Marie Redding, Senior Editor07.26.19

Folding cartons, typically paperboard or plastic, attract the consumer’s eye on-shelf. A carton serves an equally important purpose for online shoppers, since it is the first part of the packaging that the consumer sees and interacts with before using a product. It will influence the user’s initial feelings about a product—and the brand—helping to make a good first impression.

“A well-designed carton that surprises or delights consumers can add distinction, reinforce the positioning of an upscale or luxury brand, and build awareness of the company’s sustainability efforts. It is an ideal opportunity to engage and connect with consumers in a meaningful way that builds brand loyalty,” says Dennis Bacchetta, director of marketing, Diamond Packaging.

Suppliers often advise brand marketers on which type of paperboard to choose depending on design goals and how much protection the product inside requires. Paperboard is available in a range of densities, which is determined by the board’s caliper, thickness and weight. There are numerous other features to consider as well, such as ‘scorability,’ which is a board’s ability to fold without flaking—and brightness, which will affect a decoration.

Paperboard Is in Demand

Although some beauty brands choose plastic cartons (more about this below), the use of paperboard is on the rise. A renewable and recyclable resource, paperboard is an attractive material for eco-conscious brands. “With a strong pressure to use less plastic, paperboard and paper cartons are experiencing a strong demand,” Research and Markets states in a report. The firm’s analysts project the global folding carton packaging market to register a combined annual growth rate of 4.4% through 2024, rising from last year’s value of $117 billion.

Walter Shiels, chief operating officer, Arkay Packaging, says there’s a big push now for sustainable boards—as well as unique types of paperboard. “I recently found one type of paperboard to show a customer that was made from Starbucks coffee bean sacks,” he says.

Choosing recycled paperboard can help make a positive impact on the environment. According to the Sustainable Packaging Coalition, for every ton of virgin paperboard that is converted to recycled board, one ton of recovered fiber is kept out of municipal landfills. Plus, paperboard cartons may be recyclable again after use, depending on the decoration.

Pate Gustafson, executive vice president, JohnsByrne, says, “Eco-friendly packaging and sustainability are now, more than ever, a greater concern because many consumers, particularly Millennials, will choose to align themselves with skincare and cosmetic companies that are producing eco-friendly packaging.”

Gustafson continues, “For companies looking to decrease their carbon footprint, 100% recycled paperboard created with post-consumer-fiber and other recycled fibers is an ideal solution—as well as using local paperboard suppliers.”

Decorating Trends to Attract Attention

Folding cartons, and paperboard are highly compatible with various types of decorating processes. “Paperboard is durable canvas for everything from foil effects to gloss coatings. It is ideal for custom designs and cuts, to create uniquely shaped cartons,” says Gustafson.

Unique structural designs are a specialty at JohnsByrne. “It is one of our key strengths,” says Gustafson. “Our design team has the ability to prototype everything ranging from elegant folding cartons, to unique rigid boxes,” he adds.

Trends this year include bold, saturated colors, according to Gustafson. “Gradients and transitions are also particularly popular. The fluidity of a gradient brings a 3D element to a carton, allowing it to stand out in a crowded marketplace,” he says.

Also mentioning a few decorating trends for paperboard, Anthony Grinnell, chief executive officer, Harmony Paper Company, says, “Beauty brands are using more glitter, metallic and holographic films. Specialty coatings and metallic foils, are also popular—and will make a carton stand out from competitors.”

John Rebecchi, senior vice president, DISC, says, “We see an increasing use of foil decorating, matte or soft-touch coatings, and texture from embossing or specialty paperboards. Foil decorating applications, especially cold foil, can also enhance the look of a folding carton—in either a bold or subtle way.”

Designed to Convey a Product’s Attributes

A folding carton’s design usually helps convey a message about the brand, while also coordinating with the look of the product’s primary package. “Textured paperboards, as well as decorating techniques such as embossing and specialty UV coatings deliver visual and tactile cues and help a brand achieve shelf presence,” advises Bacchetta. “These elements also ‘invite’ the consumer to more closely inspect and interact with the product,” he says.

The use of multiple coatings, such as both matte and gloss finishes, is an effective way to create contrast, according to the team at Diamond Packaging. “A combination of colors, textures, and tactile effects will add distinction and reinforce the positioning of an upscale or luxury brand,” adds Bacchetta.

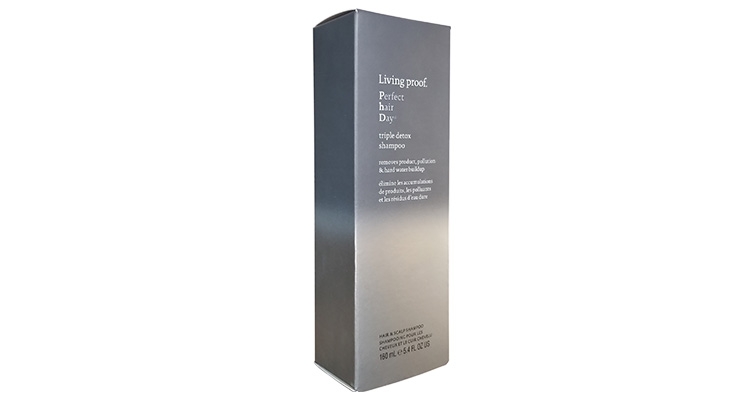

DISC worked with hair care brand Living Proof on its holiday cartons for the Perfect Hair Day product collection. The cartons were decorated using a cold foil process, embossing, and a mix of bold colors. “We also blended gradations of cool grey and silver cold foil, covered with a soft-touch coating,” says Rebecchi.

Several other brands DISC has worked with recently are choosing white textured stocks or cartons, according to Rebecchi. “These have a surface feel of canvas or felt. The monochromatic white is elegant, and the textures stimulate our sense of touch,” he says.

The new Armani Men skincare range by Giorgio Armani Beauty, part of the L’Oréal USA family, features elegant white outer cartons. They are also more lightweight than traditional cartons, and are made using FSC-certified board. (See below for more about other brands choosing FSC-certified board.)

Elie Tahari Night Eau de Parfum’s packaging was inspired by the Elie Tahari Fall/Winter 2019 RTW fashion show. The runway featured models wearing bold animal prints, navy and black jewel-toned hues, velvet textures, combined with shimmering accents and details.

Both the bottle and carton feature the color blue. “I love blue because it symbolizes strength and serenity,” says Mr. Tahari. The brand states, “Our signature modern, sophisticated structure is evident in the secondary packaging as the carton showcases the bottle’s navy crocodile pattern with exquisite gold detail.”

Elie Tahari Night Eau de Parfum will launch Fall 2019. Categorized as a Floral Amber, the perfume was created by Givaudan’s Rodrigo Flores-Roux and Nicole Mancini. It was developed in collaboration with TPR Holdings, and is the brand’s second fragrance.

Arkay’s ‘Paint on Press’ Solution

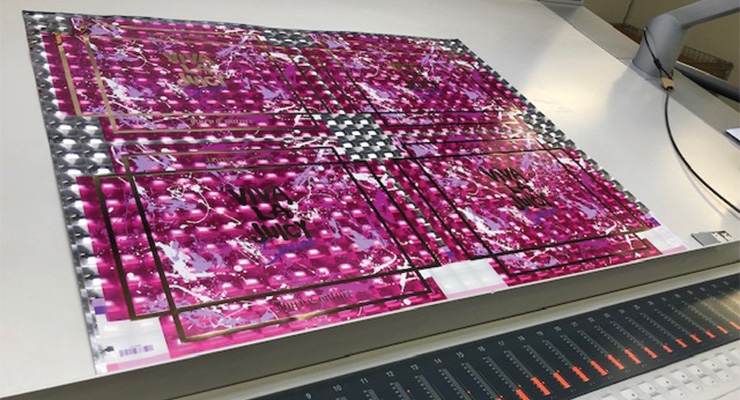

Deciding which decorating techniques will achieve the expected result on a carton can be overwhelming, especially if you’re in a time crunch or need to make last-minute changes. Arkay Packaging’s innovative solution “Paint on Press” (POP) was created to help the package development and design processes run smoothly.

Arkay’s POP process provides key advantages over silkscreened comps. Shiels explains, “It is nearly impossible to replicate a silk-screened look on a press. With our POP process, our customers see exactly how the carton will look, so there are no surprises later—it’s essentially ‘painting on the press.’ ”

Shiels says that when this process was first developed, it was out of necessity. “We were seeing projects being delayed due to our customers making design changes, and having to wait on all the necessary approvals. This was happening as a project was going to press. We knew we needed to develop a cost-effective, speed-to-market solution,” he explains. “Now, our POP process lets our customers see exactly how a decoration will look, and allows for changes to be made quickly,” he adds.

Once Arkay’s team receives a TIF file, the art is separated into printing and finishing layers. “At the same time, we develop a menu of options, such as combining different types of boards with different inks, so our customers can compare all the different ways the artwork could be printed on the press,” Shiels says.

Finished cartons are developed with every option, so brands can bring them to design meetings or focus groups before making a final decision. Since the “painting” is done on the press, all of the various options are repeatable for production orders. The artwork can be continually modified to show alternative designs. Various board types, including mylar, holograms, sustainable, bright whites, coated, and uncoated are commonly tested, and combined with stamping, leaf, pearls, film laminations, inks, coatings and more.

Plastic Cartons

Even though paperboard is more popular, some beauty brands choose plastic cartons. Glossier keeps its sunscreen stick, Invisible Shield SPF 35, securely in place and protected during shipping inside a plastic carton. The front is clear, while the sides are the brand’s signature pink hue, and adorned with the name “Glossier” in white. The brand even featured the pretty boxes stacked up in a photo on its website, and in this photo on Instagram.

“Plastic folding cartons evoke an elegant look and feel,” says Bacchetta. “At Diamond Packaging, we employ techniques such as printing, foil stamping, and embossing on plastic to achieve greater shelf impact.” Diamond Packaging offers several eco-friendly options for plastic cartons. The supplier’s PentaClear SmartCycle range includes RPET made from recycled beverage bottles, and APET made from up to 30% sugarcane.

Be Green, Without Compromises

There is no longer a need to compromise aesthetics for sustainability, suppliers say, although if challenges arise, there are ways to overcome them. According to the Sustainable Packaging Coalition’s Design for Recycled Content Guide, a high percentage of recycled fiber can affect a carton’s strength, as well as its whiteness, brightness and printability. “To navigate these challenges, brand owners and suppliers should work together to optimize packaging specifications,” the guide states.

Another resource is the Recycled Paperboard Alliance’s 100% Recycled Paperboard Conversion Guide, which states, “Higher percentages of recycled fiber may make it more difficult—but not impossible—to achieve white or brightly colored packaging, since many blends of recycled fiber produce a grey or brown color, but, as with performance, the visual appearance of recycled fiber depends largely on the feedstocks used by the recycled pulp mill.” The guide explains that some recycled pulp mills overcome aesthetic issues by using de-inking processes to create lighter-colored fiber that appears brighter. It also answers common questions about the removal of metals and other contaminants, and includes tips on making recycled paperboard more visually appealing.

Despite these potential issues, many suppliers say recent advances and developments in materials and processes are making it easier for brands to be green. “Long gone is the myth that being socially responsible means sacrificing design,” says Greg Maze, senior brand manager, Neenah. “Just about any design goal can be achieved while making sustainability a priority,” he says.

Neenah’s collection of FSC and Green-e certified papers range from the deepest dyed-through black and natural shades and colors, all the way through to a 95 bright PC 100 White.

The team often works with brands that are looking for cartons made with the highest amount of recycled content possible, without affecting the integrity of the design. “Our options include papers and boards made with up to 100% post-consumer fiber. We can also create custom solutions,” says Maze.

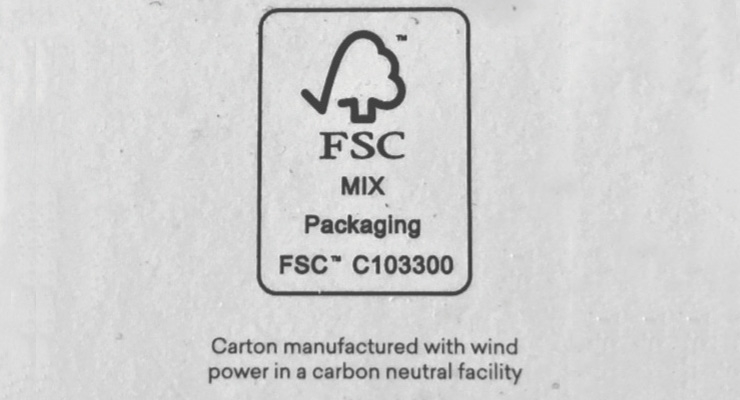

Diamond Packaging’s Green Chic packaging model says it delivers “Beauty without Compromise”—and “captures the essence of luxury brands through more sustainable converting methods.” It incorporates multiple in-line technologies for decorating cartons, which will then be recyclable. These in-line technologies include cold foiling, specialty coatings, “Liquid Metal” metallic UV coatings, and more. “Our ‘Green Chic’ technologies create stunning visual and tactile effects. Our paperboard folding cartons are also manufactured using 100% clean, renewable wind energy, and produced in a zero-manufacturing waste-to-landfill facility, which brands can communicate through on-product labeling,” says Bacchetta.

Golden Arrow is also committed to green production methods. “We are proud to say that all of our factories are completely zero net carbon. Through the adoption of solar photovoltaic panels, water recycling programs, and zero sewage discharge, we are committed to sustainability from start to finish,” says Jake Snethen, package design manager, Golden Arrow.

Harmony Paper Company also offers numerous eco-friendly options, including 100% water-based coatings and paperboard made with recyclable fibers. The company’s Plush Touch paperboard line is both luxe and cost-effective.

More Brands Are Using FSC-Certified Paperboard

It seems as though more beauty brands are using paperboard certified by the Forest Stewardship Council (FSC), and displaying the symbol on cartons. “Responsible forestry practices and the certifications that go along with them, such as FSC, are becoming more prominent,” says Harmony Papers’ Grinnell.

Bacchetta says more consumers are looking for these types of logos. “Conscientious consumers want to know that the paper products they purchase are supporting forest management,” he says. “The growing use of the FSC logo reflects a growing trend—companies are making more environmentally and socially responsible supply chain decisions,” Bacchetta adds. Diamond Packaging has obtained FSC Chain of Custody certification from the Rainforest Alliance.

Neenah’s Maze explains that all cartons that display the FSC logo must adhere to strict chain-of-custody guidelines. “This means that everyone in the supply chain that touches the project has to have that same FSC certification. So, if a brand uses an international converter or provider that doesn’t have that certification, the brand cannot put the FSC logo on their box,” he says.

Naturally Serious Skincare displays the FSC-certified logo on its cartons, which feature bold green and white graphics The brand was recently founded by June Jacobs and her daughter, Rochelle Jacobs. The cartons are also produced in a carbon-neutral factory that utilizes wind power. “Our packaging is luxurious, but also approachable. We wanted it to feel serious and premium while being relatable. The design is clean, simple, and bold with a geometric, natural pattern to convey the cleanly made, ethically developed, clinically tested message,” says Rochelle Jacobs.

Farmacy Beauty, a luxury “farm-to-face” skincare brand, uses Neenah’s paperboard for its folding cartons. The brand’s website states, “Our packaging is made with FSC-certified paper from well-managed forests, and inks based on naturally renewable raw materials.”

Sustainability is a core value for Farmacy Beauty. “Not wanting to make the choice between creating a ‘green’ or ‘luxe’ package, the designer specified our Neenah Environment Papers—and the box reflects the brand’s values, while providing a farm-meets-science aesthetic with a bright white canvas and a natural touch,” Maze says.

Hello Products, an Indie toothpaste brand, also uses FSC-certified paperboard for its cartons, which are printed with soy ink. “We’re always trying to increase the amount of post-consumer recycled content used in our packaging. Transparency is in our nature, and we are constantly striving to take meaningful steps forward in terms of innovative sustainability practices,” says the brand’s founder, Craig Dubitsky.

In yet another example of how luxurious “green” can look—and another brand using FSC-certified paperboard_the team at Inter Parfums worked with Diamond Packaging to produce the carton for Anna Sui’s new fragrance, Sui Dreams in Purple.

The folding cartons were converted utilizing FSC-certified Ecological Fibers Flexpack Lumina Pearlescent .016 paperboard, and manufactured using 100% clean, renewable wind energy, in a Zero Manufacturing Waste to Landfill (ZMWL) facility.

“This paperboard was chosen for its luxurious finish and environmental attributes,” says Bacchetta. “The Kraft board features a protective, water-based, luminescent top coat and a proprietary embossing pattern created specifically for Inter Parfums. The FSC-certified mixed sources paperboard was made with 20% post-consumer waste (PCW) fibers,” he explains.

The carton features an embossed logo and floral pattern on the front and top panels, which add dimension. The cartons are decorated using an offset printing process, with seven PMS inks in-line, as well as a satin aqueous coating. An ombré design that seamlessly blends purple, pink, yellow, and green inks. “The design creates a luxurious gradient background for the hot foil stamped and embossed accents,” says Bacchetta.

Making Molded Fiber Pulp Look Luxe

There are other materials a carton can be made from, besides paperboard and plastic—such as molded fiber, which is a type of pulp. Golden Arrow excels in using this material for uniquely shaped secondary packages, which take the place of traditional cartons, and primary packaging as well.

“When it comes to the best green materials, we believe molded fiber pulp is ideal,” says Golden Arrow’s Snethen. “As a leader in molded fiber technology, we are thrilled to say we have many advancements in molded fiber forming and secondary processes in the works,” he says. “It allows brands to choose sustainability—and a luxe look,” he says.

Golden Arrow worked with skincare brand Eighteen-B to create innovative cartons for its B-Silk Protein products—Revitalizing Hydrogel Moisturizer in a tube, and Hydrate + Restore Rich Cream in a jar. The unique container is all white, and looks elegant. The product sits in a tray inside the container.

Both the carton and tray are made with molded fiber derived from fast-growing, renewable bamboo and bagasse, which is the agricultural waste from the sugarcane extraction process. The molded fiber lids and trays are formed through tooling and heat-pressed, creating a perfect fit that holds the product, lid and tray together by friction. The brand’s logo is foil-stamped onto the molded fiber case.

A Glistening Glitter Option That’s ‘Green’

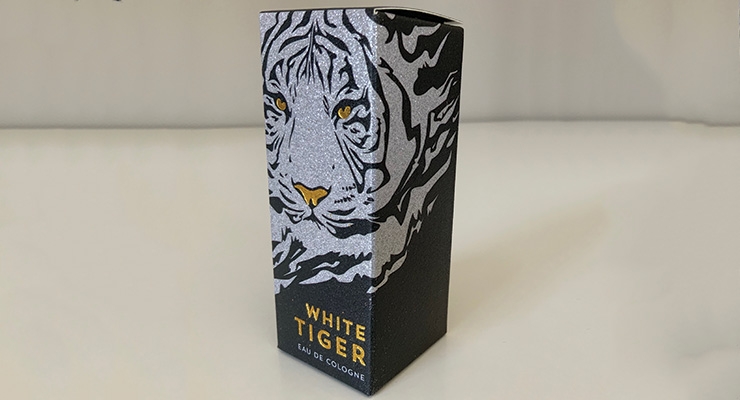

Glitter decorations often cause certain issues when applied to a carton or paperboard, and traditional UV and silk-screened glitters often aren’t recyclable. Harmony Paper Company’s Diamond Print Glitter is a recyclable, cost-efficient glitter paper option.

“We have heard countless brands and designers state that they want a glitter option that isn’t riddled with problematic issues and limitations,” says Grinnell. “Our Diamond Print Glitter is a non-shedding, printable glitter paper that doesn’t crack when folded, chip when die-cut. Plus, it is compatible with virtually every post-press process,” he explains. It is featured on the carton created for White Tiger Eau de Cologne (shown).

Diamond Print incorporates a sophisticated, elegant sparkle “into” the graphics, rather than on top of them, creating a tactile feel. “It also offers printers complete control over spot glitter effects, the amount of sparkle, and even the color of the glitter,” says Grinnell.

Harmony Paper also offers Diamond Form Glitter—a recyclable luxury option for glitter vacuum-formed trays. They are made with 100% recyclable PET film, water-based adhesive, and PET glitter flakes.

Final Tips

Some newly developed materials for folding cartons might be generating “buzz”—but they may not be a practical option, yet, suppliers say. “Potato starch paper is one example. It comes with an exorbitant cost, limited availability and very dull aesthetics,” says Grinnell.

This is expected to change. “Although there are many sustainable board materials available now that are both luxurious and affordable, we expect the cost of some of these new materials to come down as volumes increase,” says Grinnell.

With so many different materials and processes to choose from, as well as new “green” solutions for cartons, deciding what to choose can be a challenge. Grinnell offers a few final tips, saying, “Every project is unique. Identify the key performance factors for your carton—then test and prototype different materials.”