Joanna Cosgrove, Contributing Editor12.04.17

Outsourcing product development or packaging tasks in part or in whole to a contract or turnkey service provider can help straighten the line connecting product ideation and on-shelf actuality. And it’s not just for startup brands. According to a report from Research and Markets, major brands including P&G, and Unilever are outsourcing mass manufacturing and have initiated the manufacturing of innovative products to protect their intellectual property as well as to reduce the operating cost. Analysts predict the global personal care contract manufacturing market will reach $25.8 billion by 2025, driven by an increased focus on R&D and promotional activities to meet the heightened skincare and beauty demands.

A contract or turnkey partnership can be especially valuable for an emerging brand that’s still learning the ropes. “For a company looking to launch a new innovative beauty brand, working with a turnkey company eliminates the hassle of trying to manage every phase along the way which, in part, helps deliver a quicker turnaround time for the brand,” comments Tina Burd, vice president, Lady Burd Exclusive Private Label Cosmetics, Farmingdale, NY.

For companies starting out with little more than a good product idea, companies like Lady Burd can supply comprehensive services such as product research and development, package development and sourcing, total brand development, manufacturing, regulatory assistance and start-to-finish quality control.

Lady Burd also develops ready-made beauty solutions. One of the company’s recent launches is Perfect Cover Plus, a concealer and imperfection corrector formulated with a lightweight, blendable formula in a twist-up pencil format that never needs sharpening.

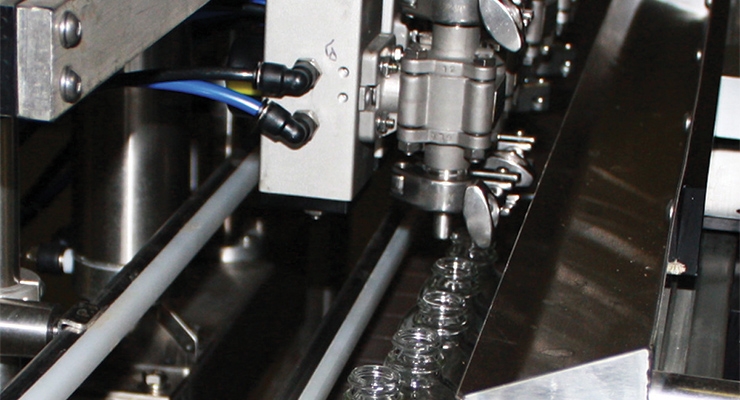

“Combining the contract manufacturing and packaging process under one roof helps streamline the development process, lowering lead times for the end customer [and] providing a cost savings by outsourcing most of the development processes,” comments Anton Meindl, director of sales and product development, Precious Cosmetics Inc., Lodi, NJ. “When providing turnkey, the QC process and testing is also streamlined. You don’t have to worry about two or three different companies providing multiple tests, it’s brought under one roof and causes less headache for the customer.”

For 21 years, Precious Cosmetics has been a partner to many large cosmetic and skincare packaging companies on the East coast, providing formulating and filling services for their turnkey operations, and turnkey solutions for new beauty startups (packaging, formulating and filling). “Most of our larger customers provide their own packaging, and we formulate, label and fill,” he says, noting that while the company’s production facility can handle any type of cosmetic/skincare product (except pressed powders), its specialties are lip glosses, foundations, eye shadows, lipsticks and skincare serums.

Another specialty is the company’s quick turnaround and lead times. “We’ve reverse engineered customer benchmark samples in our lab in 3-5 days and production lead times vary from 4-6 weeks, 8 weeks, during the busy season,” he says, pointing out that average lead times can average 10-16 weeks.

Expert Guidance

Port Jervis, NY-based Kolmar Laboratories, Inc., part of the Knowlton Development Corporation (KDC) network of manufacturing companies, leverages its collective strengths to develop and deliver innovative beauty and personal care products across skincare, color, hair care, body care and personal care products. Amy Skellett, the company’s marketing and communications manager, says this broad reach helps brands on many fronts, especially two very important ones.

Every brand has different product requirements and KDC companies’ Regulatory Departments are capable of ensuring brand-specific compliances across a global landscape. “Established and emerging brands have come to rely on our expertise to keep up-to-date on the ever-changing and most current regulations,” she says. “Our knowledge allows our customers to focus on continuing to grow and manage their business while offering forward thinking, quality products that keep them ahead of their competition.”

An expansive supplier network is another plus. KDC Kolmar just launched a new product collection within the color cosmetics category that features a formulation with a patented, natural sun care technology that provides three times more SPF protection than existing technology on the market. “Because of our relationships and expertise in the industry,” Skellet says, “we receive upfront access to proprietary ingredients that help our brand partners be the first to launch revolutionary products into the marketplace.”

In addition to having the ability to tailor individualized results for individual clients, contract and turnkey service providers also have the capacity to marry the right formula with the right processing and packaging solutions.

“For example, some lipsticks must be filled in specific mechanisms, and the mechanism choice can be a preliminary work between the contract manufacturer and the packaging supplier in order to offer a customer a turnkey solution that has an industrial solution,” says Stéphany Reymond, operational marketing manager for France-based Strand Cosmetics Europe. “For a soft [lipstick] texture called Levres Succulentes, we have made several filling industrial trials with mechanisms of different packaging partners, to select the best mechanism that would fit for such a specific texture that’s difficult to fill.”

For its Bubble Game cleanser, Strand Cosmetics Europe chose a bottle with a specific air spray foam dispenser made by Pulvorex that was free of propellant gas. “Its unique patented technology allows precise mixing of the liquid and air to obtain a high-quality foam dose with each push,” Reymond explains. “It answers clients’ request for an easy-to-use solution, push and care [delivery]; the fluid texture turns into a fine, soft and creamy foam for facial cleansing [and it’s] eco-friendly.”

Channeling Broad Expertise

For Novapac, Lincoln Park, NJ, every new project is recreating the wheel—but in the best possible way. The company’s staff of designers and chemists thrives on new challenges and they’re very firm on the things they will and won’t do for their clients. “Our motto is we do not copy,” says Jean-Marc Derez, company president. “We love working with emerging makeup, skincare and haircare brands because we don’t do minimum order quantities. We make each client’s individual product their own,” he says. “We don’t do cookie-cutter.”

Aminah Sagoe had a skincare idea that was initially born out of personal need. “I suffer from a condition known as Keratosis Pilaris (KP), which produces a goose bump type of appearance on the skin, and can appear anywhere on the body,” she says. “KP is not life threatening in any way; neither is it contagious, however it is aesthetically displeasing to the eye. I originally set out on a mission to find a natural care regimen to improve my condition, and in the process, I discovered a unique combination of ingredients that not only helps with KP, but also with body acne, ingrown hairs, uneven complexions, scaly skin, eczema, psoriasis and other skin conditions.”

Sagoe founded Emmaus Beauty with the purpose of formulating safe and healthy skincare products that are an alternative to expensive synthetic products. Emmaus’ three products contain a unique combination of natural, yet effective ingredients combined with Plant Stem Cell Technology, which she says allows for a purer concentration of natural ingredients. The products, produced by Novapac, are as well-formulated as they are stylishly packaged, with custom white bottles embellished with a custom designed, gold screen-printed logo.

“The technology and ingredients that are used in our formulation process are state of the art, and are very costly, so it was important for the design look and packaging theme to communicate these points to the user, and I believe that has been achieved,” Sagoe explains. “I did my research and met with different manufacturers, however I felt completely at home with Novapac. They listened to my ideas, shared my passion for the concept and were just as excited as I was. They created what I wanted from scratch, using my ideas and guiding me with their knowledge and expertise.”

The same was true for Lillian Tung, CMO and co-founder of Fur You, a company that markets a high-end range of intimate grooming products for women. For her line, Tung turned to Novapac for branding and packaging that reflected its unique focus and positioning. Novapac took the concept and ran with it, creating everything from the formula to the upscale packaging concept.

“We were inspired by vintage fragrances such as YSL and Chanel in packaging [and] wanted a product that was elegant and sophisticated that you could proudly display on your vanity, not something you have to hide underneath your bathroom sink,” Tung says. “Since we were creating a new category, we needed a partner who is a visionary to create something never before seen in the market. Novapac and Jean-Marc immediately understood what we were trying to do.”

Specialty Services

Crafting a successful fragrance relies on more than just an experienced nose. Darryl Do, perfumer at Delbia Do Company, Bronx, NY, says perfume development also boils down to wisely purchasing the right amount of each fragrance component, while navigating kilo conversions, optimal solution concentrations, preparations of secondary packaging and putting together regulatory documents required to register and sell in the U.S., Europe, Asia and Middle East.

“Every step of the process has its own unique language and process loss,” he says. “Manufacturing the fragrance oil, alcohol solution, filtration and fill capacity per bottle and understanding the scrap factor for each step in this process takes some getting used to every step of the way.”

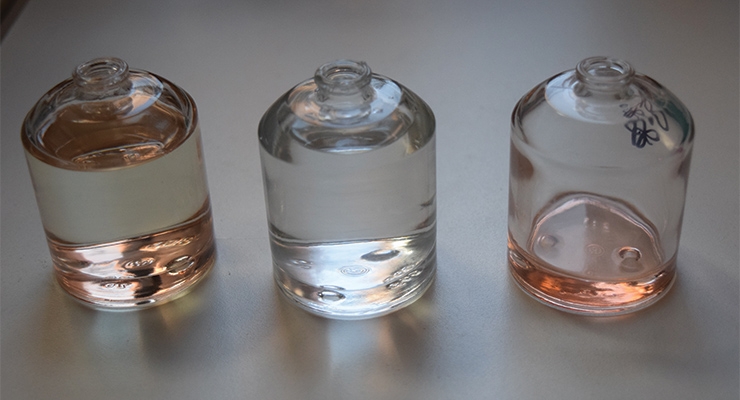

The company also assists with the look and feel of a finished fragrance product. “This can be coloring the solution or decorating the bottle if the customer doesn’t want any artificial colors added to the solution or if the oils may lead to color shift or fade,” he says. “This is something we are doing more often to achieve the look of colored juice.”

For a recent project, Do says the company tried adding color to the solution for a PMS match but it wasn’t stable, so they opted for coloring the bottom of the bottle to give the appearance of colored juice instead.

Backed by nearly 50 years of experience, Italy-based Pennelli Faro is a leading global manufacturer of private label brushes and applicators crafted with bona fide Made in Italy cachet.

According to Pennelli Faro’s marketing executive, Mariangela Porpora, each of the company’s products is designed specifically with ease of use and functionality for the end-user in mind, not to mention aesthetic creativity. The company’s investments are focused on the research and development of new dermatologically tested avant-garde fibers and since manufacturing takes place in the same locale, proximity plays a huge role in the quick manufacture of products, nearly all of which are patent-protected and shared with clients. “We go from the original idea to real-time prototype with all the advantages of testing, modifying and finding the best and utmost performing solutions,” says Porpora, noting that one of Pennelli Faro’s latest innovations, Origami, debuted at Cosmoprof Bologna 2017. “The design, shape and line of the brush are functional to the ergonomic application of the cosmetic product because they are pre-shaped to perfectly follow the facial features. Thanks to multi-faceted shape, even the less experienced consumer can apply makeup professionally.”

The depth of detail goes beyond brush shape. Fiber composition is also continually researched and developed. Dermocura, a synthetic fiber patented by Pennelli Faro, has been dermatologically tested to be “the perfect imitation of natural hair,” similar in aesthetic appearance and ability to respond to the product it applies, but with better performance and durabilty.

Stress-Free Know-How

No matter what the need, there’s a contract service provider ready to help a new product idea become a unique reality, on-time and on-budget, because of their unique vantage point when it comes to maximizing resources.

“As contract manufacturers we have a much higher buying power so our customers get better pricing and it is easier on us, the manufacturer, because we can control the process,” says Vesna Deljosevic, president and CEO, Reforma Group, a Southfield, MI-based turnkey and contract service provider that produces USDA Organic, Cosmos and FDA beauty and personal care products.

Partnering with a brand also means matching customer needs with vendors’ strengths, MOQs and lead times. “When dealing with a packaging vendor, they might have large customers and they will prioritize based on volume which would affect turnaround times for smaller accounts,” she says. “Unlike a packaging vendor, we know how to partner certain vendors with certain customers based on size, means, volumes, time lines and other needs.”

This relationship, especially when it’s coupled with demanding lead times, lets brands focus on their core competencies, be they marketing or distribution, and eliminates the possibility of stress bubbling up on the packaging or manufacturing side of things. “When a customer is a middle man there is more time and back and forth communicating that must go on [but] when a manufacturer takes over as much of the process as possible, it cuts back on some of that time,” Deljosevic concludes. “At the end of the day, everyone involved is looking for the same result: a safe, effective and quality-driven process.”

A contract or turnkey partnership can be especially valuable for an emerging brand that’s still learning the ropes. “For a company looking to launch a new innovative beauty brand, working with a turnkey company eliminates the hassle of trying to manage every phase along the way which, in part, helps deliver a quicker turnaround time for the brand,” comments Tina Burd, vice president, Lady Burd Exclusive Private Label Cosmetics, Farmingdale, NY.

For companies starting out with little more than a good product idea, companies like Lady Burd can supply comprehensive services such as product research and development, package development and sourcing, total brand development, manufacturing, regulatory assistance and start-to-finish quality control.

Lady Burd also develops ready-made beauty solutions. One of the company’s recent launches is Perfect Cover Plus, a concealer and imperfection corrector formulated with a lightweight, blendable formula in a twist-up pencil format that never needs sharpening.

“Combining the contract manufacturing and packaging process under one roof helps streamline the development process, lowering lead times for the end customer [and] providing a cost savings by outsourcing most of the development processes,” comments Anton Meindl, director of sales and product development, Precious Cosmetics Inc., Lodi, NJ. “When providing turnkey, the QC process and testing is also streamlined. You don’t have to worry about two or three different companies providing multiple tests, it’s brought under one roof and causes less headache for the customer.”

For 21 years, Precious Cosmetics has been a partner to many large cosmetic and skincare packaging companies on the East coast, providing formulating and filling services for their turnkey operations, and turnkey solutions for new beauty startups (packaging, formulating and filling). “Most of our larger customers provide their own packaging, and we formulate, label and fill,” he says, noting that while the company’s production facility can handle any type of cosmetic/skincare product (except pressed powders), its specialties are lip glosses, foundations, eye shadows, lipsticks and skincare serums.

Another specialty is the company’s quick turnaround and lead times. “We’ve reverse engineered customer benchmark samples in our lab in 3-5 days and production lead times vary from 4-6 weeks, 8 weeks, during the busy season,” he says, pointing out that average lead times can average 10-16 weeks.

Expert Guidance

Port Jervis, NY-based Kolmar Laboratories, Inc., part of the Knowlton Development Corporation (KDC) network of manufacturing companies, leverages its collective strengths to develop and deliver innovative beauty and personal care products across skincare, color, hair care, body care and personal care products. Amy Skellett, the company’s marketing and communications manager, says this broad reach helps brands on many fronts, especially two very important ones.

Every brand has different product requirements and KDC companies’ Regulatory Departments are capable of ensuring brand-specific compliances across a global landscape. “Established and emerging brands have come to rely on our expertise to keep up-to-date on the ever-changing and most current regulations,” she says. “Our knowledge allows our customers to focus on continuing to grow and manage their business while offering forward thinking, quality products that keep them ahead of their competition.”

An expansive supplier network is another plus. KDC Kolmar just launched a new product collection within the color cosmetics category that features a formulation with a patented, natural sun care technology that provides three times more SPF protection than existing technology on the market. “Because of our relationships and expertise in the industry,” Skellet says, “we receive upfront access to proprietary ingredients that help our brand partners be the first to launch revolutionary products into the marketplace.”

In addition to having the ability to tailor individualized results for individual clients, contract and turnkey service providers also have the capacity to marry the right formula with the right processing and packaging solutions.

“For example, some lipsticks must be filled in specific mechanisms, and the mechanism choice can be a preliminary work between the contract manufacturer and the packaging supplier in order to offer a customer a turnkey solution that has an industrial solution,” says Stéphany Reymond, operational marketing manager for France-based Strand Cosmetics Europe. “For a soft [lipstick] texture called Levres Succulentes, we have made several filling industrial trials with mechanisms of different packaging partners, to select the best mechanism that would fit for such a specific texture that’s difficult to fill.”

For its Bubble Game cleanser, Strand Cosmetics Europe chose a bottle with a specific air spray foam dispenser made by Pulvorex that was free of propellant gas. “Its unique patented technology allows precise mixing of the liquid and air to obtain a high-quality foam dose with each push,” Reymond explains. “It answers clients’ request for an easy-to-use solution, push and care [delivery]; the fluid texture turns into a fine, soft and creamy foam for facial cleansing [and it’s] eco-friendly.”

Channeling Broad Expertise

For Novapac, Lincoln Park, NJ, every new project is recreating the wheel—but in the best possible way. The company’s staff of designers and chemists thrives on new challenges and they’re very firm on the things they will and won’t do for their clients. “Our motto is we do not copy,” says Jean-Marc Derez, company president. “We love working with emerging makeup, skincare and haircare brands because we don’t do minimum order quantities. We make each client’s individual product their own,” he says. “We don’t do cookie-cutter.”

Aminah Sagoe had a skincare idea that was initially born out of personal need. “I suffer from a condition known as Keratosis Pilaris (KP), which produces a goose bump type of appearance on the skin, and can appear anywhere on the body,” she says. “KP is not life threatening in any way; neither is it contagious, however it is aesthetically displeasing to the eye. I originally set out on a mission to find a natural care regimen to improve my condition, and in the process, I discovered a unique combination of ingredients that not only helps with KP, but also with body acne, ingrown hairs, uneven complexions, scaly skin, eczema, psoriasis and other skin conditions.”

Sagoe founded Emmaus Beauty with the purpose of formulating safe and healthy skincare products that are an alternative to expensive synthetic products. Emmaus’ three products contain a unique combination of natural, yet effective ingredients combined with Plant Stem Cell Technology, which she says allows for a purer concentration of natural ingredients. The products, produced by Novapac, are as well-formulated as they are stylishly packaged, with custom white bottles embellished with a custom designed, gold screen-printed logo.

“The technology and ingredients that are used in our formulation process are state of the art, and are very costly, so it was important for the design look and packaging theme to communicate these points to the user, and I believe that has been achieved,” Sagoe explains. “I did my research and met with different manufacturers, however I felt completely at home with Novapac. They listened to my ideas, shared my passion for the concept and were just as excited as I was. They created what I wanted from scratch, using my ideas and guiding me with their knowledge and expertise.”

The same was true for Lillian Tung, CMO and co-founder of Fur You, a company that markets a high-end range of intimate grooming products for women. For her line, Tung turned to Novapac for branding and packaging that reflected its unique focus and positioning. Novapac took the concept and ran with it, creating everything from the formula to the upscale packaging concept.

“We were inspired by vintage fragrances such as YSL and Chanel in packaging [and] wanted a product that was elegant and sophisticated that you could proudly display on your vanity, not something you have to hide underneath your bathroom sink,” Tung says. “Since we were creating a new category, we needed a partner who is a visionary to create something never before seen in the market. Novapac and Jean-Marc immediately understood what we were trying to do.”

Specialty Services

Crafting a successful fragrance relies on more than just an experienced nose. Darryl Do, perfumer at Delbia Do Company, Bronx, NY, says perfume development also boils down to wisely purchasing the right amount of each fragrance component, while navigating kilo conversions, optimal solution concentrations, preparations of secondary packaging and putting together regulatory documents required to register and sell in the U.S., Europe, Asia and Middle East.

“Every step of the process has its own unique language and process loss,” he says. “Manufacturing the fragrance oil, alcohol solution, filtration and fill capacity per bottle and understanding the scrap factor for each step in this process takes some getting used to every step of the way.”

The company also assists with the look and feel of a finished fragrance product. “This can be coloring the solution or decorating the bottle if the customer doesn’t want any artificial colors added to the solution or if the oils may lead to color shift or fade,” he says. “This is something we are doing more often to achieve the look of colored juice.”

For a recent project, Do says the company tried adding color to the solution for a PMS match but it wasn’t stable, so they opted for coloring the bottom of the bottle to give the appearance of colored juice instead.

Backed by nearly 50 years of experience, Italy-based Pennelli Faro is a leading global manufacturer of private label brushes and applicators crafted with bona fide Made in Italy cachet.

According to Pennelli Faro’s marketing executive, Mariangela Porpora, each of the company’s products is designed specifically with ease of use and functionality for the end-user in mind, not to mention aesthetic creativity. The company’s investments are focused on the research and development of new dermatologically tested avant-garde fibers and since manufacturing takes place in the same locale, proximity plays a huge role in the quick manufacture of products, nearly all of which are patent-protected and shared with clients. “We go from the original idea to real-time prototype with all the advantages of testing, modifying and finding the best and utmost performing solutions,” says Porpora, noting that one of Pennelli Faro’s latest innovations, Origami, debuted at Cosmoprof Bologna 2017. “The design, shape and line of the brush are functional to the ergonomic application of the cosmetic product because they are pre-shaped to perfectly follow the facial features. Thanks to multi-faceted shape, even the less experienced consumer can apply makeup professionally.”

The depth of detail goes beyond brush shape. Fiber composition is also continually researched and developed. Dermocura, a synthetic fiber patented by Pennelli Faro, has been dermatologically tested to be “the perfect imitation of natural hair,” similar in aesthetic appearance and ability to respond to the product it applies, but with better performance and durabilty.

Stress-Free Know-How

No matter what the need, there’s a contract service provider ready to help a new product idea become a unique reality, on-time and on-budget, because of their unique vantage point when it comes to maximizing resources.

“As contract manufacturers we have a much higher buying power so our customers get better pricing and it is easier on us, the manufacturer, because we can control the process,” says Vesna Deljosevic, president and CEO, Reforma Group, a Southfield, MI-based turnkey and contract service provider that produces USDA Organic, Cosmos and FDA beauty and personal care products.

Partnering with a brand also means matching customer needs with vendors’ strengths, MOQs and lead times. “When dealing with a packaging vendor, they might have large customers and they will prioritize based on volume which would affect turnaround times for smaller accounts,” she says. “Unlike a packaging vendor, we know how to partner certain vendors with certain customers based on size, means, volumes, time lines and other needs.”

This relationship, especially when it’s coupled with demanding lead times, lets brands focus on their core competencies, be they marketing or distribution, and eliminates the possibility of stress bubbling up on the packaging or manufacturing side of things. “When a customer is a middle man there is more time and back and forth communicating that must go on [but] when a manufacturer takes over as much of the process as possible, it cuts back on some of that time,” Deljosevic concludes. “At the end of the day, everyone involved is looking for the same result: a safe, effective and quality-driven process.”