Trends Define Innovation

Trends in cosmetic packaging continue to influence and define “innovation” with examples ranging from sizes offered, to materials used, to special effects. While some innovation is truly breakthrough, much of it focuses on certain elements of function or design meant to capture consumer interest. Speed to market can sometimes hamper the development of truly unique products that can take years to produce.

Philip Tarrant, leader, Packaging Concept Development, Coty, tells Beauty Packaging: “I believe that when you speak of innovation in the beauty industry, there are essentially two types: true innovation, or invention that creates a new category or consumer gesture; and secondly, innovation to bring an existing technology or invention to a broader audience by making it ‘manufacturable’ and less expensive.”

For true inventions, Tarant says the timing is necessarily longer as it requires additional resources for proof of concept before accurate development cost and timing can be determined. He notes: “With truly innovative products, you must also perform intellectual property/patent searches which can be lengthy. Only after this is completed can you move through your normal development cycle. This can add months or years to the process depending on the complexity.”

Benjamin Punchard, global packaging insights director, Mintel, says he’s also seeing two strands of innovation. In his view, the first is driven by the need for brands to support ever stronger product claims, which leads them to leverage packaging functionality to help support these claims. These can be simple innovations, he says, such as Hera Rich Squeeze Mascara in South Korea, which replaces the traditional rigid mascara tube with a squeezable rubber version.” Punchard explains that this package enables the consumer “to massage the product and the applicator wand while still in the pack, in order to remove clumps and ensure an even application.”

The second strand of innovation, according to Punchard, is experiential. “With younger consumers and Millennials looking for brands to deliver memorable moments that can be shared online, decorative effects such as color-changing labels, 3-D pop-up packaging and disruptive design are all now trending.”

Social sharing “has really sped up the typical production timeline,” says Denis Maurin, vice president of sales and industrial innovation, HCT Group. He explains: “Brands that sell online-only bring products to the market at a faster rate than brands that sell to retailers. In order for these brands to stand out, they have to have a strong presence on social media, the right influencers pushing their products—and they need to be launching new innovative products and packaging on a regular basis.”

Portability is another priority for beauty consumers, according to Maurin. He says, “Many beauty brands are looking for packaging that offers their customers easy and convenient use while on-the-go. Stick foundations like the Hourglass Vanish Seamless Finish Foundation Stick are a great example of this.”

Maurin says these trends come from a collaborative effort between the supplier and the brands. “We come up with new innovations in formulation and packaging, and the brands bring their products to life with personality and marketing.”

Color Cosmetics

Not surprisingly, a number of recent creative packages revolve around makeup, as color cosmetics continue to outpace fragrance and personal care categories—especially in the Prestige sectors. In fact, in the third quarter of 2016, sales of U.S. prestige beauty products hit $3.5 billion, a gain of 8% over the same period last year. Another trend to note: Many of these innovative packages are born from California-based brands, which in general, are known for their independent thinking, risk taking and nimble decision-making—all key factors in cutting through long development times.

Smashbox is a brand noted for thinking outside the box and instilling personality in their packaging of cosmetic products. Coinciding with the strongest gift-giving season of the year, the popular cult brand has introduced the Smashbox Light It Up Holiday Collection, seven limited edition kits that hit all the right consumer notes.

Jill Tomandl, vice president, product development & innovation, Smashbox, tells Beauty Packaging that a neon colorant was used in the plastic resin to create a glowing effect on the edge of the plastic box base, but the lid is molded clear so consumers can see the actual shades of the product. The neon resin was also carried through on the compact lids. Anticipating the store display aspects, the neon boxes are stackable and impactful in an open-sell environment, and also serve as a branded keepsake item with added value. Smashbox partnered with neon artist, Meryl Pataki, who created “Light It Up” as a neon sign. The sign was photographed and used as the artwork on the front of the band.

Hourglass is known for their innovative, luxury beauty products, which combine high-performance formulas with sleek custom packaging. Most recently the brand launched its new Curator Collection, a mascara and primer bottle with a unique applicator wand. The packaging was produced by HCT Group.

Lisa Sheldon, director of sales, HCT Group, says the Hourglass Curator “combines an exquisite design with a unique function to create a product that is truly luxurious and innovative.” The high-end product features two parts; glass mascara or primer bottle and an applicator with a ZAMAC handle and a stainless steel stem PVD plated in gold. Each part is sold separately; the lash instrument is a one-time purchase that can be used with both the Realist mascara and Ascent primer refills. “The weight of the overall product not only makes the product look luxurious but it also feels luxurious,” says Sheldon, adding “the elegance of this product cannot be matched by competing brands.”

Sheldon says what makes the Collection so innovative is that this is the first time that mascara is being sold in a glass bottle separately from its application wand, as well as one of the first brushless mascara application tools to hit the market. Most beauty brands use plastic packaging for mascaras and almost always include a wand with their packaging.

The most challenging part of creating this product, according to Sheldon, was the complex construction of connecting a custom glass bottle with a collar and integrating a wiper in the middle. “Unlike plastic,” says Sheldon, “glass has more variance during the molding process. This makes it very difficult to snap any part and seal properly. The soft wiper that is between the collar and the bottle acts as a sealing element and still helps in wiping the wand to leave the right amount of product in the applicator groove.”

Collaboration also plays a key role in how Compax approaches projects. “The brands we work with each have a unique voice, a clear understanding of their audience, and their own set of nuanced expression in which they alone are the experts,” explains Brooke Dearth, creative director. She adds, “At Compax, honoring and building from their expertise is paramount. Each project is different; sometimes the idea is vague and needs design exploration from us, other times the concept is fleshed out but needs our creative engineering to bring it to life.”

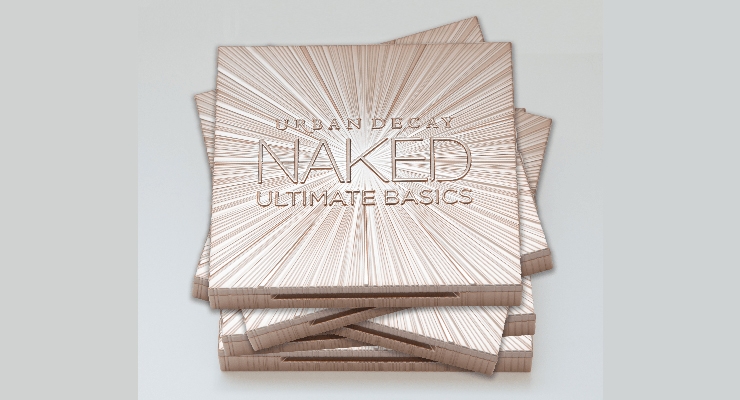

When Urban Decay approached Compax to collaborate on its newest product in the popular Naked franchise, Dearth says the supplier knew “this would be more than just a standard stock & drop.” To achieve a totally different look, they chose a custom-design path.

“The concept we developed was ambitious—brilliant rays bursting from beneath the raised lettering on the cover,” explains Dearth. While these bursts were built into the mold to wrap around the edges and create a continuous flow feeling, Dearth says the challenge was how to get tiny, detailed, specific rays shiny while the rest of the palette would be matte.

Compax created an exclusive technique that allowed for the entire palette to be matte sprayed, but only certain details to be polished, buffing away the matte spray and revealing the shiny vac metallization underneath. In order to meet demand, Compax designed a machine that could automate this new process and ensure that the dramatic difference was reliable and repeatable again and again.

“The result is a one-of-a-kind jewel that has generated buzz and remarkable demand,” says Dearth.

At global cosmetic packaging supplier Cosmopak USA, Walter Dwyer, president, says demand is strong in turnkey makeup palettes and “for anything to do with lips.”

Recently, he says, “We have seen increased demand for our airtight liquid eyeshadow pen which Cosmopak is selling as a turnkey item.” This is a patented package, and Dwyer says it is the first liquid eyeshadow in a twist pen that doesn’t dry out. The formula glides on easily and can house high metallic and iridescent formulas.

Cosmopak has just completed what Dwyer calls “a very exciting project” for a startup company that is combining technology, beauty and the makeup influencer and artistry world. It is called mylookingglass beauty and it launches in December. It is a limited edition makeup studio with a built-in camera that pairs with their app, and allows users to take photos they can edit and share on the app. Dwyer says they also are creating content to educate users and enable them to create content on their application.

“The big innovation for Cosmopak,” explains Dwyer, “was to not only create the makeup studio and all the products inside it, but we also manufactured the camera. It really is a technological breakthrough as photos get transferred via Bluetooth…it’s so cool.”

Quadpack says its Click Stylo offers a new gesture in lipstick application: One click, one dose. The supplier says the product offers an innovative delivery system for lip color. Where lipstick tends to be actuated with a twist, this stick uses a click button that doses just enough color for a single application. Its small size makes it ideal for beauty on the go.

Efficient Sizes

Mintel’s Punchard tells Beauty Packaging, “In cosmetics, we are seeing packs shift to smaller sizes, partly for on-the-go use, but also as a response to younger cosmetics wearers wanting continual experimentation with their look so a new color or styling attribute might be used one month and discarded the next.”

In addition to small sizes, suppliers are also striving to create dual packaging that can house several products in one package for ease and efficiency as well as portability.

Curt Altmann, vice president of global development, Yonwoo/PKG, says one of the most compelling trends they are seeing from Western Millennials and the emerging Asian markets is the desire for portability and for multifunctional products. He explains that multi-functional doesn’t mean just a versatile product formula; it also means having a package that can dispense or apply the same product in more than one way. “Consumers are more open to exploration of new gestures to applying product than ever before,” says Altmann. “The challenge for marketers and their packaging suppliers is to innovate these new multi-use and small packages in a way that creates newness while still being affordable and also not looking like just a premium travel size.”

Altmann says Yonwoo/PKG “continues to innovate and promote dual-use products in the color category.” One example is an airless package or airless pump tube for thick viscosity emulsions like foundation, combined with pressed or hot pour products for concealing and correction, all in one convenient, “pursable” package.

Sustainability has also entered the packaging equation more often and here, too, small sizes and innovative packages have taken hold.

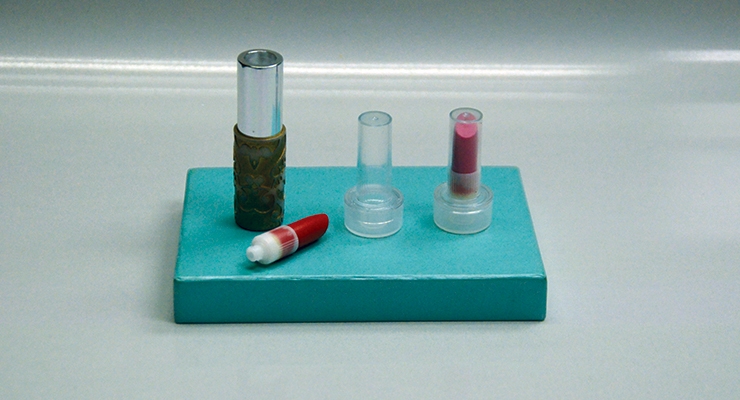

Brad-Pak has just released a globally patented lipstick container that not only allows a user to change color in seconds, but provides a green solution as well. The lipstick case houses multiple colors. When a color is used up, just remove a small cup made from recycled plastic and keep the custom case. Or keep your day color in your purse and when ready for an evening out, reach for your night shades.

Luis Alviar, who holds the patents on the lipstick container, tells Beauty Packaging: “We believe the strong awareness of global warming will influence all future packaging. Instead of just discussing the issue, most will want to provide a solution now.” Alviar adds: “Our product reduces the carbon footprint of the traditional disposable lipstick. The only part to dispose of is the cup which can be recycled and is made from recycled plastics.”

Product Level Indicators

While many white spaces have been addressed, many more remain. One area that is ripe for innovation is packaging that communicates when very little product is left in a container—or indicates that it’s past its prime.

Punchard says, “Not only could packaging play a greater role in encouraging quick repeat purchase (thus helping to preserve brand loyalty), but it could also be more active in alerting consumers to a product being past its best.” He says this would ensure that consumers only use a brand when the product is at peak efficacy (ensuring that the brand experience is not compromised by an out-of-date product).

Personal Care

A number of new ideas have emerged for Skin Care and Personal Care packaging, adding new vibrancy to the categories, especially as far as dispensing is concerned.

According to Punchard, packaging for skin care has now progressed beyond airless packaging. “We have seen the growth in airless packaging as a route to offering paraben free products; well now we’re seeing the emergence of ‘hermetically sealed’ packs that claim complete protection of the contents for the life of the product to enable very minimalist formulations. For example, La Roche Posay Toleriane Ultra Soin Réparateur Nuit retails in an “ultra-hermetic” pack with an anti-air re-entry system.

In personal care, Punchard says they’re noticing a growth in brands willing to use flexible packaging formats such as pouches.

There have been several advances in deodorant packages over the past few years, including condensed sizes. Now, there’s an airless deodorant produced in packaging from Yonwoo/PKG. Whish Deodorant Gel is an aluminum-free, all-organic ingredient, under-arm deodorant. Altmann says this airless package was made to pump-dispense with the same gesture as what consumers are used to with deodorant. It is a rotational dispensing airless pump with a turning collar.

Ultimately, a clever, innovative package can take an everyday experience and turn it into something delightful and unique. This is the case with a recently launched skin cleanser from Kao Corporation’s Kanebo brand.

Laura K. Price, senior package development engineer, R&D, Kao USA, tells Beauty Packaging that Kao USA and its parent company, Kao Corporation, “put considerable importance on developing innovative packaging daily and strive to be the creators of continuous innovation.”

“We strive to develop innovative products and brands to maximize consumer satisfaction by determining the needs of consumers and fusing them with the seeds of R&D,” explains Price, adding, “we always incorporate consumer research when we develop new packaging and work to find their known and unknown needs.” She says they pay attention to the unknown and create a new value that the consumer would never expect. Further, Price says, “Meeting consumer needs and bringing unexpected delight to daily beauty routines is where we strive to be for all packaging.”

Kao’s Evita Beauty Whip Soap, a Japanese market launch from Kanebo Cosmetics, illustrates the company’s goals. Providing a little background, Price says, “When you think of the beauty ritual, there are some elements that just feel more ‘routine.’” She says the opportunity is to improve this unknown need, and surprise and delight the consumer daily so she actually enjoys her beauty ritual instead of simply performing it.”

Price says the packaging for the Evita Beauty Whip Soap “delivers the need for rich, velvety facial cleansing foam and brings extra delight to the consumer through the aerosol packaging and unique dispensing head, creating a beautiful rose shape with one easy pump.” It’s more than your normal face wash or foam cleanser, it brings the element of “wow” through packaging innovation.

Skin Care: a Carton Shapes a Brand

When it comes to skin care, the dispenser can play a large role in attracting attention, but what often draws the customer’s eye to the shelf is the outer package. Advances in carton printing and decorating techniques can turn a head—and turn around a brand’s image almost instantaneously.

Walter Shiels, Arkay Packaging COO, tells Beauty Packaging: “We are seeing a significant trend toward developing new creative designs with a greater emphasis on unique base materials, specialty coatings, soft touch laminations, micro embossing, and exclusive processing techniques—all done to attract and delight consumers at point of purchase.”

Arkay works closely with its customers to provide special services that ensure stand-out packages. Shiels says, “Many innovative processing techniques and materials are developed and promoted through our unique ‘paint on press’ (POP) process. POP allows us to create art on actual production equipment, which gives our customers the opportunity to realize the artwork’s true potential before it is reproduced (as opposed to a screened proof that can’t be matched on lithographic equipment).”

How does the development process work at Arkay? Shiels explains: “For developing an innovative package, the process starts with 2D flat artwork, which is reviewed with the customer in order to clarify a specific vision for the brand.” He says they then convert the 2D artwork into finished 3D folding cartons. Arkay’s creative team reviews the artwork and develops a plan that includes a full color press proof utilizing various base boards, printing techniques, coatings, and laminations, etc. When completed, there can be 20-25 different iterations of the original 2D artwork, which is now in 3D carton form. Shiels says, “Our sales team then presents the final proofs to the customer, at which time the direction can be quickly determined.”

This was how Arkay Packaging worked with Olay, one of P&G’s hero brands, on their recently launched cartons. Olay Eyes cartons feature .014 APET, lithographic printing, and flexographic coatings with Rainbow cold foil on the inside of the plastic. The hologram is reversed. The Rainbow cold foil on the inside of the box has never been done before, according to Shiels.

The cartons contributed greatly to the line’s success. Ultimate Eye Cream won an Allure 2016 Best of Beauty Award.

Applicators

As discussed, consumers are becoming more aware of applicators, and innovations here range from ease of use to added benefits.

With droppers playing a major role in skin care packaging, Virospack has laid claim to “the first real autofill bulb dropper,” describing it as “a dispenser container with high precision and safety that allows a drop by drop dosage always keeping the formula intact until its application.”

Rosa Porras, marketing & communication manager for Virospack, explains that this is an innovative dispenser because it’s a push button dropper with a bulb inside that has an automatic autofill system that ensures an exact formula intake in every click. While there are other autofill packs, Porras says this is the only one with a rubber bulb dropper—and also, a hermetic closure.

Cosmetic brushes have seen a number of advances in fibers, but now HCT Group’s Magnetic Therapy Brushes for makeup and skin care application offer a benefit even beyond application proficiency.

The basic theory behind magnetic therapy, according to HCT Group, is that the force of the positively/negatively charged particles is able to influence the molecules in the body, without touching them, and is believed to possess both anti-inflammatory and detoxifying properties. Magnets have been used as medical therapeutic devices since the time of the ancient Greeks. There’s even a legend telling of Cleopatra wearing a magnet around her forehead at night to prevent wrinkles from forming.

HCT has captured the beauty benefits of magnetic therapy by producing a filament that harnesses the powers of magnetic fields, attracting iron and drawing it to the skin, which results in increased blood flow and decreased inflammation. Ultimately, the magnetic therapy can reduce the appearance of fine lines and wrinkles and enhance natural beauty from within, resulting in a renewed glow.

Opportunities with ‘The Messenger’

Online shopping also offers a number of opportunities to fill white spaces.

Mintel’s Punchard tells Beauty Packaging that he thinks it is important to consider the rapid growth in online shopping for beauty and personal care (BPC) products. “One area that we know is of concern for consumers is the ‘postage’ packaging that the retail packaging is mailed in,” says Punchard. He explains that, typically, little thought is put into this aspect of the consumer experience leading to packaging that is difficult to get into, often feels over-packaged, and importantly misses an important opportunity to build on the brand experience.

“Given that for many who shop online the first experience of the brand may be when the package arrives, giving the consumer an unbranded, difficult to get into brown box is a massive fail,” says Punchard.

He adds: “Also the growth in online shopping, particularly for prestige beauty, is increasing consumer concern over counterfeit products. While the category has not previously adopted much in the way of overt anti-counterfeit packaging, it might be that to continue the growth in online sales, packaging that can address consumers’ concerns that they might have bought a fake should be investigated.”

While prestige sales are topping the charts, innovative concepts await in both Mass and Prestige sectors.

Coty’s Tarant says he doesn’t really see a split between the amount of innovation in Mass and Prestige.

Punchard notes that Mintel’s GNPD (Global New Products Database) shows that Luxe and Super Luxe have become the most important sectors in terms of number of new launches in the U.S. over the past 12 months. Here, he says, “Prestige leads the way particularly on those innovations that have a bigger cost barrier.” According to Punchard, prestige areas such as hermetic sealing technologies and other functional innovation is being seen in skin care, while fragrances still focus heavily on aesthetics.

But that isn’t to say that the mass market isn’t innovative.

“Perhaps what we are seeing is brands becoming more cautious and focused in their budget/mass innovation,” says Punchard. “With consumers becoming more discerning in their BPC purchases and with high brand competition, pack function and design innovation is becoming an increasingly important part of brand strategy even at the budget level.”

An innovative package offers a new way to apply and blend in liquid foundation using simple gestures.

Written by Tim Tobin, Director, Global Package Development for Face category at Estée Lauder

The Estée Lauder Double Wear Nude Cushion Stick Radiant Makeup is a makeup + pro tool in one innovative package. This innovation capitalizes on the growing cushion trend that started in Korea. The cushion stick package is designed to both apply and blend in liquid foundation in simple gestures whether at home or on the go; consumers can easily “Touch On, Buff and Blend” for a flawless finish. Due to the unique design, the package allows consumers to apply a full face of makeup or to use on skin where needed. The turning mechanism allows consumers to have better control over the amount of product and coverage as they can propel and repel the stick. To overcome hygiene concerns that many traditional cushion compacts have, this product has a removable sponge head that allows the consumer to wash the applicator as needed. The package was designed and developed with HCT Group.

One of the initial challenges was developing a system that combines two unique forms—a foundation package and a sponge applicator—into one affordable package. Another challenge was to provide an acceptable label claim while maintaining an ergonomic shape for consumers to apply foundation to the face with only one hand. The design required a streamlined turning mechanism to allow consumers to hold it with one hand but also provide a large enough opening to fill the product on its high-speed production line. Both of these challenges were answered by the final design.

Another thing to consider was how to show the product shade as this is a key element in foundation packaging. We designed the body to be molded clear in order to present the true foundation shade.

Consumers also want to know how much of their foundation they have used and how much is left. Thus, we developed a very unique attribute of this package: The body gets smaller as product is used. The turning mechanism is captured within the base, exposing only the gold metal base. As the product’s height is lowered during usage, it becomes more compact and even more convenient for on-the-go touch-ups. And as the base is turned during usage, it continues to show its shade. Another benefit of the design is that by turning the body of the package into the base, it achieves nearly full evacuation of the product. There is no need to cut open the package or use a cotton swab to get contents out of the bottom.