what StrangeLove NYC has done with its fragrance collection, Dead of Night, sold on its website and exclusively at Harrod’s.

Helena Christensen, one of the world’s original supermodels, is the creative director at StrangeLove NYC. Christensen promotes the fragrance brand by wearing it herself, to every industry event. "Helena really wears the perfume anytime, not just to industry events," explains Elizabeth Gayes, founder, StrangeLove NYC. "We both just love the fragrance so much," adds Gaynes.

The fragrance packaging for the Dead of Night collection includes traditional bottles, a rollerball and a fragrance necklace—all adorned with 18 kt gold plated caps that resemble roses. They were designed by NYC jeweler Marcus Mera.

Robert Du Grenier, a well-known sculptor and glass blower who has worked with many fragrance brands, was recruited to create a hand-engraved decoration on a version of the Dead of Night's rose cap, created for the brand’s eau de parfum, for its 50 ml and 100 ml bottles.

“Producing these caps was not an easy task. We worked with Robert because of his engineering skills, to ensure that the design that was created for the cap would work and fit perfectly on the bottle’s pump and collar, and still look beautiful,” explains Gaynes.

A Sparkling Cap

When a brand wants a fragrance bottle to have a little “bling” that doesn’t look too over-the-top, adorning a cap with crystals is one way to accomplish this. This is the design direction Michel Germain took with the launch of the Sexual Paris women’s fragrance.

Germain collaborated with bottle designer Pierre Dinand to create the bottle shape for Sexual Paris for Women, and Men. “The ladies cap is one of a kind, unlike any other on the market today. It is a sparkling, gorgeous, glamorous jewel,” says Germain, excitedly.

The cap is a dome shape, molded in polypropylene plastic and decorated using a light pink metallization process. The cap is adorned with 180 sparkling pink crystals, which are all hand-glued. “This is a laborious process that requires precision,” says Germain.

The parfum miniature, which is only available in the holiday gift set, has 240 crystals per cap. “These crystal caps have a high cost of goods—10 times that of a regular cap,” says Germain.

The cost and effort it took to execute this design is worth it, Germain says without hesitation. “The cap is opulently wrapped with the sparkling pink crystals, which attract the eye and present the flacon as a jewel, with a precious fragrance inside.”

The bottle shape may look simple and elegant, but achieving its concave feature was not easy. “The concave detail suggests the midriff of a woman’s body,” says Germain. “The smooth organic shape of glass was a challenge to perfect,” he says.

One of the details that added to the difficulty of producing the heavyweight bottles is the lip on its neck, which becomes the pedestal for the cap. “The small bottle contains 160 grams of glass, and the large has 215 grams. The defect rates are high, which results in an expensive piece of glass,” says Germain.

Sexual Paris for Men is sprayed black, and the women’s is clear—to show off the pink juice. Getting the juice to be just the right shade of pink wasn’t easy, according to Germain. He adds, “This pink was a very challenging color to achieve due to the complexity of this fragrance and the high concentration of natural aphrodisiac oils.”

Decorating with Color

Even if minimal looks are “in,” some brands still go for a more colorful look.

Decotech recently decorated the glass bottles for Kate Spade’s fragrance duo, Live Colorfully. The decoration on the women’s bottle required masking the top, bottom and sides; spraying the front and back with two different colors; and decorating multiple panels with hot stamping.

“Masking for spray has been very hot,” says Richard Engel, president & COO, Decotech Inc. He says, “In this year alone, we have developed over 20 new items that require masking before spray coating. That’s an unbelievable number for us—for the past several years we’ve only had about half a dozen masking requests per year.”

When it comes to decorating plastic, Engel says brands often strive to replicate the look of glass—especially when designing the packaging for products that are an extension of a fragrance, such as body oils, fragrance mists and scented lotions.

“We are seeing our customers begin to think of their plastic bottles more like glass, in terms of decoration, and more brands have been coming to us with this type of request,” says Engel.

“We’re also seeing a move away from simple labels to direct decoration such as digital printing, spray coating and better hot stamping on plastic. Our ability to use the same colors and techniques on our clients’ glass and plastic containers gives the lines more visual consistency and harmony on the shelves,” he explains.

Engel says Decotech is a leader in digital printing. “Our technology was the first to market, and continues to be the only one that can pass all adhesion and compatibility tests without additional treatment,” says Engel. He adds, “We can say the same about our hot stamping foil technology as well. We use a foil system with a unique construction that has never once failed adhesion or compatibility testing.”

In addition, Decotech doesn’t have a minimum order requirement for custom foil colors, which is a boon for an Indie brand. “The fact that we offer this service is unique in the industry,” Engel says.

Metallized looks are a popular decorative effect for glass as well as plastic. Suppliers have been fielding requests from brands to replicate the type of vacuum metallized look typically seen on plastic components, but on glass, using a spray coating.

John Schofield, Screen Tech/Spraye Tech, says, “Many of our customers want to try to get as close as possible to the look of vacuum metallization, using a spray process. This seems to be the challenge for all the decorators right now.” He explains, “It is a very difficult process to metallize glass—there are very few suppliers who can do this, and do it well, to achieve the results that brands want.”

Screen Tech/Spraye Tech is currently working on additional decorating options for glass, and new techniques that can be used as alternatives to metallization. “I can’t give more details just yet, it’s a work in progress,” he says.

Dave Desai, director of sales, Beauty Division, Piramal Glass USA, also says metallization is still one of the most often requested decorations lately—and he discusses the challenges. “Brands want to see bright, shiny metallized finishes on glass, but the decorating processes that are traditionally used to achieve this look aren’t very cost-effective,” explains Desai. He adds, “To address this issue and meet our customers’ requests, we will be installing new metallization capabilities in 2016. We will have the ability to decorate glass using high-speed metallization processes, which will be both cost- and time-efficient.”

Bottle Coatings, Inc., a division of SunDial Powder Coatings, offers its customers a number of ways to decorate a glass bottle, colorfully.

“We are one of the only ones doing an eco-friendly powder coating technique, which gives the cosmetics industry a ‘green’ solution. And we continue to make new inroads in the complexity of the designs we can create,” says Shivie Dhillon, president, Bottle Coatings.

Bottle Coatings offers its coatings in a number of options that include a wide range of vibrant colors and innovative patterns. “As the cosmetics market gets more competitive, clients are looking for increasingly creative designs, challenging traditional powder coating methods and calling for even greater ingenuity,” says Dhillon.

A new decorating process that Bottle Coatings has recently developed is Sublimation. “This is the process of using VOC/toxic-free powder coating and then embedding an image into the coating. The final product is more vibrant and durable than any other labeling technique,” says Dhillon. “There is no limitation to the styles and patterns available. Custom artwork can be created to offer the best possible impact on the shelf.”

The team at Bottle Coatings is also working on a coating for glass bottles and jars that is designed to mimic a wood grain finish. It is being done in collaboration with a startup brand.

“When trying to match a particular look and feel like wood, there are many challenges,” Dhillon explains. “The first challenge is the ‘touch.’ Wood has a very distinct feel to it. Creating a powder coating to feel like wood was the first obstacle to overcome; we made it low-gloss and slightly textured.” (This effect is shown above.)

Trends in Decorating Nail Polish Bottles

“We’re seeing a move back to direct printing on nail polish bottles, which we haven’t seen make a comeback since the 80s,” says Desai. “Everyone moved away from this, wanting bottles that they could label, but now that’s changing,” he explains. Piramal recently had to increase its production capacity to keep up with the global demand for printing on nail polish bottles, according to Desai.

Spraying a nail polish bottle with either a black or white coating is another common type of decoration that Piramal does often, since certain types of nail polish need protection from UV light.

Bottle Coatings is also known for its protective solutions for nail polish bottles. The supplier offers a patent-pending UV-protectant coating for glass bottles that contain UV sensitive contents, which includes nail polish gel formulations. The powder coating process helps to prolong the product’s shelf life by blocking UV light.

What’s New for Cartons?

Fragrance bottles are getting luxe treatments, and cartons are getting just as much attention.

A great carton begins with the right paperboard, and Papierfabrik Scheufelen is introducing a new board grade for its North American customers called phoenolux. Its development was driven by requests from brand owners, according to Leif Dahlberg, VP sales North America, Papierfabrik Scheufelen.

“Every paperboard manufacturer strives to achieve a whiter, brighter look, and I believe we have managed to reach a higher level of whiteness than anyone else at the moment,” Dahlberg explains. “Due to this board’s whiteness and brightness levels, phoenolux will help cosmetics and skin care brands using white cartons, with minimal decoration, to stand out among competitors. However, when using a lot of ink coverage, the colors will also stand out vividly thanks to the surface properties of the board.”

There are several challenges involved in creating a board that will stay white. “The key is to minimize yellowing due to exposure to light,” Dahlberg says. “Brands that use white cartons don’t want a store to receive a new order and have it look different from the product already on the shelf,” he explains.

Phoenolux is also ideal to use in conjunction with any type of decorative effect,since it ensures that a decoration will appear true to color — and exactly what a designer expected.

Decorative Effects for Cartons

Color Optics by Arcade offers two unique decorating processes for cartons—Opti-Glitter and Opti-Kote—and both offer brands several advantages.

Opti-Glitter is Color Optics’ proprietary process. “It looks and feels like a traditional silkscreen process that would be done off-line, but we developed an in-line litho process, which was a challenge to accomplish. This process delivers a great look at an affordable price, and it takes less time to complete,” says Joe Cicci, president, Color Optics by Arcade.

Opti-Kote is another time-saving printing solution. “It is a coating process that can achieve embossed looks with pinpoint registration, for detailed designs,” explains Cicci.

Need a scented carton? Color Optics’ Pre-Scent decorating process allows for a scented coating to be printed right on a carton.

Fragrance brands have been taking advantage of Color Optics’ Pre-Scent packaging concept. Color Optics used this process to produce the cartons for the Chrome by Azzaro fragrance, among others.

Working in conjunction with its plant in Chattanooga, TN, Color Optics uses a micro-encapsulation process to ensure that the scented coating on the carton smells just like the real juice. “Our fragrance brand customers love our Pre-Scent packages,” says Cicci, explaining that he has heard great feedback from many brands, as well as retailers. He continues, “Since we’re a part of Arcade Beauty, which is a leader in sampling technology, our fragrance samples are accurate.”

Fielding Requests for Cold Foiling

Suppliers say there are many benefits to using a cold foil process to decorate a carton. It’s a process that’s done in-line, so both the printing and foiling for a carton can be done on the press.

Color Optics has the ability to decorate a carton using a cold foil process, and Cicci says its customers have been requesting this process more often lately.

Arkay recently produced cartons for a collection by MAC Cosmetics for Holiday 2015. The supplier worked with the team at The Estée Lauder Companies to produce the cartons shown, which demonstrate the versatility of cold foil stamping, according to Gregg Goldman, director of sales at Arkay Packaging.

Goldman explains how this decoration was created, saying, “We lay down silver leaf on press in the cold foil unit and then over-print multiple colors. Before we perfected this technology, executing this design would have required multiple passes of hot stamping.”

Arkay is also currently using a cold foil process in a unique way on a carton for another product that will launch soon. “This project is very exciting,” says Goldman, adding, “but we’ll have to wait before further details are revealed.”

When developing a project that will use cold foil, Goldman says it’s important that the collaboration with a brand’s packaging and design teams begins early on in the development process.

“As opposed to hot stamping, which you know will be applied over the printing, the cold foil creates a layer that, during the development process, needs to be treated as if it were a printed color,” Goldman says. He works with brands to figure out all the specifications, some of which include the correct rotation and the considerations that need to be made with regard to print register and spot coatings.

“Arkay specializes in this kind of creative collaboration with our clients, through face-to-face review and on-press proofing, to ensure that the end result is something special,” says Goldman. He adds, “I personally feel that the potential of cold foil is still largely untapped from a creative standpoint. There is a huge opportunity to create a multi-layered, multi-textured tapestry of metallic leaf, printed color, spot coatings and embossed texture—we are only just beginning to scratch the surface.”

Dennis Bacchetta, director of marketing, Diamond Packaging, says he is seeing cold foil processes continue to grow in popularity. Diamond has recently announced the first U.S. installation of the new CF1000PM (press mounted) cold foil module from Compact Foilers.

“Our new cold foil unit, which is mounted on one of Diamond’s Heidelberg XL105 offset presses, cost effectively delivers inline metallic and holographic effects,” says Bacchetta.

Bacchetta says that Diamond’s in-line decorating processes offer a solution for brands looking for a way to quickly capture the consumers’ attention in a retail environment. “We’re offering an in-line enhancement that will attract consumers’ attention faster and retain attention longer than packaging without foil stamping,” he says.

In-line decorative techniques such as cold foiling are a natural evolution of Diamond’s ‘greenbox’ initiative, Bacchetta explains, which the supplier developed to research, design and implement packaging solutions that are both innovative and sustainable.

“We’re meeting our customers’ needs for high-end decorative effects, and we’re doing it in fewer steps so that it is faster, more economical, and provides sustainability benefits,” he says. He adds, “We continually challenge ourselves to deliver cost innovation and this is one more way of achieving it.”

Diamond’s other numerous in-line decorating technologies include specialty coatings like Soft Touch and Texture, and special effects that include a holographic effect, Cast and Cure.

“These in-line converting techniques enable brand owners to develop more cost effective and sustainable packaging, especially when factoring in the material and energy costs that would be associated with multiple runs or off-line production processes,” Bacchetta explains.

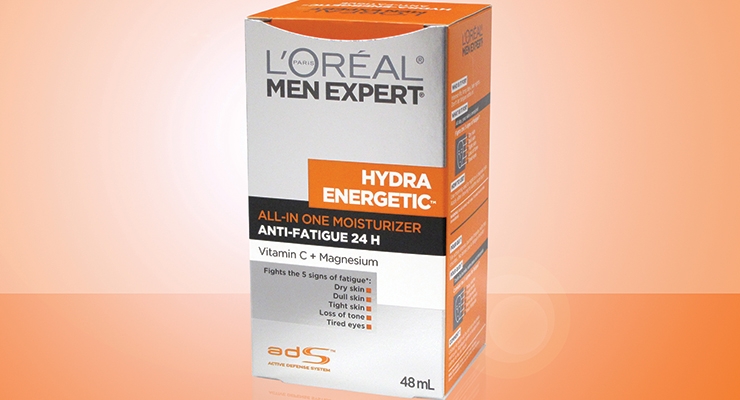

Diamond Packaging recently worked with the team at L’Oréal on the carton for the launch of a moisturizer, L’Oréal Men Expert Hydra Energetic. “The carton was converted utilizing FSC-certified Invercote G paperboard, and offset printed with six colors, along with UV matte and UV gloss spot coating,” says Bacchetta. “Silver cold foil stamping enhances the front, side, rear, and bottom panels.”

What’s Next?

We asked suppliers what we can expect to see next.

“Matte finishes are becoming increasingly popular,” says Bottle Coatings’ Dhillon. “Depending on the industry, transparent matte finishes and bright neon matte finishes seem to be the trend at the moment,” he adds.

Arkay’s Goldman says that he’s most excited about continuing to explore and develop the numerous ways to utilize a cold foil process. He adds, “Looking forward, it will be interesting to see how designers integrate holographic cold foils into high-end packaging in an upscale way—creating movement, but retaining subtlety.”

Read More

Online Exclusive: Calling on a Craftsman To Make a Fragrance Bottle Look Fancy

Slideshow: Ultra-Luxe Bottles Designed for Thousand Dollar Fragrances

“This was a year marked with customers’ desires to see really beautiful flint glass with minimal or no deco—the glass purity, shape and heavy weight were at the forefront,” says Olga Bursac, vice president of sales & marketing, Bormioli Luigi. “Every other year the push is back for simply elegant glass, with very little distraction through complex decorating processes,” she adds.

While fragrance bottles often trend toward minimalist looks, cartons often require a decoration that’s a bit flashier, since the outer packaging bears the burden of getting a product noticed on store shelves.

“One of the challenges we keep hearing is how can a brand stand out, especially in duty free stores, for instance, when shoppers have limited time to browse,” says Leif Dahlberg, vice president sales North America, Papierfabrik Scheufelen.

“The outer packaging has to have that ‘wow’ factor on shelf—but it has become challenging to differentiate, as printers and converters are consistently delivering imaginative designs, with higher levels of quality,” he explains.

Hand Crafted Techniques

The new fragrance, Norell New York, is a modern updated version of the 1968 iconic Norell, and the new bottle was designed with the original in mind, according to the team at Parlux.

Norell partnered with Baccarat to produce a limited edition Norell New York Parfum that pays homage to traditional glass-making techniques. Baccarat only produced 500 bottles handmade at their factory in France, and the uber-exclusive fragrance retails for $1,500. Each bottle is numbered, and hand-sealed with gold thread.

“A flat cut was decided upon for the bottle’s design, which is featured in Baccarat’s oldest and most iconic collection to date, the Harcourt collection, which dates back to 1941,” a spokesperson for the brand stated, continuing to explain, “Each bottle was individually hand crafted, much like the bespoke garments of Norman Norell.”

The bottle was designed by the team at Norell in an effort to highlight Baccarat’s exceptional know-how in technical craftsmanship and artistry. A Baccarat creation involves the best blowers, cutters, engravers and guilders—some of them fifth generation craftspersons who have a required minimum of 15 years training in their fields before they are allowed to create a Baccarat piece.

Hand-Engraved Caps From a Jeweler

Sometimes all it takes is a standout cap to transform a simple bottle shape into a luxuriously elegant package that makes a statement. This is what StrangeLove NYC has done with its fragrance collection, Dead of Night, sold on its website and exclusively at Harrod’s.

Helena Christensen, one of the world’s original supermodels, is the creative director at StrangeLove NYC. Christensen promotes the fragrance brand by wearing it herself, to every industry event. "Helena really wears the perfume anytime, not just to industry events," explains Elizabeth Gayes, founder, StrangeLove NYC. "We both just love the fragrance so much," adds Gaynes.

The fragrance packaging for the Dead of Night collection includes traditional bottles, a rollerball and a fragrance necklace—all adorned with 18 kt gold plated caps that resemble roses. They were designed by NYC jeweler Marcus Mera.

Robert Du Grenier, a well-known sculptor and glass blower who has worked with many fragrance brands, was recruited to create a hand-engraved decoration on a version of the Dead of Night's rose cap, created for the brand’s eau de parfum, for its 50 ml and 100 ml bottles.

“Producing these caps was not an easy task. We worked with Robert because of his engineering skills, to ensure that the design that was created for the cap would work and fit perfectly on the bottle’s pump and collar, and still look beautiful,” explains Gaynes.

A Sparkling Cap

When a brand wants a fragrance bottle to have a little “bling” that doesn’t look too over-the-top, adorning a cap with crystals is one way to accomplish this. This is the design direction Michel Germain took with the launch of the Sexual Paris women’s fragrance.

Germain collaborated with bottle designer Pierre Dinand to create the bottle shape for Sexual Paris for Women, and Men. “The ladies cap is one of a kind, unlike any other on the market today. It is a sparkling, gorgeous, glamorous jewel,” says Germain, excitedly.

The cap is a dome shape, molded in polypropylene plastic and decorated using a light pink metallization process. The cap is adorned with 180 sparkling pink crystals, which are all hand-glued. “This is a laborious process that requires precision,” says Germain.

The parfum miniature, which is only available in the holiday gift set, has 240 crystals per cap. “These crystal caps have a high cost of goods—10 times that of a regular cap,” says Germain.

The cost and effort it took to execute this design is worth it, Germain says without hesitation. “The cap is opulently wrapped with the sparkling pink crystals, which attract the eye and present the flacon as a jewel, with a precious fragrance inside.”

The bottle shape may look simple and elegant, but achieving its concave feature was not easy. “The concave detail suggests the midriff of a woman’s body,” says Germain. “The smooth organic shape of glass was a challenge to perfect,” he says.

One of the details that added to the difficulty of producing the heavyweight bottles is the lip on its neck, which becomes the pedestal for the cap. “The small bottle contains 160 grams of glass, and the large has 215 grams. The defect rates are high, which results in an expensive piece of glass,” says Germain.

Sexual Paris for Men is sprayed black, and the women’s is clear—to show off the pink juice. Getting the juice to be just the right shade of pink wasn’t easy, according to Germain. He adds, “This pink was a very challenging color to achieve due to the complexity of this fragrance and the high concentration of natural aphrodisiac oils.”

Decorating with Color

Even if minimal looks are “in,” some brands still go for a more colorful look.

Decotech recently decorated the glass bottles for Kate Spade’s fragrance duo, Live Colorfully. The decoration on the women’s bottle required masking the top, bottom and sides; spraying the front and back with two different colors; and decorating multiple panels with hot stamping.

“Masking for spray has been very hot,” says Richard Engel, president & COO, Decotech Inc. He says, “In this year alone, we have developed over 20 new items that require masking before spray coating. That’s an unbelievable number for us—for the past several years we’ve only had about half a dozen masking requests per year.”

When it comes to decorating plastic, Engel says brands often strive to replicate the look of glass—especially when designing the packaging for products that are an extension of a fragrance, such as body oils, fragrance mists and scented lotions.

“We are seeing our customers begin to think of their plastic bottles more like glass, in terms of decoration, and more brands have been coming to us with this type of request,” says Engel.

“We’re also seeing a move away from simple labels to direct decoration such as digital printing, spray coating and better hot stamping on plastic. Our ability to use the same colors and techniques on our clients’ glass and plastic containers gives the lines more visual consistency and harmony on the shelves,” he explains.

Engel says Decotech is a leader in digital printing. “Our technology was the first to market, and continues to be the only one that can pass all adhesion and compatibility tests without additional treatment,” says Engel. He adds, “We can say the same about our hot stamping foil technology as well. We use a foil system with a unique construction that has never once failed adhesion or compatibility testing.”

In addition, Decotech doesn’t have a minimum order requirement for custom foil colors, which is a boon for an Indie brand. “The fact that we offer this service is unique in the industry,” Engel says.

Metallized looks are a popular decorative effect for glass as well as plastic. Suppliers have been fielding requests from brands to replicate the type of vacuum metallized look typically seen on plastic components, but on glass, using a spray coating.

John Schofield, Screen Tech/Spraye Tech, says, “Many of our customers want to try to get as close as possible to the look of vacuum metallization, using a spray process. This seems to be the challenge for all the decorators right now.” He explains, “It is a very difficult process to metallize glass—there are very few suppliers who can do this, and do it well, to achieve the results that brands want.”

Screen Tech/Spraye Tech is currently working on additional decorating options for glass, and new techniques that can be used as alternatives to metallization. “I can’t give more details just yet, it’s a work in progress,” he says.

Dave Desai, director of sales, Beauty Division, Piramal Glass USA, also says metallization is still one of the most often requested decorations lately—and he discusses the challenges. “Brands want to see bright, shiny metallized finishes on glass, but the decorating processes that are traditionally used to achieve this look aren’t very cost-effective,” explains Desai. He adds, “To address this issue and meet our customers’ requests, we will be installing new metallization capabilities in 2016. We will have the ability to decorate glass using high-speed metallization processes, which will be both cost- and time-efficient.”

Bottle Coatings, Inc., a division of SunDial Powder Coatings, offers its customers a number of ways to decorate a glass bottle, colorfully.

“We are one of the only ones doing an eco-friendly powder coating technique, which gives the cosmetics industry a ‘green’ solution. And we continue to make new inroads in the complexity of the designs we can create,” says Shivie Dhillon, president, Bottle Coatings.

Bottle Coatings offers its coatings in a number of options that include a wide range of vibrant colors and innovative patterns. “As the cosmetics market gets more competitive, clients are looking for increasingly creative designs, challenging traditional powder coating methods and calling for even greater ingenuity,” says Dhillon.

A new decorating process that Bottle Coatings has recently developed is Sublimation. “This is the process of using VOC/toxic-free powder coating and then embedding an image into the coating. The final product is more vibrant and durable than any other labeling technique,” says Dhillon. “There is no limitation to the styles and patterns available. Custom artwork can be created to offer the best possible impact on the shelf.”

The team at Bottle Coatings is also working on a coating for glass bottles and jars that is designed to mimic a wood grain finish. It is being done in collaboration with a startup brand.

“When trying to match a particular look and feel like wood, there are many challenges,” Dhillon explains. “The first challenge is the ‘touch.’ Wood has a very distinct feel to it. Creating a powder coating to feel like wood was the first obstacle to overcome; we made it low-gloss and slightly textured.” (This effect is shown above.)

Trends in Decorating Nail Polish Bottles

“We’re seeing a move back to direct printing on nail polish bottles, which we haven’t seen make a comeback since the 80s,” says Desai. “Everyone moved away from this, wanting bottles that they could label, but now that’s changing,” he explains. Piramal recently had to increase its production capacity to keep up with the global demand for printing on nail polish bottles, according to Desai.

Spraying a nail polish bottle with either a black or white coating is another common type of decoration that Piramal does often, since certain types of nail polish need protection from UV light.

Bottle Coatings is also known for its protective solutions for nail polish bottles. The supplier offers a patent-pending UV-protectant coating for glass bottles that contain UV sensitive contents, which includes nail polish gel formulations. The powder coating process helps to prolong the product’s shelf life by blocking UV light.

What’s New for Cartons?

Fragrance bottles are getting luxe treatments, and cartons are getting just as much attention.

A great carton begins with the right paperboard, and Papierfabrik Scheufelen is introducing a new board grade for its North American customers called phoenolux. Its development was driven by requests from brand owners, according to Leif Dahlberg, VP sales North America, Papierfabrik Scheufelen.

“Every paperboard manufacturer strives to achieve a whiter, brighter look, and I believe we have managed to reach a higher level of whiteness than anyone else at the moment,” Dahlberg explains. “Due to this board’s whiteness and brightness levels, phoenolux will help cosmetics and skin care brands using white cartons, with minimal decoration, to stand out among competitors. However, when using a lot of ink coverage, the colors will also stand out vividly thanks to the surface properties of the board.”

There are several challenges involved in creating a board that will stay white. “The key is to minimize yellowing due to exposure to light,” Dahlberg says. “Brands that use white cartons don’t want a store to receive a new order and have it look different from the product already on the shelf,” he explains.

Phoenolux is also ideal to use in conjunction with any type of decorative effect,since it ensures that a decoration will appear true to color — and exactly what a designer expected.

Decorative Effects for Cartons

Color Optics by Arcade offers two unique decorating processes for cartons—Opti-Glitter and Opti-Kote—and both offer brands several advantages.

Opti-Glitter is Color Optics’ proprietary process. “It looks and feels like a traditional silkscreen process that would be done off-line, but we developed an in-line litho process, which was a challenge to accomplish. This process delivers a great look at an affordable price, and it takes less time to complete,” says Joe Cicci, president, Color Optics by Arcade.

Opti-Kote is another time-saving printing solution. “It is a coating process that can achieve embossed looks with pinpoint registration, for detailed designs,” explains Cicci.

Need a scented carton? Color Optics’ Pre-Scent decorating process allows for a scented coating to be printed right on a carton.

Fragrance brands have been taking advantage of Color Optics’ Pre-Scent packaging concept. Color Optics used this process to produce the cartons for the Chrome by Azzaro fragrance, among others.

Working in conjunction with its plant in Chattanooga, TN, Color Optics uses a micro-encapsulation process to ensure that the scented coating on the carton smells just like the real juice. “Our fragrance brand customers love our Pre-Scent packages,” says Cicci, explaining that he has heard great feedback from many brands, as well as retailers. He continues, “Since we’re a part of Arcade Beauty, which is a leader in sampling technology, our fragrance samples are accurate.”

Fielding Requests for Cold Foiling

Suppliers say there are many benefits to using a cold foil process to decorate a carton. It’s a process that’s done in-line, so both the printing and foiling for a carton can be done on the press.

Color Optics has the ability to decorate a carton using a cold foil process, and Cicci says its customers have been requesting this process more often lately.

Arkay recently produced cartons for a collection by MAC Cosmetics for Holiday 2015. The supplier worked with the team at The Estée Lauder Companies to produce the cartons shown, which demonstrate the versatility of cold foil stamping, according to Gregg Goldman, director of sales at Arkay Packaging.

Goldman explains how this decoration was created, saying, “We lay down silver leaf on press in the cold foil unit and then over-print multiple colors. Before we perfected this technology, executing this design would have required multiple passes of hot stamping.”

Arkay is also currently using a cold foil process in a unique way on a carton for another product that will launch soon. “This project is very exciting,” says Goldman, adding, “but we’ll have to wait before further details are revealed.”

When developing a project that will use cold foil, Goldman says it’s important that the collaboration with a brand’s packaging and design teams begins early on in the development process.

“As opposed to hot stamping, which you know will be applied over the printing, the cold foil creates a layer that, during the development process, needs to be treated as if it were a printed color,” Goldman says. He works with brands to figure out all the specifications, some of which include the correct rotation and the considerations that need to be made with regard to print register and spot coatings.

“Arkay specializes in this kind of creative collaboration with our clients, through face-to-face review and on-press proofing, to ensure that the end result is something special,” says Goldman. He adds, “I personally feel that the potential of cold foil is still largely untapped from a creative standpoint. There is a huge opportunity to create a multi-layered, multi-textured tapestry of metallic leaf, printed color, spot coatings and embossed texture—we are only just beginning to scratch the surface.”

Dennis Bacchetta, director of marketing, Diamond Packaging, says he is seeing cold foil processes continue to grow in popularity. Diamond has recently announced the first U.S. installation of the new CF1000PM (press mounted) cold foil module from Compact Foilers.

“Our new cold foil unit, which is mounted on one of Diamond’s Heidelberg XL105 offset presses, cost effectively delivers inline metallic and holographic effects,” says Bacchetta.

Bacchetta says that Diamond’s in-line decorating processes offer a solution for brands looking for a way to quickly capture the consumers’ attention in a retail environment. “We’re offering an in-line enhancement that will attract consumers’ attention faster and retain attention longer than packaging without foil stamping,” he says.

In-line decorative techniques such as cold foiling are a natural evolution of Diamond’s ‘greenbox’ initiative, Bacchetta explains, which the supplier developed to research, design and implement packaging solutions that are both innovative and sustainable.

“We’re meeting our customers’ needs for high-end decorative effects, and we’re doing it in fewer steps so that it is faster, more economical, and provides sustainability benefits,” he says. He adds, “We continually challenge ourselves to deliver cost innovation and this is one more way of achieving it.”

Diamond’s other numerous in-line decorating technologies include specialty coatings like Soft Touch and Texture, and special effects that include a holographic effect, Cast and Cure.

“These in-line converting techniques enable brand owners to develop more cost effective and sustainable packaging, especially when factoring in the material and energy costs that would be associated with multiple runs or off-line production processes,” Bacchetta explains.

Diamond Packaging recently worked with the team at L’Oréal on the carton for the launch of a moisturizer, L’Oréal Men Expert Hydra Energetic. “The carton was converted utilizing FSC-certified Invercote G paperboard, and offset printed with six colors, along with UV matte and UV gloss spot coating,” says Bacchetta. “Silver cold foil stamping enhances the front, side, rear, and bottom panels.”

What’s Next?

We asked suppliers what we can expect to see next.

“Matte finishes are becoming increasingly popular,” says Bottle Coatings’ Dhillon. “Depending on the industry, transparent matte finishes and bright neon matte finishes seem to be the trend at the moment,” he adds.

Arkay’s Goldman says that he’s most excited about continuing to explore and develop the numerous ways to utilize a cold foil process. He adds, “Looking forward, it will be interesting to see how designers integrate holographic cold foils into high-end packaging in an upscale way—creating movement, but retaining subtlety.”

Read More

Online Exclusive: Calling on a Craftsman To Make a Fragrance Bottle Look Fancy

Slideshow: Ultra-Luxe Bottles Designed for Thousand Dollar Fragrances