Marie Redding, Associate Editor12.04.17

Deciding whether to use a bottle, tube or jar is only the first step in the packaging process—it is the decoration that completes the look and conveys a brand’s image, striving to form an emotional connection with the consumer. The right decoration can elevate a stock package, and tell a story about what’s inside a bottle, jar or tube. When a product’s carton also reflects the brand’s story in its design, it elevates the user’s experience with the product. It is the first part of the package the user opens at home.

Shiny surfaces on collars and caps, which are often achieved using metallization processes, might convey a “sleek” look, and a skincare product’s smoothing benefits. Hot-stamping or various labeling techniques might add shine, to make a holiday carton sparkle and look “giftable.” A minimalist design on a label is often a good fit for an apothecary-inspired bath and body brand. A realistic photo-like image on a bottle or tube might focus the consumer’s attention on a specific ingredient in a haircare product.

“Color, texture, and effects are all design cues that can turn a package into a sensory experience, and powerfully connect with the consumer at the point-of-purchase,” says Sheherazade Chamlou, vice president of sales and marketing, Verescence North America.

When deciding on a decoration for a fragrance, Chamlou offers a few insights. “The physical characteristics of a package, which include the quality and the look of the materials, as well as the colors and finishes that are chosen, all suggest the ‘olfactory universe’ to the consumer,” she says. “The sensory aspects of the packaging give consumers emotional cues which help convey the fragrance story,” she adds.

The same is true for cosmetics. TIGI Cosmetics just launched at CVS Pharmacy stores nationwide. Selling a professional brand at a major nationwide retailer requires the packaging to look prestige, or “masstige” — so deciding on the right type of decoration was key. The line includes round compacts and triangular-shaped lipstick cases. The packaging is predominantly white, with shiny silver accents and lots of clear windows.

Laurie Enright, director of marketing for TIGI Cosmetics says, “We chose a high-shine chrome look to resemble a mirror finish. The finish on the top of the lipstick cap allows it to function as a mirror, for on-the-go application,” she says. The shiny silver parts are all vacuum metallized. Shiny accents were created using silk-screening, cold-foiling and hot-stamping processes.

A decoration on a package can have a direct effect on the sales of a product. “Our films create an illusion of depth, which draws the customer in—making them want to touch the product. Once a shopper picks up a product, the chance of purchasing it skyrockets,” says Joel Petersen, president, WaveFront Technology, Inc. (WFT). The supplier’s Fresnel Lens film is featured on the La Mia Perla fragrance carton, which is described in detail later in this article.

In another example of how a package’s decoration may affect sales, Sensodyne toothpaste created new cartons featuring WFT’s Fresnel Lens film, and the brand moved up from the second best-selling brand for sensitive teeth to the top seller in Europe, according to Petersen.

Terri Goldstein, of The Goldstein Group, explains why and how a decoration affects sales. “Shoppers scan on-shelf products in five seconds or less before deciding to make a purchase,” says Goldstein. The company uses its Shelf Sight Sequence as a guiding principle when advising brands on the types of decorating techniques to choose. “This is the way we naturally recall many things in our lives, from people to directions—using color, shape, symbols and words. Color is the first identifier that shoppers notice and recall, even before noticing a package’s shape or reading any words on a package,” Goldstein says. “Consumers, especially women, respond to premium and luxe design cues on packaging, which can include jewel tones and pearlescent effects,” she adds.

There are plenty of options and experts to help create decorations that will transform a generic package into one that conveys a brand’s story. The following suppliers describe a few of the numerous processes, materials, and machinery they specialize in, intended to help bring a designer’s vision to market.

A Pretty Vacuum Metallizing Process in Pastels

Takemoto Packaging develops hundreds of molds each year to produce packaging for its customers, worldwide, and offers both stock and custom designs, but its team knows the decoration counts just as much as the container. The supplier offers silk screening, raised ink printing, metallic printing, hot stamping, labeling, shrink films, and more. With its Hairline Hot Stamping process for bottles, patterns and lettering can be printed with superfine detail.

Takemoto recently developed a new type of vacuum metallization process called Luminist. It is shown in the photo on the cap of the company’s new powder sifter low profile jar. “With Luminist, soft and ‘milky’ vacuum metallized colors can be achieved,” says Atsko Fukada, senior director, Takemoto Packaging.

This decorating process entails using a silver vacuum metallization process, followed by the application of a coating of Luminist lacquer. Any color can be done, but the supplier recommends using light, pastel colors. “It looks completely different from the typical shiny vacuum metallized looks, in shiny silver and gold,” Fukada says. “Luminist achieves a more nuanced high-end look with a feminine touch and youthfulness. This type of decoration is ideal for cosmetics packaging, as it invites the consumer to touch the product,” she adds.

Environmentally Friendly Machinery

All types of decorating usually require specialized machinery, and Tapematic, an equipment manufacturer for over 40 years, provides environmentally friendly production solutions. “Our technology is relatively new, but at the same time, proven. It is not the way packaging is traditionally decorated—it’s a much more environmentally friendly process,” says Tony Denning, president, Tapematic USA. (See a video of Tapematic’s machinery on BeautyPackaging.com Videos section.)

“We make sure our machinery is more eco-friendly, in regards to the various components of our equipment that are used during the decorating process. We have installations worldwide in the cosmetic and beverage closure markets,” says Denning.

On Tapematic’s production line system where packaging components move along a line and are sprayed with a coating, the sprayers work “on demand,” rather than spraying continuously. “This ensures that less VOCs are released into the environment than on traditional machinery,” Denning explains. “Also, we utilize a ‘load-lock’ chamber for metallization, which we designed. It allows the main chamber to remain at high-vacuum—reducing the need to constantly create it. This greatly reduces energy consumption,” he adds.

Also, every aspect of the decorating process, including coating, metallizing and graphic decoration can be done in-line on Tapematic’s machinery. “This adds no extra cost, because we have an IDM—an In-Line Decoration Module,” Denning explains. “Less handling of the product by humans results in lower costs,” he says. “Plus, we have in-line inspection—for higher yields with less waste,” he adds.

Tapematic listens to feedback from decorators that use its machinery, to make improvements. “It’s a constant evolution,” Denning says, adding, “We’re continuously making enhancements, so it’s an on-going process as we build upon the technology.”

Choosing Labels

Labels often offer the flexibility of printing limited edition designs in small quantities. Schmidt’s Naturals, which was just acquired by Unilever, is one brand that often customizes its labels for limited edition launches. The personal care brand launched a holiday deodorant collection—Oh Christmas Tree, Snow Day and Holiday Spice—with labels that feature festive looks.

Olcott Plastics, a supplier that produces plastic jars and closures, provides its customers with the option of purchasing its jars custom-decorated. “When we provide decorating services in-house, the benefits for a brand are shorter lead times and lower costs,” says Joseph Brodner, president, Olcott Plastics. “When you order one-hundred thousand jars from us, labeled, for example, you will get one-hundred thousand—not ninety-seven thousand due to scrap,” he adds.

Olcott Plastics utilizes three main decorating processes: off-set printing, silk-screening and labeling. Five-color printing is ideal for high volume runs, and the supplier has the capacity to deliver more than 2 million pieces per month. Indie brands might want to take advantage of its labeling services, which require a 15k-piece minimum order.

“We see a trend toward labeling, versus printing, on jars,” says Brodner. “Printing technologies have advanced, the colors look vibrant, and labels offer the flexibility of using special effects and holograms,” he adds.

Olcott Plastics’ beauty customers include hair care and skin care brands. “One of our customers uses a jar decorated with off-set printing on the front, an end-label on the bottom and an accordion style label on the back, which is printed in three languages,” Brodner says, adding, “labels offer this flexibility in design to fit a brand’s needs and requirements.”

Heat Transfer Labeling Offers Advantages

A heat transfer process is one way to apply a label to a cosmetics package, such as a jar or compact, and it is a method that is sometimes overlooked, according to Darren Eade, vice president of sales at Kemas USA. “Heat transfer labeling is a one-step, secondary process, and more brands should take advantage of the benefits it offers,” says Eade.

One of the advantages of this process is the ability to achieve multiple colors on one label, with precision, detail, and definition, according to Eade. “Achieving multiple colors on a label using typical methods, such as hot-stamping with foil, or silk-screening with inks, would require multiple passes. And with each pass, you are incurring additional costs, as well as the risk of misalignment,” he explains.

If a brand’s artwork is very detailed with several colors, Eade says he always recommends using a heat transfer label. “Hot-stamping and silk-sceeening are requested more often, but when a design has two or more colors, we always suggest using a heat transfer label instead. It is so much more cost-effective—coupled with its ability to provide superior detail,” Eade adds.

One tip: Choosing a heat transfer label requires a longer development time. “Package development teams should take this into account when creating a product development timeline, but the benefits will be worth it in the end,” says Eade.

Kemas has established a reputation as one of the leading suppliers of lipstick cases. The company also produces compacts, lipgloss packaging, pots, eyeliner and jars, with many stock packaging options available. Executing highly detailed decorations is also a key strength. The supplier offers an extensive list of decorating processes in addition to heat transfer labeling, including in-mold labeling, pad printing, laser etching, metallization and in-mold fabric transfer.

Decorating Tubes

Tubes are popular for body care products, and are decorated in numerous ways to reflect a brand’s personality. Scentbird just launched Rose & Prosecco Hand Cream, and it is decorated with an illustration that looks hand-drawn. Other brands choose to decorate tubes with vibrantly colored labels.

JSN Cosmetic Packaging, a family-owned company based in California that oversees the entire manufacturing process of its plastic tubes and closures, including in-house decoration, works with leading companies as well as indie brands. The decoration most often requested for its tubes is offset printing, according to Sandy Nagel, co-owner and vice president, JSN Cosmetic Packaging.

JSN offers off-set printing in up to eight colors. “This printing process typically allows for very tight registration and is cost effective for our customers. We also offer up to five-color silk screen printing, and hot-stamp foil applications to give a tube a rich highly reflective look,” she says.

Nagel says she is also hearing an increasing number of requests for hot-stamping and varnishing, which can make a tube look more luxe. When a label is requested, JSN offers full-wrap, overlapping and spot label applications.

Nagel says the team at JSN is often asked to combine various processes, in new ways. “We are always exploring new printing, decoration, and finishing technologies. We love to collaborate with brands to come up with a custom look, featuring an innovative cutting-edge decoration,” says Nagel.

Luxe Looks with WFT’s Specialty Films & Fresnel Lens Technology

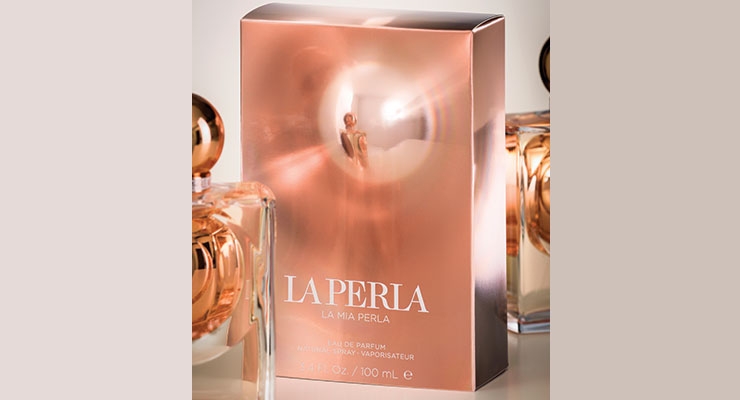

For a stand-out decoration that can make a carton look glamorous, take a look at the carton created for the fragrance, La Mia Perla, which launched in May. The carton is rose gold to resemble the inside of an oyster shell. It is decorated with a reflective pearl design that coordinates with the Eau de Parfum’s bottle’s unexpected, glamorous look—a shiny, suspended pearl in its center. La Perla states in its press release: “The outer packaging is developed with reflective Fresnel technology—new to the beauty industry, it continues to illustrate the spherical storytelling behind this precious scent.” Liquor companies were among the first brands to use the innovative material.

The decoration on the carton was created using one of WaveFront Technology, Inc.’s (WFT)’s specialty films called Fresnel Lens. “Using a Fresnel lens to simulate the pearl offered the perfect solution,” says Simon Thompson, head of design for WFTE, which is WFT’s European sales distributor.

WFT’s Fresnel Lens film is ideal for creating eye-catching decorations on folding cartons, boxes and labels. The film is created using linear and circular Fresnel lenses and can be combined with holographic effects. “We developed proprietary techniques and the tooling necessary to replicate micro-structures in a roll-to-roll format,” says Joel Petersen, president, WFT.

The supplier offers a range of unique lens patterns and will also collaborate directly with a brand’s creative team to custom design lenses for specific projects. The production process includes coating a roll of PET with a special lacquer, curing the polymer with UV lights against a microstructure drum, and applying a thick coating of aluminum to create a reflective surface. “Our lamination customer will then laminate the film to paperboard and typically sheet it in register. These sheets are then printed in a sheet feed printer,” Petersen explains.

The film gets its name from the original Fresnel Lens, first invented in 1822 by French physicist Augustin-Jean Fresnel who studied light transmission. Fresnel realized his invention would enable a lighthouse lamp to focus and project a beam of light. WFT’s Fresnel Lens films for packaging are also designed to capture light. “The lens facets in the original invention were many centimeters thick, but WFT was the first to make it a thin film with less than 10 micron facets,” explains Petersen. “The facets are used to bend light like a thick lens—so it is a flat film that looks 3-dimensional,” he explains. “But unlike a hologram, it shines no matter where the light source is or where you are standing. You don’t need to move a package around to see the effect,” he adds.

Other brands are using the supplier’s Fresnel Lens, as well as other specialty films, in various ways. WFT has worked with Taittinger champagne for many years, which has used its films to create shiny colored bubbles on one of its boxes. “When Taittinger launched a ‘nighttime’ champagne, a unique lens feature was used inside the squares, and they reflect light like mirrors at different angles giving it a disco ball effect,” Petersen says. Bombay Sapphire Gin’s carton features a different type of look. “They use multiple lenses, and each looks like it is magnifying the graphics, because the print over the lenses was distorted that way,” says Petersen.

WFT works with brands to execute a designer’s vision and ensure a decoration is applied, perfectly. “We are skilled in ensuring the proper registration and alignment,” says Petersen, explaining that accuracy is key when laminating the films in register onto paperboard before it is converted to a carton. “We often develop specific tools for a brand, to ensure that the lenses print exactly where they are intended to be,” he says.

Innovative Effects for Glass

Glass suppliers and decorators see more of a demand for differentiation, premiumization, and personalization in the fragrance market, according to Verescence North America’s Chamlou. The company’s innovative decorations for glass offer brands the solutions to meet these needs.

Verescence counts prestige fragrance brands, many with fashion roots, among its customers. The supplier has worked on fragrance launches for Burberry, Prada, Miu Miu, Tom Ford and many more.

“Today’s consumers are ‘multi-sensorial,’ and our R&D team continuously works on developing innovative decorating processes that will attract their attention,” says Chamlou. “The emergence of new segments, and the rise of niche brands over the past few years presents challenges for fragrance brands, due to increased competition,” she says, which is further driving the need for unique designs.

Verescence featured several of its newest decorating techniques at the recent Luxe Pack Monaco show, including a new spotted effect for its Color’In process. This patented technology coats the inside of a bottle, and multiple unique colored effects can be achieved, including a spotted or “splattered” pattern. It is typically compatible with the juice, so a pouch isn’t required, but, a brand should always conduct testing.

The Narciso Rodriguez fragrances are known for pioneering this decoration. “The inside decoration is such a huge part of the fragrance brand’s identity now—it keeps the fragrance ‘secret’ from the eyes of the user, so that the mystery of it is revealed at the moment it is sprayed,” says Chamlou.

Verescence also offers Sculpt’In, a decoration that features unique shapes inside a glass bottle, or engraving inside a jar. “Combining this with colored juice, or our Color’In technique, will highlight these shapes,” says Chamlou.

Another innovative look is Verescence’s High Jewelry Glass, a patented technology that includes precious stones ‘inside’ the glass. “The light of the gemstones will echo the brightness of the glass. This technique can be used to create one-of-a-kind bottles,” says Chamlou.

A Colorful Foil Decoration for Glass

Another decorating option to ensure a glass bottle stands out is to use foils, according to Peyer and its U.S.-based subsidiary, Peyer America. The supplier has a mission to spread the word to brand owners about the numerous benefits of its new foils for glass, the GXO series. Ideal for fragrance bottles, the foils are alcohol-resistant and scratch-resistant. They are available in metallic colors, or with holographic effects.

Decorating glass with foils requires the use of a coating system. Peyer developed a new process in partnership with ink manufacturer Marabu, using its UV-primer system. “In a UV primer system, a machine decorates the glass bottle, one station applies the primer, then it goes under a UV light to cure. Next, the foil is applied,” explains Todd Waxgiser, director of sales, Peyer America. “In a more traditional solvent-based coating system, a long oven is used to cure,” he says.

Foiling is done with either system, but a UV system ensures consistency, requires less energy use, and is high-speed, which makes it extremely cost-effective, according to Waxgiser. “Plus, you can achieve a very fine edge definition, which works well for detailed designs or lots of text,” Waxgiser adds.

Most of Peyer’s customers are packaging suppliers, but the company would love to work with more brand owners to demonstrate its new system’s benefits. “In recent years, the only way to achieve the same look was by using precious metals, which is expensive and only available in limited color options. Our foiling system delivers the same look, at a fraction of the cost. Plus, we can deliver just about any color a designer requests,” he says.

Peyer’s team will work to ensure its coatings are successfully applied using a company’s existing coating system. “We ensure a project’s success, no matter what type of system is being used. However, our equipment supplier partner can help if a company is interested in switching to a UV coating system—and we will demonstrate how much more effective it is,” Waxgiser explains.

Waxgiser notes that there aren’t many companies in North America taking advantage of Peyer’s foiling system yet. “It is much more in demand in Europe,” he says. This may soon change, since Peyer is currently doing line trials with several brands now.

More Ways to Customize Glass

Spraying glass is another decorating option, and a simple way for a brand to create different looks for flanker scents, when the same bottle shape is used. ScreenTech/Spraye Tech Group specializes in using spray processes to decorate glass, as well as using hot-stamping processes and various printing techniques.

“Spraying is one of the best ways to customize a stock bottle,” says John Schofield, owner, ScreenTech/Spraye Tech. “We have the ability to spray up to five colors in a single pass, which can give a bottle a unique look.” The supplier’s spray process is also environmentally friendly. “It is a water-based process that meets all the testing requirements of the industries we service,” says Schofield.

Brands turn to ScreenTech/Spraye Tech for its expertise in hot-stamping challenging designs. “Our development team always welcomes a challenge from creative teams,” says Schofield. When printing, the supplier uses primarily organic inks, which are environmentally friendly. The company uses semi-automatic, automatic, and robotic processes, depending on the project and quantities.

ScreenTech/Spraye Tech has flexibility, and is able to manufacture small quantities as well as large orders, so the company partners with both small and large companies.

Protection Is Bottle Coatings’ Specialty

Sometimes a decoration is only for aesthetic purposes, and other times it is a necessity—to protect a formula. Bottle Coatings, a division of Los Angeles-based Sundial Powder Coatings, was initially known for its powder coatings that were used in the metal and architectural industries. The supplier became a go-to source for the beauty industry several years ago when nail polish brands needed to protect certain long-wearing gel polish formulas from curing inside the bottle when exposed to light.

Bottle Coatings came to the rescue with its patent-pending UV-protectant powder coating, which creates an adhesive bond between the powder and glass. “The first beauty brands we worked with were nail polish brands, to develop the methods and processes necessary to quantify how much light needed to be blocked and which types of wavelengths, for specific types of products,” says Shivie Dhillon, president and owner of Bottle Coatings.

Now that the specifications are set, Bottle Coatings offers beauty brands different coating options based on gloss level, chemical resistance, and smoothness. “We also have a highly accurate color matching system so that our powder coated bottles effectively duplicate the color of the product inside,” says Dhillon. Brands can choose from thousands of color options, including glossy, metallic and glitter variations. The supplier’s powder coating process is also environmentally friendly.

Dhillon says he gets lots of requests lately from skincare brands. Neutrogena’s new Rapid Winkle Repair Cream is in a glass jar is decorated with a silver coating by Bottle Coatings. “Our coatings are sometimes chosen for aesthetics; other times to preserve a formula that contains high levels of essential oils or certain ingredients, which is often the case in skincare,” explains Dhillon.

Several skincare brands are also now using the suppliers’ powder coatings as a solution for masking the color of the product inside the bottle or jar. “They want to use more natural ingredients, and fewer ingredients. Instead of using additional additives and colorants to make a product look whiter, brighter, or more aesthetically pleasing, they are coating the bottle to mask the color of the product,” says Dhillon.

A Graphic Innovation for Cans

A supplier that specializes in innovative graphic solutions for aluminum cans is Ball Corporation. The company is a global leader in metal packaging and innovative aerosol technologies. In decorations, the company’s stock finishes include matte, gloss, semi-matte and pearlescent, among other options.

Mary Frash, marketing manager, Ball Corporation, says, “Our Matte & Gloss technology combines matte and gloss finishes on the same can. This printing technique is best suited for darker colors and is a great fit for many personal care product categories,” she says.

While this technique is not new to the industry, or Ball Corporation, how it is executed makes all the difference.The supplier developed a new technique over the past year that is an innovation in graphics. Ball’s proprietary process offers improved ink lay and better contrast between the matte and gloss inks.

Ball Corporation’s Matte & Gloss technique delivers a premium look without a high cost. “It offers high value, and it is being utilized by both larger and smaller brands, since it is appealing to the consumer and it helps with shelf differentiation,” Frash says.

Ball Corporation worked with Henkel Schwarzkopf for the launch of got2b’s Mann-O-Mann hairspray. Ball used specialized inks and coatings on the can to achieve a matte or a gloss over-varnish finish in the different printed areas.

“Our new Matte & Gloss application can be run on standard printing and coating equipment using modified process parameters. This allows brand owners to accentuate different areas of the can for marketing purposes,” Frash adds.

The tuxedo depicted in the can decoration is highlighted with a gloss varnish that pops against the predominately matte can. “The can’s eye-catching graphics and distinctive presence stand out on the shelf—setting it apart from the competition,” Frash says.

Ball Corporation demonstrated the look of its Matte & Gloss technique by decorating a can (shown) in black, with red flowers. “The black on black has a lush, peaceful look, and the design conveys ‘luxury.’ The red flowers provide eye-catching accents,” Frash says.

The supplier has a Graphics Center of Excellence in Mexico dedicated specifically for its customers, which offers full artwork separations and on-site computer-to-plate (CTP) plate-making capabilities. Brands have the opportunity to visit the facility to meet with ink vendors, while its offline printers and neckers provide opportunities to run innovative ink and varnish trials and test as innovative shapes, shoulders and embossing.

Final Tips

It takes a great deal of collaboration among suppliers and brands to execute a package designer’s vision. Choosing the best decorating process for a project is key—and the right supplier that will be able to achieve the look a creative team is visualizing.

One tip nearly every supplier repeatedly suggests is for brands to collaborate with suppliers early on in the package development process. Projects often require multiple steps and revisions to take a package design from the concept stage to production. When a supplier knows which decorating processes are best to create the look a brand marketer wants to achieve, the process runs more quickly, and smoothly.

“It is always a collaboration,” says Screentech/Spray Tech’s Schofield. “Everyone involved needs to arrive at a concept that is aesthetically pleasing to the creative group, while also being within the supplier’s manufacturing parameters—and we are often challenged to come up with new ways to achieve innovative designs,” he explains.

Ball Corporation’s Frash agrees, saying, “We always prefer to work with our customers on their design early in the process. They know their brand best, and we know the package and printing technique best. When we partner on a project, we ensure the optimal aesthetic is achieved,” she says.

JSN’s Nagel adds, “We love to be challenged, especially if it is an innovative look or complex decoration a brand is trying to achieve. Work with us from the beginning, and we will come up with innovative solutions together.”