Jamie Matusow, Editor-in-Chief12.13.18

It’s unlikely that rocker Rod Stewart would have envisioned back in 1971 just how much the title of his hit song “Every Picture Tells a Story” would resonate with today’s consumers, many of whom rely on a single image to make a purchasing decision or seek more information about a product they’ve glimpsed on social media.

Never has a first impression been more important when it comes to retail success—or sharing something cool on a social feed—and brands and suppliers are increasingly keeping this in mind when innovating products and packaging. A great visual can make a consumer want a product before they even know what’s inside.

Many cosmetic industry suppliers say the importance of visuals and the influence of social media are changing the whole packaging design and development process.

Bruno Lebeault, marketing director, North America, Viva, says Instagram is more and more influential, “especially for Indie brands where any influential blogger can launch a new product ‘overnight.’”

“Instagram is very influential,” says Kevin Jean, creative innovation lead for World Wide Packaging (WWP). “Customers now are sharing their collection of beauty and skincare collections and hash tagging #shelfie #topshelfie. Brands today are constantly making sure that their package is ‘Instagram-able.’ ”

At HCP UK, Christelle Godefroit, product manager, tells Beauty Packaging: “As consumers increasingly research their next beauty buy through Instagram and YouTube tutorials, the aesthetic and functionality of the product and its packaging are demonstrated prior to purchase—so it must make a good impression. The buzz that prominent beauty influencers can create around a favored new launch is invaluable to brands.”

Which packaging elements attract the most attention?

“Much of today’s innovation presents itself through artwork, finishes and shapes. This is the Instagram factor,” says Kristen O’Connell, director of marketing and product development at Roberts Beauty. “A photogenic package will be selected over a traditional package, no matter the performance—just to get that perfect photo in your feed. If the innovative aspect can only be seen during the use of the product, the significance of the unique properties of the package can get lost if they don’t communicate through the photograph,” says O’Connell.

Roberts Beauty recently worked closely with the Smashbox team to re-vamp and re-launch their Always On Liquid Eyeliner. The packaging was inspired by a calligraphy pen with ergonomic finger notches for extra control during application. The precision tip applicator allows the consumer to get close to the lash line and easily shape the cat-eye wing. One look at the package convinces you it’s “a must-have”—and you’ll want to share your resulting perfectly drawn lines with your friends.

Another innovative eye product, this one for brows, recently launched from Benefit. The design for the fun and functional 4-in-1 Brow Contour Pro tool revitalizes the multi-ink writing pens that were a novelty years ago. Now the red, blue and green inks have been swapped with a range of shades to fill, define and highlight your way to beautiful brows. One pen, four settings.

“Branding and packaging matter now more than ever in a saturated marketplace where trends don’t last that long,” says Sheherazade Chamlou, vice president of sales & marketing at Verescence North America “Instagram has become an eye-catching home for all up-and-coming brands that might otherwise have little or no way of reaching the public eye. Beauty brands under the spell of social media are tailoring their packaging to make it Instagram-worthy to catch the eye of shoppers. The right packaging can boost brand awareness and tell the brand’s story at a glance.”

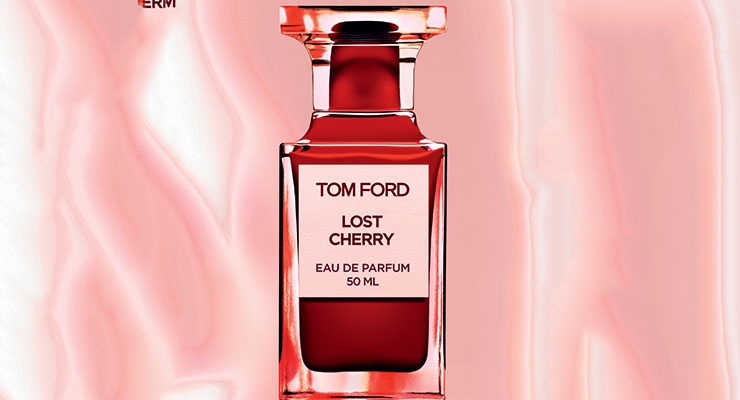

The 50ml Lost Cherry fragrance bottle that Verescence manufactured for Tom Ford Beauty ticks all the boxes for innovation and for being Instagram-able.

For this edition, the interior of the glass bottle is color-coated thanks to Verescence’s innovation, COLOR’in, an exclusive patented technology that’s compatible with fragrance, so no inside pouch is needed.

Chamlou tells Beauty Packaging: “What is unique with this process is that it enhances the interior glass distribution of the bottle and you can’t see the declining level of the perfume. It is the same at the beginning as it is at the end. And at the end it can be considered as an art piece.”

According to the brand, the packaging for the Tom Ford Lost Cherry presentation “evokes the scent’s dichotomy of sweet and dark. The luscious cherry red bottle in a 50ml is inspired by a sleek chess piece. It displays a red-on-palest pink label on the front.”

A Different Approach

Isaure de La Noue, sales manager and co-founder, Metapack, says that up to now, Instagram has not been part of their creative process, as they continue to present innovations “in the traditional methods.” Most effective, she says, “is one-on-one with our most valued customers, where we have the opportunity to share innovations privately. We also continue to present innovation at industry shows and events and through industry publications.

Recently, the luxury supplier created a pendant fragrance roll-on holder, called The Piece, which they did for a Swedish brand called NCP. It’s made in stainless steel, refillable and gold colored by PVD. “The concept is innovative as well as the way we colored it,” explains de La Noue. “This is a new way to have your perfume with you at all times and it is a real piece of fashion jewelry.”

Innovation First

While definitions surrounding innovation vary widely—from Instagram-able to sustainable—experts concur that innovation, in whatever form, is essential to success.

Denis Maurin, vice president of sales, industrial innovation, HCT Group, tells Beauty Packaging: “Innovation in today’s beauty market is qualified as anything that hasn’t already been done, or an upgrade on an existing item that isn’t already on the market.

This could be a new way of application, an upgrade on packaging or a more efficient component. There is of course a high demand for innovative products that are flashy and are easy to photograph for social media purposes. If a client has that in mind, we will take that into consideration when determining the design of the packaging.”

Yonwoo/PKG has a special department that focuses on nothing but innovation and “is not encumbered with the day-to-day operations,” says Kelly Cunningham, marketing department. She says Yonwoo/PKG has a global staff of over 30 industrial designers “who create and test these items to make sure quality is delivered with every innovation launch. We like to put our best foot forward at all times.” says Cunningham.

Yonwoo/PKG recently launched the Oval Clear Drop. “This item was developed to give our existing dropper tube a more luxurious look with the same precise application that our customers love,” says Cunningham. “Old and new customers wanted this in their hands immediately.”

According to Boris Schaefer, vice president, sales, TNT Global Manufacturing Inc., “Innovation manifests itself on all fronts: physical—the product itself; sensory—what it inspires in its contact; and virtual—the story it tells and how consumers appropriate it and continue it through the social networks in particular.”

Schaefer says, “The first contact with the consumer is usually virtual, and all the complexity aims to establish an overall coherence between a product and its world so that the story sounds good and right. Packaging plays a key role in this first virtual contact, which is audio-visual most of the time.” He says Instagram is “the power of the image, instantly, and has a huge and fast-sharing potential.” It also has an immediate impact. “It’s the danger if negative, says Schaefer, “hence the need for a brand to follow ‘a red thread’ with deep meaning. The limit of Instagram is its catch-all side.”

One of TNT’s latest innovations is R2AD, a patented massaging, removable and rotatable 360° metal ball applicator, combined with an airless refill. It is intended for the application of cosmetics for face and body, in spa and/or at home. Its magnetic stainless-steel ball provides an unlimited movement, as well as a 300% increased contact zone compared to a conventional roll-on applicator. Cooled, it optimizes the application for decongestant and draining care. While warm, it promotes the opening of pores for better absorption. As an option, and for a softer feel, the ball can be covered with a plastic shell. A single press on the airless cartridge is enough to deliver a precise dose, without risk of air return and contamination of the formula. After use, the removable ball of the R2AD applicator can be washed completely, or even sterilized, so it’s a “perfectly hygienic system.”

Finally, says Schaefer, “R2AD’s design is part of a sustainable development approach and has the advantage of offering brands a loyalty solution for their customers, thanks to the recharges.” He says it is particularly suitable for deodorants, essential oils, after- shave and facial care.

Innovation in the Throes of Speed to Market

Of course, the dilemma of speed to market often comes into play when determining the course that innovation will take. And the path is not always an easy one.

“Creating a package is not easy and certainly requires experience, as well as creativity because a novel idea is not enough,” says Rosa Porras, marketing communications manager, Virospack. “The packaging, in addition to surprising, must then be functional, hermetic, safe, easy-to-use, preserve the qualities of the formula, not deteriorate with transportation or during use or conservation in conditions not always suitable... In addition to creativity and knowledge of consumer needs (we always have to think about the end user and what he expects from his cosmetic and the container that contains it) must be added the engineering development.

And also, in record time. You have to surprise the market constantly and for this you have to be fast.”

HCP’s Godefroit also notes the challenges. “True innovation inevitably takes time and resources to be effectively executed; a combination of market research to determine consumer need, creative thinking, technical engineering and manufacturing expertise is the ideal route to success. Yet in a beauty industry with a huge recent influx of new brands and heritage brands looking for reinvention with speed-to-market as a top priority, this presents a challenge to suppliers in terms of innovation, over a flash-in-the-pan gimmick.”

At Roberts Beauty, O’Connell agrees. “It is incredibly difficult to create innovation in a fast-moving market. To be successful, it often takes courage and risk in terms of up-front investment to complete production tools so that your innovations are ready for market. There isn’t much appetite for shopping around concepts that would still have to move into tooling phases if desired by a brand.”

Meanwhile, Metapack’s de La Noue believes, “Creating innovation and speed to market are separate issues. She says, “We create innovations internally, taking the time necessary to ensure we have a working concept prior to presenting it to our customers. This way, once presented, the innovation can be quickly brought to market.”

Taking Stock

One solution to the intersection of innovation and speed to market is stock items. HCT Group’s Maurin explains: “In order to meet demands for speed to market while still creating innovative packaging, we’ve added a few stock items like the Kat Kit that offer both customization and speed to market.” The Kat Kit has a recess in the lid where a plaque is placed for added decoration capabilities. This offers customers the option to customize their component while still meeting the speed-to-market demand.

HCT Group worked with Hourglass to help design their Veil Translucent Setting Powder. The main innovation part of this design is the sifter. “It is a custom-designed gold sifter that allows you to transfer formula onto your brush in a nice domed shape,” says Maurin. “When the cap is closed and the jar is checked, it leaves the perfect amount of product on the sifter ready to be picked up for application. It also eliminates the mess of traditional sifters.”

Two new standard curved droppers are Virospack’s latest market entry. Porras says, “This renews the image of the classic dropper with a shapely design, more eye-catching and sensual. Thanks to its innovative design of a subtle curved shape of both the bulb and the cap, the cosmetic dropper benefits from a seductive look.”

Virospack recently worked with Too Faced Cosmetics on their Unicorn Tears package. that captivates consumers with “shimmering and highlighting cosmetics.” It’s a dropper made with standard components and decorated and assembled in the company’s facilities, in a totally customized way for Too Faced. Porras says these “illuminators” for face, lips, eyes and cheekbones are always dispensed in droppers, for a drop by drop and precise application. The dropper features an injected bulb in custom baby blue, with a gold metal shell cap and glass pipette. The fun and colorful image features a unicorn and the rainbow as a source of inspiration.

Stock is also important at International Cosmetic Suppliers (ICS), where CEO Susanne Nichols, says, “It is difficult to keep up with the fast-paced demands in color cosmetics, but not impossible. Many of the newest innovations have been in innovative finishes.

One way we have been able to reduce time to market is working with our clients to utilize classic, standard primary packaging that has passed compatibility testing and develop new innovative finishes/second processes reflecting the newest trends, resulting in faster turnaround and speed to market.”

Agility and Anticipation

Developing innovation can be challenging, according to WWP’s Jean, “as it demands the agility to shuffle through the wave of trends and see where customers are heading.” He explains, “In order to be truly speed-to-market-friendly, we need to analyze and anticipate the needs from customers and their clients. Sometimes it takes just a little adjustment to an idea and it moves like wildfire.”

Jean says dual-purpose and “on the go” sized packages continue to be a dominant theme as far as innovation. “For example,” he says, “Our Skinny Jeans Squeeze was designed and engineered with the ability to dispense various types of products, all in a package that can easily slip in the back pocket of your jeans.”

Sophie Maxwell, Futures Director, Pearlfisher, also sees portability as a key area of innovation as far as cosmetics packaging.

She tells Beauty Packaging: “It’s true that it is much easier to iterate with popular colors or ingredients as innovating quickly within the structural solution is a longer process. However, we are seeing portability and scaling being addressed and where real innovation lies—and where we want to see it—is in how we create more sustainable and functional packaging that dials up desire in itself with more lightweight, minimal, clean and efficient structures that fit into our lifestyles and can be re-used and recycled.”

(See Jamie Matusow’s full exclusive interview with Maxwell here.)

K-Beauty brand sensation Kaja has created what it calls “bite-sized beauty packed with Korean innovation that once you experience, you’ll want to share.” The brand says “our packaging is as beautiful on the outside as the product is on the inside—feel-good formulas made for everyone, all skin types and skin tones.” Think heart-shaped stamp applicators, mood-color-changing lip formulas and bouncy bulk in petite palettes—all arranged neatly on arms of various skin tones.

“Innovation is not difficult; it just requires smart planning,” according to Jeremy Garrard, director of design & advanced technologies, Quadpack Industries. “Younger consumers want more than just a pack, they want an experience. “The way they use a pack can form part of new rituals that they can share on social media.”

He says, “Innovation today also means reimagining existing formats as formulas evolve. Pack types designed for one segment are being used for another. Packaging becomes transversal.”

Garrard says that Quadpack approaches speed to market by offering an “outstanding portfolio of smart, modular solutions.”

Brands can mix and match components and they apply the latest decoration techniques to create something unique. “We can also stock standard components for just-in-time decoration. We ensure our supply chain is optimized, and work with fillers to pre-validate packs wherever possible.”

Quadpack also offers custom solutions. As an example, makeup category manager, Sonia Cerato, cites the bespoke 4ml Twist Flow Pen which they developed for Charlotte Tilbury’s Magic Away Liquid Concealer. The pen has an aluminum-sheathed body with a viewing window. Everything from the twisting base, through the body and the precision sponge applicator, to the cap, was custom designed for the brand.

At HCP, Godefroit says, “One of the biggest areas of innovation we’ve worked on is to give both opportunity for customization and personalization.”

For color cosmetics, this is usually achieved via the brand customizing a stock pack with HCP’s extensive decoration options; whether a decorative top-plate is added to give the pack eye-catching appeal or special finishes that attract the consumer.

Godefroit says, “Instagram is having a huge impact on how customers are attracted to a product; packaging must work on a screen and ideally in video format to really stand out and achieve online sales. Packaging that offers the ‘big reveal’ such as glitter, holographic and color-shift finishes are still proving extremely popular with our customers due to the mesmerizing effect they give in social media videos as they catch the light.”

The launch of HCP’s Glitter Storm compacts has proved to be a huge success for limited edition products, says Godefroit. “The suspension of glitter and sequins in liquid within the top-plate links to several key trends such as interactive packaging and glitter, while offering our customer the opportunity to customize the design with a wide choice of glitter mix, or the option to print on the back of the plate.”

A stunning stock tooling collection from Elcos is its water-drop series. It is plastic but looks like glass due to the heavy wall thickness.

An Eco Message at a Glance

With the power of Instagram, today’s cosmetic packaging is also becoming more of a story-telling device. Sustainably-based brands are sharing their unique narratives at a glance, making an instant impression on eco-consumers.

Mylan Nguyen, senior analyst at Euromonitor International, says, “Packaging innovations tend to answer the key criteria of portability and convenience—in terms of product usage and dispensing—as well as sustainability. And sustainability, more than a nice-to-have product feature, is now a requirement.” This remains a demand although there are many challenges to be met with the whole recycling process, says Nguyen, “from numerous logos present on packaging to the differences in recycling regulations between areas within a single country, without mentioning what consumers understand of recycling.”

Nguyen says some brands have therefore decided to convey a clear message to consumers through the look of the packaging they choose for their products, using, for instance, raw paper-based containers, clearly conveying their recyclability even without stating it or adding an appropriate logo on the packaging.

Viva recently launched the Dream State tube with Pacifica, and Bruno Lebeault, marketing director, North America, says “it is loaded with innovations.” The tube is an injection-molded tube with In Mold Label, 100% polypropylene-PP), 100% recyclable, and uses up to 35% less energy to produce. The tube is made with 50% PCR (post-consumer recycled PP).

And in partnership with Preserve, a recycler specialized in polypropylene, Pacifica sends its users a pre-paid shipping label for consumers to send old Pacifica products to Preserve who will upcycle them into razors or toothbrushes. Pacifica users receive points for the products they recycle that can be used on the web site to buy the razors or toothbrushes. The program encompasses Viva tubes made with No. 5 plastic.

The eye-catching tube also uses a rainbow holographic substrate as well as gold cold foil. Lebault says, “The result is simply spectacular and truly in line with our slogan “beauty with a conscience.” The eco-friendly attributes are clearly noted in photos of the tube.

Brook Harvey-Taylor, founder, Pacifica, comments: “We are always thinking about ways we can be innovative. Partnering with incredible suppliers like Viva to push the boundaries in super creative ways has been major for us.”

According to Pearlfisher’s Maxwell, “Holistic, sustainable and multi-functional is driving innovation in both graphic and structural packaging solutions to meet the phenomenal new range of beauty offers hitting our shelves.” As examples, she cites BYBI Beauty, which currently has two products out—Babe Balm and Prime Time—both of which are multi-purpose, vegan and cruelty-free with sugar-cane derived, plastic-free packaging.

The use of an unconventional material can also serve as an innovative breakthrough.

Recently ICS announced what they call their “newest innovation in environmentally friendly and sustainable packaging—an exclusive, patented Bio Form material.”

According to Dave Thompson, director of technical and design at ICS, “Bio Form is a 100% biodegradable, 100% natural food-based material.” He says, “It is perfect for any environmentally conscious brand and consumer since it will biodegrade within two months once in the ground, and it leaves no residue.”

ICS has partnered with the developers of the technology and the patented process is exclusive to ICS. The versatile material can be used to create custom injected-molded primary packaging such as compacts and palettes, as well as secondary packaging.

“We can also utilize the cutting-edge material for packing material,” says Thompson.

Bio Form is available in a variety of colors and Thompson says it is ideal for use with dry formulations, but can also be paired with other formulations and materials. Brands can further customize Bio Form products with embossed or debossed designs or print.

Looking Beyond Instagram

Innovation will always be essential in the cosmetics packaging world, but the emphasis will vary according to consumer trends.

Pearlfisher’s Maxwell says innovative packaging extends beyond the physical package in what some brands are trying to achieve.

“The idea of a new sense of community, and access, is big business for the beauty industry—as every other.” She says, “Instagram and influencer sharing is still making a huge impact but, as consumers seek new collectives to expand their worlds, they are looking for brands to facilitate this; not only by opening up new brand-to-consumer dialogues, but also by helping connect them to other consumers more directly through the product offer and brand-specific communication.” For example, Maxwell cites brands such as Wander Beauty, a collection of multi-tasking beauty essentials, that credit their success “to rooting the brand in a ‘pull not push’ marketing approach with an interactive community of fans driving unique input and innovation for new products.”

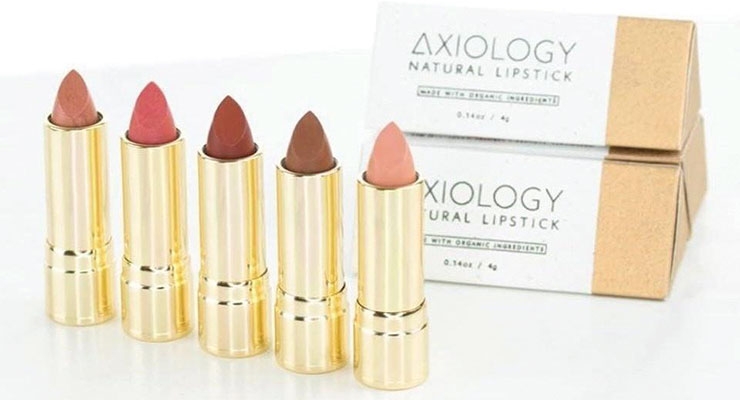

Another brand Maxwell points to is Axiology, which she says “is positioned as a premium, every-day luxury with its phenomenal range of on-trend colors and gold-packaged tubes of lipstick.” The brand is also organic, vegan and cruelty-free, but its mission doesn’t stop there. Axiology is a member of PETA and currently partners with and donates a percentage of their profits to the International Orangutan Foundation, whilst the Axiology boxes are sourced from women in Bali that recycle local rubbish into paper.

One thing is certain. As Euromonitor’s Nguyen, says: “In an ever more competitive environment where consumers are increasingly demanding when it comes to packaging, innovation will be essential to sustain growth, particularly in saturated markets, where volume expansion can be limited.”