Joanna Cosgrove, Contributing Editor07.25.16

It’s usually the primary packaging vessel that attracts the lion’s share of consumer attention at retail. After all, bottles, tubes and jars are made to be handled and to communicate brand information. But the essential role of caps and closures shouldn’t be overlooked. They guard against product leaks, protect dispensers and, in some cases, also serve double duty as dispensers, too. Packaging suppliers have continued to innovate and expand their cap and closure offerings, creating options that not only enhance the user experience but also contribute to a package’s overall design scheme.

“Aesthetics and consumer appeal have been the focus over the last few years,” says Juan Bruna, president, Bruna Seals, Doral, FL. “Companies are offering new material options (such as wood and soft touch finishes), new designs and especially new decoration technologies.”

Bruna Seals, a provider of high-quality liner and sealing products, recently worked with an unnamed brand to provide a seal closure for a new product expected to launch this August. The brand chose Bruna Seals’ LuxeSeal solution over standard traditional seals and cosmetic discs. They also decorated their 33- and 89mm seals with a custom embossed logo and a custom designed Luxe Tab.

Bruna explains that the Luxe Tab Custom embossed seal replaces cosmetic discs/covers and adds a hermetic seal designed to increase product shelf life. Its inherent tamper evidence feature reduces product damages and returns (representing a cost savings for the brand), while the single, foldable tab design offers an “easy peel” solution that works seamlessly with the brand’s existing packaging components.

Functional & Decorative

In the realm of traditional caps and closures, metal is the big trend. “We’re finding more and more customers looking for a high end, jewelry like polished finish,” says Anthony Di Maio, COO, Cameo Metal Products Inc., Brooklyn, NY, a provider of closures with a traditional, luxurious buff-and-lacquer finish. “Clients are looking for a mirror polish finish on their parts to match things like antiques, jewelry and fine silverware.”

Lucie Trocherie, marketing and key accounts assistant, Technicaps, Challes, France, remarks that the feel of closures has emerged as another important consideration. “Weight is becoming an increasingly important criterion on the packaging design,” she comments. “Indeed, our customers are looking for increasingly heavier caps.”

And while closures might afford minimal space for design in comparison to other packaging vehicles, brands are working with cap suppliers to make the most of that real estate. “Engraving is also very trendy, it allows for a particularly elegant finish,” Trocherie says. “Technicaps is continually working to improve its techniques. It is now possible to produce ‘thermodur’ caps with very thin debossed, but also embossed, engraving,” which can be seen on the cap the company produced for Zlatan Ibrahimovic.

After two years of work, the world renowned Swedish football player launched his first fragrance. The packaging collaboration, Trocherie says, gave rise to the creation of a matte black, Bakelite over cap embellished with a thin, elegant engraving that represents Zlatan’s two favorite tattoos: the fish and the feather with the initials M and V, for his sons Maximilian and Vincent.

In addition to Zlatan Ibrahimovic, Technicaps has provided caps to a veritable who’s who of beauty brands, having produced metallized, color-matched caps for Marionnaud’s recent Milky Bath Oil range, as well as a stunning, tailor-made, metal-plated cap for Lalique’s high-end Noir Premier 1905 fragrance.

Trocherie says Technicaps offers more than 250 standard caps that are ready for customization to help brands create unique closures that gel with their overall packaging design. “Technicaps uses a variety of printing methods (hot stamping, screen printing, pad printing, etc.), enabling the customer to customize the caps with the brand’s name or logo,” she says. “We have also developed close working relationships with our subcontractors with a view to offering the customer an even wider range of finishes: plating, varnishing, lacquering pad printing and more.

The cap business at Coverpla, Long Island City, NY, is comprised of stock caps with custom decoration. Gilda Cutri, the company’s national sales manager, says the deco options for customization on caps is virtually limitless and the payoff for brands is excellent.

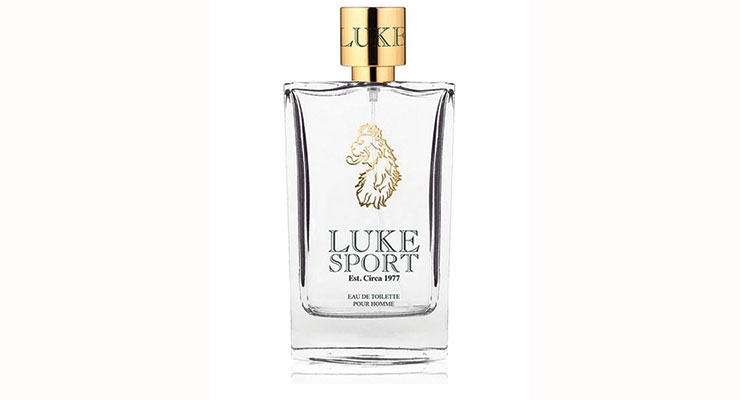

Coverpla recently executed a custom-weighted, gold-colored cap for Luke Roper’s eponymous fragrance in the UK, by silkscreening the brand’s logo in a striking hunter green color all around the cap. “The cap was small – only 26mm in diameter and 23mm in height,” Cutri says. “What’s really nice about this cap is that it sits apart from the decoration on the bottle; it’s perched on the bottle’s collar, as opposed to sitting atop the bottle’s shoulder. It really draws emphasis to the cap and the brand name on the cap.”

One of Coverpla’s most recent cap developments is Carrement, a Surlyn over-molded one-piece unit that’s actually two caps in one. “Aesthetically it really has a beautiful look to it and lends itself to a variety of design ideas,” Cutri says. “You could have an opaque cap inside and a color outside or translucent on top of translucent, depending on the look you’re trying to achieve, because Surlyn has the translucence of glass.”

An increasingly popular trend in beauty and personal closures involves magnetizing the cap componentry. “Magnetic caps instill a sense of luxury, offer a high-end feel and securely hold the cap to the bottle,” says Cutri, noting that Coverpla offers magnetic caps in a heavy plastic material that “feels like ceramic.”

Wooden Cap Creations

Wooden caps are currently in demand because they impart an unexpected and tactile sense of luxury. After producing the wooden compact for Guerlain’s Terracotta Sun Celebration range, Barcelona, Spain-based Quadpack also produced the wooden cap for the line’s signature fragrance. “The cap, like the compact, is made of PEFC-certified beech wood, stained a rich, dark brown, and embraces a gold anodized aluminum screw neck cap,” according to the supplier. “The cap matches the elegant rounded curves of the bottle and the compact, while its soft finish is pleasant to the touch.”

Based in Barcelona, Spain, Pujolasos Wood & Pack has manufactured upwards of 25 million wood caps in diameters ranging from 2- to 120mm for many products in the perfumery and cosmetics industries.

“Within the premium segment, the most commonly used woods are ash and maple where the grain is very marked; woods of beech, maple or oak are also used,” says CEO Angel Pujolasos. The chief benefit of wood is that there are no molds or costs like those associated with other materials like plastic or aluminum. “Our final products are adapted to briefings and final designs, getting exclusive products for each one, with a 100% personalization, from the outside shape, color, decoration (thermographic, laser, screen printing, etc.), touch and sensorial transmission from the appearance,” Pujolasos says. “Also, if the client wants, we have plastic interiors with ‘own’ molds, and are developing new technologies to decorate and varnish, to strengthen the product exclusivity.”

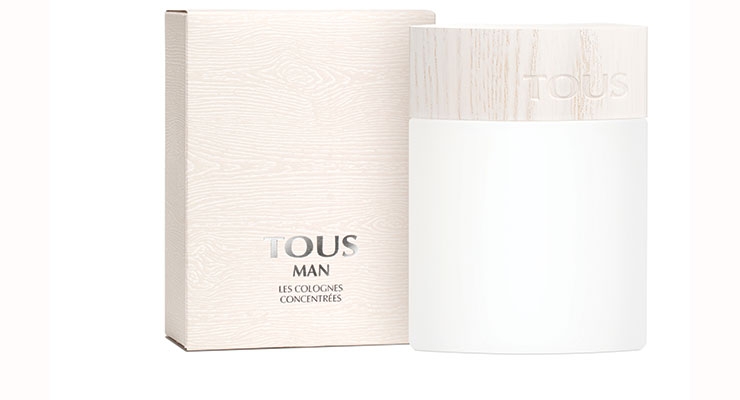

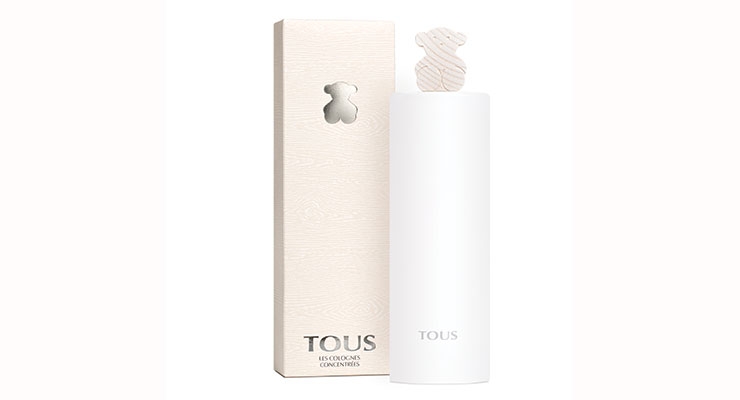

This year Pujolasos has provided wood caps to new products from two brands. Launched in June, the Tous women’s fragrance required the development of a new technology to shape the bas-relief of an ash wood, teddy bear-shaped cap. On the male companion fragrance, the Tous logo was executed in “low relief” on the curved cap surface. Both caps were finished with a distinctive white varnish.

Improving Cap Functionality

Norcross, GA-headquartered WestRock does more than simply supply closures for lotions and hair care products, the company prides itself on being a problem solver, especially as it relates to improving closure efficiencies and eliminating product messes.

“Consumers are looking for ease of use and functionality; they don’t want product messes, lost components or complex closures that require extra steps,” says John Ferro, the company’s vice president of marketing, home and beauty. “WestRock’s goal is to streamline dispensing.”

No one wants a cap that spills and leaks. WestRock focuses on the design element and the technology around the orifice design, paying close attention to the flow pattern of the product formula itself, determining the precise angle of product shear, so customers get a clean, no mess cut-off of the product during dispensing. “We spend a lot of time tinkering with how closures impact a product’s flow properties, working with flow paths and developing flow chambers to eliminate product ‘globs’,” Ferro says. “We also study the angles to make sure liquid shears properly using a ‘suck back’ action that draws the product back into the bottle after dispensing.”

One cap that’s proven successful for WestRock is the Latch Back cap, which is outfitted with a hinge that connects the cap to the closure and prevents it from falling forward into the product stream trajectory during dispensing. Ferro says this is one example of how the company considers the total product in the cap design process, paying close attention to details like the way a cap closes and the way an orifice is designed to optimize liquid viscosity.

Each year, WestRock conducts its own Packaging Matters survey about a variety of packaging needs and trends. This year’s study, which surveyed 2,000 consumers and 200 packaging professionals across America, revealed that 60% of consumers said they would repeat a purchase because of packaging functionality. Other revelations include the demand for new cost and sustainability solutions. To that end, WestRock is working on how to take silicone valves out of closures. “Not only are they costly, they aren’t recyclable,” Ferro says. “We have a baffled orifice (or a baffled keyhole) technology that creates chambers that influence the flow path of fluids to create less drip or pre-dispensing before the consumer is ready.”

Caps are terrific vehicles for dispensing product formulations, and sometimes formula dispensing is accomplished in ways other than squeezing or squirting methods. Virospack of Badalona, Spain, offers highly customizable, in-cap spatulas for a range of standard packages with capacities spanning 3- to 20ml. Rosa Porras, the company’s marketing and communication manager, says these formats make products easy to apply because the applicator is attached to the cap and conveniently pulls product out of the package each time the cap is opened.

In the personal care segment, Beiersdorf collaborated with St. Cloud, France-based Global Closure Systems (GCS) on the packaging for its new generation of Nivea Body Moisturizers. According to Isabelle Bennar, head of marketing and communication for GCS, the new Nivea bottle was designed to accommodate a headstand cap with a 180°, bi-injected hinge closure that coordinates with the bottle to provide a monoblock look. “An important success factor can be to offer a solution that delivers a positive consumer experience,” she says, adding that dispensing technologies continue to evolve towards optimized performance in order to provide added value to the consumer. “This combination of a great product and a dispensing feature that provides ease of use for the consumer is a significant motive for re-purchase and hence brand success.”

Virospack recently produced a spatula cap for L’Occitane’s Essence Lumiére Immortelle Brightening Essence. The injection molded plastic cap features an aluminum shelf and fits onto the small, 8ml glass bottle.

“This skin lightening formula is viscous and the spatula allows a precise application right on top of each spot,” remarks Porras. “The spatula is soft and flexible, done in an excellent material totally compatible to contact with the skin; it’s not hard or aggressive.”

Porras said the caps that accommodate the spatulas are made of urea and have “triseal” liners to preserve product integrity. “Urea [is] an excellent material that runs very well, and with our long experience working with it and developing molds, getting specific molds is easier, faster and, consequently, cheaper for the brands,” she says.

To ensure the compatibility of each of the packaging components, Virospack developed and manufactured the complete package for L’Occitane. The bottle was part of the company’s standard line and is coated white (other coating colors are available to ensure products are protected against damaging UV rays). The bottle was also silk-screened in two colors to meet with L’Occitane’s design needs. All of the manufacturing and decorating work was performed in-house by Virospack.

Selecting the right closure for a product in an important consideration. Though it’s a small detail in comparison to picking the right jar, bottle or tube, smart closure choices not only add functionality but provide the finishing touch to a design.

“Aesthetics and consumer appeal have been the focus over the last few years,” says Juan Bruna, president, Bruna Seals, Doral, FL. “Companies are offering new material options (such as wood and soft touch finishes), new designs and especially new decoration technologies.”

Bruna Seals, a provider of high-quality liner and sealing products, recently worked with an unnamed brand to provide a seal closure for a new product expected to launch this August. The brand chose Bruna Seals’ LuxeSeal solution over standard traditional seals and cosmetic discs. They also decorated their 33- and 89mm seals with a custom embossed logo and a custom designed Luxe Tab.

Bruna explains that the Luxe Tab Custom embossed seal replaces cosmetic discs/covers and adds a hermetic seal designed to increase product shelf life. Its inherent tamper evidence feature reduces product damages and returns (representing a cost savings for the brand), while the single, foldable tab design offers an “easy peel” solution that works seamlessly with the brand’s existing packaging components.

Functional & Decorative

In the realm of traditional caps and closures, metal is the big trend. “We’re finding more and more customers looking for a high end, jewelry like polished finish,” says Anthony Di Maio, COO, Cameo Metal Products Inc., Brooklyn, NY, a provider of closures with a traditional, luxurious buff-and-lacquer finish. “Clients are looking for a mirror polish finish on their parts to match things like antiques, jewelry and fine silverware.”

Lucie Trocherie, marketing and key accounts assistant, Technicaps, Challes, France, remarks that the feel of closures has emerged as another important consideration. “Weight is becoming an increasingly important criterion on the packaging design,” she comments. “Indeed, our customers are looking for increasingly heavier caps.”

And while closures might afford minimal space for design in comparison to other packaging vehicles, brands are working with cap suppliers to make the most of that real estate. “Engraving is also very trendy, it allows for a particularly elegant finish,” Trocherie says. “Technicaps is continually working to improve its techniques. It is now possible to produce ‘thermodur’ caps with very thin debossed, but also embossed, engraving,” which can be seen on the cap the company produced for Zlatan Ibrahimovic.

After two years of work, the world renowned Swedish football player launched his first fragrance. The packaging collaboration, Trocherie says, gave rise to the creation of a matte black, Bakelite over cap embellished with a thin, elegant engraving that represents Zlatan’s two favorite tattoos: the fish and the feather with the initials M and V, for his sons Maximilian and Vincent.

In addition to Zlatan Ibrahimovic, Technicaps has provided caps to a veritable who’s who of beauty brands, having produced metallized, color-matched caps for Marionnaud’s recent Milky Bath Oil range, as well as a stunning, tailor-made, metal-plated cap for Lalique’s high-end Noir Premier 1905 fragrance.

Trocherie says Technicaps offers more than 250 standard caps that are ready for customization to help brands create unique closures that gel with their overall packaging design. “Technicaps uses a variety of printing methods (hot stamping, screen printing, pad printing, etc.), enabling the customer to customize the caps with the brand’s name or logo,” she says. “We have also developed close working relationships with our subcontractors with a view to offering the customer an even wider range of finishes: plating, varnishing, lacquering pad printing and more.

The cap business at Coverpla, Long Island City, NY, is comprised of stock caps with custom decoration. Gilda Cutri, the company’s national sales manager, says the deco options for customization on caps is virtually limitless and the payoff for brands is excellent.

Coverpla recently executed a custom-weighted, gold-colored cap for Luke Roper’s eponymous fragrance in the UK, by silkscreening the brand’s logo in a striking hunter green color all around the cap. “The cap was small – only 26mm in diameter and 23mm in height,” Cutri says. “What’s really nice about this cap is that it sits apart from the decoration on the bottle; it’s perched on the bottle’s collar, as opposed to sitting atop the bottle’s shoulder. It really draws emphasis to the cap and the brand name on the cap.”

One of Coverpla’s most recent cap developments is Carrement, a Surlyn over-molded one-piece unit that’s actually two caps in one. “Aesthetically it really has a beautiful look to it and lends itself to a variety of design ideas,” Cutri says. “You could have an opaque cap inside and a color outside or translucent on top of translucent, depending on the look you’re trying to achieve, because Surlyn has the translucence of glass.”

An increasingly popular trend in beauty and personal closures involves magnetizing the cap componentry. “Magnetic caps instill a sense of luxury, offer a high-end feel and securely hold the cap to the bottle,” says Cutri, noting that Coverpla offers magnetic caps in a heavy plastic material that “feels like ceramic.”

Wooden Cap Creations

Wooden caps are currently in demand because they impart an unexpected and tactile sense of luxury. After producing the wooden compact for Guerlain’s Terracotta Sun Celebration range, Barcelona, Spain-based Quadpack also produced the wooden cap for the line’s signature fragrance. “The cap, like the compact, is made of PEFC-certified beech wood, stained a rich, dark brown, and embraces a gold anodized aluminum screw neck cap,” according to the supplier. “The cap matches the elegant rounded curves of the bottle and the compact, while its soft finish is pleasant to the touch.”

Based in Barcelona, Spain, Pujolasos Wood & Pack has manufactured upwards of 25 million wood caps in diameters ranging from 2- to 120mm for many products in the perfumery and cosmetics industries.

“Within the premium segment, the most commonly used woods are ash and maple where the grain is very marked; woods of beech, maple or oak are also used,” says CEO Angel Pujolasos. The chief benefit of wood is that there are no molds or costs like those associated with other materials like plastic or aluminum. “Our final products are adapted to briefings and final designs, getting exclusive products for each one, with a 100% personalization, from the outside shape, color, decoration (thermographic, laser, screen printing, etc.), touch and sensorial transmission from the appearance,” Pujolasos says. “Also, if the client wants, we have plastic interiors with ‘own’ molds, and are developing new technologies to decorate and varnish, to strengthen the product exclusivity.”

This year Pujolasos has provided wood caps to new products from two brands. Launched in June, the Tous women’s fragrance required the development of a new technology to shape the bas-relief of an ash wood, teddy bear-shaped cap. On the male companion fragrance, the Tous logo was executed in “low relief” on the curved cap surface. Both caps were finished with a distinctive white varnish.

Improving Cap Functionality

Norcross, GA-headquartered WestRock does more than simply supply closures for lotions and hair care products, the company prides itself on being a problem solver, especially as it relates to improving closure efficiencies and eliminating product messes.

“Consumers are looking for ease of use and functionality; they don’t want product messes, lost components or complex closures that require extra steps,” says John Ferro, the company’s vice president of marketing, home and beauty. “WestRock’s goal is to streamline dispensing.”

No one wants a cap that spills and leaks. WestRock focuses on the design element and the technology around the orifice design, paying close attention to the flow pattern of the product formula itself, determining the precise angle of product shear, so customers get a clean, no mess cut-off of the product during dispensing. “We spend a lot of time tinkering with how closures impact a product’s flow properties, working with flow paths and developing flow chambers to eliminate product ‘globs’,” Ferro says. “We also study the angles to make sure liquid shears properly using a ‘suck back’ action that draws the product back into the bottle after dispensing.”

One cap that’s proven successful for WestRock is the Latch Back cap, which is outfitted with a hinge that connects the cap to the closure and prevents it from falling forward into the product stream trajectory during dispensing. Ferro says this is one example of how the company considers the total product in the cap design process, paying close attention to details like the way a cap closes and the way an orifice is designed to optimize liquid viscosity.

Each year, WestRock conducts its own Packaging Matters survey about a variety of packaging needs and trends. This year’s study, which surveyed 2,000 consumers and 200 packaging professionals across America, revealed that 60% of consumers said they would repeat a purchase because of packaging functionality. Other revelations include the demand for new cost and sustainability solutions. To that end, WestRock is working on how to take silicone valves out of closures. “Not only are they costly, they aren’t recyclable,” Ferro says. “We have a baffled orifice (or a baffled keyhole) technology that creates chambers that influence the flow path of fluids to create less drip or pre-dispensing before the consumer is ready.”

Caps are terrific vehicles for dispensing product formulations, and sometimes formula dispensing is accomplished in ways other than squeezing or squirting methods. Virospack of Badalona, Spain, offers highly customizable, in-cap spatulas for a range of standard packages with capacities spanning 3- to 20ml. Rosa Porras, the company’s marketing and communication manager, says these formats make products easy to apply because the applicator is attached to the cap and conveniently pulls product out of the package each time the cap is opened.

In the personal care segment, Beiersdorf collaborated with St. Cloud, France-based Global Closure Systems (GCS) on the packaging for its new generation of Nivea Body Moisturizers. According to Isabelle Bennar, head of marketing and communication for GCS, the new Nivea bottle was designed to accommodate a headstand cap with a 180°, bi-injected hinge closure that coordinates with the bottle to provide a monoblock look. “An important success factor can be to offer a solution that delivers a positive consumer experience,” she says, adding that dispensing technologies continue to evolve towards optimized performance in order to provide added value to the consumer. “This combination of a great product and a dispensing feature that provides ease of use for the consumer is a significant motive for re-purchase and hence brand success.”

Virospack recently produced a spatula cap for L’Occitane’s Essence Lumiére Immortelle Brightening Essence. The injection molded plastic cap features an aluminum shelf and fits onto the small, 8ml glass bottle.

“This skin lightening formula is viscous and the spatula allows a precise application right on top of each spot,” remarks Porras. “The spatula is soft and flexible, done in an excellent material totally compatible to contact with the skin; it’s not hard or aggressive.”

Porras said the caps that accommodate the spatulas are made of urea and have “triseal” liners to preserve product integrity. “Urea [is] an excellent material that runs very well, and with our long experience working with it and developing molds, getting specific molds is easier, faster and, consequently, cheaper for the brands,” she says.

To ensure the compatibility of each of the packaging components, Virospack developed and manufactured the complete package for L’Occitane. The bottle was part of the company’s standard line and is coated white (other coating colors are available to ensure products are protected against damaging UV rays). The bottle was also silk-screened in two colors to meet with L’Occitane’s design needs. All of the manufacturing and decorating work was performed in-house by Virospack.

Selecting the right closure for a product in an important consideration. Though it’s a small detail in comparison to picking the right jar, bottle or tube, smart closure choices not only add functionality but provide the finishing touch to a design.