Jean-Yves Bourgeois, European correspondent, Beauty Packaging06.10.19

Quite a track record for this German company founded in 1996 under the impulse of a born entrepreneur, Dieter Bakic, with an original idea at the time: Design, make and market standard packaging lines with a unique and attractive design that could be customizable for any line of products in the Beauty sector.

Over the years, the offering was complemented with specific lines and, from being a designer/owner of models and molds (more than 1,800), the company, which today employs a total of 150 people, started to build its own manufacturing plant near Frankfurt with 24 injection machines.

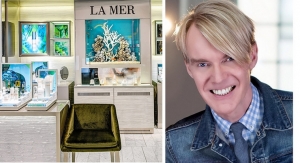

Overview with Dominic Bakic, owner and CEO, who succeeded his father Dieter in 2010.

Jean-Yves Bourgeois: What actually makes your offer so unique and original?

Dominic Bakic: It is the combination of the products and services that we offer in an integrative way. We connect and combine packaging and product design, standard packaging lines and bespoke developments, manufacturing and decoration, as well as all necessary brand communication means.

Jean-Yves Bourgeois: The concept “Unique packaging lines are a primary factor in the brand building process” helped your company make a name for itself…but there are other reasons behind this success.

Dominic Bakic: There has always been a high affinity in our DNA for design and aesthetics.

Bakic Design is a recognized branding and design agency. We assist our international customers through all steps of the process: from the brand concept and strategy, to packaging and structural design, right up to brand implementation. Bakic Design acts very often detached from the offerings of Bakic Packaging or Bakic Production because its foremost task is to create the ideal structures and touchpoints for the respective brand.

However, there are multiple projects as well, where the creative team from Bakic Design works together with our packaging and technical experts from Bakic Packaging and Bakic Production and where our project management and decoration competences come into play.

Since we have a huge standard packaging portfolio, which consists of many lines that within itself have a very homogeneous shape language and which cover bottles, tottles, jars, closures, airless, compacts, lipsticks, pumps and much more, there is a great potential to build on these stock molds and customize the brand appearance via color, decoration and graphics.

In case a bespoke or partly bespoke development is needed, we leverage our in-house rapid prototyping and development capabilities and build on our highly automated manufacturing technologies. Today, our site covers 24 injection molding machines with up to 300t clamping force, 1K and 2K machines and automatic assembly and decoration lines for compacts and jars.

At the end, we manage many projects in a ‘full-service’ way, starting with the relaunch or brand creation and leading to the final packaging manufacturing and supply of the components via Bakic Production.

Taking into consideration that we cover Beauty and Color Cosmetics, this is a pretty wide portfolio that we can offer our customers.

Jean-Yves Bourgeois: Going global immediately turned out to be the right impetus for growth…

Dominic Bakic: Absolutely. It was from the beginning an essential part of our business. Our employees speak 20 different languages in 8 offices worldwide. We are committed to offering innovative, reliable and proficient services to our customers and this means that we have to be close to them.

We are doing business with customers in more than 50 countries. Our global perspective on design and trends combined with a healthy dose of German technical know-how enables our customers to become more successful in their markets. Our international presence and our years of experience in sales and customer service and project management enable us to fulfill complex requirements and consistently implement them in successful projects. In recent years we have ventured into building a successful sales structure in the Chinese market.

Jean-Yves Bourgeois: Environment is obviously ‘THE’ key issue nowadays. How do you deal with it?

Dominic Bakic: You are absolutely right, and this topic gained super momentum in the last year.

We are very well set-up here because we have been dealing with sustainable packaging since 2012, where we developed for one of our customers our first bottle made out of 100% R-PET. Throughout the years we continued to develop in this segment and today 78% of all the packaging components that we have in our portfolio are recyclable and 73% can be manufactured out of recycling material.

Sustainability really requires a circular thinking which starts at the beginning of a packaging creation process and where you need to define how packaging material can be reduced, what materials and decorations are allowed to ensure recyclability, what potential there is for reuse and refill concepts and where you can aim for the application of recycling materials. Our holistic working approach, i.e. to oversee the entire process from design creation to manufacturing, always required a circular design thinking and since we have been doing this for many years, it has become a strong part of our DNA. Hence, together with our customers, we evaluate the sustainable goals that are appropriate and that they want to achieve and then design and implement the packaging along these goals and guidelines.

Moreover, we have established a wide network and take part in numerous organizations to make sure that we are in tune with the newest insights and developments with respect to sustainability, and explore their potential.