Jamie Matusow, Editor-in-Chief04.28.16

We frequently hear of new or experimental sustainable packaging solutions, especially in the categories of food and beverages. In one of the latest, Ari Jónsson a design student at the Iceland Academy of the Arts garnered worldwide attention for a biodegradable water bottle that could greatly impact the environment. Made of red algae, the bottle can completely break down after time, eliminating any waste.

Much progress has also been made in developing environmentally responsible cosmetics packaging, but barriers such as limited recycling facilities, non-oil-based materials, costs—and even demand—still hamper the way. And obstructions to generating “green” vessels have been further complicated by the increased needs for compatible packaging that protects sensitive formulations and matches the appearance of prestige—and mass—products.

But the situation may be on the cusp of change. Millennial consumers and young executives are on the road to speeding things up. At the same time, promising new material solutions are emerging from sources including the bottom of the ocean, carnivorous plants—and even thin air.

Millennials Lead the Way

For years, the idea of sustainability has captured the interest of corporate boardrooms as a path to efficiency and cost savings throughout the supply chain. As the Millennial population becomes more dominant in corporate management, sustainability measures are expected to continue to grow, leading suppliers in beauty and elsewhere to further pursue the development of environmentally responsible packages and practices.

In the past few years, the cosmetics industry has seen a growing trend toward incorporating larger percentages of post consumer recycled materials, and light weighting has become almost a matter of course. More refillable and reusable packs are also satisfying demand for conscientious choices. Smaller size products that can be used up before their expiration dates have also been increasingly entering the beauty marketplace. And suppliers’ manufacturing processes are adding to a reduced carbon footprint.

Mark Sng, director of marketing, Neenah Packaging, credits Millennials for an uptick in eco-friendly packaging requests from customers. He tells Beauty Packaging, “Without question, consumer expectations continue to drive growth in eco-friendly packaging. Today’s Millennials are three times more focused on the environment than their parents’ generation; two-thirds of Millennials say they are willing to pay more for products from sustainability-focused companies.”

Sng says as marketers create branding to appeal to consumers with environmentally minded expectations, “Brands are considering every facet of the packaging they develop: the environmental footprint, the lifecycle analysis, and the selection of recyclable and post-consumer recycled materials.”

In addition, Sng says corporate metrics are driven by customer expectations. “We see many of our beauty and cosmetics customers striving for continuous improvement in their sustainability practices. More want to publicly share their year over year progress. We see it on their packaging, on their websites and in annual sustainability reports.”

Consumer Delights

When it comes to using containers that are earth-friendly, both smaller brands and key global players have achieved success with consumers who share their environmental goals, but it can be a challenge nonetheless.

Greta Fitz, director of global marketing for Fusion Brands America, Inc., makers of Clean Reserve products, tells Beauty Packaging: “From what we’ve seen, consumers, especially Millennials, are very conscious of lowering their carbon footprint and expect companies to do the same. As a brand we believe in sustainable beauty, and to us this means working to preserve nature’s resources and keeping our products out of landfills. Our story has resonated with those who look for this in their purchases, and has also raised awareness and interest in those who haven’t yet.”

Still, Rudi Becker, senior director of packaging and industrial design, at method, a leading global company with environmentally responsible packaging at its core, says: “Consumer awareness is growing, but there is still only a small subset of consumers who are actively seeking green products. Given that, the challenge for companies that make green products is to make them equally (if not more) compelling for the consumer compared to traditional products outside the naturals set.”

Fitz agrees, saying, Clean Reserve strives to create a luxurious product with minimal treatments “that will look great in store and feel great in the client’s hand.” The challenge, she says, is to work with less and deliver more. “That’s what makes our brand stand out from the clutter,” she explains. And consumers are responding well. Fitz says that Sephora, their exclusive retailer in the U.S., “is thrilled with the response from their clients thus far. We have sold out on our introductory sets and have gained a strong following in a matter of a few months, and this is just the beginning.”

Gel hand washes from method’s Spring 2016 limited-edition collection with Brooklyn-based designer Rebecca Atwood are available exclusively at Target. The gray bottles for Ocean Plastic Dish + Hand Soap were made with recovered ocean plastic. The product is a permanent part of the company’s product line—and is available exclusively at Whole Foods. (See Beauty Packaging’s exclusive interview with Becker in this issue.)

Burt’s Bees is another brand that’s always striving for sustainability, emphasizing both the formulations and the packaging. Their newly released lipsticks are 60% post-consumer recycled plastic. Empty tubes can be mailed back to the brand for recycling using a prepaid mailing label.

Increased Consumer Focus on Packaging

According to Ameripen (American Institute for Packaging and the Environment), Americans spend $50 billion annually for beauty and personal care products, including shampoo and conditioner, cosmetics, toothpaste, and soap and body wash. The organization recognizes the critical role of packaging for these products, and recently issued guidelines to inform consumers about recycling, buying the right size for the right occasion, and purchasing refillable systems for items like liquid soap, shampoo, and conditioner.

The advice comes as consumers are starting to take a closer look at eco-friendly packaging. A recent global cosmetics packaging market report from Technavio Research identifies an “increase in demand for sustainable cosmetic packaging as a key trend in the market.” Technavio’s research analyst predicts the global cosmetic packaging market will grow at a CAGR of around 5% between 2016 and 2020.

According to Technavio: “The growing need for sustainable and eco-friendly packaging is a leading trend in the global cosmetic packaging market. In many countries, environmental and sustainability issues are being raised with packaging manufacturers. Numerous cosmetics manufacturers prefer using eco-friendly packaging material as it provides an opportunity to promote environmental sustainability. Increased environmental concern and the need to reduce pollution have led to the adoption of recyclable materials, such as plastic and the use of resins derived from renewable resources. These factors encourage vendors to develop new materials and incorporate eco-friendly designs that encourage the minimal use of non-biodegradable materials in packaging.

For instance, recycled paper, bamboo, and recycled glass are considered eco-friendly materials for packaging. In addition, sustainable packaging enables consumer goods manufacturers to improve their brand image and reduce their carbon footprint.”

We’ve all become used to the many symbols evident on cosmetics packaging, as to recycling, standards and ecological organizations. In addition, some brands are now mentioning elements of reduced packaging right on the bottle or carton, itself. For instance, John Masters Organics Facial Oil states clearly on top of the carton’s flap: “Our new box uses 50% less material.”

Making Demands

Corporate Social Responsibility has become a priority in a number of organizations worldwide—and retailers and brands, both large and small, from Walmart and Target, to Estée Lauder and L’Oréal, to method, Lush and Kiehl’s, have instituted sustainability plans that include reducing their environmental footprint.

Almost all of the suppliers Beauty Packaging spoke to for this article say that environmentally responsible packaging is more and more a focus of their customers and potential customers—but the reasoning can be complicated.

Dennis Bacchetta, director of marketing at Diamond Packaging, which specializes in folding cartons and contract packaging services, notes that many companies are looking at sustainable packaging design as one aspect of the larger role of Corporate Social Responsibility, which includes sustainability, diversity, and socially responsible business practices. “They recognize that brands, including many smaller boutique brands, are winning over consumers by doing ‘the right thing,’ ” he explains.

But Jonathan Dudlak, general manager of Multi Packaging Solutions/Chicago Paper Tube (MPS Paper Tube), cautions that, while looking to use eco-friendly packaging, it’s important to keep the intention clear. “The demand we see today for responsible packaging still stems from folks realizing long ago that we need to reduce waste in the way we get products to consumers, whether that’s in the harvesting of raw materials or sheer mass of product packaging that ends up on the shelf. And we’ve got lots of smaller clients who still really embrace this ideology, and they’re generally the ones who challenge us the most to produce packaging that makes a tangible impact somewhere along the line.” But here’s the complication: Dudlak says this original intention has “definitely gotten lost on some, usually with larger companies, where the interest seems to be driven by what’s marketable. “That’s not always in line with what really makes a difference,” says Dudlak.

While Dudlak says he’s seeing increased interest from customers, he also mentions a shift in intent and purpose. He says, “I think the focus has shifted a bit from eco-friendly to the even more rudimentary, ‘Is my packaging safe?’ ”

So while 100% recycled is still a big request, as is all-paperboard packaging in place of paper/plastic or paper/metal hybrids, according to Dudlak, he says, “We used to have a lot more people concerned about things like forest certifications and carbon footprint. Now what we hear most often is people wanting to make sure there are no hazardous substances or manufacturing processes involved first and foremost. This has always been a given for us, as we’re dealing with local sources on almost everything that are clean processes and are domestically regulated, but we’ve taken on clients who used to source overseas and had no real way of knowing what’s going into their packaging. It’s also a little tough for us to gauge small movements in eco interest because all of our packaging is inherently eco friendly, so folks may be coming to us to get away from other non-paper materials knowing we’ll automatically be a greener solution but never requesting anything specific in terms of sustainability.”

Customers’ Expectations

As brand customers learn more about sustainability in the supply chain, they come to expect more from their suppliers.

Gone are the days when “green packaging” consisted only of plain glass bottles, printed labels and brown paper cartons. As suppliers’ expertise grows, brands have far more choices, which increases interest—and as Dudlak mentioned, customers are expecting more from suppliers in this way—both in terms of “doing the right thing” and in developing new options for appearance. Brands increasingly “want it all.”

Diamond Packaging’s Bacchetta comments on the trend: “Environmentally friendly packaging has become an expectation of our customers.”

According to Bacchetta, “Brands want their packaging to be disruptive and visually appealing, and eco-friendly at the same time. They want to differentiate their products with the latest converting techniques, including specialty coatings, foil, or tightly registered embossing. Our goal is to wrap a customer’s brand in beauty, glamour or luxury, in order to attract the consumer’s attention when and where it matters most—on the store shelf.”

Diamond’s Green Chic packaging technologies create stunning visual and tactile effects while helping to conserve raw materials and energy, reduce greenhouse gas emissions, and minimize discards, says Bachetta. New equipment and manufacturing processes often provide the added benefit of reduced costs.

In addition, Bacchetta explains that all of Diamond’s folding cartons are manufactured using 100% clean, renewable wind energy and produced in a Zero Manufacturing Waste to Landfill facility. Brands can choose to communicate these benefits to consumers through on-product labeling.

Customer interest in sustainable solutions tends to focus on different priorities, including corporate practices, and can vary according to global region or brand.

At Iggesund Paperboard, public relations manager Staffan Sjöberg, says, “We’ve seen a gradually growing interest from the market over the past eight to ten years and we perceive no sign of this lessening. We believe much of the growth is due to brand owners’ greater interest plus increasingly organized sustainability work.”

However, Sjöberg says different parts of the world place a different value on various aspects of the company’s sustainability work. In some areas, he says, the most important thing is the raw material’s documented origin. In other places it might be that you should always have a certain percentage of recycled fiber in the material. Others value a low carbon footprint.

Clients of Dapy are also “more and more requesting to integrate an eco-friendly concept in their new development,” according to David Jacquet, manager Dapy Americas. He says, “Over the past years we modified our working process to adapt our production method and our factories in order to satisfy clients’ requests.”

Leif Scheufelen of Papierfabrik Scheufelen, tells Beauty Packaging: “The custody certifications (FSC, etc.) are a given nowadays, and in general, the expectations are that we, as packaging material suppliers, commit to follow the best possible practices and continuously strive to improve the ecological footprint.”

Richard Engel, president & COO, Decotech, Inc., agrees. He says, “Customers’ expectations in this area are also pushing companies to look further at their whole supply chain.” He explains that his clients are beginning to understand that eco-friendly packaging means much less if it is produced in an environmentally harmful way. They are beginning to push up the supply chain to validate that suppliers are using sustainable operational practices.

What’s more, Engel says some clients are beginning to use vendor scorecards for sustainable practices. “They measure things like where you get your energy from, what types of fuel sources you have, how you manage your waste streams, etc.” He tells Beauty Packaging that Decotech has been a top performer on every scorecard “due to our advanced sustainability practices.” He explains, “We are a Zero-Waste-to-Landfill company and we participate in a Waste-to-Energy program in NJ in which anything we can’t re-use or recycle gets converted to energy and is pumped back into the electrical grid. In addition, we have a 700,000 kW solar panel array on our roof that supplies around 40% of the energy needs for all our operations. We began doing all this years ago, before any clients began measuring these practices.”

Decotech’s newest metallization offering is a good example of the company’s environmentally responsible technology. Waste generated through their sustainable metallization process is returned to their raw material supplier in a closed loop. Thus, Engel says, “That supplier can then reuse our material waste to produce new raw material for our process and it all keeps going in a circle. This was a critical requirement in order to align with our Zero-Waste-to-Landfill policy.”

Brands’ Requests

What are brands specifically requesting as far as sustainable packaging and practices?

Iggesund Paperboard’s Sjöberg, replies, “Good sustainability work by us plus the documentation, and certifications. Everyone wants to ‘cover their behind’.”

Sjöberg takes issue in regard to increased requests for incorporating larger percentages of post consumer recycled materials. He says, “From our perspective, the demand for mixing in recycled fiber is paradoxical. If we added recycled fiber to our paperboard, it would have worse performance, for example, in terms of the protection it offers.” He says that to compensate for this, packagers would have to use either more and heavier material, or risk more transport damage occurring along the value chain.”

At Dapy, Jacquet sees increased interest in reusable packaging. He says, “Today, clients are looking to extend the life of the secondary packaging by finding an additional usage after the consumer has purchased the primary item. How can the secondary packaging be reused? Can it have a second life after purchase?”

Jacquet says concern over the carbon footprint of a product is another important point. “Can we keep the strength of the item by using less material? Produce more quantity at once, grouping orders, filling up containers… all these little steps to help reduce unnecessary wastage…”

Dapy’s Airypack was developed to be 50% more eco-friendly than a conventional pack. Jacquet says the lightweight material requires minimal gluing, and is easy to recycle. Even better, he says it has an identical appearance to conventional packaging. He adds that 17 trees will be saved from one ton of recycled paper.

Many brands are coming to Neenah Packaging looking for custom environmental packaging solutions, according to Sng. For instance, Neenah recently worked with Aveda—a brand widely recognized for its environmental leadership.

Sng explains that Aveda’s design team had approached Johnson Printing & Packaging, “a noted leader in environmentally friendly production processes” to help them develop a high-end packaging material for their Invati line. The design brief was to create a folding board with seemingly opposite requirements. First, the packaging material needed to be beautiful and high end, as well as print effortlessly—with a solid flood of ink. Next, Aveda desired the best environmental pedigree possible including 100% post consumer waste, FSC Certification, renewable energy usage and complete recyclability.

Johnson and Neenah Packaging worked together to create a completely new custom product to meet Aveda’s criteria. The base material is Neenah Folding Board. Then, Neenah developed a special environmentally friendly coating to offer the “enhanced” printing Aveda desired. The result is Aveda’s exclusive, custom packaging material, JPP100—JPP named for the converter, and the “100” speaks to the product’s post consumer waste content.

“Neenah’s ability to create special environmental solutions made it possible to develop a product that was in conjunction with Aveda’s desire for high end printing, beauty, and remarkable environmental credentials; a product that wasn’t available on the market,” says Sng.

Commenting on the project, Deb Darling, director packaging materials and innovations initiatives for Aveda, says, “With every product package we develop, we are mindful of our environmental impact. Our focus for folding cartons includes materials that maximize post-consumer recycled content, carrying the FSC certification, and preventing contamination of the mixed paper recycling stream. For the Aveda Love Composition Oil folding carton, custom-made JPP100 by Johnson Printing & Packaging and Neenah Packaging was the right choice. JPP100 is comprised of 100% post-consumer recycled content, is FSC certified and provides a lustrous, bright white printing surface. The product was launched in memory of our founder, Horst Rechelbacher. Together we delivered a beautiful package that honors his environmental leadership and reflects our love for the Earth.”

Brands are also taking advantage of the increasing options for high-end decorative effects now available on cartons and paper made from environmentally responsible materials.

At Diamond Packaging, Bacchetta says: “Brands are requesting more high-end decorative effects, but produced faster, more economically and with sustainability benefits. This is often achieved through a reduction in weight or components, a greater use of FSC-certified paperboards, or in-line converting techniques (e.g., specialty coatings, specialty effects, cold foiling).” He says in-line techniques are cost effective and more sustainable, especially when factoring in the material and energy costs associated with multiple runs or off-line production processes.

Diamond recently produced a folding carton for L’Oréal Paris Age Perfect Hydra-Nutrition, a product with “a rich, luxurious Golden Balm that intensely moisturizes to nourish and strengthen skin.” Bachetta says the new carton design—featuring metallic ink and foil stamping—conveys the essence of the product and transforms its perceived value, brand differentiation, and shelf prominence. The carton was converted utilizing FSC-certified Invercote G paperboard and offset printed with four color process, metallic brown and opaque white inks, and UV gloss coating. The cartons were manufactured using 100% clean, renewable wind energy and produced in a Zero Manufacturing Waste to Landfill facility.

Green Alternatives

As designers, brands and suppliers continue to experiment with various materials and eco-friendly solutions in the beauty world, interesting alternatives are popping up. Some can be accessed now, while others are still in the “what if” stage.

Heather Deeth, ethical buying manager, Lush Cosmetics (see Lush online exclusive at BeautyPackaging.com), says, “When it comes to packaging, we continue to believe that less is more. Reducing the overall amount of unnecessary packaging across the beauty/personal care industry would be a win for all.”

But Deeth says where packaging is required, there have been some great evolutions in sustainable packaging with new compostable materials, alternatives to petroleum-based plastics, refillable and reusable options, mushroom and plant-based materials, and even trials of plastics made from carbon sequestered from the atmosphere.

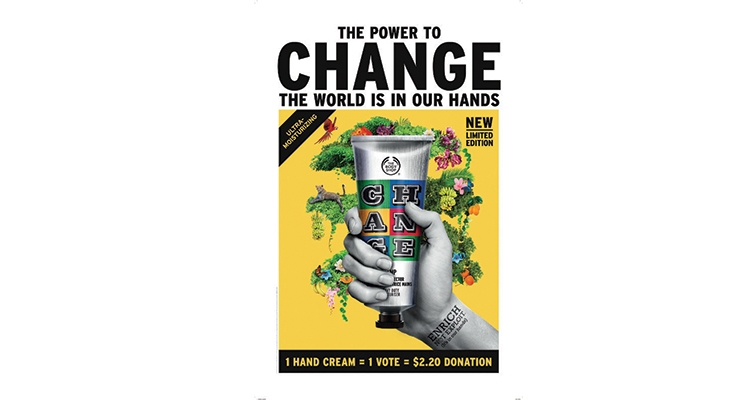

BodyShop CHANGE

Recently, The Body Shop announced that they will start pulling the plastic for some of their packaging “from thin air.” The eco-friendly chain said it will use a special plastic made of greenhouse gases from the atmosphere to make lids and containers for skin creams. By 2020, the new packaging could reduce the company’s use of plastics made from oil by 70%. The move is in line with the 40-year-old brand’s new commitment, entitled Enrich Not Exploit, as well as L’Oréal’s global sustainability strategy called Sharing Beauty with All. Part of this goal is, by 2020, to ensure that 100% of the company’s products show environmental or social improvement. (For more on L’Oréal’s plan, please see sidebar interview with Jonathan Maher, vice president CSR & Sustainability at L’Oréal USA.)

Julien Floc’h LeafLAB marketing manager, SWM International, says the various organic materials used in the company’s paper are ideal for a number of packaging options from cartons to bags, wrapping to masks.

Floc’h describes the botanical papers made of plants as “eco-efficient, indeed, since we use by-products considered as waste most of the time”—such as coca husk for coca paper, coffee chaff for coffee paper, tea leaf for tea paper—as well as botanical fibers as pulp component for papers embedded with conventional plants such as rose or chamomile. The company does not yet hold certificates for these products.

Designer Marilu Valente of Merged Vertice put a lot of thought into the components of hair care bottles and how they could be created with more of an eco-consciousness.

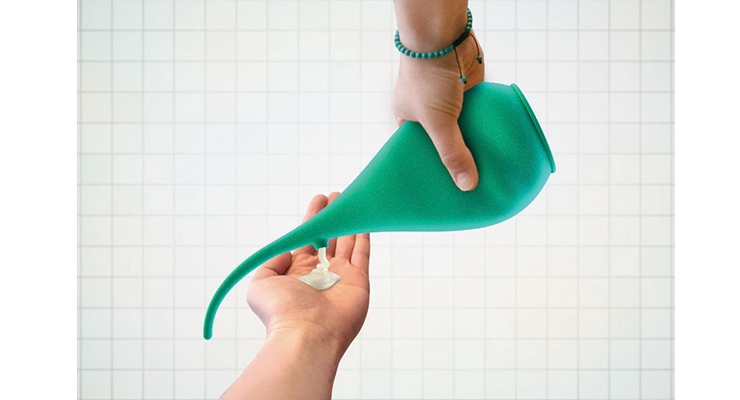

Valente says her inspiration came from two main factors—the first one being that personal care packaging is usually made with different types of plastics (one for the cap and one for the body). She says, “I wanted to have a shape which integrated the body of the bottle and the cap. Since I follow biomimicry as a design principle, I have looked at the natural shape Nepenthes which are carnivorous plants.”

With the plant as her guideline, she created a new prototype of a reusable container called Nephentes, which was designed to be attention-getting, as well as reusable and recyclable. The bottle design eliminates the necessity for a cap; instead, the tip of the Nephentes uses a “plug” with a narrow, nozzle-like tip.

Further, according to an interview with Fast Company, Valente envisions her design existing in an eco-conscious world in which products such as shampoo are sold in bulk and customers bring their own containers.

Looking Ahead

With eco-conscious baby boomers, globally aware Millennial consumers and exciting progress in research and development, sustainable packaging in the beauty industry is undeniably on a growth path, and brands and suppliers will continue to innovate in this area to meet consumer demand.

Diamond’s Bacchetta, says, “We expect that our customers will continue to demand more sophisticated packaging options that are produced cost effectively and sustainably. We also expect brands to embrace a global movement toward Corporate Social Responsibility as it relates to their companies and their suppliers.”

Neenah Packaging’s Sng, says, simply, “More of the same; our customers want us to continue to develop trend-setting colors, unique textures, and high-touch decorative finishes—all with an impeccable environmental degree. Today’s marketers want it all—material beauty, environmental integrity and performance.”

Sng reiterates: “This will be an interesting area to watch going forward. More Millennials will soon be in a position to call the shots as they grow into brand management positions. One thing we know for sure, they are going to continue to raise the bar when it comes to the environment.”

The latest development from Papierfabrik Scheufelen—coated solid bleached board phoenolux—launched last year. Its outstanding brightness and whiteness make it ideally suited for graphic applications as well as high-quality packaging. Made from a top-quality FSC-certified pulp (FSC C009951) or PEFC (PEFC/04-31-0688), phoenolux is produced exclusively using either totally chlorine-free or elementally chlorine-free bleaching processes.

Papierfabrik Scheufelen is located in the biosphere reservation area of the Swabian Mountains in southern Germany. With a company history stretching back over 160 years, the supplier says this responsibility adds an extra dimension to their tradition of taking a conscientious approach to raw materials, water and air. They say the legal environmental requirements and their special geographical location between the steep wooded ravines around the company’s premises drive their environmental goals.More info: www.scheufelen.com; in North America: Leif Dahlberg, [email protected]

Rudi Becker

Rudi Becker, Senior Director of Packaging and Industrial Design, method, tells Jamie Matusow about the rewards and challenges of the commitment.

JM: Is environmentally responsible packaging part of method’s DNA?

RB: We’ve always believed in business as a force for good and in creating products that are beautifully designed as well as planet-friendly. Pushing ourselves to continuously become more environmentally friendly in every aspect of our business has been a core principle since method began 15 years ago—and packing is no exception. We want to create products that people are proud to display on their countertops and that they can feel good about using because both the packaging and what’s inside it are planet-friendly. All of our transparent bottles are made from 100% recycled plastic (PCR PET) and all of our packaging is 100% recyclable. We were one of the first Cradle to Cradle endorsed companies and have among the most C2C certified products of any company in the world.

JM: How has consumer interest/acceptance evolved over the years?

RB: Consumer awareness is growing but there is still only a small subset of consumers who are actively seeking green products. Given that, the challenge for companies that make green products is to make them equally (if not more) compelling for the consumer compared to traditional products outside the naturals set. At method we work to achieve this by producing products that appeal to consumers on many levels (efficacy, fragrance, design) and are also sustainably produced and kind to people and the planet. Looking forward, as consumers turn more of their attention from what a product can do for them to how a product is made, CPG companies will need to follow the lead of brands like ours to maintain their relevance with consumers.

JM: What are the challenges faced on the supplier and brand sides?

RB: Having a consistent supply chain to support needed volume is one of the greatest challenges here. Supply chain has a direct impact on volatility across a product’s supply, quality and cost. If the supply chain can’t deliver, a product line is compromised—at best with a slower response to demand, at worst at such pervasive levels it can kill a product line. There’s an inherent tension between innovation and supply in that a brand is often challenging a supplier to innovate. Smaller brands may not bring a volume of business that justifies a supplier investing to create a new solution, while larger brands may have supply needs that can’t be met for new innovation. For brands, sustainable packaging also doesn’t necessarily translate into a financial return—investing in recycled packaging alone isn’t generally enough to get consumers to pay a premium. We think it’s incumbent on innovator brands like method to bring more sustainable products to market to help raise awareness and create that dialogue with consumers.

JM: method seems always to be taking new steps in sustainable packaging—such as recovering ocean plastic?

RB: We created the ocean plastics product line to spark awareness and conversation about where packaging comes from and where it goes. The bulk of products out there are made from virgin materials and we wanted to shine a spotlight on the opportunity to instead take waste, recycle it and use it to create new products. In this case, that waste is plastic we’re helping remove from the oceans it’s polluting, and in the case of many other products it’s plastic that would be going into landfills. In all cases, we’re taking plastic out of the waste stream and giving it a second life as a plastic bottle. We hope our ocean plastics line has been a catalyst for consumers to think about where their products come from, what they do with them, and where they go once they’re done.

JM: How do you imagine the future of beauty and personal care in regard to environmentally responsible packaging and practices—from brand, consumer and retailer perspectives?

RB: Consumer interest in environmental responsibility is increasing, but in the world of beauty and personal care it’s more isolated to transparency around what’s in a product versus how that product is packaged. It remains to be seen if consumer demand for more sustainable packaging will increase and drive change in the industry. For businesses, there are hurdles and implications for design, supply chain and profitability when it comes to executing more sustainable packaging. Higher-end beauty products also use more mixed materials, so that sector likely faces an even greater challenge in creating more responsible packaging compared to mass beauty products. Ultimately those choices will come down to individual companies’ stance on responsible business and the priority they place on reducing the footprint of their products. For many of the materials used in beauty and personal care packaging, there’s no recycle stream out there. Even when typically recyclable materials are used, color is often added—making them unrecyclable in traditional streams. That’s why method uses transparent packaging that’s made from 100% recycled plastic and 100% recyclable. We hope to serve as an example to the industry on how sustainable materials can be used without compromising a brand’s design and aesthetic.

Rudi Becker will be speaking more with Jamie Matusow on this topic during a panel at Cosmoprof NA on July 25.

L’Oréal’s Ambitious Sustainability Strategy

Jonathan Maher

By 2020, L’Oréal will ensure that 100% of their products show environmental or social improvement. Here, Jamie Matusow asks Jonathan Maher, vice president CSR & Sustainability at L’Oréal USA, how packaging comes into play.

Jamie Matusow: What is the plan over the next five years or so?

Jonathan Maher: In 2013 we launched our global sustainability strategy called Sharing Beauty with All (SBWA) with the goal by 2020 to have more sustainable business practices embedded into every aspect of our value chain. As part of this commitment, by 2020, L’Oréal will ensure that 100% of our products show environmental or social improvement.

Our product packaging is an important component of our SBWA strategy. We’re continuing to expand and enhance the design of our packaging, both primary and secondary, and working to ensure that all of our future product launches and product renovations, for all of our brands, are being assessed for possible environmental improvements to the packaging.

Matusow: Are you looking at light weighting, energy usage, packaging materials, etc.?

Kiehl’s Superbly Restorative Argan Body Lotion uses packaging that is made of 100% PCR PET.

Maher: We’re assessing all of our packaging formats, using the indicators that are most relevant to the packaging’s environmental profile, such as packaging weight and optimization, and the use of renewable or recycled content. These attributes are recognized by the Global Protocol on Packaging Sustainability 2.0 as the best measures to lower the pack’s environmental impact.

Matusow: Which brands in particular follow a strident eco-friendly packaging philosophy and how?

Maher: Under our strategy Sharing Beauty with All, all of our brands across all categories must examine the ways to improve their packaging. We’re proud that some of our brands are already leaders in the industry. The Body Shop recently announced that by 2020, 70% of its total product packaging will not contain fossil fuels. Other brands, including our mass retail and luxe brands, have environmentally responsible packaging, like our Garnier Fructis Shampoo & Conditioner bottles, which are very light for their category and contain 30% PCR plastics.

Matusow: Does L’Oréal educate consumers as to what it’s doing in this regard?

Maher: This is one of our areas of focus because we know consumer behavior is critical in determining the product’s lifecycle. We already have some effective brand initiatives, such as the Garnier Beauty Brigade and Kiehl’s Recycle and Be Rewarded program to increase recycling. We’re also exploring other ways to improve our consumers’ awareness of the packaging’s end-of-life and recyclability.

Matusow: What else would our readers be interested in knowing?

Maher: I’d like readers to understand that our packaging innovation, including our sustainable packaging innovations, are usually the outcome of a broad collaborative process within L’Oréal among the marketing teams, our research and innovation labs and packaging teams. Some of L’Oréal’s finest examples of innovation can be traced back to a close collaboration between our formulators and our packaging team. For example, La Roche-Posay was able to develop preservative-free formulas for sensitive skin by designing pump bottles that prevent any back flow of air. Also, L’Oréal Paris’ Million Lashes is a highly performant mascara thanks to the combined results of its innovative formula and its high-precision applicator tool. We’re excited to see future sustainable innovations coming from our other brands, which will impact consumers and the environment in a positive way.

Much progress has also been made in developing environmentally responsible cosmetics packaging, but barriers such as limited recycling facilities, non-oil-based materials, costs—and even demand—still hamper the way. And obstructions to generating “green” vessels have been further complicated by the increased needs for compatible packaging that protects sensitive formulations and matches the appearance of prestige—and mass—products.

But the situation may be on the cusp of change. Millennial consumers and young executives are on the road to speeding things up. At the same time, promising new material solutions are emerging from sources including the bottom of the ocean, carnivorous plants—and even thin air.

Millennials Lead the Way

For years, the idea of sustainability has captured the interest of corporate boardrooms as a path to efficiency and cost savings throughout the supply chain. As the Millennial population becomes more dominant in corporate management, sustainability measures are expected to continue to grow, leading suppliers in beauty and elsewhere to further pursue the development of environmentally responsible packages and practices.

In the past few years, the cosmetics industry has seen a growing trend toward incorporating larger percentages of post consumer recycled materials, and light weighting has become almost a matter of course. More refillable and reusable packs are also satisfying demand for conscientious choices. Smaller size products that can be used up before their expiration dates have also been increasingly entering the beauty marketplace. And suppliers’ manufacturing processes are adding to a reduced carbon footprint.

Mark Sng, director of marketing, Neenah Packaging, credits Millennials for an uptick in eco-friendly packaging requests from customers. He tells Beauty Packaging, “Without question, consumer expectations continue to drive growth in eco-friendly packaging. Today’s Millennials are three times more focused on the environment than their parents’ generation; two-thirds of Millennials say they are willing to pay more for products from sustainability-focused companies.”

Sng says as marketers create branding to appeal to consumers with environmentally minded expectations, “Brands are considering every facet of the packaging they develop: the environmental footprint, the lifecycle analysis, and the selection of recyclable and post-consumer recycled materials.”

In addition, Sng says corporate metrics are driven by customer expectations. “We see many of our beauty and cosmetics customers striving for continuous improvement in their sustainability practices. More want to publicly share their year over year progress. We see it on their packaging, on their websites and in annual sustainability reports.”

Consumer Delights

When it comes to using containers that are earth-friendly, both smaller brands and key global players have achieved success with consumers who share their environmental goals, but it can be a challenge nonetheless.

Greta Fitz, director of global marketing for Fusion Brands America, Inc., makers of Clean Reserve products, tells Beauty Packaging: “From what we’ve seen, consumers, especially Millennials, are very conscious of lowering their carbon footprint and expect companies to do the same. As a brand we believe in sustainable beauty, and to us this means working to preserve nature’s resources and keeping our products out of landfills. Our story has resonated with those who look for this in their purchases, and has also raised awareness and interest in those who haven’t yet.”

Still, Rudi Becker, senior director of packaging and industrial design, at method, a leading global company with environmentally responsible packaging at its core, says: “Consumer awareness is growing, but there is still only a small subset of consumers who are actively seeking green products. Given that, the challenge for companies that make green products is to make them equally (if not more) compelling for the consumer compared to traditional products outside the naturals set.”

Fitz agrees, saying, Clean Reserve strives to create a luxurious product with minimal treatments “that will look great in store and feel great in the client’s hand.” The challenge, she says, is to work with less and deliver more. “That’s what makes our brand stand out from the clutter,” she explains. And consumers are responding well. Fitz says that Sephora, their exclusive retailer in the U.S., “is thrilled with the response from their clients thus far. We have sold out on our introductory sets and have gained a strong following in a matter of a few months, and this is just the beginning.”

Gel hand washes from method’s Spring 2016 limited-edition collection with Brooklyn-based designer Rebecca Atwood are available exclusively at Target. The gray bottles for Ocean Plastic Dish + Hand Soap were made with recovered ocean plastic. The product is a permanent part of the company’s product line—and is available exclusively at Whole Foods. (See Beauty Packaging’s exclusive interview with Becker in this issue.)

Burt’s Bees is another brand that’s always striving for sustainability, emphasizing both the formulations and the packaging. Their newly released lipsticks are 60% post-consumer recycled plastic. Empty tubes can be mailed back to the brand for recycling using a prepaid mailing label.

Increased Consumer Focus on Packaging

According to Ameripen (American Institute for Packaging and the Environment), Americans spend $50 billion annually for beauty and personal care products, including shampoo and conditioner, cosmetics, toothpaste, and soap and body wash. The organization recognizes the critical role of packaging for these products, and recently issued guidelines to inform consumers about recycling, buying the right size for the right occasion, and purchasing refillable systems for items like liquid soap, shampoo, and conditioner.

The advice comes as consumers are starting to take a closer look at eco-friendly packaging. A recent global cosmetics packaging market report from Technavio Research identifies an “increase in demand for sustainable cosmetic packaging as a key trend in the market.” Technavio’s research analyst predicts the global cosmetic packaging market will grow at a CAGR of around 5% between 2016 and 2020.

According to Technavio: “The growing need for sustainable and eco-friendly packaging is a leading trend in the global cosmetic packaging market. In many countries, environmental and sustainability issues are being raised with packaging manufacturers. Numerous cosmetics manufacturers prefer using eco-friendly packaging material as it provides an opportunity to promote environmental sustainability. Increased environmental concern and the need to reduce pollution have led to the adoption of recyclable materials, such as plastic and the use of resins derived from renewable resources. These factors encourage vendors to develop new materials and incorporate eco-friendly designs that encourage the minimal use of non-biodegradable materials in packaging.

For instance, recycled paper, bamboo, and recycled glass are considered eco-friendly materials for packaging. In addition, sustainable packaging enables consumer goods manufacturers to improve their brand image and reduce their carbon footprint.”

We’ve all become used to the many symbols evident on cosmetics packaging, as to recycling, standards and ecological organizations. In addition, some brands are now mentioning elements of reduced packaging right on the bottle or carton, itself. For instance, John Masters Organics Facial Oil states clearly on top of the carton’s flap: “Our new box uses 50% less material.”

Making Demands

Corporate Social Responsibility has become a priority in a number of organizations worldwide—and retailers and brands, both large and small, from Walmart and Target, to Estée Lauder and L’Oréal, to method, Lush and Kiehl’s, have instituted sustainability plans that include reducing their environmental footprint.

Almost all of the suppliers Beauty Packaging spoke to for this article say that environmentally responsible packaging is more and more a focus of their customers and potential customers—but the reasoning can be complicated.

Dennis Bacchetta, director of marketing at Diamond Packaging, which specializes in folding cartons and contract packaging services, notes that many companies are looking at sustainable packaging design as one aspect of the larger role of Corporate Social Responsibility, which includes sustainability, diversity, and socially responsible business practices. “They recognize that brands, including many smaller boutique brands, are winning over consumers by doing ‘the right thing,’ ” he explains.

But Jonathan Dudlak, general manager of Multi Packaging Solutions/Chicago Paper Tube (MPS Paper Tube), cautions that, while looking to use eco-friendly packaging, it’s important to keep the intention clear. “The demand we see today for responsible packaging still stems from folks realizing long ago that we need to reduce waste in the way we get products to consumers, whether that’s in the harvesting of raw materials or sheer mass of product packaging that ends up on the shelf. And we’ve got lots of smaller clients who still really embrace this ideology, and they’re generally the ones who challenge us the most to produce packaging that makes a tangible impact somewhere along the line.” But here’s the complication: Dudlak says this original intention has “definitely gotten lost on some, usually with larger companies, where the interest seems to be driven by what’s marketable. “That’s not always in line with what really makes a difference,” says Dudlak.

While Dudlak says he’s seeing increased interest from customers, he also mentions a shift in intent and purpose. He says, “I think the focus has shifted a bit from eco-friendly to the even more rudimentary, ‘Is my packaging safe?’ ”

So while 100% recycled is still a big request, as is all-paperboard packaging in place of paper/plastic or paper/metal hybrids, according to Dudlak, he says, “We used to have a lot more people concerned about things like forest certifications and carbon footprint. Now what we hear most often is people wanting to make sure there are no hazardous substances or manufacturing processes involved first and foremost. This has always been a given for us, as we’re dealing with local sources on almost everything that are clean processes and are domestically regulated, but we’ve taken on clients who used to source overseas and had no real way of knowing what’s going into their packaging. It’s also a little tough for us to gauge small movements in eco interest because all of our packaging is inherently eco friendly, so folks may be coming to us to get away from other non-paper materials knowing we’ll automatically be a greener solution but never requesting anything specific in terms of sustainability.”

Customers’ Expectations

As brand customers learn more about sustainability in the supply chain, they come to expect more from their suppliers.

Gone are the days when “green packaging” consisted only of plain glass bottles, printed labels and brown paper cartons. As suppliers’ expertise grows, brands have far more choices, which increases interest—and as Dudlak mentioned, customers are expecting more from suppliers in this way—both in terms of “doing the right thing” and in developing new options for appearance. Brands increasingly “want it all.”

Diamond Packaging’s Bacchetta comments on the trend: “Environmentally friendly packaging has become an expectation of our customers.”

According to Bacchetta, “Brands want their packaging to be disruptive and visually appealing, and eco-friendly at the same time. They want to differentiate their products with the latest converting techniques, including specialty coatings, foil, or tightly registered embossing. Our goal is to wrap a customer’s brand in beauty, glamour or luxury, in order to attract the consumer’s attention when and where it matters most—on the store shelf.”

Diamond’s Green Chic packaging technologies create stunning visual and tactile effects while helping to conserve raw materials and energy, reduce greenhouse gas emissions, and minimize discards, says Bachetta. New equipment and manufacturing processes often provide the added benefit of reduced costs.

In addition, Bacchetta explains that all of Diamond’s folding cartons are manufactured using 100% clean, renewable wind energy and produced in a Zero Manufacturing Waste to Landfill facility. Brands can choose to communicate these benefits to consumers through on-product labeling.

Customer interest in sustainable solutions tends to focus on different priorities, including corporate practices, and can vary according to global region or brand.

At Iggesund Paperboard, public relations manager Staffan Sjöberg, says, “We’ve seen a gradually growing interest from the market over the past eight to ten years and we perceive no sign of this lessening. We believe much of the growth is due to brand owners’ greater interest plus increasingly organized sustainability work.”

However, Sjöberg says different parts of the world place a different value on various aspects of the company’s sustainability work. In some areas, he says, the most important thing is the raw material’s documented origin. In other places it might be that you should always have a certain percentage of recycled fiber in the material. Others value a low carbon footprint.

Clients of Dapy are also “more and more requesting to integrate an eco-friendly concept in their new development,” according to David Jacquet, manager Dapy Americas. He says, “Over the past years we modified our working process to adapt our production method and our factories in order to satisfy clients’ requests.”

Leif Scheufelen of Papierfabrik Scheufelen, tells Beauty Packaging: “The custody certifications (FSC, etc.) are a given nowadays, and in general, the expectations are that we, as packaging material suppliers, commit to follow the best possible practices and continuously strive to improve the ecological footprint.”

Richard Engel, president & COO, Decotech, Inc., agrees. He says, “Customers’ expectations in this area are also pushing companies to look further at their whole supply chain.” He explains that his clients are beginning to understand that eco-friendly packaging means much less if it is produced in an environmentally harmful way. They are beginning to push up the supply chain to validate that suppliers are using sustainable operational practices.

What’s more, Engel says some clients are beginning to use vendor scorecards for sustainable practices. “They measure things like where you get your energy from, what types of fuel sources you have, how you manage your waste streams, etc.” He tells Beauty Packaging that Decotech has been a top performer on every scorecard “due to our advanced sustainability practices.” He explains, “We are a Zero-Waste-to-Landfill company and we participate in a Waste-to-Energy program in NJ in which anything we can’t re-use or recycle gets converted to energy and is pumped back into the electrical grid. In addition, we have a 700,000 kW solar panel array on our roof that supplies around 40% of the energy needs for all our operations. We began doing all this years ago, before any clients began measuring these practices.”

Decotech’s newest metallization offering is a good example of the company’s environmentally responsible technology. Waste generated through their sustainable metallization process is returned to their raw material supplier in a closed loop. Thus, Engel says, “That supplier can then reuse our material waste to produce new raw material for our process and it all keeps going in a circle. This was a critical requirement in order to align with our Zero-Waste-to-Landfill policy.”

Brands’ Requests

What are brands specifically requesting as far as sustainable packaging and practices?

Iggesund Paperboard’s Sjöberg, replies, “Good sustainability work by us plus the documentation, and certifications. Everyone wants to ‘cover their behind’.”

Sjöberg takes issue in regard to increased requests for incorporating larger percentages of post consumer recycled materials. He says, “From our perspective, the demand for mixing in recycled fiber is paradoxical. If we added recycled fiber to our paperboard, it would have worse performance, for example, in terms of the protection it offers.” He says that to compensate for this, packagers would have to use either more and heavier material, or risk more transport damage occurring along the value chain.”

At Dapy, Jacquet sees increased interest in reusable packaging. He says, “Today, clients are looking to extend the life of the secondary packaging by finding an additional usage after the consumer has purchased the primary item. How can the secondary packaging be reused? Can it have a second life after purchase?”

Jacquet says concern over the carbon footprint of a product is another important point. “Can we keep the strength of the item by using less material? Produce more quantity at once, grouping orders, filling up containers… all these little steps to help reduce unnecessary wastage…”

Dapy’s Airypack was developed to be 50% more eco-friendly than a conventional pack. Jacquet says the lightweight material requires minimal gluing, and is easy to recycle. Even better, he says it has an identical appearance to conventional packaging. He adds that 17 trees will be saved from one ton of recycled paper.

Many brands are coming to Neenah Packaging looking for custom environmental packaging solutions, according to Sng. For instance, Neenah recently worked with Aveda—a brand widely recognized for its environmental leadership.

Sng explains that Aveda’s design team had approached Johnson Printing & Packaging, “a noted leader in environmentally friendly production processes” to help them develop a high-end packaging material for their Invati line. The design brief was to create a folding board with seemingly opposite requirements. First, the packaging material needed to be beautiful and high end, as well as print effortlessly—with a solid flood of ink. Next, Aveda desired the best environmental pedigree possible including 100% post consumer waste, FSC Certification, renewable energy usage and complete recyclability.

Johnson and Neenah Packaging worked together to create a completely new custom product to meet Aveda’s criteria. The base material is Neenah Folding Board. Then, Neenah developed a special environmentally friendly coating to offer the “enhanced” printing Aveda desired. The result is Aveda’s exclusive, custom packaging material, JPP100—JPP named for the converter, and the “100” speaks to the product’s post consumer waste content.

“Neenah’s ability to create special environmental solutions made it possible to develop a product that was in conjunction with Aveda’s desire for high end printing, beauty, and remarkable environmental credentials; a product that wasn’t available on the market,” says Sng.

Commenting on the project, Deb Darling, director packaging materials and innovations initiatives for Aveda, says, “With every product package we develop, we are mindful of our environmental impact. Our focus for folding cartons includes materials that maximize post-consumer recycled content, carrying the FSC certification, and preventing contamination of the mixed paper recycling stream. For the Aveda Love Composition Oil folding carton, custom-made JPP100 by Johnson Printing & Packaging and Neenah Packaging was the right choice. JPP100 is comprised of 100% post-consumer recycled content, is FSC certified and provides a lustrous, bright white printing surface. The product was launched in memory of our founder, Horst Rechelbacher. Together we delivered a beautiful package that honors his environmental leadership and reflects our love for the Earth.”

Brands are also taking advantage of the increasing options for high-end decorative effects now available on cartons and paper made from environmentally responsible materials.

At Diamond Packaging, Bacchetta says: “Brands are requesting more high-end decorative effects, but produced faster, more economically and with sustainability benefits. This is often achieved through a reduction in weight or components, a greater use of FSC-certified paperboards, or in-line converting techniques (e.g., specialty coatings, specialty effects, cold foiling).” He says in-line techniques are cost effective and more sustainable, especially when factoring in the material and energy costs associated with multiple runs or off-line production processes.

Diamond recently produced a folding carton for L’Oréal Paris Age Perfect Hydra-Nutrition, a product with “a rich, luxurious Golden Balm that intensely moisturizes to nourish and strengthen skin.” Bachetta says the new carton design—featuring metallic ink and foil stamping—conveys the essence of the product and transforms its perceived value, brand differentiation, and shelf prominence. The carton was converted utilizing FSC-certified Invercote G paperboard and offset printed with four color process, metallic brown and opaque white inks, and UV gloss coating. The cartons were manufactured using 100% clean, renewable wind energy and produced in a Zero Manufacturing Waste to Landfill facility.

Green Alternatives

As designers, brands and suppliers continue to experiment with various materials and eco-friendly solutions in the beauty world, interesting alternatives are popping up. Some can be accessed now, while others are still in the “what if” stage.

Heather Deeth, ethical buying manager, Lush Cosmetics (see Lush online exclusive at BeautyPackaging.com), says, “When it comes to packaging, we continue to believe that less is more. Reducing the overall amount of unnecessary packaging across the beauty/personal care industry would be a win for all.”

But Deeth says where packaging is required, there have been some great evolutions in sustainable packaging with new compostable materials, alternatives to petroleum-based plastics, refillable and reusable options, mushroom and plant-based materials, and even trials of plastics made from carbon sequestered from the atmosphere.

BodyShop CHANGE

Recently, The Body Shop announced that they will start pulling the plastic for some of their packaging “from thin air.” The eco-friendly chain said it will use a special plastic made of greenhouse gases from the atmosphere to make lids and containers for skin creams. By 2020, the new packaging could reduce the company’s use of plastics made from oil by 70%. The move is in line with the 40-year-old brand’s new commitment, entitled Enrich Not Exploit, as well as L’Oréal’s global sustainability strategy called Sharing Beauty with All. Part of this goal is, by 2020, to ensure that 100% of the company’s products show environmental or social improvement. (For more on L’Oréal’s plan, please see sidebar interview with Jonathan Maher, vice president CSR & Sustainability at L’Oréal USA.)

Julien Floc’h LeafLAB marketing manager, SWM International, says the various organic materials used in the company’s paper are ideal for a number of packaging options from cartons to bags, wrapping to masks.

Floc’h describes the botanical papers made of plants as “eco-efficient, indeed, since we use by-products considered as waste most of the time”—such as coca husk for coca paper, coffee chaff for coffee paper, tea leaf for tea paper—as well as botanical fibers as pulp component for papers embedded with conventional plants such as rose or chamomile. The company does not yet hold certificates for these products.

Designer Marilu Valente of Merged Vertice put a lot of thought into the components of hair care bottles and how they could be created with more of an eco-consciousness.

Valente says her inspiration came from two main factors—the first one being that personal care packaging is usually made with different types of plastics (one for the cap and one for the body). She says, “I wanted to have a shape which integrated the body of the bottle and the cap. Since I follow biomimicry as a design principle, I have looked at the natural shape Nepenthes which are carnivorous plants.”

With the plant as her guideline, she created a new prototype of a reusable container called Nephentes, which was designed to be attention-getting, as well as reusable and recyclable. The bottle design eliminates the necessity for a cap; instead, the tip of the Nephentes uses a “plug” with a narrow, nozzle-like tip.

Further, according to an interview with Fast Company, Valente envisions her design existing in an eco-conscious world in which products such as shampoo are sold in bulk and customers bring their own containers.

Looking Ahead

With eco-conscious baby boomers, globally aware Millennial consumers and exciting progress in research and development, sustainable packaging in the beauty industry is undeniably on a growth path, and brands and suppliers will continue to innovate in this area to meet consumer demand.

Diamond’s Bacchetta, says, “We expect that our customers will continue to demand more sophisticated packaging options that are produced cost effectively and sustainably. We also expect brands to embrace a global movement toward Corporate Social Responsibility as it relates to their companies and their suppliers.”

Neenah Packaging’s Sng, says, simply, “More of the same; our customers want us to continue to develop trend-setting colors, unique textures, and high-touch decorative finishes—all with an impeccable environmental degree. Today’s marketers want it all—material beauty, environmental integrity and performance.”

Sng reiterates: “This will be an interesting area to watch going forward. More Millennials will soon be in a position to call the shots as they grow into brand management positions. One thing we know for sure, they are going to continue to raise the bar when it comes to the environment.”

The latest development from Papierfabrik Scheufelen—coated solid bleached board phoenolux—launched last year. Its outstanding brightness and whiteness make it ideally suited for graphic applications as well as high-quality packaging. Made from a top-quality FSC-certified pulp (FSC C009951) or PEFC (PEFC/04-31-0688), phoenolux is produced exclusively using either totally chlorine-free or elementally chlorine-free bleaching processes.

Papierfabrik Scheufelen is located in the biosphere reservation area of the Swabian Mountains in southern Germany. With a company history stretching back over 160 years, the supplier says this responsibility adds an extra dimension to their tradition of taking a conscientious approach to raw materials, water and air. They say the legal environmental requirements and their special geographical location between the steep wooded ravines around the company’s premises drive their environmental goals.More info: www.scheufelen.com; in North America: Leif Dahlberg, [email protected]

Rudi Becker

JM: Is environmentally responsible packaging part of method’s DNA?

RB: We’ve always believed in business as a force for good and in creating products that are beautifully designed as well as planet-friendly. Pushing ourselves to continuously become more environmentally friendly in every aspect of our business has been a core principle since method began 15 years ago—and packing is no exception. We want to create products that people are proud to display on their countertops and that they can feel good about using because both the packaging and what’s inside it are planet-friendly. All of our transparent bottles are made from 100% recycled plastic (PCR PET) and all of our packaging is 100% recyclable. We were one of the first Cradle to Cradle endorsed companies and have among the most C2C certified products of any company in the world.

JM: How has consumer interest/acceptance evolved over the years?

RB: Consumer awareness is growing but there is still only a small subset of consumers who are actively seeking green products. Given that, the challenge for companies that make green products is to make them equally (if not more) compelling for the consumer compared to traditional products outside the naturals set. At method we work to achieve this by producing products that appeal to consumers on many levels (efficacy, fragrance, design) and are also sustainably produced and kind to people and the planet. Looking forward, as consumers turn more of their attention from what a product can do for them to how a product is made, CPG companies will need to follow the lead of brands like ours to maintain their relevance with consumers.

JM: What are the challenges faced on the supplier and brand sides?

RB: Having a consistent supply chain to support needed volume is one of the greatest challenges here. Supply chain has a direct impact on volatility across a product’s supply, quality and cost. If the supply chain can’t deliver, a product line is compromised—at best with a slower response to demand, at worst at such pervasive levels it can kill a product line. There’s an inherent tension between innovation and supply in that a brand is often challenging a supplier to innovate. Smaller brands may not bring a volume of business that justifies a supplier investing to create a new solution, while larger brands may have supply needs that can’t be met for new innovation. For brands, sustainable packaging also doesn’t necessarily translate into a financial return—investing in recycled packaging alone isn’t generally enough to get consumers to pay a premium. We think it’s incumbent on innovator brands like method to bring more sustainable products to market to help raise awareness and create that dialogue with consumers.

JM: method seems always to be taking new steps in sustainable packaging—such as recovering ocean plastic?

RB: We created the ocean plastics product line to spark awareness and conversation about where packaging comes from and where it goes. The bulk of products out there are made from virgin materials and we wanted to shine a spotlight on the opportunity to instead take waste, recycle it and use it to create new products. In this case, that waste is plastic we’re helping remove from the oceans it’s polluting, and in the case of many other products it’s plastic that would be going into landfills. In all cases, we’re taking plastic out of the waste stream and giving it a second life as a plastic bottle. We hope our ocean plastics line has been a catalyst for consumers to think about where their products come from, what they do with them, and where they go once they’re done.

JM: How do you imagine the future of beauty and personal care in regard to environmentally responsible packaging and practices—from brand, consumer and retailer perspectives?

RB: Consumer interest in environmental responsibility is increasing, but in the world of beauty and personal care it’s more isolated to transparency around what’s in a product versus how that product is packaged. It remains to be seen if consumer demand for more sustainable packaging will increase and drive change in the industry. For businesses, there are hurdles and implications for design, supply chain and profitability when it comes to executing more sustainable packaging. Higher-end beauty products also use more mixed materials, so that sector likely faces an even greater challenge in creating more responsible packaging compared to mass beauty products. Ultimately those choices will come down to individual companies’ stance on responsible business and the priority they place on reducing the footprint of their products. For many of the materials used in beauty and personal care packaging, there’s no recycle stream out there. Even when typically recyclable materials are used, color is often added—making them unrecyclable in traditional streams. That’s why method uses transparent packaging that’s made from 100% recycled plastic and 100% recyclable. We hope to serve as an example to the industry on how sustainable materials can be used without compromising a brand’s design and aesthetic.

Rudi Becker will be speaking more with Jamie Matusow on this topic during a panel at Cosmoprof NA on July 25.

L’Oréal’s Ambitious Sustainability Strategy

Jonathan Maher

Jamie Matusow: What is the plan over the next five years or so?

Jonathan Maher: In 2013 we launched our global sustainability strategy called Sharing Beauty with All (SBWA) with the goal by 2020 to have more sustainable business practices embedded into every aspect of our value chain. As part of this commitment, by 2020, L’Oréal will ensure that 100% of our products show environmental or social improvement.

Our product packaging is an important component of our SBWA strategy. We’re continuing to expand and enhance the design of our packaging, both primary and secondary, and working to ensure that all of our future product launches and product renovations, for all of our brands, are being assessed for possible environmental improvements to the packaging.

Matusow: Are you looking at light weighting, energy usage, packaging materials, etc.?

Kiehl’s Superbly Restorative Argan Body Lotion uses packaging that is made of 100% PCR PET.

Matusow: Which brands in particular follow a strident eco-friendly packaging philosophy and how?

Maher: Under our strategy Sharing Beauty with All, all of our brands across all categories must examine the ways to improve their packaging. We’re proud that some of our brands are already leaders in the industry. The Body Shop recently announced that by 2020, 70% of its total product packaging will not contain fossil fuels. Other brands, including our mass retail and luxe brands, have environmentally responsible packaging, like our Garnier Fructis Shampoo & Conditioner bottles, which are very light for their category and contain 30% PCR plastics.

Matusow: Does L’Oréal educate consumers as to what it’s doing in this regard?

Maher: This is one of our areas of focus because we know consumer behavior is critical in determining the product’s lifecycle. We already have some effective brand initiatives, such as the Garnier Beauty Brigade and Kiehl’s Recycle and Be Rewarded program to increase recycling. We’re also exploring other ways to improve our consumers’ awareness of the packaging’s end-of-life and recyclability.

Matusow: What else would our readers be interested in knowing?

Maher: I’d like readers to understand that our packaging innovation, including our sustainable packaging innovations, are usually the outcome of a broad collaborative process within L’Oréal among the marketing teams, our research and innovation labs and packaging teams. Some of L’Oréal’s finest examples of innovation can be traced back to a close collaboration between our formulators and our packaging team. For example, La Roche-Posay was able to develop preservative-free formulas for sensitive skin by designing pump bottles that prevent any back flow of air. Also, L’Oréal Paris’ Million Lashes is a highly performant mascara thanks to the combined results of its innovative formula and its high-precision applicator tool. We’re excited to see future sustainable innovations coming from our other brands, which will impact consumers and the environment in a positive way.