Marie Redding, Associate Editor05.01.17

Makeup is glistening for Spring/Summer 2017, with a slew of shiny, glittery and metallic formulations to illuminate the eyes, lips and skin. The packaging designed for these products shines just as bright.

Metal and metallized plastic are being used to create statement-making packages. Beauty brands are working with suppliers to create caps, palettes, compacts and lipstick cases with high-shine finishes. Specialty coatings make glass shine, and metallic foils make paperboard cartons pop.

Ciate London’s new Dewy Stix Luminous Highlighting Balm promises a “lit-from-within” glow. Its rose gold metallic stick package looks as shiny as the wet-look sheen the product leaves on the skin. Urban Decay’s new Vice Special Effects Water-Resistant Lip Topcoat includes 12 shades with a glitter finish. The line includes Ritual, a smoky blue-gray lip color with iridescent 3-D sparkle. The clear lipgloss tube has a super-shiny platinum silver cap, with a metallic gold band.

Smashbox’s Be Legendary Liquid Lip collection includes nine “Liquid Metal” colors, in metallic finishes. Although the lipgloss tube is clear to show off the sparkly, highly pigmented hues, the carton is decorated with an image of “dripping color” in a glossy sheen. (See these and more at BeautyPackaging.com)

“Metallic effects are the ‘bling’ that attracts the customer’s eye for a few seconds, allowing a brand to stand apart from competitors,” says Jeff Truan, global business development, Nobelus.

Too Faced Cosmetics’ new Love Light Prismatic Highlighter looks decked out in “bling.” The liquid-to-powder face highlighter contains a “luminosity boosting agent to deliver a pearl radiance to the skin,” the brand says. The heart-shaped compact “glows” as well, with a mirror-like sheen. The compacts match each of the three makeup shades, perfectly. Ray of Light is rose gold; You Light Up My Life is gold (shown); and Blinded By The Light is silver.

Dior Addict’s new high-pigment lip color, Dior Addict Lacquer Stick, delivers high-shine and one-coat coverage. Its packaging is the brand’s signature design, which uses a combination of metal and plastic. The product’s silver tube and iconic cap feature a super-shiny finish that mimics the lip color’s shine.

Peter Philips, creative and image director for Dior Makeup, says, “For this new generation of lacquers, I wanted the comfort of a hydrating balm without compromising on color intensity and shine.” The square cap features the Dior logo and has shiny silver accents.

“Packaging needs to resonate with the customer, especially in the makeup category,” says Scott Rusch, president/CEO, Anomatic. “Brands are always looking for ways to enhance a package for a more luxe look—and both anodizing and metallization can achieve this,” he says.

Brands often choose to metallize plastic instead of using metal, due to design constraints. Now, Anomatic offers metallization for plastic, beginning this year. “Injection-molded components offer more options and flexibility, and look completely different after metallizing,” says Rusch. “The project dictates the chosen material. An upgraded look is what our business is all about, and whether it’s a metal part or metallized plastic, it will achieve the same goal of luxury,” he says.

Anomatic already has several brand partners in line for future projects that involve metallizing plastic. “We see lots of interest, so we’ve put together a plan for additional capacity. We will have our third machine delivered by the end of this year, and over the next two years, we will exceed a capacity of over 100 million units per year,” says Rusch.

Suppliers expect the demand for metals and metallic looks to remain constant. “Metallization of cosmetics and perfumes went from a fad to a look that is always requested. The demand in North America is high. We have been in continuous metallization production since the beginning of the year,” says Richard Engel, president/COO, Decotech.

April Lytle, marketing coordinator, Kurz Transfer Products, agrees, saying, “Metallized decorations are always in demand, and show little signs of slowing. Hot-stamping foil and vacuum metallization techniques are being used on palettes, closures and tubes, while foils are primarily used on folding cartons.”

Kurz Transfer Products provides a full range of plastic and formulation foils, including foils for pigment, metallization and in-mold decorating. “We have also expanded our portfolio to offer direct-to-glass decoration foils,” says Lytle.

Luminous Packaging for High-Shine Formulas

As more beauty brands pair shiny products with shiny packaging, suppliers are helping to skillfully deliver luxe metal packages and metallic finishes. Charlie Eitel, CEO, WS Packaging Group says metallic effects are a sure way for a brand to literally “outshine” the competitors. “Special effects, including metallic inks, foils and prismatic materials, will all help a brand create emotions that will draw a shopper in, and encourage them to reach for that product on a shelf,” he says.

Lytle says that Kurtz Transfer Products’ rose gold foil is popular, for cartons, bottles, caps and tubes. “Our rose gold foils are highly sought after by cosmetic brands since the color was trending in both fashion and accessories,” she says. “Trends are also shifting toward other metallic colors. We are currently working with several makeup brands to create custom-branded colors for metallic foils,” she adds.

Toby Cattermole, CEO, TNT Global Manufacturing, says gold metallics are requested most. “We produce metal and metallized packaging for several cosmetic and fragrance brands. One of our new decorations is our Ecoating technique. It is a metallic coating available in a wide range of finishing options,” he says.

Stila Cosmetics recently redesigned its entire line, using mostly gold packaging with contrasting shiny and matte finishes on various parts. Stila’s Magnificent Metals Glitter & Glow Liquid Eye Shadow comes in a clear square bottle that showcases the glittery eye shadow colors. Square caps in matte gold give the product a luxe look. Stila’s logo, hot-stamped on the bottle in shiny foil, glistens.

Metals & Metallics to Elevate a Brand’s Image

Metal and metallic finishes will elevate any product or accessory, including brush sets. Sonia Kashuk’s Simply Complete Face Brush Set, sold at Target, combines wood handles with lavender aluminum ferrules that shine.

Cargo Cosmetics’ Swimmables Longwear Eye Shadow Stick is a twist-up pen, decorated to entice consumers to take a second look. The plastic pen features a shiny silver finish, which matches the brand’s single eye shadows housed in round silver aluminum tins.

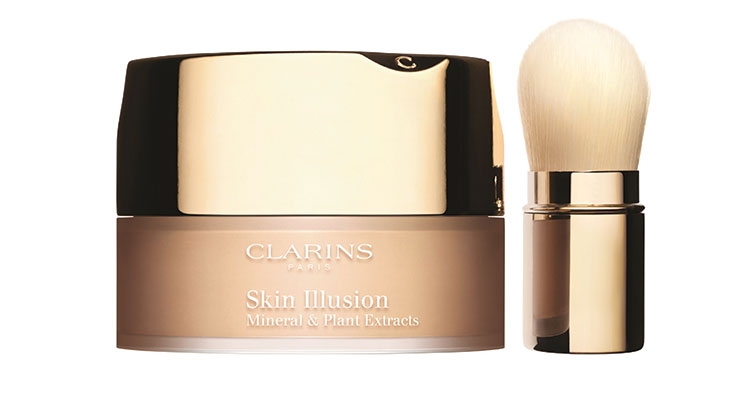

Clarins partnered with Cosmogen to give its loose powder foundation, Skin Illusion, an upscale look. The jar’s cap is metallized in shiny gold, while the brush handle is anodized aluminum, with a matching shiny gold finish. The package is Cosmogen’s exclusive airtight Shake’n Powder jar, which dispenses a controlled amount of product. “Our challenge was to insert two stainless steel pads and magnets into the cap, to hold the brush in place,” says Maud Lelièvre, marketing manager, Cosmogen.

When metal is chosen for a cap, it has certain advantages. “Metal brings a weight and solidity— a symbol of quality,” says TNT Global’s Cattermole. “It has a cold touch that adds to the luxury sensation,” he says.

Gilda Cutri, VP of operations & business development, Coverpla, says that metal components have certain features that can’t be replicated in plastic, which is why the material is requested often.

“Metal allows a designer to develop components with thinner walls than plastic, which is appealing for brands that want a slimmer, streamlined look,” she says. “Metal’s weight, cold feel, surface quality and durability are also very enticing,” she adds.

Coverpla recently launched a collection of new stock caps. “We offer many different metal caps in various shapes and colors. Our customers appreciate our large stock selection to avoid having to produce a custom component,” says Cutri.

Coverpla has partnered with Reboul, and utilizes the supplier’s tooling expertise. “We guarantee an exceptional level of quality in the appearance of complex metal parts, such as caps in unusual shapes,” says Cutri. “Through this partnership, we have the ability to achieve the most technically challenging designs, including square shapes with curves, caps that have a very low radii, deep parts and complex cuts,” she explains.

TNT Global Manufacturing recently worked with Penhaligon’s on its Portraits fragrance collection, which features zamac caps in unusual shapes. The fragrance, “The Tragedy of Lord George” (shown), features a striking gold cap in the shape of a deer head. The bottle’s collar is aluminum and brass.

The cap’s extreme shine comes from manual polishing followed by a gold galvanization process, which are the same techniques a goldsmith uses, says Cattermole. “The complex production process includes injection, demolding, and assembly. It requires an exceptional level of detailed accuracy,” he explains.

Die-casting skills are also required to produce a cap in a metal shape, Cattermole says. “How well it is cast will affect how the surface of the metal looks. A poor die-casting will create many pittings after polishing,” Cattermole warns. “The quality of the electroplating is also essential to avoid the appearance of oxidation after a few weeks,” he adds.

HCT Packaging has a dedicated Metals division to keep up with its customers’ demands for metal palettes, compacts, lipstick cases and more. Some of its metal palettes are magnetic and refillable or designed to be keepsakes.

Adrian Apodaca, global director of engineering, HCT Packaging, says, “Metal conveys ‘value’ to the consumer, and has more longevity than plastic. Consumers can collect metal packages and reuse them,” he says. “Our Metals team continually comes up with innovative ways to integrate metal into different types of packaging,” he adds.

Apodaca suggests choosing zamac for a “green story” that a brand’s marketing team can share with consumers. “Zamac utilizes better coating options that have a lower waste percentage than injection molded plastic,” he says. “Zamac can also be completely melted down and re-used in other pieces. There is an environmentally friendly aspect to metal manufacturing that some brands, and most consumers, aren’t aware of,” he explains.

Anodizing Aluminum, Metallizing Glass

Specialty decorating processes are used to achieve a metallized look on different types of materials, such as aluminum and glass. Anomatic specializes in color anodizing aluminum components, including caps, and offers a wide range of colors and finishes. “Anodization is our core expertise,” says Anomatic’s Rusch. “Over the past few years, we’ve introduced additional finishing processes as pre-treatments to achieve different looks,” he says. “Our customers are often interested in antique looks,” he adds.

Anomatic designs and executes the entire production process, from fabricating the tooling to custom assembly machines. “This gives us total control, end-to-end, which is important from a speed-to-market standpoint, as well as cost-control,” says Rusch.

Metallized finishes are an eye-catching and unexpected decorative effect for glass packaging, especially fragrance bottles. A few suppliers have the ability to create shiny, vibrant patterns in bold metallic hues, which can look stunning on glass.

Decotech offers a full range of metallization processes for glass. “Full opaque metallization is pretty standard. It’s a look that has always been done using a typical vacuum metallization or sputtering process. These are techniques that haven’t changed in 60 years. Many of our customers often challenge us to create more innovative designs,” says Decotech’s Engel.

Decorating glass with any type of metallization process has its challenges. “Metallization is tricky, because it will magnify any type of surface defect. Glass usually requires fire polishing at the glass maker to smooth any surface defects,” Engel explains. “We can achieve a true metallized gradient, and also have the ability to create translucent metallized finishes. Our customers have been requesting these types of looks,” he adds.

Decorating Machinery

Decorating packaging components requires specialized machinery. Tapematic is known for its innovative PST Line. The fully automated system applies metal coatings to different types of packaging components, such as caps, to create a high-end, luxe metallic surface.

“Our PST Line is capable of achieving innovative types of decorations, at a cost-savings. We can combine digital printing before coating and metallization, for example, for an interesting effect,” says Tony Denning, president, Tapematic. “The PST Line applies a UV lacquer base coat, a thin metallic decorative sputtered film, and a protective UV lacquer top coat,” he adds.

Tapematic also offers in-line decorations, as a pre- or post-metallization process, and each produces a different effect. “In pre-metallization, the decoration is processed after the base coat is applied, so the decoration slightly ‘raises’ the base coat and underlying material for a very subtle effect,” Denning explains. “Post-metallization is a process that will remove the metallization down to the base coat. This allows the base color of the material to show through. It is the most cost-effective decorating process, since no materials are required,” he says.

Foils & Finishes to Entice & Elevate

Foils are a key material in achieving metallized looks and are used in multiple ways on various substrates. Kurz Transfer Products’ Lytle says, “Foil effects deliver benefits that laminates and metallic inks can’t,” she says, adding: “A foiled or embossed image on a package, or carton, instantly elevates a product’s perceived worth.”

Todd Waxgiser, director of sales, Americas, Peyer-America, agrees, saying, “Foil decorations are one of the quickest ways to create a metallic look, for ‘instant’ shelf impact.”

Kurz Transfer Products has several new types of foils that are ideal for paperboard cartons, including Spatial FX, which looks three-dimensional. “Spatial FX is based on a specially developed, diffractive structure where objects appear to rise off the page. It is similar to a three-dimensional embossing, although the design actually remains flat on the surface,” Lytle explains. “It will entice shoppers to pick up the carton,” she adds.

Spatial FX creates an innovative, customizable finish. “This type of decorating technique is new to the market. It offers the answer to ‘interactive packaging’ that most brands are beginning to dive into,” Lytle says.

Nobelus’ Truan also says that texture is important—and enticing to consumers. “Metallized looks are classic, but certain variations come and go, in line with trends. Brushed looks were once often requested, but not lately. Next, it was holographs—until the toothpaste brands claimed this look. Now, everyone wants textured metallics,” he says.

Truan says he’s seeing requests for a combination of gold with its Karess Softouch finish on top, to create a texturized metallic look. “All types of luxury gold finishes are very popular for folding cartons, including our Gilt Metallized look,” he says. “Brands are using these finishes with special effects on top, which are key for a high-end product,” he adds.

Truan mentions a few key colors that are being requested most often. “We see more requests for special whites, including our Pearlescent Cavitated product that adds a sheen and glitter. Our micro sparkle clear laminate is ideal for any type of printed substrate, and will take a design to the next level,” he says.

Nobelus has a new Matte Chrome foil, which is ideal for folding cartons and labels. “It can be spot-treated on the surface to create a stunning combination of gloss and matte effects. It will also resist all types of fingerprints,” says Truan. Nobelus also offers “Streams of Light,” a clear holographic material that can be applied to any surface, including metallized finishes. “It adds a layer of gloss, and has built-in lines of rainbow holography that add dimension,” Truan says.

WS Packaging’s Eitel says he still sees a high demand for holographic foils. “A holographic foil catches the consumer’s eye from all angles, since it reflects different colors depending on the viewing angle. It has this advantage over traditional silver or gold foil,” he says.

WS Packaging Group recently worked with Keratin to give the hair care brand’s cartons a metallic look using holographic foil board. The cartons are decorated with images of molecules, meant to represent how the product is formulated to work with the chemistry of the hair.

WS Packaging Group’s Eitel says, “We used an opaque white to block out all the holographic shine except for certain areas on the molecules, as well as some of the type. We created a gradient of opacity to give the molecules a round shape. The center of each molecule is the most reflective part, which gives the design dimension, rather than have a flat circle of holographic foil.”

WS Packaging Group offers a full spectrum of special effects, including foils, embossing, debossing, metallic inks, varnishes and prismatic materials. The company has also developed its own patented label stock called PromoPrism, which provides a holographic rainbow effect.

Tricks & Tips for Stand-Out Designs

Suppliers suggest several ways to use metallic elements to achieve different types of looks, while preventing issues, meeting budget constraints and making production deadlines.

Anomatic offers a decorating technique for aluminum that Rusch describes as selective texturizing, and it offers several advantages. Different textures can be used on the same fully anodized part, to create a unique look. “It is done during the fabrication stage,” says Rusch. “We can complete the texturizing process right in the same tooling, which makes it cost-effective,” he explains.

The texturizing process is done first, before anodizing. “Since this type of decorating process doesn’t require a secondary operation, it eliminates any potential compatibility issues with the product—the complete part is anodized,” says Rusch. This makes the process ideal for a fragrance bottle or skin care jar, for example, since the decoration won’t cause any issues when in contact with a product.

Peyer-America offers a Full Surface Hot Stamping process, which can be done instead of a metallizing process for plastic. “Full Surface Hot Stamping creates a metal look, and provides many benefits,” says Waxgiser. “Various colors can be used on one closure, for example. The process is low cost, with fast turnaround times. Small lot sizes are also possible, including a sample of just one,” he says.

When working with metallized foil decorations, challenges often arise when a specific color is replicated on different types of packages. “A brand might request a foil accent in red, for example, but it has to look the same across different substrates. We are able to supply consistent color matches, so that a foil accent on glass over a UV varnish will look the same as the color of the foil on an extruded tube, as well as on a plastic cap,” explains Waxgiser. “This can get complicated,” he says, “but we are able to meet these demands and color-match with consistency, every time.”

WS Packaging’s Eitel offers a few ways to eliminate some common design concerns relating to metallic looks. “If a holographic foil board seems too ‘busy,’ one solution is to print inks in different opacities on top of the foil,” Eitel says. “This allows only a controlled amount of foil to shine through, and is a technique that can be used to ensure a design remains consistent with a brand’s image,” he explains.

Nobelus’ Truan suggests brand marketers always consider combining metallic effects with other types of decorations, especially for upscale cosmetic products. “A metallic package on its own isn’t enough anymore. Many lower priced personal care products use metallized films and holography on cartons, so beauty brands have to do more. Multiple layers, added textures, and spot treatments will all take a package to another level when combined—and we’re seeing the demand skyrocket for these processes,” he explains.

Truan gives an example of how to create a multi-textured surface, which also offers the practical benefit of being smudge-resistant. “Aqueous and UV coatings, in both matte and gloss finishes, will show fingerprints and blemishes quite badly unless they’re protected. With our ScuffProof, FineLinen, and FineLeather laminates, the decorator can go back over the inks to add a protective coating. They can matte the surface, which will allow for the application of spot treatments on top,” he explains.

This combination of coatings gives a carton a textured feel, according to Truan. “It will look like it has a multi-faceted depth,” says Truan. “Plus, the carton won’t need any further protection from fingerprints or smudges. It can be shipped to retailers without the risk of burnishing or blemishing, greatly reducing rejects during inspection,” he adds.

A Coordinated Effort

Although producing a package that includes metal or metallic components will often pose a unique set of challenges that suppliers point out, anticipating any possible issues early on will help ensure production runs smoothly.

These projects often require a well-coordinated effort, up until parts are shipping from a decorator to a brand’s assembly line. “Shipping metallized parts requires planning ahead,” says Decotech’s Engel. “We don’t use shipping boxes with the partitions that are typically used for decorated components. Some of our customers ask us to poly-bag the parts individually. Others provide special packaging, like vac-formed trays, that will keep each part locked in position during transit,” he explains.

In the end, coordinating the production of metal components or metallic packaging will prove worth the extra effort, especially when you can spot your product glistening from across the room.

Metal and metallized plastic are being used to create statement-making packages. Beauty brands are working with suppliers to create caps, palettes, compacts and lipstick cases with high-shine finishes. Specialty coatings make glass shine, and metallic foils make paperboard cartons pop.

Ciate London’s new Dewy Stix Luminous Highlighting Balm promises a “lit-from-within” glow. Its rose gold metallic stick package looks as shiny as the wet-look sheen the product leaves on the skin. Urban Decay’s new Vice Special Effects Water-Resistant Lip Topcoat includes 12 shades with a glitter finish. The line includes Ritual, a smoky blue-gray lip color with iridescent 3-D sparkle. The clear lipgloss tube has a super-shiny platinum silver cap, with a metallic gold band.

Smashbox’s Be Legendary Liquid Lip collection includes nine “Liquid Metal” colors, in metallic finishes. Although the lipgloss tube is clear to show off the sparkly, highly pigmented hues, the carton is decorated with an image of “dripping color” in a glossy sheen. (See these and more at BeautyPackaging.com)

“Metallic effects are the ‘bling’ that attracts the customer’s eye for a few seconds, allowing a brand to stand apart from competitors,” says Jeff Truan, global business development, Nobelus.

Too Faced Cosmetics’ new Love Light Prismatic Highlighter looks decked out in “bling.” The liquid-to-powder face highlighter contains a “luminosity boosting agent to deliver a pearl radiance to the skin,” the brand says. The heart-shaped compact “glows” as well, with a mirror-like sheen. The compacts match each of the three makeup shades, perfectly. Ray of Light is rose gold; You Light Up My Life is gold (shown); and Blinded By The Light is silver.

Dior Addict’s new high-pigment lip color, Dior Addict Lacquer Stick, delivers high-shine and one-coat coverage. Its packaging is the brand’s signature design, which uses a combination of metal and plastic. The product’s silver tube and iconic cap feature a super-shiny finish that mimics the lip color’s shine.

Peter Philips, creative and image director for Dior Makeup, says, “For this new generation of lacquers, I wanted the comfort of a hydrating balm without compromising on color intensity and shine.” The square cap features the Dior logo and has shiny silver accents.

“Packaging needs to resonate with the customer, especially in the makeup category,” says Scott Rusch, president/CEO, Anomatic. “Brands are always looking for ways to enhance a package for a more luxe look—and both anodizing and metallization can achieve this,” he says.

Brands often choose to metallize plastic instead of using metal, due to design constraints. Now, Anomatic offers metallization for plastic, beginning this year. “Injection-molded components offer more options and flexibility, and look completely different after metallizing,” says Rusch. “The project dictates the chosen material. An upgraded look is what our business is all about, and whether it’s a metal part or metallized plastic, it will achieve the same goal of luxury,” he says.

Anomatic already has several brand partners in line for future projects that involve metallizing plastic. “We see lots of interest, so we’ve put together a plan for additional capacity. We will have our third machine delivered by the end of this year, and over the next two years, we will exceed a capacity of over 100 million units per year,” says Rusch.

Suppliers expect the demand for metals and metallic looks to remain constant. “Metallization of cosmetics and perfumes went from a fad to a look that is always requested. The demand in North America is high. We have been in continuous metallization production since the beginning of the year,” says Richard Engel, president/COO, Decotech.

April Lytle, marketing coordinator, Kurz Transfer Products, agrees, saying, “Metallized decorations are always in demand, and show little signs of slowing. Hot-stamping foil and vacuum metallization techniques are being used on palettes, closures and tubes, while foils are primarily used on folding cartons.”

Kurz Transfer Products provides a full range of plastic and formulation foils, including foils for pigment, metallization and in-mold decorating. “We have also expanded our portfolio to offer direct-to-glass decoration foils,” says Lytle.

Luminous Packaging for High-Shine Formulas

As more beauty brands pair shiny products with shiny packaging, suppliers are helping to skillfully deliver luxe metal packages and metallic finishes. Charlie Eitel, CEO, WS Packaging Group says metallic effects are a sure way for a brand to literally “outshine” the competitors. “Special effects, including metallic inks, foils and prismatic materials, will all help a brand create emotions that will draw a shopper in, and encourage them to reach for that product on a shelf,” he says.

Lytle says that Kurtz Transfer Products’ rose gold foil is popular, for cartons, bottles, caps and tubes. “Our rose gold foils are highly sought after by cosmetic brands since the color was trending in both fashion and accessories,” she says. “Trends are also shifting toward other metallic colors. We are currently working with several makeup brands to create custom-branded colors for metallic foils,” she adds.

Toby Cattermole, CEO, TNT Global Manufacturing, says gold metallics are requested most. “We produce metal and metallized packaging for several cosmetic and fragrance brands. One of our new decorations is our Ecoating technique. It is a metallic coating available in a wide range of finishing options,” he says.

Stila Cosmetics recently redesigned its entire line, using mostly gold packaging with contrasting shiny and matte finishes on various parts. Stila’s Magnificent Metals Glitter & Glow Liquid Eye Shadow comes in a clear square bottle that showcases the glittery eye shadow colors. Square caps in matte gold give the product a luxe look. Stila’s logo, hot-stamped on the bottle in shiny foil, glistens.

Metals & Metallics to Elevate a Brand’s Image

Metal and metallic finishes will elevate any product or accessory, including brush sets. Sonia Kashuk’s Simply Complete Face Brush Set, sold at Target, combines wood handles with lavender aluminum ferrules that shine.

Cargo Cosmetics’ Swimmables Longwear Eye Shadow Stick is a twist-up pen, decorated to entice consumers to take a second look. The plastic pen features a shiny silver finish, which matches the brand’s single eye shadows housed in round silver aluminum tins.

Clarins partnered with Cosmogen to give its loose powder foundation, Skin Illusion, an upscale look. The jar’s cap is metallized in shiny gold, while the brush handle is anodized aluminum, with a matching shiny gold finish. The package is Cosmogen’s exclusive airtight Shake’n Powder jar, which dispenses a controlled amount of product. “Our challenge was to insert two stainless steel pads and magnets into the cap, to hold the brush in place,” says Maud Lelièvre, marketing manager, Cosmogen.

When metal is chosen for a cap, it has certain advantages. “Metal brings a weight and solidity— a symbol of quality,” says TNT Global’s Cattermole. “It has a cold touch that adds to the luxury sensation,” he says.

Gilda Cutri, VP of operations & business development, Coverpla, says that metal components have certain features that can’t be replicated in plastic, which is why the material is requested often.

“Metal allows a designer to develop components with thinner walls than plastic, which is appealing for brands that want a slimmer, streamlined look,” she says. “Metal’s weight, cold feel, surface quality and durability are also very enticing,” she adds.

Coverpla recently launched a collection of new stock caps. “We offer many different metal caps in various shapes and colors. Our customers appreciate our large stock selection to avoid having to produce a custom component,” says Cutri.

Coverpla has partnered with Reboul, and utilizes the supplier’s tooling expertise. “We guarantee an exceptional level of quality in the appearance of complex metal parts, such as caps in unusual shapes,” says Cutri. “Through this partnership, we have the ability to achieve the most technically challenging designs, including square shapes with curves, caps that have a very low radii, deep parts and complex cuts,” she explains.

TNT Global Manufacturing recently worked with Penhaligon’s on its Portraits fragrance collection, which features zamac caps in unusual shapes. The fragrance, “The Tragedy of Lord George” (shown), features a striking gold cap in the shape of a deer head. The bottle’s collar is aluminum and brass.

The cap’s extreme shine comes from manual polishing followed by a gold galvanization process, which are the same techniques a goldsmith uses, says Cattermole. “The complex production process includes injection, demolding, and assembly. It requires an exceptional level of detailed accuracy,” he explains.

Die-casting skills are also required to produce a cap in a metal shape, Cattermole says. “How well it is cast will affect how the surface of the metal looks. A poor die-casting will create many pittings after polishing,” Cattermole warns. “The quality of the electroplating is also essential to avoid the appearance of oxidation after a few weeks,” he adds.

HCT Packaging has a dedicated Metals division to keep up with its customers’ demands for metal palettes, compacts, lipstick cases and more. Some of its metal palettes are magnetic and refillable or designed to be keepsakes.

Adrian Apodaca, global director of engineering, HCT Packaging, says, “Metal conveys ‘value’ to the consumer, and has more longevity than plastic. Consumers can collect metal packages and reuse them,” he says. “Our Metals team continually comes up with innovative ways to integrate metal into different types of packaging,” he adds.

Apodaca suggests choosing zamac for a “green story” that a brand’s marketing team can share with consumers. “Zamac utilizes better coating options that have a lower waste percentage than injection molded plastic,” he says. “Zamac can also be completely melted down and re-used in other pieces. There is an environmentally friendly aspect to metal manufacturing that some brands, and most consumers, aren’t aware of,” he explains.

Anodizing Aluminum, Metallizing Glass

Specialty decorating processes are used to achieve a metallized look on different types of materials, such as aluminum and glass. Anomatic specializes in color anodizing aluminum components, including caps, and offers a wide range of colors and finishes. “Anodization is our core expertise,” says Anomatic’s Rusch. “Over the past few years, we’ve introduced additional finishing processes as pre-treatments to achieve different looks,” he says. “Our customers are often interested in antique looks,” he adds.

Anomatic designs and executes the entire production process, from fabricating the tooling to custom assembly machines. “This gives us total control, end-to-end, which is important from a speed-to-market standpoint, as well as cost-control,” says Rusch.

Metallized finishes are an eye-catching and unexpected decorative effect for glass packaging, especially fragrance bottles. A few suppliers have the ability to create shiny, vibrant patterns in bold metallic hues, which can look stunning on glass.

Decotech offers a full range of metallization processes for glass. “Full opaque metallization is pretty standard. It’s a look that has always been done using a typical vacuum metallization or sputtering process. These are techniques that haven’t changed in 60 years. Many of our customers often challenge us to create more innovative designs,” says Decotech’s Engel.

Decorating glass with any type of metallization process has its challenges. “Metallization is tricky, because it will magnify any type of surface defect. Glass usually requires fire polishing at the glass maker to smooth any surface defects,” Engel explains. “We can achieve a true metallized gradient, and also have the ability to create translucent metallized finishes. Our customers have been requesting these types of looks,” he adds.

Decorating Machinery

Decorating packaging components requires specialized machinery. Tapematic is known for its innovative PST Line. The fully automated system applies metal coatings to different types of packaging components, such as caps, to create a high-end, luxe metallic surface.

“Our PST Line is capable of achieving innovative types of decorations, at a cost-savings. We can combine digital printing before coating and metallization, for example, for an interesting effect,” says Tony Denning, president, Tapematic. “The PST Line applies a UV lacquer base coat, a thin metallic decorative sputtered film, and a protective UV lacquer top coat,” he adds.

Tapematic also offers in-line decorations, as a pre- or post-metallization process, and each produces a different effect. “In pre-metallization, the decoration is processed after the base coat is applied, so the decoration slightly ‘raises’ the base coat and underlying material for a very subtle effect,” Denning explains. “Post-metallization is a process that will remove the metallization down to the base coat. This allows the base color of the material to show through. It is the most cost-effective decorating process, since no materials are required,” he says.

Foils & Finishes to Entice & Elevate

Foils are a key material in achieving metallized looks and are used in multiple ways on various substrates. Kurz Transfer Products’ Lytle says, “Foil effects deliver benefits that laminates and metallic inks can’t,” she says, adding: “A foiled or embossed image on a package, or carton, instantly elevates a product’s perceived worth.”

Todd Waxgiser, director of sales, Americas, Peyer-America, agrees, saying, “Foil decorations are one of the quickest ways to create a metallic look, for ‘instant’ shelf impact.”

Kurz Transfer Products has several new types of foils that are ideal for paperboard cartons, including Spatial FX, which looks three-dimensional. “Spatial FX is based on a specially developed, diffractive structure where objects appear to rise off the page. It is similar to a three-dimensional embossing, although the design actually remains flat on the surface,” Lytle explains. “It will entice shoppers to pick up the carton,” she adds.

Spatial FX creates an innovative, customizable finish. “This type of decorating technique is new to the market. It offers the answer to ‘interactive packaging’ that most brands are beginning to dive into,” Lytle says.

Nobelus’ Truan also says that texture is important—and enticing to consumers. “Metallized looks are classic, but certain variations come and go, in line with trends. Brushed looks were once often requested, but not lately. Next, it was holographs—until the toothpaste brands claimed this look. Now, everyone wants textured metallics,” he says.

Truan says he’s seeing requests for a combination of gold with its Karess Softouch finish on top, to create a texturized metallic look. “All types of luxury gold finishes are very popular for folding cartons, including our Gilt Metallized look,” he says. “Brands are using these finishes with special effects on top, which are key for a high-end product,” he adds.

Truan mentions a few key colors that are being requested most often. “We see more requests for special whites, including our Pearlescent Cavitated product that adds a sheen and glitter. Our micro sparkle clear laminate is ideal for any type of printed substrate, and will take a design to the next level,” he says.

Nobelus has a new Matte Chrome foil, which is ideal for folding cartons and labels. “It can be spot-treated on the surface to create a stunning combination of gloss and matte effects. It will also resist all types of fingerprints,” says Truan. Nobelus also offers “Streams of Light,” a clear holographic material that can be applied to any surface, including metallized finishes. “It adds a layer of gloss, and has built-in lines of rainbow holography that add dimension,” Truan says.

WS Packaging’s Eitel says he still sees a high demand for holographic foils. “A holographic foil catches the consumer’s eye from all angles, since it reflects different colors depending on the viewing angle. It has this advantage over traditional silver or gold foil,” he says.

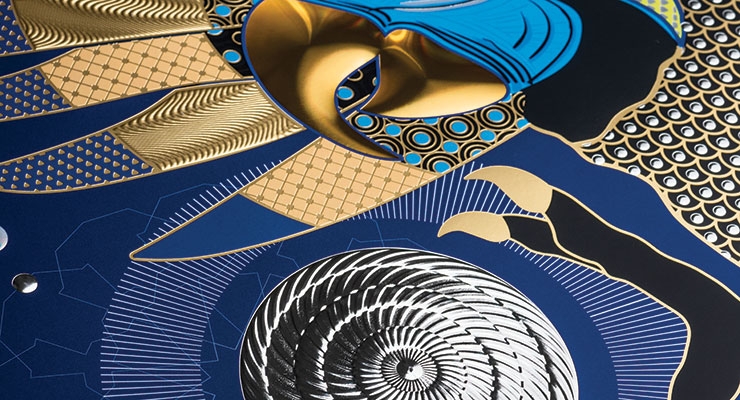

WS Packaging Group recently worked with Keratin to give the hair care brand’s cartons a metallic look using holographic foil board. The cartons are decorated with images of molecules, meant to represent how the product is formulated to work with the chemistry of the hair.

WS Packaging Group’s Eitel says, “We used an opaque white to block out all the holographic shine except for certain areas on the molecules, as well as some of the type. We created a gradient of opacity to give the molecules a round shape. The center of each molecule is the most reflective part, which gives the design dimension, rather than have a flat circle of holographic foil.”

WS Packaging Group offers a full spectrum of special effects, including foils, embossing, debossing, metallic inks, varnishes and prismatic materials. The company has also developed its own patented label stock called PromoPrism, which provides a holographic rainbow effect.

Tricks & Tips for Stand-Out Designs

Suppliers suggest several ways to use metallic elements to achieve different types of looks, while preventing issues, meeting budget constraints and making production deadlines.

Anomatic offers a decorating technique for aluminum that Rusch describes as selective texturizing, and it offers several advantages. Different textures can be used on the same fully anodized part, to create a unique look. “It is done during the fabrication stage,” says Rusch. “We can complete the texturizing process right in the same tooling, which makes it cost-effective,” he explains.

The texturizing process is done first, before anodizing. “Since this type of decorating process doesn’t require a secondary operation, it eliminates any potential compatibility issues with the product—the complete part is anodized,” says Rusch. This makes the process ideal for a fragrance bottle or skin care jar, for example, since the decoration won’t cause any issues when in contact with a product.

Peyer-America offers a Full Surface Hot Stamping process, which can be done instead of a metallizing process for plastic. “Full Surface Hot Stamping creates a metal look, and provides many benefits,” says Waxgiser. “Various colors can be used on one closure, for example. The process is low cost, with fast turnaround times. Small lot sizes are also possible, including a sample of just one,” he says.

When working with metallized foil decorations, challenges often arise when a specific color is replicated on different types of packages. “A brand might request a foil accent in red, for example, but it has to look the same across different substrates. We are able to supply consistent color matches, so that a foil accent on glass over a UV varnish will look the same as the color of the foil on an extruded tube, as well as on a plastic cap,” explains Waxgiser. “This can get complicated,” he says, “but we are able to meet these demands and color-match with consistency, every time.”

WS Packaging’s Eitel offers a few ways to eliminate some common design concerns relating to metallic looks. “If a holographic foil board seems too ‘busy,’ one solution is to print inks in different opacities on top of the foil,” Eitel says. “This allows only a controlled amount of foil to shine through, and is a technique that can be used to ensure a design remains consistent with a brand’s image,” he explains.

Nobelus’ Truan suggests brand marketers always consider combining metallic effects with other types of decorations, especially for upscale cosmetic products. “A metallic package on its own isn’t enough anymore. Many lower priced personal care products use metallized films and holography on cartons, so beauty brands have to do more. Multiple layers, added textures, and spot treatments will all take a package to another level when combined—and we’re seeing the demand skyrocket for these processes,” he explains.

Truan gives an example of how to create a multi-textured surface, which also offers the practical benefit of being smudge-resistant. “Aqueous and UV coatings, in both matte and gloss finishes, will show fingerprints and blemishes quite badly unless they’re protected. With our ScuffProof, FineLinen, and FineLeather laminates, the decorator can go back over the inks to add a protective coating. They can matte the surface, which will allow for the application of spot treatments on top,” he explains.

This combination of coatings gives a carton a textured feel, according to Truan. “It will look like it has a multi-faceted depth,” says Truan. “Plus, the carton won’t need any further protection from fingerprints or smudges. It can be shipped to retailers without the risk of burnishing or blemishing, greatly reducing rejects during inspection,” he adds.

A Coordinated Effort

Although producing a package that includes metal or metallic components will often pose a unique set of challenges that suppliers point out, anticipating any possible issues early on will help ensure production runs smoothly.

These projects often require a well-coordinated effort, up until parts are shipping from a decorator to a brand’s assembly line. “Shipping metallized parts requires planning ahead,” says Decotech’s Engel. “We don’t use shipping boxes with the partitions that are typically used for decorated components. Some of our customers ask us to poly-bag the parts individually. Others provide special packaging, like vac-formed trays, that will keep each part locked in position during transit,” he explains.

In the end, coordinating the production of metal components or metallic packaging will prove worth the extra effort, especially when you can spot your product glistening from across the room.