Marie Redding, Associate Editor04.30.18

All types of metals, plus metallized finishes for plastics, and foils, are making packaging look luxurious. These designs and decorations are on fragrance bottle caps, makeup compacts, palettes, cartons, lipstick packages—and more.

Metal and metallic elements might look “flashy,” which is sometimes the look that a package designer intends to convey. The same materials, depending on the color choice and finishing process, can look understated and elegant; classic and luxurious; or sleek and modern.

What colors are most often requested, in metals and metallics, for packaging? “Traditional colors like gold, in both satin and shiny finishes, as well as silver remain popular,” says Rob Lynch, president, Capstone Manufacturing. “We continue to see distressed, weathered, rough looks across the board from brands ranging from younger to more mature. Also, antique and old-world inspirations like early Byzantine colors and surfaces are a popular choice for prestige items,” Lynch says.

Glossy finishes are by far the most requested in foils for most beauty products, according to Todd Waxgiser, director of sales, Peyer-America—except in eyeliner pencils. “They are using up all our matte foils,” he says, jokingly. All kidding aside, beauty brands seem drawn to matte colors for eyeliner pencils, while both matte and shiny foils are being requested for mascara, Waxgiser says.

Rosa Porras Mansilla, marketing and communication manager, Virospack, says that finishes with shiny, metallic effects that reflect light are a clear trend—and it is “everywhere.” She says, “We see ‘shine’ in beauty, on celebrities…on the Red Carpet.” With so much “brightness,” packages that play with contrast and include shiny and matte finishes look very modern now, Porras says. “Beauty brands are looking for luxury finishes, and metallic effects are delivering,” she adds.

David Peters, creative director, API Group, says that metals in gold and silver will always be synonymous with “luxe.” He says, “During the past year, we’ve also seen a growing demand for precious metals, such as copper, rose gold and zinc finishes.” API offers a Precious Metals Palette, which includes zinc, magnesium, nickel and other alloys.

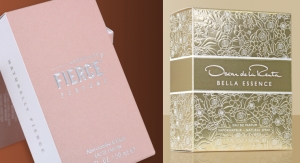

Peters explains, “We developed our 2018 - 2019 Trends Folio, which showcases foils, laminates and holographic effects. These looks are effective in empowering brands to create unique shelf appeal. Our Ethereal illumination trend creates texture and illumination through the use of reflective high shine finishes, as well as extreme matte foils. These color and decorating trends will continue into 2019,” he says.

Don Romine, packaging specialist, Impress Communications, says, “There are some really interesting decorating techniques that use metallic substrates, metallic inks and foil stamping. During the past year I have seen a huge increase in the use of these techniques. And in my opinion, they are still under-utilized.” Impress Communications is a California-based company that works with lots of Indie beauty brands, and uses Kurz foils for many projects.

Jing Santos, sales director, Compax, feels that often the use of metal or metallics is less about following trends, and more about establishing a luxe look. “Metals and metal finishes add cost and are out of reach for most mass-market brands. Prestige brands, such as Hourglass and Urban Decay, are known to always use metals and metal finishes, and it’s just a part of their image,” Santos says.

In decorating, Santos does see some trends. “Hot-stamp foil will always be a popular way to achieve a metallic look, but heat-transfer labeling is becoming more popular right now, as well as holographic foils.

Richard Engel Jr., president & COO, Decotech Inc., says beauty and fragrance brands are requesting more metallization, and setting up projects for the next 18 months that will utilize the company’s production line. “We specialize in metallizing glass and plastic bottles and jars, so that’s where we are seeing the demand increasing. One of our customers recently said that our metallization process is so eye-catching that it gives existing bottle forms ‘new life,’ ” says Engel.

Ellen Manning, vice president of marketing, Eagle Systems, says more brands are using foils. “Foil is back—stronger than ever this year, because it attracts attention. A recent study by Clemson University and the Foil and Specialty Effects Association has proven that buyers are attracted to foiled products,” Manning says. “Shiny packages on store shelves is a definite advantage that more brands are utilizing,” she adds.

Metallic Looks Are Everywhere

Many makeup brands are featuring super-shiny products right now—especially for the eye. There are all types of glitter eye shadow, eye gloss, and metallic hues for eyelids and lips. The trend began several seasons ago and seems to have finally trickled down from the runways to Walmart.

Hard Candy, which sells at Walmart, has a Spring 2018 collection that literally “outshines” anything else on mass-market shelves. The brand’s look book features glitter mascara, rainbow brows, and a product called Metal Glaze, which is a 12-hour liquid metallic foil for eyes and lips. There are also face primers in shiny tubes, eye makeup palettes that are decorated with criss-crossing foil strips that look inspired by light sabers, and aluminum tins that hold lip gloss and makeup kits—one of which is Metal Eyes.

Hard Candy’s Metal Eyes Kit has an aluminum case that adds value and is designed to attract the attention of shoppers. The lightweight case is easy to carry in a purse, and gives the consumer a sturdy re-usable tin.

Since the brand is sold through mass-market channels where seeing the product is essential, the tin has a clear plastic window. An eye shadow brush, eyeliner, 4 metallic eye shadows, a liquid setting spray in a mini plastic botttle, and an empty aluminum mixing well are all neatly arranged inside the tin, held in place inside a vacuum-form tray. The tin makes it easy to mix together one or more of the eye shadows with the setting spray, and then apply, even on-the-go. (See BeautyPackaging.com for a slideshow featuring the entire Hard Candy collection.)

Choosing the Right Material for a Design

Metal, as well as metallic components, often give fragrance packaging a chic, stylish look. It’s important to choose the right type of metal, suppliers say, and know when metallized plastic is the better option.

Capstone Manufacturing is one supplier that uses metal, as well as other materials—letting the design be the guide. “We strive to make material and process choices in ways that best suit our customer’s objectives and the required functionality of the design,” says Lynch. “We continue to see great interest in materials like zamac that give a heavier, more luxurious feel to caps, compacts, plaques and similar items, but we often combine metals with metallized ABS and polypropylene to enhance the design,” he adds.

The new fragrance Tory Burch Just Like Heaven features the brand’s signature cap design, which debuted on the brand’s first fragrance, Tory Burch Eau de Parfum in 2013. The gold cap is instantly recognizable and may have been a challenge if it were made entirely from metal. It is metallized plastic, and features a fretwork design inspired by ornamental, hand-carved wood-work.

Burch says the elegant cap and bottle design were inspired by her mom’s bedroom vanity, and the classic perfume bottles and atomizers she displayed on top of it. The cap’s fretwork-inspired look is an important design element to the brand, and in Burch’s life. Burch remembers the look on a pair of Chinese Chippendale chairs in her childhood home, which also inspired the look of the brass details at the Tory Burch Madison Avenue flagship store.

Burch states, “I have always been inspired by my parents. Fretwork was very much a part of their design sensibility. It was a part of their vernacular, and now it’s become a signature of the brand, and the perfect accent for the fragrance.”

TNT Global Manufacturing produced a plaque for Valentino Absolu Eau de Parfum, and it is made using brass. The embossed gold electroplated brass plate is affixed to the front of the chic glass bottle. “Brass was the preferred material, as it offers rigidity and prevents deformation,” the supplier explains. “Furthermore, it’s malleability helps achieve a sharp brand mark,” the company states.

The corners of the plate feature small studs, which were a challenge to create due to their size. TNT Global also had to come up with a way to avoid the hanging marks that often occur during the electroplating process, and the supplier developed a process to achieve this.

TNT Global designs, develops and manufactures all types of metal, as well as plastic components, and the team says it takes pride in being able to technically execute and engineer a designer’s vision.

Creating ‘Gun-Metal’

Just about any product will look more luxe in metal, or with a metallized finish—even a brow gel, especially when it is in a custom color. Hourglass Cosmetics worked with Compax to create a specific gun-metal brown for its Brow Gel. The bottle is covered in an anodized aluminum overshell. “The color was not easy to achieve,” says Santos. “This package is also decorated using a shiny gold metallic finish that is achieved by hot-stamp foil,” Santos says.

Color-matching an injection-molded plastic component is usually simple, but anodizing aluminum can be more challenging. “This project required manufacturing different components in various places. Trying to match a brown gun-metal color between three factories in two different countries was not an easy task,” says Santos.

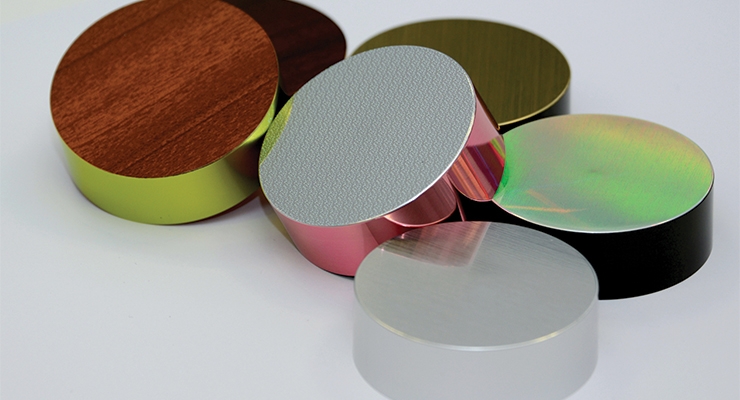

Compax has a primary manufacturing partner in China that has recently built a new state-of-the-art facility, with its own aluminum and anodizing factories. “The new facility also has four vacuum metallizing chambers. By bringing everything in-house, we’re able to get our customers to market faster,” adds Santos.

Combining Metals & Textures

One way to add visual interest—whether it is anodized metal or a metallized package—is to use a textured decoration. “A matte finish with one small part that is textured will add interest, since that part will refract light and catch the eye,” says Steven Rusch, vice president of marketing, Anomatic. “Many of our customers are requesting metallic effects to enhance a package,” he adds.

Anomatic’s team has recently worked on projects for a number of mascara brands, creating metallized bottles with secondary decorations. “We’re hearing requests for matte finishes combined with different types of textures, and we have been working on unique ways to combine various technologies,” Rusch says. Anomatic offers different textures that are created using secondary processes such as tumbling. “We can also create different looks during the metallizing process, using different techniques, such as stippling,” Rusch explains.

Anomatic has the advantage of having in-house machinery, and the company says they are known as color experts in anodizing due to their ability to match metal components with metallized finishes. “We have the tightest tolerances, and can also achieve any color in metal, which is a capability that brands appreciate,” says Rusch. We are making a significant investment in equipment this year,” he adds.

Metallized Gradients & Translucent Finishes

A metallized decoration can transform a glass bottle, and it is especially useful for a brand that uses the same bottle shape for different fragrances in a collection. Decotech recently worked on a project for a prestige fragrance. “We did a custom metallized gold. It began as solid gold at the base and gradually transitioned to translucent gold, then into amber at the top,” says Decotech’s Engel. “The development and production process was complicated, but it turned out to be one of the most beautiful bottles that we have seen in a long time,” he says.

Decotech is one of the few decorators in the world, and the only in the U.S., to offer true metallized gradients, translucent metallized finishes and multi-color metallized looks on glass and plastic bottles or jars, according to Engel. “Many of these types of looks are not achievable with traditional vacuum metallization or sputtering, which only offer solid, opaque colors,” Engel says.

Decotech’s liquid metallization technology offers several advantages. “It helps to smooth over and hide many common glass defects, which eliminates the need and extra expense of heavily sorting or fire-polishing,” Engel says. “That is a unique characteristic of our technology,” he adds.

An Alternative to Metallizing

One alternative to metallizing plastic is to use full-surface hot-stamping, which is a decoration that Peyer-America offers. “The benefit of this technique is the ability to use various colors on one closure,” says Waxgiser. ”We’re the only supplier in the world, that I’m aware of, that can do a full-foil cap. This technique offers the same look as metallization, but it is lightweight, and offers fast turnaround times” he says.

Peyer-America is also launching a new reflective foil that has the clarity of a mirror. Waxgiser says it took six months for the company’s technical team to develop it. It comes in chrome and black, and the company’s team will begin to show it to brands this month.

A Sleek Metal Compact Shines

Metal was the material of choice for a compact that “starred” in The Cosmopack Factory’s live demonstration this year at Cosmoprof Bologna. The process of compacting a pressed powder, Powderful, was demonstrated using HCP’s Magnum Pressed Powder Compact. “Our premium stock Magnum range presents the allure of metal combined with strong shapes, sleek contours, and unique decoration possibilities. The unique “soft close” magnetic opening and closing feature, and its full size glass mirror in the lid, add an extra luxurious feel,” according to HCP.

The compact was fitted with a specially designed full-size brush by Pennellifaro. Vetraco provided a geometric insert and Ancorotti Cosmetics filled it with the all-in-one product, which can be used as a face illuminator, eyeshadow, blush, and lipstick.

HCP decorated the sleek, luxurious metal compact using three different colors. The gold compact has a glossy gold anodized cover and base, with black inner parts. The lid is decorated with the name “Powderful” in a shiny black typographic design. The black compact has a shiny black anodized finish on the cover and base, with a metallic silver logo on the lid. The silver compact has a high-shine silver anodized cover and base, paired with a crisp, white graphic logo. The mirrors inside each compact are decorated with the names of all the supplier partners that worked on the project.

A Modern Metal Lipstick

Metal and metallized looks are a classic for lipstick packaging, but World Wide Packaging (WWP) has a new design that looks modern. The supplier’s new Skinny Lip is part of its new “on the go” product line developed by WWP’s design team. The line offers ergonomic appeal, as well as key functional attributes.

The Skinny Lip features WWP’s new easy-glide mechanism, an aluminum outer shell, and an airtight sealing feature to support natural bullet materials.

Sleek Looks for Skincare

When skincare packaging looks metallic, it can help convey a ‘serious’ look, which may send a subliminal message to consumers about the product’s efficacy, some package designers say. “Metallic finishes and effects suggest luxury, quality, product performance—and beauty,” says API Group’s Peters.

API Group’s development team recently worked with a California-based skincare brand to supply various packaging effects and finishes that could reflect the product and brand’s personality. “By referencing our beautiful metallic portfolio and taking inspiration from our 2018/19 trends, we supplied our high-shine water effect samples to portray hydration,” Peters says.

Virospack says its dropper packs, which are widely used for skincare serums, are usually paired metal and metallized components for a premium look. “Classic droppers with metallic caps or caps that have a metal shell are common, and they are often decorated with matte screen printing,” says Virospack’s Porras. “The number of units that we manufacture each year that are metallized, or with metal shell caps, is much higher than plastic caps and other materials,” she says. “Metallic buttons, combined with push-button droppers decorated with a matte finish are also a popular combination recently,” she adds.

Virospack’s metallized bulbs are often requested for skincare products, and can be color-matched to a brand’s specifications. “We developed a process two years ago that allows us to metalize rubber bulbs without causing a loss of elasticity,” Porras says.

Porras advises brand marketers to remember that colors will not look the same on different materials, such as a rubber bulb, plastic cap, and glass bottle. “Often, many adjustments are necessary when creating metallic looks. Our advantage is that we manufacture and decorate every component in our own facilities, so we maintain control over these processes,” Porras explains.

Virospack recently provided a dropper for Josie Maran’s Argan Reserve serum bottle. The package’s champagne gold color had to match on different materials—the bottle and cap’s metal shell, and the metallized rubber bulb. “It wasn’t easy, but the result is spectacular, eye-catching, and luxurious,” Porras says.

Quality control issues often arise as well, due to the compatibility of product formulations with metallic inks. “Skincare formulas and ingredients are becoming increasingly aggressive, so we have had to incorporate new inks and new compositions in our metallizing, painting, and screen printing sections to ensure compatibility. Our ability to do this is one skill that differentiates us from other suppliers,” Porras adds.

Making Cartons Shine Bright

Jeffree Star Cosmetics worked with Impress Communications to create a box for the makeup product, 24 Karat Gold, so the box had to shine. It was made using gold foil board. “We have worked with Jeffree and his team to develop some cutting-edge cartons,” says Impress Communications’ Romine.

Jeffree Star Cosmetics’ Platinum Ice eye shadow collection features cartons made with foil board and decorated with hot-stamping. Embossing a custom foil board created a brushed texture. “It is almost like an old-school linen paper finish,” says Romine.

Romine says his team at Impress tinted the foil board with a transparent color to achieve the right “icy” shade of light blue, which allowed the board’s shimmer to pop through. “We added two hits of white ink, and black for the bar code, all in one pass on our press. In finishing, we added a specially ordered Kurz foil to get the logo to ‘scream,’ ” he explains.

Tips for Working With Foils and Coatings

The way that a foil board is printed—and the type of machinery used—will make all the difference in the end result, according to Romine. Impress offers several unique pearlized, raised, and sparkle coatings. The company has its own in-house ink lab, to mix inks and coatings for each product.

Traditional inks will never dry completely on foil or synthetics, Romine notes. “Even if you put a hard coating on top, the inks underneath will remain wet. I am sure everyone reading this has seen their share of packaging, even on traditional stock, where the inks have been smeared or rubbed off,” he says.

Romine explains that he feels one of the reasons that foil board is under-utilized is that it should be printed on a UV or H-UV press. “Older, oil-based technology does not yield the best result,” he says. Impress has three Komori presses that run UV and H-UV. “Our flagship 8-color press is the first of its kind. It was custom built by Komori to our specifications, after every other press manufacturer said it could not be done.”

Using UV inks and lamps allow inks to dry immediately, so layering is possible. “If you want to print using a 4-color process on foil, or if you want your bar code to read properly, it is best to put two coats of white down underneath for hold out. If you want to do push/pull or gloss dull effects, you must be able to dry trap your inks and coatings. We have developed several proprietary formulas and methods to accomplish this.”

Another benefit of UV and H-UV is the minimal amount of out-gassing VOC’s into the environment. “We also run our presses without any spray powders. Most of our clients are looking for the “greenest” method of producing their materials, and this is a huge benefit,” Romine explains.

Tapematic USA also offers “green” machinery, for coatings and metallization. “Our system is the most environmentally friendly process for the metallic decoration of closures and caps,” says Tony Denning, president, Tapematic USA. “It has spray on-demand features, a load-lock vacuum chamber, and requires low power consumption, just to name a few benefits,” Denning says. “We offer the most environmentally friendly solution for the coating and metallization of beauty packages,” he adds.

Denning says he is seeing the industry move toward utilizing in-line decorating processes for caps and closures. “Our system is 100% an in-line process, offering in-feed material handling, cleaning, pre-treatment, base coating, metallization, top coating, in-line decoration, quality inspection, and automated offloading,” he says.

Advantages & Advances in Cold Foil Technology

More brands are creating metallic looks using cold foil decoration, some suppliers say. “Cold foil has the ability to create different effects, depending on the substrate it is applied to. Since it is applied, not stamped, it takes on the look of the substrate and creates striking visuals in foil,” says Eagle Systems’ Manning.

Eagle Systems is a machine manufacturer that provides equipment to printers. “We have been building foil machinery for over 35 years. Since this is all we build, our knowledge of hot foiling and cold foiling is extensive,” Manning says.

Up until 2016, cold foil was only used on coated stock, according to Manning. “Since then, Eagle Systems has created the process to apply cold foil to uncoated stock, which many brands now use,” she explains.

Eagle Systems created FoilCURE, which is still in the testing stage. “It is a very shiny cold foil,” says Manning. “We often listen to what printers say their customers are looking for and work with them to achieve the desired look,” she adds.

Recent advances in film and cold foil technology have expanded what is possible for brand managers and designers in the beauty industry, according to Bob Almer, vice president of sales, Americas, and global key accounts, API Group.

API developed a product called TA cold foil. “It is a metallic technology that offers intricate detailing, which makes it ideal for the small size of most beauty packages,” Almer says. “It is our most advanced cold foil to date and offers pack designers and printers exceptionally fine detail and the capability to cover large solid areas, as well as outstanding over-printability, meaning there is no limit to the range of colors and effects they can produce,” he explains.

API offers an end-to-end product and service capability across its foils and holographics. “Together with our design knowledge, particularly with the recent launch of our Holonique Boutique service, which showcases the capabilities and effects of our holographic foils, we are helping to make these techniques more accessible to brands,” says Almer.

Final Tips

Eagle Systems’ Manning recalls a project for a whitening toothpaste company, and the challenges that arose. “Their cartons were metallized board, overprinted with opaque white,” she says. Since cold foil is placed only where needed, the white of the board was left for printing—or blank, but, it looked gray in certain areas, which was obviously a huge issue. Manning jokes, “When selling ‘white,’ remember to show white.”

Impress Communications’ Romine says that no matter how tricky metallic substrates can be to use, inks and foils can really add a “wow” factor to a package. Romine advises, “Think about these materials differently than more traditional material and find a great partner to work with, because when a metallic look is properly executed, the reward far outweighs the effort put into development.”