Jamie Matusow, Editor-in-Chief11.01.18

Both Indie and global brand representatives attended ADF&PCD New York 2018 at the Altman Building & Metropolitan Pavilion in Manhattan, September 5-6, just a couple of days after Labor Day. ADF&PCD New York is billed as North and South America’s only dedicated event for the aerosol, dispensing, perfume and cosmetic packaging and design community.

Show management put an emphasis on Indies this year with a number of specially designed programs, showcasing the increasing demand for more sophisticated and innovative packaging and the need to compete with the larger brands. Organizers also strived to create an upbeat environment complete with music piped in and an Indie designer fashion show with models who paraded through the exhibit areas on Day 1.

Alli McEntyre-Gaharan, event director of the ADF&PCD Portfolio told Beauty Packaging (watch McEntyre-Gaharan speak to us in this video) the show was a huge success, with the aerosol and packaging portions equally divided among this year’s 130 exhibitors. Next year, however, the show will move to a later date—September 17-18, 2019—and plans are to take over the second floor of the Altman Building to expand the Aerosol and Dispensing portion of the show.

With content in mind, ADF&PCD New York also ran a very popular two-day educational seminar program. Sustainability was the major focus for 2018, with sessions packed with visitors eager to know more about this overriding topic of interest.

On the Show Floor

A walk around the PCD portion of the show floor revealed lots of first-time New York packaging exhibitors, with representation from Asia, Croatia, Italy and France, and with many companies selling direct to the U.S. Beauty Packaging spoke with a couple of suppliers positioned as disrupters in dispensing and decorative solutions. There was also talk of tariffs in the air…

Aerosol Alternative

MiniMist, from Alternative Packaging Solutions drew interest for what it calls “a new dispensing system to disrupt the aerosol industry.” Robert Tate, chief operating officer, explained how it uses a very fine spring rather than a traditional dispensing system—so “you get pure product, nothing else.” Press down for 4-5 seconds, and spray in any orientation.

Tate said MiniMist produces a continuous spray without any chemical propellants, adding, “Its innovative construction remains cost competitive with a significantly lower carbon footprint than aerosols.” Further, Tate says MiniMist’s spray characteristics and customizable design allow for almost any packaging shape and material to suit different brands and product categories.

Taking Stock in Glass

While custom designs were certainly available, there was an emphasis on stock packaging.

ABA Packaging showcased a complete line of simple shaped stock line glass bottles which include roll-on’s and treatment bottles (see a few of ABA's bottles in this video). Liana Marchese, account associate, ABA Packaging, showed Beauty Packaging five new lines of high-end fragrance glass available in low quantities and especially desirable for Indie brands, in sizes ranging from 50-100ml and available in 6-8 weeks. An assortment of suitable pumps and various decorative options is also available.

At New High Glass, Alonso Herrerra told Beauty Packaging they are moving toward “a lot more green choices,” such as using recyclable materials including PE green and plastic from sugarcane. Herrerra said Europe is so far ahead of the U.S. in this way, “but they also have superior recycling capabilities and facilities.” New High offers jars made of 60-90% recycled glass, which in some cases, have a green tint. A number of attractive glass bottles featured wood cap combos.

Hangzhou XINLI plastic & Hardware Co., Ltd, which specializes in perfume packaging, offered a selection of bottles and caps and deco for fragrance, plastic, glass, metal and wood.

Plastics Plus

Made in the USA and low MOQs were special points of interest at Colt’s Plastics, where Mark Egan, vice president, global sales and marketing, told Beauty Packaging that caps, jars and more, can be decorated and delivered in 6-8 weeks. (Egan shows a Colt's jar in this video.)

With talk of potential tariffs on goods from China, Egan said they had seen increased interest from brands looking for U.S.-based manufacturers. Located in Dayville, CT, the supplier offers elegant deco finishing with no tooling investment. Low MOQs stand at 1,000 pieces. Turnaround is 6-8 weeks. Egan says specialties include 3ml-16oz heavy-wall PETG recyclable jars and urea-based biodegradable caps.

Bridging a variety of materials, from glass to plastics, RS Group, represented by Maggie Wedemeyer, Benevolent Beauty, Inc.—a seasoned beauty professional who does private label packaging projects for brands including Anthropologie—said: “Trump’s new tariffs—adding a nickel to a dime per piece for export tax is not going to affect purchases.” She told Beauty Packaging, “You can economically source glass, caps, tubes, pumps—all with low MOQs.”

The 10-year-old company offered stock packaging “in different shapes than we’ve seen before,” said Wedemeyer. They also have the ability to do custom in 3-14 months. A pretty stock cream jar was available in 15-, 30-, 50- and 100g sizes. A serum and oil dropper bottle in glass is a new design, available in 10- 15- 30- and 60ml.

APR Packaging highlighted a patented concealed nozzle for airless bottles (see APR's concealed nozzle here). The locking feature makes it especially convenient for on-the-go use. Available for bottles in sizes 15-, 30-, and 50ml, it includes a locking feature; just turn and click, and the actuator pops out to prevent leakage and spillage. Multiple colors and decorative options are available.

Started in 1991, Ever-Rich Fountain, from Taiwan, featured plastic injection airless bottles in PP, PET and double wall, as well as cream jars. A new offering was a two-component bi-injection cream jar; droppers and pumps are also available. Decorative options include ink printing, hot stamping, spray coating, water transfer and digital printing. Double Wall Airless bottles are available in 15-, 30- and 50ml; the outer bottle is SAN, the inner, PP. Large and mini sizes are also available.

Strazaplastika DD, is a plastic tube manufacturer from Croatia. The 60-year old company offers two complete lines, and produces more than 25 million tubes per year. They offer tubes, caps and deco, including silkscreen and hot stamp.

Printing & Decorating Details

Sun Chemical highlighted their expertise in metal decorating, which can be done on any material. They were showing screen inks that can be done on metal, glass and plastic. The supplier also offers brand protection features integrated into the inks. Textured and screen effects are also available.

Val Laquage is a French company, specializing in decorating on glass bottles with techniques including screen printing, hot stamping and automatic coating. The Group, comprised of three companies, provides a full range of decoration—coating, silk-screening, hot stamping and pad printing—on glass products for markets including cosmetics, perfumery, pharmacy and spirits. All companies take an eco-responsible approach and 100% of their products are Made in France. The supplier exhibited bottles for luxe brands including Creed and Miu Miu.

Iggesund was offering a new metal substrate for use on digital press printing, which laminates metal film to Invercote, calling it MetalPrint. Metalprint Digital was developed in close cooperation with HP Indigo. Invercote Metalprint Digital is adopted to be run without a priming step in the HP Indigo one shot mode on 10 000 and 12 000 machines. The first grade to be produced is 300gsm (13.6 pt) Invercote G + METPET, which is the standard product; it will be available next May.

Digital direct-to-shape decoration for mass production was a highlight at Velox Ltd., which offers end-to-end, high-quality printing for both long and short runs of cylindrical containers such as plastic and aluminum tubes, aerosol cans, laminated tubes and more.

According to Velox, this solution is the first “to expand digital processes beyond short runs to offer a compelling replacement for mass-production analog decoration.” By enabling decoration at full production speed, along with “a dramatic value leap in the form of unique printing features, highly flexible decoration capabilities, and mass production economics,” Velox says it “opens a new world of operational and marketing opportunities for converters and brand owners.” The supplier’s proprietary DTS-Inkjet technology is based on uniquely formulated inks and dedicated deposition architecture, and “introduces an entirely new approach to digital printing that is poised to disrupt the packaging decoration market.”

Turnkey Development

Full service packaging options were a popular topic at ADF&PCD as elsewhere.

At Essentia, Cinzia Bessi, sales and marketing director, showed Beauty Packaging some of the projects they had recently completed. The turnkey services company works for private label brands in categories including makeup, fragrance and accessories. The Italian supplier just opened an office in Shanghai. Offers include digitally connected packaging, eco-friendly packaging, packaging concepts and ready-to-go formulas. One cute product is a magnetic lipstick package with a removable mirror that clips on.

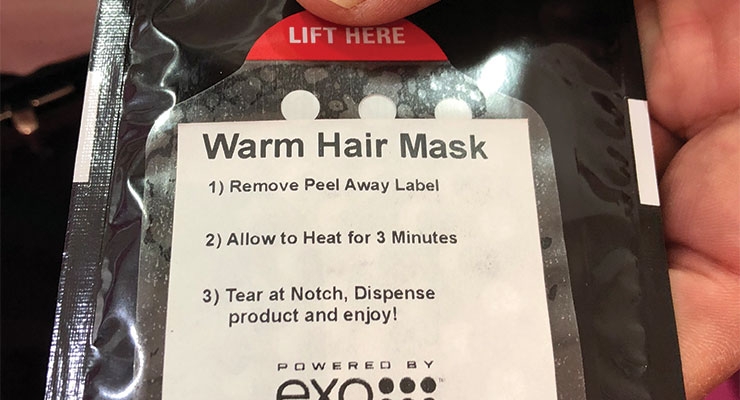

A New Heat & Dose System was available at Klocke, a contract packager specializing in unit dose packages. The Heat & Dose system, powered by Exothermix, is available in a sachet or blister format. It can also be sold at retail. The consumer can safely heat products prior to application—so it’s ideal for products from skincare to hair care, and also face masks.

Eco Material Highlights

At Quadpack Group, wood made a strong statement as a sustainable material option for cosmetics, skincare and fragrance packaging (see video at beautypackaging.com).

Christin Cupo, client account manager, Quadpack Group, told Beauty Packaging (in this video): “Wood is a trendy material that’s on an upswing especially for Indies looking for sustainability and an immediate ‘green’ message.” Quadpack Group’s Technotraf Wood Packaging factory near Barcelona specializes in the renewable resource, and plants six trees for every one taken down. Quadpack is now partnering with East Hill Industries as a distributor. In the first part of 2019, East Hill will be inventorying a variety of full packs from Quadpack.

One beautiful wood product at Quadpack combined sophistication and environmentally friendly material in a compact crafted from wood sourced from sustainable forests certified by the PEFC. The wooden compact is hewn from maple wood for an exceptionally smooth finish.

At ADF& PCD, Corpack highlighted their sustainable cork blend called Sughera (see Sughera in this video), which can be substituted for plastic components, according to Jean Paul Corbeil, managing director.

With a natural look and feel, Sughera is described as “a revolutionary material consisting of a synthetic rubber-blend mixed with ground pieces of natural cork. For the first time, a micro-agglomerated natural cork is injection molded and formed without using glue.”

Aside from its special composition, connecting nature with technology, the distinctive features of Sughera are a good resistance to various elements and versatility in application. This new material (70% cork, 30% rubber-blend) uses less petroleum-based materials, while giving the component a natural look and feel. Components can be made in a variety of colors. The material has now been introduced in a wide range of cosmetic packaging.