Joanna Cosgrove, Contributing Editor06.01.16

Tubes are, in a word, convenient. Available in a variety of portable shapes and sizes, tubes hygienically enable consumers to squeeze nearly 100% of the product out of the package, usually with easy, one-handed dispensing. Their frequent recyclability also strikes a chord with consumers increasingly concerned with environmental sustainability.

Jouvé is a luxury, clean-label skin care brand that believes strongly in taking care of both the body and the environment. When deciding on packaging for its Instant Tightening and Restoring Serum, the company wanted a beautiful tube that balanced sustainability and recyclability. Jouvé selected PE and ABL tubes from Express Tubes of Kent, WA.

“Jouvé wanted increased usability and their high-value brand standard for their sample-sized packaging,” says Shanna Johns, sales manager, Express Tubes. “Instead of a packette, we went with tubes that showed off their beautiful art design. They have an LDPE material for soft pliability during consumer use and the five-layer structure for product stability with the Jouvé specially formulated ingredient deck.”

For the larger sizes, Express Tubes used an ABL material to achieve the Jouvé brand metallic rose gold color that matched the artwork on their sample-sized tube. “We were able to achieve their needs utilizing stock options that allowed them cost savings and time efficiency for their new product launch,” Johns says.

Robert McDermott, director of technical sales, East Hill Industries Inc., Carrollton, TX, says that from a brand perspective, tubes deliver a lot of bang for the buck as a highly deco-friendly packaging solution that can be produced quickly in comparison to other packaging mediums.

Tubes give brands an abundance of surface real estate to display product information and decoration for on-shelf differentiation. “A large, 360-degree printable area gives ample room for brands to clearly display their logo, their product, its benefits and all of the increasing regulatory information required of a cosmetic product,” McDermott says. “Add to that custom colors, metallic effects, graduated printing, life-like flexo-printing and a multitude of header and cap options and you have one versatile, squeezable, advertising board for your products.”

Lou Della Pesca, president, 3C Inc., Hawthorne, NJ, agrees. “The cost to decorate a tube by silk screening, offset printing, heat transfer or flexoprint is less expensive than that of a bottle or a jar [and] the printing will be more colorful,” he says.

Tubes are also produced relatively quickly. “With the proliferation of automatic tube filling machinery in the U.S., tube filling costs can also be kept low to give a total delivered product which can provide brands with great margins,” McDermott says, adding that today’s tube manufacturing is typically executed in a high-output, highly-automated manufacturing and decoration environment. “New brands or established brands with new product lines can utilize this great benefit of tube packaging to react more quickly to market forces.”

Madison Reed turned to East Hill when it sought a tube that reflected its hair brand’s Color Reviving Gloss. Made with “healthier” ingredients, the product is formulated to keep hair looking fresh-from-the-salon vibrant. “Utilizing a five-layer aluminum laminate structure, East Hill was not only able to meet Madison Reed’s product stability requirements, but also achieve an understated matte metallic luster to the tubes,” McDermott says.

The tube features an extended nozzle tip to improve ease of application and is finished with a foil seal and a “natural effect” PP screw cap. “The offset printed vignettes were color-matched to Madison Reed’s eight available colors to match the shade held within, keeping the launch within Madison Reed’s ease-of-use mantra,” notes McDermott, concluding that the tubes were finished with Madison Reed’s signature off-center MDSNRD logo.

Airless Advantages

Airless tubes have become increasingly popular among cosmetic and personal care brands that market products with air- and light-sensitive formulations.

“Airless tubes in particular are a great option for brands because they combine the generally lower price point of a tube with the packaging benefits of airless dispensing—including quicker strokes to prime, metered dosing, and a 100% metal-free product pathway that does not allow air back into the package to protect the formula from contamination,” comments Lesley Gadomski, business development officer, Fusion Packaging, Dallas, TX.

Fusion offers standard, airless, center-dispensing and Shine FX tubes for formulations in need of barrier protection. “Our standard EVOH (Ethylene Vinyl Alcohol) tubes provide a five-layer barrier between the formula and outside elements,” she says, adding that the Shine FX Tube collection is also available in four varying film materials—ABL, CAL, VMPE, and HAL—each of which provide both functional and aesthetic benefits for brands.

Urban Decay selected Fusion’s 40ml Shine FX Airless Tru Tube with barrier-resistant ABL metallic film to house its new One & Done Hybrid Complexion Perfector Broad Spectrum SPF 20. The tube fits in with the brand’s existing Naked Skin collection, which includes Weightless Ultra Definition Liquid Makeup in Fusion’s 30ml Allure bottle, and Ultra Definition Loose Finishing Powder in a Fusion custom sifter jar design. “One & Done Hybrid Complexion Perfector SPF 20, features a stunning gradient effect with shiny silver hot stamp and coordinating gunmetal pump and over cap,” Gadomski says. “Urban Decay’s edgy aesthetic incorporates many metallic gunmetal embellishments, so the vibrant Shine FX collection was a perfect fit.”

An airless tube was also the right choice for doTERRA’s Essential Skin Care “all natural” Verage essential oil-based cleanser. The company worked with La Habra, CA-based Global Packaging Inc., and their partner CasePak Inc. of Salt Lake City UT.

The gel cleanser is infused with Certified Pure Therapeutic Grade (CPTG) essential oils and emollients that are sensitive to oxidation. “Airless packaging components...protect the products from exposure to air, offer precise and repeatable dosing, allow almost 100% product evacuation rate, and contain no metal parts that touch the product while dispensing,” says Vinay Upasani, Global Packaging’s president. “Airless is a very sleek package design and generally connotes a high-tech, high-end, luxury image.”

To ensure a 100% leak-proof fit, the company designed the five-layer, co-extruded Verage tube with a ratchet on the head of the tube and a corresponding ratchet on the pump. “This unique design not only ensures a perfect leak-proof assembly by applying the predetermined torque, but also provides protection against accidental opening of the pump by the user,” Upsani says. Each dose of the airless pump is 0.22cc.

Multi-Dimensional Decorating

Advances in decorating technologies have given brands more options to play with, and have broadened the appeal of tubes for mass and prestige brands.

“Offset printing equipment continues to improve with servo driven pinpoint accuracy, and print to print registration is now highly utilized, with offset to silk screen to hot stamping combination printing effects,” says Jim Farley, vice president of global business development for World Wide Packaging (WWP), Florham Park, NJ. “Additionally, background vignettes and fades are executed with higher resolution and accuracy do to digital plate manufacturing.”

He adds that in the personal care market segment it’s become difficult to delineate from a print type offering standpoint, given the influx of injection in-mold labeled tubes, more sophisticated laminate tubes, over the shoulder labeled tubes and some flexo-combination printing. “Silk screening is being utilized in other formats than spot printing for opacity [and] mattified, penalized and iridescent screen inks are now coming into play,” he says. “Direct flexographic printing on tubes is beginning to emerge at reasonable output levels but still comes with an almost extreme equipment price point production.”

WWP recently produced a series of tubes for a flanker line of bath/shower gel, hair/body wash and body lotions for Elizabeth Arden’s Curve fragrance brand. “The tube extrusion color vibrancy utilizing pearl effects was quite challenging in matching Elizabeth Arden’s creative team’s direction,” Farley says. “The graphics platform has two different formats: a silk screen base decoration followed by a highly registered large coverage hot stamping execution; and a two-pass silk screen decoration followed by the same highly registered hot stamp execution.”

Executing the graphics required painstaking attention to registration. “The most complex part of the graphic execution is the hot foil stamping over the silk screen line copy, creating an ‘underline’ in the large format foil, a very interesting end result,” he says.

When Project Underground LLC sought tubes that were as fun and bold as the formulations in its You Are Amazing range of bath and body products, the company selected Charlotte, NC-based CTL Packaging USA Inc.

Brightly colored tubes and vibrant scents like grapefruit, lemon meringue and mango papaya “inspire and empower” consumers. “They really wanted to make an impact on the shelf, not only for the obvious reasons but also to be consistent with their brand positioning,” explains CTL’s Ines Vieira Varela, marketing manager.

She adds that with the high stakes of on-shelf competition, tubes provide plenty of real estate for communicating a brand message. “Brands know that 70% of buying decisions are made in front of the shelf, so they really need to be able to make an impact, especially if they have such a great message for girls as ‘You Are Amazing’ has,” she says. “Our design team works hard to collaborate with brands to make sure that they get the most out of this opportunity to stand out. Plus, they wanted the tubes to be made in the USA, which is something not every company can provide.

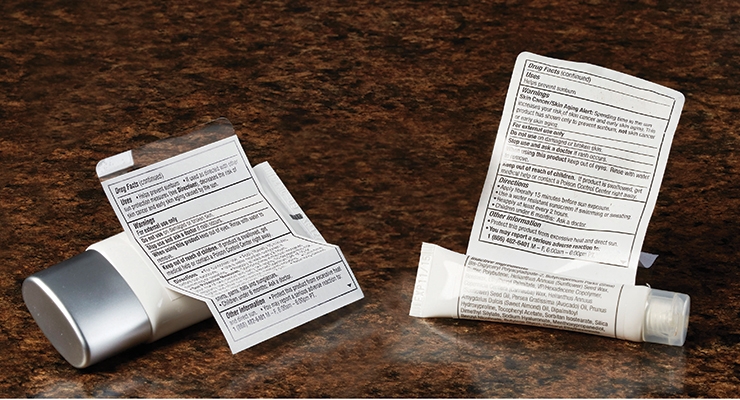

There are two options for getting product and marketing information on a tube: direct printing or label application. Generally speaking, the smaller the tube, the tougher it is to label. That’s why Green Bay, WI-based WS Packaging Group got creative when itproducing the .33 oz. HPDE oval tube with a flip-top cap for Beach Body’s Derm Exclusive Volume Lip Therapy product.

“Beach Body came to WS Packaging after its regulatory department decided all SPF labeling regulations would be printed on the primary package, regardless of the secondary packaging. This meant they needed 14 square inches of space on a .33 oz. tube,” explains Paulette Gramse, WS Packaging’s MultiVision product development manager. “While it’s possible to apply a PS label to something as small as a pencil, the challenge for beauty brands comes in meeting Federal Regulations for labeling products containing a sun protectant factor (SPF) ingredient. There are content and minimum space requirements for both the prime label and the back label.”

Gramse says tubes that are 3 oz. and smaller do not have enough space for the 10-15 square inches of label area to meet the minimum copy requirements. Enter peelable and multi-layer labels. WS developed the engineering drawings to make sure the stacked tolerances for the tube manufacturer to print the timing marks, for the label copy to meet die cut registration, for the contract decorator to meet the label application tolerances, and for the filler to meet the tube crimping tolerances. “All of these elements have tolerances from 1/8-1/32 inches so there isn’t much room for error,” she says.

Labeling for the .33 oz. Volume Lip Therapy product tubes required technical communication with the tube manufacturer in China to ensure the labels could be machine applied at a contract manufacturer in the U.S. “Working as a team, we were able to create a low-cost method to ensure label application was able to run at 45 tubes per minute,” Gramse says.

Tubes continue to reign as “total package” packages, delivering multi-functional ease of use and cost-effective customizations tailor made to attract brands and the consumers they serve. BP

Jouvé is a luxury, clean-label skin care brand that believes strongly in taking care of both the body and the environment. When deciding on packaging for its Instant Tightening and Restoring Serum, the company wanted a beautiful tube that balanced sustainability and recyclability. Jouvé selected PE and ABL tubes from Express Tubes of Kent, WA.

“Jouvé wanted increased usability and their high-value brand standard for their sample-sized packaging,” says Shanna Johns, sales manager, Express Tubes. “Instead of a packette, we went with tubes that showed off their beautiful art design. They have an LDPE material for soft pliability during consumer use and the five-layer structure for product stability with the Jouvé specially formulated ingredient deck.”

For the larger sizes, Express Tubes used an ABL material to achieve the Jouvé brand metallic rose gold color that matched the artwork on their sample-sized tube. “We were able to achieve their needs utilizing stock options that allowed them cost savings and time efficiency for their new product launch,” Johns says.

Robert McDermott, director of technical sales, East Hill Industries Inc., Carrollton, TX, says that from a brand perspective, tubes deliver a lot of bang for the buck as a highly deco-friendly packaging solution that can be produced quickly in comparison to other packaging mediums.

Tubes give brands an abundance of surface real estate to display product information and decoration for on-shelf differentiation. “A large, 360-degree printable area gives ample room for brands to clearly display their logo, their product, its benefits and all of the increasing regulatory information required of a cosmetic product,” McDermott says. “Add to that custom colors, metallic effects, graduated printing, life-like flexo-printing and a multitude of header and cap options and you have one versatile, squeezable, advertising board for your products.”

Lou Della Pesca, president, 3C Inc., Hawthorne, NJ, agrees. “The cost to decorate a tube by silk screening, offset printing, heat transfer or flexoprint is less expensive than that of a bottle or a jar [and] the printing will be more colorful,” he says.

Tubes are also produced relatively quickly. “With the proliferation of automatic tube filling machinery in the U.S., tube filling costs can also be kept low to give a total delivered product which can provide brands with great margins,” McDermott says, adding that today’s tube manufacturing is typically executed in a high-output, highly-automated manufacturing and decoration environment. “New brands or established brands with new product lines can utilize this great benefit of tube packaging to react more quickly to market forces.”

Madison Reed turned to East Hill when it sought a tube that reflected its hair brand’s Color Reviving Gloss. Made with “healthier” ingredients, the product is formulated to keep hair looking fresh-from-the-salon vibrant. “Utilizing a five-layer aluminum laminate structure, East Hill was not only able to meet Madison Reed’s product stability requirements, but also achieve an understated matte metallic luster to the tubes,” McDermott says.

The tube features an extended nozzle tip to improve ease of application and is finished with a foil seal and a “natural effect” PP screw cap. “The offset printed vignettes were color-matched to Madison Reed’s eight available colors to match the shade held within, keeping the launch within Madison Reed’s ease-of-use mantra,” notes McDermott, concluding that the tubes were finished with Madison Reed’s signature off-center MDSNRD logo.

Airless Advantages

Airless tubes have become increasingly popular among cosmetic and personal care brands that market products with air- and light-sensitive formulations.

“Airless tubes in particular are a great option for brands because they combine the generally lower price point of a tube with the packaging benefits of airless dispensing—including quicker strokes to prime, metered dosing, and a 100% metal-free product pathway that does not allow air back into the package to protect the formula from contamination,” comments Lesley Gadomski, business development officer, Fusion Packaging, Dallas, TX.

Fusion offers standard, airless, center-dispensing and Shine FX tubes for formulations in need of barrier protection. “Our standard EVOH (Ethylene Vinyl Alcohol) tubes provide a five-layer barrier between the formula and outside elements,” she says, adding that the Shine FX Tube collection is also available in four varying film materials—ABL, CAL, VMPE, and HAL—each of which provide both functional and aesthetic benefits for brands.

Urban Decay selected Fusion’s 40ml Shine FX Airless Tru Tube with barrier-resistant ABL metallic film to house its new One & Done Hybrid Complexion Perfector Broad Spectrum SPF 20. The tube fits in with the brand’s existing Naked Skin collection, which includes Weightless Ultra Definition Liquid Makeup in Fusion’s 30ml Allure bottle, and Ultra Definition Loose Finishing Powder in a Fusion custom sifter jar design. “One & Done Hybrid Complexion Perfector SPF 20, features a stunning gradient effect with shiny silver hot stamp and coordinating gunmetal pump and over cap,” Gadomski says. “Urban Decay’s edgy aesthetic incorporates many metallic gunmetal embellishments, so the vibrant Shine FX collection was a perfect fit.”

An airless tube was also the right choice for doTERRA’s Essential Skin Care “all natural” Verage essential oil-based cleanser. The company worked with La Habra, CA-based Global Packaging Inc., and their partner CasePak Inc. of Salt Lake City UT.

The gel cleanser is infused with Certified Pure Therapeutic Grade (CPTG) essential oils and emollients that are sensitive to oxidation. “Airless packaging components...protect the products from exposure to air, offer precise and repeatable dosing, allow almost 100% product evacuation rate, and contain no metal parts that touch the product while dispensing,” says Vinay Upasani, Global Packaging’s president. “Airless is a very sleek package design and generally connotes a high-tech, high-end, luxury image.”

To ensure a 100% leak-proof fit, the company designed the five-layer, co-extruded Verage tube with a ratchet on the head of the tube and a corresponding ratchet on the pump. “This unique design not only ensures a perfect leak-proof assembly by applying the predetermined torque, but also provides protection against accidental opening of the pump by the user,” Upsani says. Each dose of the airless pump is 0.22cc.

Multi-Dimensional Decorating

Advances in decorating technologies have given brands more options to play with, and have broadened the appeal of tubes for mass and prestige brands.

“Offset printing equipment continues to improve with servo driven pinpoint accuracy, and print to print registration is now highly utilized, with offset to silk screen to hot stamping combination printing effects,” says Jim Farley, vice president of global business development for World Wide Packaging (WWP), Florham Park, NJ. “Additionally, background vignettes and fades are executed with higher resolution and accuracy do to digital plate manufacturing.”

He adds that in the personal care market segment it’s become difficult to delineate from a print type offering standpoint, given the influx of injection in-mold labeled tubes, more sophisticated laminate tubes, over the shoulder labeled tubes and some flexo-combination printing. “Silk screening is being utilized in other formats than spot printing for opacity [and] mattified, penalized and iridescent screen inks are now coming into play,” he says. “Direct flexographic printing on tubes is beginning to emerge at reasonable output levels but still comes with an almost extreme equipment price point production.”

WWP recently produced a series of tubes for a flanker line of bath/shower gel, hair/body wash and body lotions for Elizabeth Arden’s Curve fragrance brand. “The tube extrusion color vibrancy utilizing pearl effects was quite challenging in matching Elizabeth Arden’s creative team’s direction,” Farley says. “The graphics platform has two different formats: a silk screen base decoration followed by a highly registered large coverage hot stamping execution; and a two-pass silk screen decoration followed by the same highly registered hot stamp execution.”

Executing the graphics required painstaking attention to registration. “The most complex part of the graphic execution is the hot foil stamping over the silk screen line copy, creating an ‘underline’ in the large format foil, a very interesting end result,” he says.

When Project Underground LLC sought tubes that were as fun and bold as the formulations in its You Are Amazing range of bath and body products, the company selected Charlotte, NC-based CTL Packaging USA Inc.

Brightly colored tubes and vibrant scents like grapefruit, lemon meringue and mango papaya “inspire and empower” consumers. “They really wanted to make an impact on the shelf, not only for the obvious reasons but also to be consistent with their brand positioning,” explains CTL’s Ines Vieira Varela, marketing manager.

She adds that with the high stakes of on-shelf competition, tubes provide plenty of real estate for communicating a brand message. “Brands know that 70% of buying decisions are made in front of the shelf, so they really need to be able to make an impact, especially if they have such a great message for girls as ‘You Are Amazing’ has,” she says. “Our design team works hard to collaborate with brands to make sure that they get the most out of this opportunity to stand out. Plus, they wanted the tubes to be made in the USA, which is something not every company can provide.

There are two options for getting product and marketing information on a tube: direct printing or label application. Generally speaking, the smaller the tube, the tougher it is to label. That’s why Green Bay, WI-based WS Packaging Group got creative when itproducing the .33 oz. HPDE oval tube with a flip-top cap for Beach Body’s Derm Exclusive Volume Lip Therapy product.

“Beach Body came to WS Packaging after its regulatory department decided all SPF labeling regulations would be printed on the primary package, regardless of the secondary packaging. This meant they needed 14 square inches of space on a .33 oz. tube,” explains Paulette Gramse, WS Packaging’s MultiVision product development manager. “While it’s possible to apply a PS label to something as small as a pencil, the challenge for beauty brands comes in meeting Federal Regulations for labeling products containing a sun protectant factor (SPF) ingredient. There are content and minimum space requirements for both the prime label and the back label.”

Gramse says tubes that are 3 oz. and smaller do not have enough space for the 10-15 square inches of label area to meet the minimum copy requirements. Enter peelable and multi-layer labels. WS developed the engineering drawings to make sure the stacked tolerances for the tube manufacturer to print the timing marks, for the label copy to meet die cut registration, for the contract decorator to meet the label application tolerances, and for the filler to meet the tube crimping tolerances. “All of these elements have tolerances from 1/8-1/32 inches so there isn’t much room for error,” she says.

Labeling for the .33 oz. Volume Lip Therapy product tubes required technical communication with the tube manufacturer in China to ensure the labels could be machine applied at a contract manufacturer in the U.S. “Working as a team, we were able to create a low-cost method to ensure label application was able to run at 45 tubes per minute,” Gramse says.

Tubes continue to reign as “total package” packages, delivering multi-functional ease of use and cost-effective customizations tailor made to attract brands and the consumers they serve. BP