Marie Redding, Senior Editor12.13.18

Whether a brand is launching a new makeup palette, lipstick, skin cream or fragrance, all packages require decorating—and most decorative effects aren’t as simple to achieve as they look. A combination of decorating processes and specialized techniques are usually needed, whether the deco is minimal or ornate.

Deciding which types of decorating processes will achieve the look your team envisions is often a challenge, but working with the right supplier partners often makes all the difference.

“We welcome a challenge and encourage close collaboration with our customers to achieve a desired look,” says John Schofield, owner of Screentech/Sprayetech. Many of Screentech/Sprayetech’s customers ask for advice about the best ways to bring a designer’s vision to market.

Mark Bellard, president/owner, Siloa, says the brands he works with usually know the type of look they want to create, but often need advice on the best way to achieve it. “When a customer comes to us with just an idea, the dialogue begins, a conversation about all the possibilities,” he says. Siloa offers silk screening, lithography, offset, pad printing, hot stamping, anodizing, electroplating and vacuum metallizing—and various spray finishing techniques—and often advises brands on which techniques are best suited for a project.

At Anomatic, Steve Rusch, vice president marketing & business development, says one challenge he often sees is the difficulty visualizing the different types of looks that can be achieved using various decorating techniques. “Brands—as well as the supplier partners we work with—don’t often consider all the ways to combine processes; different combinations will produce truly custom effects,” he says. “A straightforward approach is always easier, but never the most innovative. We love to challenge our customers to come up with truly unique designs, to elevate a brand,” he adds.

The team at Plexus agrees. Choosing a decorating process can be a complex process. When the team was deciding which decorating techniques to use for its skincare brand Joyome (shown and described in more detail below), settling on a strategy to execute its vision was slightly more complicated than anticipated. Commenting on the package development process, Garren Lofgreen, art director, Plexus Worldwide, says, “A collaborative effort ensued with many great concepts and ideas brought to the table—in a whirlwind of fast timelines.”

When a brand is facing time constraints or a small company needs low MOQs, digital printing is often an ideal decoration to choose, some suppliers say. SamHwa USA’s country manager, Philip Cho, says, “Digital printing has become much more popular in recent years. The process offers lower MOQs, which gives more brands the ability to create customized looks for limited edition packages, such as holiday collections.”

Siloa’s Bellard also mentions digital printing, saying, “Digital printing is becoming a go-to solution for certain projects. No screens, no plates—just direct computerized printing,” he says. “We also see more brands request laser engraving as well,” he adds.

Decotech offers digital printing, as well as numerous other decorating processes. “We have more items on the market decorated with digital printing than any other decorator,” says Richard Engel, president/COO, Decotech. “The combinations of the wide array of techniques that we offer are what enables us to produce designs that aren’t seen anywhere else.”

Decotech’s capabilities include screen printing, pad printing, metallization, hot stamping, spray coating, labeling, masking, decaling, and more, and all are done under one roof.

Chiara Badavelli, marketing manager, Premi Beauty Industries, says the most often requested decorations are inkjet printing and lacquering processes, with gradient effects. “Inkjet 3D is one of our newest and most innovative techniques. Brands always request solutions to ensure a product stands out and looks unique, and we are happy to fulfill any challenge,” she says.

Many brands looking for eco-friendly solutions often work with Screentech/Sprayetech. “We are most known for our water-based environmentally-friendly spray, as well as our hot-stamping capabilities, says Schofield. “We offer solutions for all types of customers—from major companies to Indie brands,” he says. The supplier’s capabilities include screen printing, tampo printing, labeling and gluing.

Decorated to Match the Makeup

Before deciding on a decorating process, however, the first step is for a brand’s marketing team to decide on the colors, materials, and design elements that will best tell a brand’s story, or convey a specific message about a product. Sometimes the most literal designs work, brilliantly.

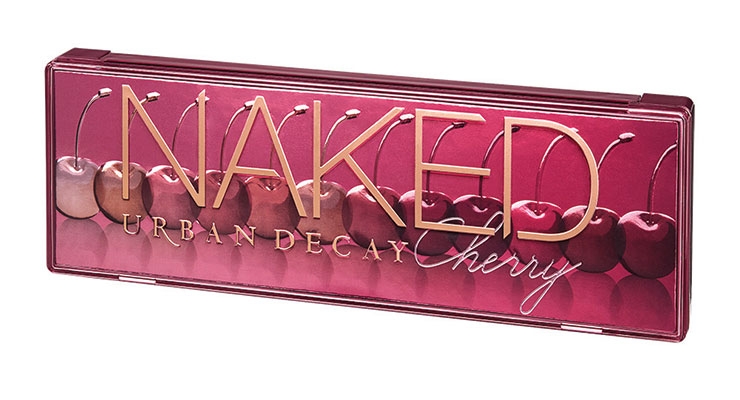

Urban Decay recently launched a new version of its iconic Naked Palette, Naked Cherry. Everything about the new palette’s decoration is linked to the name—and to the 12 cherry-hued eyeshadow colors inside, which range from creamy ivory and shimmering rose gold to a deep mauve and metallic burgundy.

The crimson palette features a foil deco, and images of metallic cherries on its lid. The cherries are printed on a foil card, which sits underneath the palette’s tinted plastic outer lid.

The color of each cherry corresponds to an eyeshadow in the palette, and they are all lined up in a row, in the same order as the makeup. The palette’s base is decorated with a metallic spray, and its light pink carton is printed with a pop-art-style cherry pattern.

Why choose “cherries” as an inspiration for the name, makeup colors, and decoration? Wende Zomnir, chief creative officer and founding partner, Urban Decay, says, “I always screenshot looks I like…I realized so many of my favorite eyeshadow looks were ink and berry tones, in a ‘naked’ neutral way…When we saw them all together, the name ‘Cherry’ was obvious.”

Enter the Wu Tang…And Milk Makeup

Milk Makeup’s latest launch, on November 1, incorporates several stunning design elements to tell the story about its new, and surprising, collaboration—a lipstick collection developed with the iconic hip-hop group, the Wu-Tang Clan.

The luxe lipstick, is beautifully bold, in “flashy gold and black,” with an ornate, custom-sculpted dragon winding around its barrel. The square, black packaging is a drastic departure from Milk’s signature minimalist modern look, which is usually clear and white.

Kali Perez, product design director, Milk Makeup, says, “We wanted to speak to Wu-Tang’s fascination with Shaolin Kung Fu culture, so we chose to include a dragon on the barrel itself.” The lipstick cap and deluxe boxes are decorated with an original graphic—Wu-Tang’s ubiquitous “W” logo—plus, the Mandarin character for beauty combined with Milk Makeup’s logo. The boxes also feature hidden affirmations.

Milk Makeup’s founder, Mazdack Rassi, adds, “We wanted our first collaboration to be with a seminal icon who moves between culture and music and helped shape a generation. It had to transcend time and culture; it had to be a global idea, but it also had to be ‘New York’ at its roots, because that’s where we’re from.” The launch coincides with the 25-year-anniversary of Wu-Tang’s 1993 debut album, Enter the Wu-Tang (36 Chambers).

Conveying a Message with Color

When a brand adds a new product to an existing product line, its design needs to look “connected” to the brand, and this is often achieved by using color. The team at BioClarity, a plant-based skincare brand, recently launched a new moisturizer, Hydrate. It is in a tube, like the brand’s other products, but rather than a solid color, the team chose to decorate it with an ombré effect.

Melissa Reinking, chief marketing officer, BioClarity, says, “We wanted to visually highlight Hydrate’s specific benefits while keeping it connected to our brand aesthetic. Combining blue and green represents ‘moisturizing’ and our proprietary, chlorophyll hero ingredient, Floralux.”

The tube is injection molded with its base color and then decorated with a spraying process to achieve its ombré look. A silk-screened double leaf symbol, in light green, is a common design element that unites all of the brand’s products. BioClarity is launching in Urban Outfitters stores this month.

Tubes are a popular packaging choice. “Many brands are requesting tubes with pearl pigments,” says Siloa’s Bellard. The supplier offers many packages with low MOQs.

JSN Cosmetic Packaging is known for its expertise in a variety of in-house decorating techniques for tubes. “We have been extremely busy this year, with brands requesting tubes in colors at both ends of the spectrum—muted soft pearls, as well as dark blues and blacks,” says Sandy Nagel, JSN’s co-owner and vice president.

The company recently worked with several brands, decorating tubes with offset printing, silk-screening, and labeling. “We also see an unusually strong demand right now for hot-stamping tubes, in both overall volume and in challenging graphics,” Nagel adds.

While ombré is a design that blends two colors, a gradient effect features darker colors transitioning to lighter hues, and it is a decorating technique that is often requested, suppliers say.

“We have seen a sizable increase in requests for gradient applications,” says Bryce Peacher, marketing manager, APC Packaging. A few of the supplier’s bottles are shown, decorated with a gradient spray and vacuum metallization effects. APC is a go-to source for airless packaging, but can decorate any type of package. The company’s extensive decorating capabilities include silk-screening, offset printing, water and heat-transfer processes, hot-stamping, UV-coating and laser etching.

Decotech’s Engel also says gradient effects are a popular decoration on various types of packages and materials, including glass fragrance bottles. “Among all our decorating techniques, some standout technologies include our spray metallization line—and it can apply true gradient metallized effects,” he says.

The three-dot decoration on Joyome’s bottles have a gradient effect, with colors inspired by a sunrise for the AM Serum, and a sunset for the PM. The circular dots represent “wholeness,” also conveying the skincare formula’s microbiome benefits.

Kelly Pennica, senior designer at Plexus, led the design team that developed the packaging. The square, white plastic bottles look luxe, featuring matte silver metallized collars and actuators. To ensure the unique, three-dot design “popped,” the inside surface of the bottle’s outer chamber was painted white.

Lofgreen, at Plexus Worldwide, says, “We considered different methods to decorate the bottles with the dots, but we ran into numerous restraints, such as seams from labels, limitations in screen printing, and registration issues. In the end, we chose a heat-transfer process. It is a less popular method, but was a perfect solution for us.” Lofgreen adds, “In the end, Kelly and our team came together to create a beautiful bottle that captured the essence of the Joyome brand.”

Anodized Aluminum Conveys Luxury

When a brand wants to ensure a product feels luxe, aluminum is often chosen. Amazing Cosmetics’ new AmazingConcealer Hydrate is in an aluminum package, and it was one of the brand’s more expensive packaging components, according to the brand’s co-founder, Lisa Thurman.

“Our goal with our new concealer was to develop a luxurious formula, so we had to hold the package to a high standard” says Thurman. “We chose aluminum, and wanted it to feel weighty in the hand.” The ultra-creamy formula claims to boost skin’s moisture level while concealing dark circles, “banishing” blemishes, and erasing fine lines.

The package’s hot pink color is Pantone’s “Rhodemine Red,” and is achieved using an anodization process on the aluminum component. “The logo is silk-screened,” says Thurman. “We love the shade—and pink is one of our brand’s colors,” she adds.

Anodizing aluminum is Anomatic Corporation’s main area of expertise, as the company has been driving global innovation in anodized aluminum decorative techniques for more than 50 years. Now, the supplier offers many stock packages in aluminum, and it will expand its stock line in early 2019 with many new options for skincare products.

Anomatic’s Rusch says, “We see an uptick in requests for customizing our stock packages, which gives brands more options to launch new products quickly, while also using decoration to create innovative looks. We are using customizable technologies such as hot foil stamping, gradient finishing, screen printing, embossing, debossing, laser engraving and double-anodizing—plus, a virtually unlimited color palette. Combining processes adds a level of creativity to stock packaging that most suppliers can’t offer.”

Siloa is also skilled in anodizing processes, and often decorates aluminum packages using various types, including double-anodizing. “This process allows us to combine two metallic colors on one aluminum component, and it can create striking effects,” says Siloa’s Bellard.

Siloa’s electrophoretic coating can be applied clear or any color, and the durable, high-quality finish is ideal for most types of metal packaging, including stamped aluminum and plated zamac. “It brightens the component and adds the perception of value. It also offers stunning results on epoxy-filled components with graphic elements,” says Bellard.

Combining Glass and Metal

When different materials are combined, along with different decorating processes, the result can be surprising—and beautiful. Premi Beauty Industries’ Badavelli says the company’s expertise lies in combining various specialized decorating techniques on glass bottles and jars.

Badavelli explains, “Our new type of decorating technology provides a way to reproduce artwork on a package with very fine graphic details, for a custom look.” The supplier recently worked with a fragrance brand to decorate a cylindrical glass bottle, which is shown, using a combination of lacquering, metallization and laser-etching processes.

Badavelli explains, “We have a multi-material and multi-technology know–how. Our new technologies make it possible to create infinite effects and colors—with no limits to creativity.”

Innovations in Metallizing, Glitter Finishes and More

There are many suppliers that are offering new ways to create unique looks, on all types of packaging—especially plastic components, which can be metallized to look luxe. Anomatic recently introduced an innovative metallization process for caps, and the process can be done on hinged and dispensing closures. The supplier also introduced two new decorative effect finishes.

Anomatic’s Mika finish features metallic flecks. “We can vary Mika’s size, from a fine-spec glitter to a larger confetti size, to create a range of unique effects,” says Rusch. Another new finish, Iridescent, appears to sparkle and change colors depending on the angle of the light. “Both finishes can be combined with a metallization process for hinged closures and applied to a variety of substrates including plastics and anodized aluminum,” says Rusch.

SamHwa offers a decoration that can make plastic resemble leather, and another that provides a sparkling finish. “These work well for luxury products,” says Philip Cho, country manager, SamHwa. The supplier recently worked with L’Oréal to decorate YSL compacts with high-end finishes, including one that looks like sparkling glitter.

SamHwa has fully vertical-integrated production capabilities in-house, and offers metallization, spray coating, digital printing, laser etching, silkscreening and more. “Our many locations around the world enable us to work with many global luxury brands,” says Cho.

Tapematic USA, a machinery supplier, offers equipment that provides suppliers with unique decorating capabilities that are often helpful and time-saving. The company’s PST line is fully-automated, and used to coat and metallize packages; it can accommodate various shapes. It is often used to decorate lipstick and mascara packages, as well as closures.

Tony Denning, president, Tapematic, says, “Our PST line includes various modules, including pre-treatment, UV base coat, and metallization, which can be configured for all types of in-line decoration processes. “Depending on where the module is placed, the decoration will appear different,” Denning says. One benefit of Tapematic’s in-line decoration module is that it can remove a package’s metallic layer to reveal its base coat, and the color of the plastic underneath, which can then be colored. “We do this process in-line, and then a top coat is applied. Our machinery ensures that a finished product meets a brand’s technical requirements,” Denning says.

Siloa’s Bellard says using the right machinery and equipment are crucial. “The equipment is key to developing the processes that will fulfill a designer’s intent and ensure a decoration replicates what they have imagined.” Bellard says, “Equipment usually has to be adapted and modified to meet the challenges a project poses, and this often leads to a ‘magical’ cooperation among various teams, including engineering and design.”

In the End, Compatibility Is Key

Suppliers say there is often more than one way to execute a designer’s vision, but by choosing the best decorating processes for a specific material, you’ll achieve a better end result.

“There are many techniques that will achieve similar design objectives, so decisions are often based on cost, quantity and component type,” says Siloa’s Bellard. “Most important, however, is product compatibility, and that must be considered first,” he says.

No matter which type of decorating method you choose, don’t cut corners on compatibility testing, and choose suppliers based on their experience working with similar products, advises Bellard. Choosing a supplier that can execute a designer’s vision is key, but in the end, it is perhaps more important to know that the decoration won’t rub off a bottle, smudge on a carton, or fade in the sunlight.