Jamie Matusow, Editor-in-Chief12.10.19

The “green” dilemma continues. Consumers have spoken: They want both luxury products and earth-friendly packaging—but can the two be married? At the 32nd edition of Luxe Pack Monaco, which took place September 30-October 2, a record 470 exhibitors showed how far their efforts have come in this respect, from engineering new materials to eliminating metal hinges to clarifying PCR, to light weighting glass and paper—among other things. As Cheryl Morgan, creative marketing manager, HCP Packaging, told Beauty Packaging: “The government is likely to bring in environmental legislation, sustainability is gathering momentum with consumers and HCP is working to develop practical solutions without losing the appeal of ‘green and gorgeous.’ ” (Read more about HCP’s eco-friendly offerings later in this article.)

Specifications have also become much more exacting and, subsequently, buyers much more knowledgeable. For instance, a number of suppliers offered attendees a variety of choices as to which version of PCR they were interested in. It’s now a question of clarity: less PCR means a clearer or whiter container, which many brands feel speaks to more of a luxury look.

Meanwhile, various percentages of PCR are suitable options for other brands’ needs. Albéa, Cosmogen, Arkay, BillerudKorsnäs and others offer bright white surfaces in various materials that have outstanding environmentally responsible credentials.

The overarching theme was in evidence at first glance on the show floor, from booths decked out in living green walls to brown paper shopping bags with recycled fabric ribbon handles. There was even green juice at Metsa Board, and someone wearing a wooden bowtie at Stora Enso.

However, innovation in the Grimaldi Forum also stretched beyond green topics.

Award-winning packaging designer Marc Rosen told Beauty Packaging that he found one of the most innovative areas of the show to be the Digital Village, which featured ways to incorporate videos and data through new technologies by scanning your smartphone over areas of the packaging. (Read more from Rosen later in this article.)

This year’s show was more international than ever, with 55% of visitors coming from 110 countries. For those of the nearly 9,000 attendees interested in educational sessions, Luxe Pack Monaco offered 36 topical conferences and roundtables over the three days, featuring more than 80 speakers.

Show Floor Trends

As noted, while the industry continues on a steep learning curve, suppliers have made great progress in environmentally responsible packaging—from “pick your PCR percentage”—to components that can be separated to make recycling easier. Refillable options were also a widely available option. An increase in sustainable wood and paper—and in recyclable glass and aluminum—are making headway. Luxe paper is tactile—with finishes including sandy, leather and linen feels. Partnerships between formulators and packaging companies ensure delivery of turnkey products to market faster than ever. More suppliers touted regionalization capabilities for manufacturing in-market. Partnerships are forming to avoid tariffs. And more luxury brands are using stock packaging—and customizing through high-quality deco, impressive advances in digital printing and more.

Beauty Multitaskers

A number of large exhibitors at Luxe Pack Monaco offered a vast array of solutions for products from makeup to skincare, caps to tubes, while others were very specific as to categories, materials and containers.

Albéa was one exhibitor that featured a wide-ranging variety of options from mascaras to tubes to digital design.

Cecile Tuil, vice-president communications, Albéa, showed Beauty Packaging an assortment of dazzling caps for fragrance bottles, made possible due to a collaboration with a 3D startup for innovation. Tuil explained that Albéa provides 3D add-on covers for mascara, lipstick and fragrance. A 3D printed “Desert” family of mascara brushes featured an extremely flexible brush “with no limit to design.” What’s more, the brushes are available in quantities from one piece to numbers on an industrial scale.

A large part of Albéa’s stand was devoted to their sustainable packaging accomplishments, including all new green, recyclable bags and pouches made of recycled or recyclable materials.

When it comes to lipstick, Albéa is working on reusable packaging, in which the consumer can keep the outer package, and swap out the mechanism. Attractive carton board cases with high gloss, CMYK printing and lamination, had been developed for lipstick and mascara.

There were also lots of advances in tubes, including a new PCR tube and pump made in the USA, which was first developed 10 years ago, according to Tuil. Three new tubes with different PCR concentrations were designed to meet different market expectations: Max PCR is 70% PCR; Beautiful PCR is designed with an inner layer and virgin fossil-based PE outer layer of 70% PCR; Ultimate PCR, is 70% PCR and 30% bioplastic. At the center of tube innovation was a carton board-based tube developed in partnership with L’Oréal, in which “plastic is for the most part replaced with a bio-based and certified paper-like material.”

Another talking point at Albéa: Regionalization—many packages can be manufactured in the U.S., in Connecticut, as well as in Europe.

Quadpack presented numerous packaging solutions for cosmetics, skincare, fragrance and more. The company was also celebrating their recent acquisitions of Innotech and Louvrette, which Quadpack CEO and co-founder Tim Eaves told Beauty Packaging he had been working on for some time. The Louvrette acquisition, said Eaves, “is a perfect fit, and places Quadpack among the top ten cosmetic packaging providers in Europe.” Louvrette specializes in thick-walled injection molding, particularly in the skincare packaging market. Germany-based Innotech’s process knowledge and pioneering bi-injection molding technology will boost Quadpack’s ability to offer an exclusive product range, designed and manufactured in-house. In addition, Eaves said Quadpack has developed a 4-part strategy to be more sustainable, and going forward, all new packs will now have one of the following: Recycle, Replace, Re-use, Reduce. Currently, East Hill, in the U.S., offers Quadpack’s modular standard line that can be decorated for quicker lead times.

Surveying Glass Solutions with Marc Rosen

On my annual Luxe Pack Monaco show floor tour with award-winning packaging designer Marc Rosen, we visited century-old Waltersperger, where semi-automatic glass was in the spotlight.

Based in Normandy, France, the boutique glassmaker creates very specific crystal and lead crystal high-end bottles and factices for fragrance and spirits. One especially different and attractive bottle used cracked glass—they crack the flacon in hot water; then blow it to its finished form. With its long history of luxury manufacturing, Adrien Tourres said that they have 5,000 molds in stock, so “brands can search for old flacons for rejuvenation—and pay no mold, no design.” Waltersperger can produce 1-20,000 pieces. Rosen explained the advantages of semi-automatic glass: “They can do very complex forms that are not feasible in the automatic process. They have the expertise to do surface and texture right.” Tourres added that they can remove the lead from the inside of a lead crystal bottle to make it compatible with a fragrance.

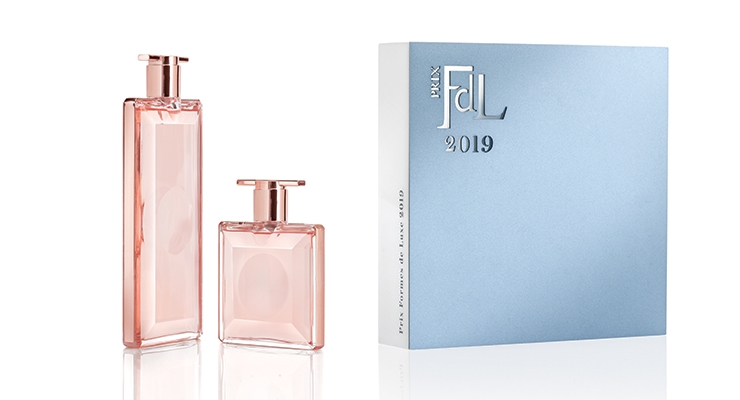

Rosen was also impressed with an innovative fragrance bottle on display at Bormioli Luigi—the bottle for Lancôme Idole Eau de Parfum. Designed by architect and industrial designer Chafik Gasmi, the Idôle bottle is one of the slimmest in the world at just 15mm thick—and “a fitting tribute to the industry technical advances and innovations,” according to the brand. Available in several refillable formats (25-, 50- and 75ml), Idôle is accompanied by a perfume fountain at selected points of sale.

Rosen commented that what made this bottle especially interesting was the case around it. He told Beauty Packaging: “I feel that it’s the first environmentally responsible bottle to achieve a luxe look—by encasing the thin bottle with a rose gold casing beveling the glass. Other bottles presenting sustainability with 50% less glass can compromise/trade luxe for sustainability.”

Also on display at Bormioli was the lightning bolt-shaped bottle for the men’s fragrance Bad Boy by Carolina Herrera (following Bad Girl, for women, in the shape of a stiletto).

Coverpla works hand in hand with brands on sustainability commitments, and Bruno Diépois, CEO, showed Rosen and me a range of standard and custom glass bottles they were offering through relationships with glass suppliers Bormioli Luigi and Pochet.

Just a few months after partnering with Bormioli for the launch of the Ecoline range, Diépois said demand was far beyond initial expectations. Coverpla offers all the benefits of customization both in terms of presentation and thanks to its “mix and match” strategy. Screw necks are available for refilling or separating.

“The value of eco-friendly packaging is an addition to our broad standard offer, an added service that it is natural to bring to our customers,” said Diépois. The choice of a lightweight bottle is part of Coverpla’s turnkey offer: bottle, custom pump, choice of cap, and made-to-measure décor for a 100% personalized product.

Situated in front of a living green wall, Verescence fittingly displayed a number of sustainable options in glass. The new jar for Guerlain Abeille Royal was produced in very lightweight glass.

Michel Levisse, VP product development, explained that they had reduced the glass by 42% weight, from 163 grams to 95 grams. It has an available level of 25% PCR, 65% PIR, 10% regular raw material. For the new Illuminare launch for Vince Camuto, Verescence worked with the designer to create a two-color Murano effect. The asymmetrical organic inner shape was achieved thanks to Verescence’s SCULPT’in patented technology, creating a play of light with the rounded outer shape of the molded glass and the delicate pink hued fragrance. The bottle was manufactured at Verescence’s U.S. glass manufacturing site in Covington, Georgia.

Piramal Glass showcased its latest range of innovations and designs in sustainable glass packaging for the Premium cosmetics perfumery market. As part of its continued efforts to enhance its capabilities, Piramal Glass recently invested 15 million euro to add three new premium perfume bottle manufacturing lines to provide an additional capacity of 50 million pieces. The company also invested 15 million euro to modernize and expand its decoration facility in Kosamba, India, by doubling its current capacity with the addition of new automated printing and color coating lines. Mr. Shah explained that they are heavily investing in using advanced digital techniques such as RTMI manufacturing 4.0—tracking manufacturing at every stage for maximum efficiency and quality. Piramal Glass aims to be a green facility as much as possible, with wind farms, solar panels, etc.

Virospack was highlighting their new “Last Drop” molded glass bottle with 50ml of capacity and 20/410 neck. The new format offers the same high quality, weight, transparency and excellent compatibility level as the rest of the range.

One focus at Gerresheimer was on their recycled glass for cosmetics and fragrance packaging, with a whole clear glass furnace dedicated to the production of PCR glass. The company also produces plastics packaging from PCR.

Capardoni Italy offers glass and plastic full packaging standard and custom solutions. At Luxe Pack Monaco, they were highlighting their full Ecogreen range, including bottles, jars, closures and flip-top caps, produced in different eco-friendly raw materials derived from renewable resources or recycled plastic—100% recyclable with the same features as traditional plastic, and a lower weight during transport. Components can be recycled in the same recycling chain as traditional polyethelene. The supplier introduced their new green line—a full range of packaging and caps that’s been developed and tested, using PCR and green PE, with less weight; and sugar cane derived plastic. They’re also working with wood—cellulose pulp—to get the right balances. With the cellulose pulp, every bottle looks slightly different because the distribution changes when it is machined. It’s available in large quantities, and two layers can be mixed for complete compliance—such as internal, green PE; external PCR. Another plus:

It’s available in bright white.

Board and Paper Previews

At Luxe Pack Monaco, Mitchell Kaneff, CEO, Arkay Packaging, told Beauty Packaging that Arkay continues to seek environmentally responsible materials and was proud to announce that Arkay was awarded Gold Medal recognition due to its high EcoVadis CSR Rating. This rating includes companies that advocate sustainability, which Arkay does. At Luxe Pack, for instance, their customer gifts were made of two boards, Monadnock Kona folding box board from reclaimed coffee bean bags, with variegated fibers that convey a natural aesthetic; and Monadnock’s Astrolite folding box board, which is FSC certified, and more luxe and smooth.

Kaneff also showed us examples of their “Paint on Press” capabilities, which he said are very popular. “The technique gives gorgeous touches and brand realization far in advance of printing the actual product. It takes 2D artwork and enhances designs,” explained Kaneff. He also spoke about Arkay’s successful relationship with Switzerland-based Model Group (with whom Arkay shared a booth), noting: “Regionalization is very real and Arkay is prepared for it.”

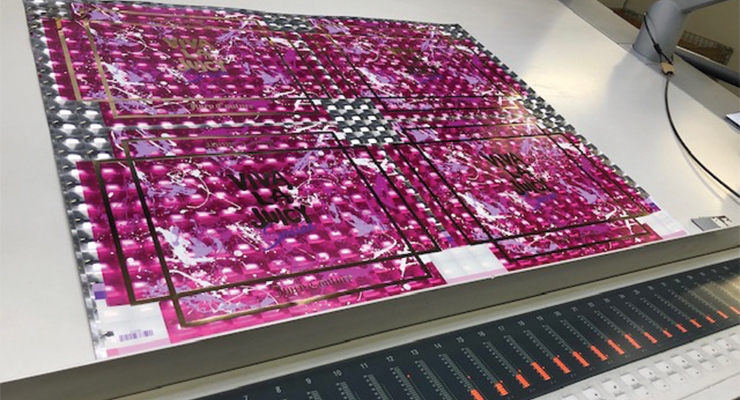

Big Arkay news at the show: Arkay announced its purchase of the Drupa model Primefire 106, the first commercially available industrial inkjet digital printing system in the 70 x 100 (40-in.) format. According to Kaneff, the Primefire 106 has the ability to match offset print quality, giving customers the option of printing digitally or offset, based on job length. Arkay looks forward to the installation of the Primefire 106 in its Roanoke, VA plant in March 2020.

With a focus on sustainability, the Neenah booth featured the company as a holistic, custom solutions partner for all premium packaging and retail graphics needs. Known for its high precision color matching, Neenah allows global brands to present a consistent brand presence across multiple locations. Greg Maze, director of marketing, packaging and retail solutions, said, “Whether customers are purchasing products in Los Angeles or Hong Kong they expect to find brand consistency. Seeing varying shades of a signature color, or finding an unfamiliar texture on a box can weaken the customer’s trust in the product and create a questionable brand experience. Neenah’s custom matching capabilities provide brands with the certainty that their customers have come to expect.”

Neenah also emphasized a big launch in Monaco—the Neenah Folding Board Portfolio, with a focus on sustainability and a wide format. The supplier introduced its new Hemp Board

papers, which are available in a vellum finish, in three of Neenah Folding Board’s most popular shades, including a bright white, 80% PCW sheet with highly visible hemp fibers for brands that want to clearly identify the use of hemp papers in their package design. Neenah’s FSC-certified folding board papers range from 30-100% PCW content.

At Sweden-based BillerudKorsnäs, Anders Gathu, marketing manager, told Beauty Packaging that they “have entered a new era with the introduction of CrownBoard”—a new cartonboard available in white, prestige, high-gloss, for digital printing. It can be embossed, debossed, made highly textural, light weighted, even in some cases using 5-10% less paper. Gathu spoke about the “incredible textural colorful glossy effects,” and said there are also “lots of ways to save resources.”

According to Gathu, CrownBoard is so strong that it allows for substantial reduction of packaging weight. “The launch of CrownBoard gives customers new opportunities to save cost and reduce environmental impact,” said Gathu. “With the stronger board, a lower basis weight does the job.” In addition to light-weighting saving costs, less raw material is used and less energy and production resources are needed. Less transport and warehousing requirements, too. “It adds up to great savings along the entire value chain,” adds Gathu.

Cosmetics and Skincare Specialties

In front of its living green wall at Luxe Pack Monaco, SamHwa was featuring dual-formula dip tube airless bottles. They were also showcasing their continuing development in PCR and glass. For example, twist-up airless bottles are being reconfigured into more sustainable packaging such as PCR replacements.

ShyaHsin, specialists in lipstick and mascara, featured a plethora of stock and custom packaging. The company’s new chairman, Howard Clark, told Beauty Packaging that everything is produced in house in a brand-new, state-of-the-art 2-million square foot facility in Shanghai. Capabilities include metal forming, anodizing, decorating and in-house tool machining. “It’s soup-to-nuts, build-it-all production,” said Clark.

Geka presents a new collection at nearly every industry show, and Luxe Pack Monaco was no exception; in fact, here, they showed two: the Polymorph mascara collection, with an innovative packaging solution for a smart and elegant prestige mascara; and the pureOBSESSION collection, a premium collection featuring high-end components and luxury decoration finishes.

The pureOBSESSION collection includes a mascara, a lip gloss, a liquid concealer, a liquid eyeshadow as well as a multi-benefit makeup brush and a clutch.

A focus on green—punctuated with a living wall and grassy settings for several new products—instantly got the sustainability message across at Cosmogen, where new CEO Priscille Caucé, showed Beauty Packaging new developments including brushes with FSC beechwood, bamboo, and coconut handles. Additional accessories such as spatulas and massagers are also made with FSC wood. Engraved logos avoid the use of ink. Also on display, different accessories developed with varying percentages of PCR plastic, depending on what clarity a brand wishes to achieve. New brush sets without ferrules avoid aluminum with just the tuft and handle.

Maud Lelievre, key account manager, Cosmogen, showed Beauty Packaging tubes made with bio-based sugarcane—both squeeze and roll on systems. They now separate for easier recycling—you can detach the roller and recycle the applicator. Cosmogen’s Tense tube also has a removable applicator, and can be refillable too. PCR can be used in all tubes and caps—in various mixes/percentages.

Mascara remains a popular product category at HCP, according to Jackie Mantle, managing director HCP-UK, who told Beauty Packaging, “We are experiencing lots of mascara business—in the U.S. and elsewhere.” She added: “We’re also seeing more desire for regionalization capabilities.”

As far as environmentally responsible solutions, HCP is focusing on developing primary packaging that optimizes the opportunity to ‘reduce, reuse and recycle.’ The HCP Eco Lab team is using PCR and “exploring cutting-edge options such as bio-materials, as well as identifying how the rapidly evolving beauty landscape should inform the stock development program.”

Cheryl Morgan, creative marketing manager, HCP, showed Beauty Packaging an exclusive green sustainable material called EcoWood, a bi-product of the paper industry, made from FSC waste products—100% wood and vegetable waxes, of several different grades. She explained that it has undergone lots of trials, and is available in compacts to jars, and with no metal hinges.

At Axilone, beautiful custom and stock—and combinations of the two—lipsticks drew attention as always. A By Killian lipstick featured a stock item inside; for the outside, Axilone created the fashion part using just a few tools: 1 mold (just 1 tool), cap and bottom. It’s available in smaller quantities of 20,000-25,000 pieces. New elongated lipsticks for YSL featured a square bulk and cap shape; this lipstick featured 100% custom new tools for everything.

More Luxe Pack

The next edition of Luxe Pack will take place February 11-12, at the Los Angeles Convention Center, co-located with MakeUp in LosAngeles.

At this year’s Luxe Pack Monaco, BillerudKorsnäs presented the first Grand Finale winner of PIDA (Packaging Impact Design Award), an international competition arranged by BillerudKorsnäs and carried out in collaboration with leading universities and colleges in Sweden, the UK, France and Germany. For the first time an overall European winner was named in a celebration at the supplier’s stand, with four finalists present—and their packaging projects showcased.

Bois underwear was the winner, for a banana-shaped package created in an environmentally friendly way.

Specifications have also become much more exacting and, subsequently, buyers much more knowledgeable. For instance, a number of suppliers offered attendees a variety of choices as to which version of PCR they were interested in. It’s now a question of clarity: less PCR means a clearer or whiter container, which many brands feel speaks to more of a luxury look.

Meanwhile, various percentages of PCR are suitable options for other brands’ needs. Albéa, Cosmogen, Arkay, BillerudKorsnäs and others offer bright white surfaces in various materials that have outstanding environmentally responsible credentials.

The overarching theme was in evidence at first glance on the show floor, from booths decked out in living green walls to brown paper shopping bags with recycled fabric ribbon handles. There was even green juice at Metsa Board, and someone wearing a wooden bowtie at Stora Enso.

However, innovation in the Grimaldi Forum also stretched beyond green topics.

Award-winning packaging designer Marc Rosen told Beauty Packaging that he found one of the most innovative areas of the show to be the Digital Village, which featured ways to incorporate videos and data through new technologies by scanning your smartphone over areas of the packaging. (Read more from Rosen later in this article.)

This year’s show was more international than ever, with 55% of visitors coming from 110 countries. For those of the nearly 9,000 attendees interested in educational sessions, Luxe Pack Monaco offered 36 topical conferences and roundtables over the three days, featuring more than 80 speakers.

Show Floor Trends

As noted, while the industry continues on a steep learning curve, suppliers have made great progress in environmentally responsible packaging—from “pick your PCR percentage”—to components that can be separated to make recycling easier. Refillable options were also a widely available option. An increase in sustainable wood and paper—and in recyclable glass and aluminum—are making headway. Luxe paper is tactile—with finishes including sandy, leather and linen feels. Partnerships between formulators and packaging companies ensure delivery of turnkey products to market faster than ever. More suppliers touted regionalization capabilities for manufacturing in-market. Partnerships are forming to avoid tariffs. And more luxury brands are using stock packaging—and customizing through high-quality deco, impressive advances in digital printing and more.

Beauty Multitaskers

A number of large exhibitors at Luxe Pack Monaco offered a vast array of solutions for products from makeup to skincare, caps to tubes, while others were very specific as to categories, materials and containers.

Albéa was one exhibitor that featured a wide-ranging variety of options from mascaras to tubes to digital design.

Cecile Tuil, vice-president communications, Albéa, showed Beauty Packaging an assortment of dazzling caps for fragrance bottles, made possible due to a collaboration with a 3D startup for innovation. Tuil explained that Albéa provides 3D add-on covers for mascara, lipstick and fragrance. A 3D printed “Desert” family of mascara brushes featured an extremely flexible brush “with no limit to design.” What’s more, the brushes are available in quantities from one piece to numbers on an industrial scale.

A large part of Albéa’s stand was devoted to their sustainable packaging accomplishments, including all new green, recyclable bags and pouches made of recycled or recyclable materials.

When it comes to lipstick, Albéa is working on reusable packaging, in which the consumer can keep the outer package, and swap out the mechanism. Attractive carton board cases with high gloss, CMYK printing and lamination, had been developed for lipstick and mascara.

There were also lots of advances in tubes, including a new PCR tube and pump made in the USA, which was first developed 10 years ago, according to Tuil. Three new tubes with different PCR concentrations were designed to meet different market expectations: Max PCR is 70% PCR; Beautiful PCR is designed with an inner layer and virgin fossil-based PE outer layer of 70% PCR; Ultimate PCR, is 70% PCR and 30% bioplastic. At the center of tube innovation was a carton board-based tube developed in partnership with L’Oréal, in which “plastic is for the most part replaced with a bio-based and certified paper-like material.”

Another talking point at Albéa: Regionalization—many packages can be manufactured in the U.S., in Connecticut, as well as in Europe.

Quadpack presented numerous packaging solutions for cosmetics, skincare, fragrance and more. The company was also celebrating their recent acquisitions of Innotech and Louvrette, which Quadpack CEO and co-founder Tim Eaves told Beauty Packaging he had been working on for some time. The Louvrette acquisition, said Eaves, “is a perfect fit, and places Quadpack among the top ten cosmetic packaging providers in Europe.” Louvrette specializes in thick-walled injection molding, particularly in the skincare packaging market. Germany-based Innotech’s process knowledge and pioneering bi-injection molding technology will boost Quadpack’s ability to offer an exclusive product range, designed and manufactured in-house. In addition, Eaves said Quadpack has developed a 4-part strategy to be more sustainable, and going forward, all new packs will now have one of the following: Recycle, Replace, Re-use, Reduce. Currently, East Hill, in the U.S., offers Quadpack’s modular standard line that can be decorated for quicker lead times.

Surveying Glass Solutions with Marc Rosen

On my annual Luxe Pack Monaco show floor tour with award-winning packaging designer Marc Rosen, we visited century-old Waltersperger, where semi-automatic glass was in the spotlight.

Based in Normandy, France, the boutique glassmaker creates very specific crystal and lead crystal high-end bottles and factices for fragrance and spirits. One especially different and attractive bottle used cracked glass—they crack the flacon in hot water; then blow it to its finished form. With its long history of luxury manufacturing, Adrien Tourres said that they have 5,000 molds in stock, so “brands can search for old flacons for rejuvenation—and pay no mold, no design.” Waltersperger can produce 1-20,000 pieces. Rosen explained the advantages of semi-automatic glass: “They can do very complex forms that are not feasible in the automatic process. They have the expertise to do surface and texture right.” Tourres added that they can remove the lead from the inside of a lead crystal bottle to make it compatible with a fragrance.

Rosen was also impressed with an innovative fragrance bottle on display at Bormioli Luigi—the bottle for Lancôme Idole Eau de Parfum. Designed by architect and industrial designer Chafik Gasmi, the Idôle bottle is one of the slimmest in the world at just 15mm thick—and “a fitting tribute to the industry technical advances and innovations,” according to the brand. Available in several refillable formats (25-, 50- and 75ml), Idôle is accompanied by a perfume fountain at selected points of sale.

Rosen commented that what made this bottle especially interesting was the case around it. He told Beauty Packaging: “I feel that it’s the first environmentally responsible bottle to achieve a luxe look—by encasing the thin bottle with a rose gold casing beveling the glass. Other bottles presenting sustainability with 50% less glass can compromise/trade luxe for sustainability.”

Also on display at Bormioli was the lightning bolt-shaped bottle for the men’s fragrance Bad Boy by Carolina Herrera (following Bad Girl, for women, in the shape of a stiletto).

Coverpla works hand in hand with brands on sustainability commitments, and Bruno Diépois, CEO, showed Rosen and me a range of standard and custom glass bottles they were offering through relationships with glass suppliers Bormioli Luigi and Pochet.

Just a few months after partnering with Bormioli for the launch of the Ecoline range, Diépois said demand was far beyond initial expectations. Coverpla offers all the benefits of customization both in terms of presentation and thanks to its “mix and match” strategy. Screw necks are available for refilling or separating.

“The value of eco-friendly packaging is an addition to our broad standard offer, an added service that it is natural to bring to our customers,” said Diépois. The choice of a lightweight bottle is part of Coverpla’s turnkey offer: bottle, custom pump, choice of cap, and made-to-measure décor for a 100% personalized product.

Situated in front of a living green wall, Verescence fittingly displayed a number of sustainable options in glass. The new jar for Guerlain Abeille Royal was produced in very lightweight glass.

Michel Levisse, VP product development, explained that they had reduced the glass by 42% weight, from 163 grams to 95 grams. It has an available level of 25% PCR, 65% PIR, 10% regular raw material. For the new Illuminare launch for Vince Camuto, Verescence worked with the designer to create a two-color Murano effect. The asymmetrical organic inner shape was achieved thanks to Verescence’s SCULPT’in patented technology, creating a play of light with the rounded outer shape of the molded glass and the delicate pink hued fragrance. The bottle was manufactured at Verescence’s U.S. glass manufacturing site in Covington, Georgia.

Piramal Glass showcased its latest range of innovations and designs in sustainable glass packaging for the Premium cosmetics perfumery market. As part of its continued efforts to enhance its capabilities, Piramal Glass recently invested 15 million euro to add three new premium perfume bottle manufacturing lines to provide an additional capacity of 50 million pieces. The company also invested 15 million euro to modernize and expand its decoration facility in Kosamba, India, by doubling its current capacity with the addition of new automated printing and color coating lines. Mr. Shah explained that they are heavily investing in using advanced digital techniques such as RTMI manufacturing 4.0—tracking manufacturing at every stage for maximum efficiency and quality. Piramal Glass aims to be a green facility as much as possible, with wind farms, solar panels, etc.

Virospack was highlighting their new “Last Drop” molded glass bottle with 50ml of capacity and 20/410 neck. The new format offers the same high quality, weight, transparency and excellent compatibility level as the rest of the range.

One focus at Gerresheimer was on their recycled glass for cosmetics and fragrance packaging, with a whole clear glass furnace dedicated to the production of PCR glass. The company also produces plastics packaging from PCR.

Capardoni Italy offers glass and plastic full packaging standard and custom solutions. At Luxe Pack Monaco, they were highlighting their full Ecogreen range, including bottles, jars, closures and flip-top caps, produced in different eco-friendly raw materials derived from renewable resources or recycled plastic—100% recyclable with the same features as traditional plastic, and a lower weight during transport. Components can be recycled in the same recycling chain as traditional polyethelene. The supplier introduced their new green line—a full range of packaging and caps that’s been developed and tested, using PCR and green PE, with less weight; and sugar cane derived plastic. They’re also working with wood—cellulose pulp—to get the right balances. With the cellulose pulp, every bottle looks slightly different because the distribution changes when it is machined. It’s available in large quantities, and two layers can be mixed for complete compliance—such as internal, green PE; external PCR. Another plus:

It’s available in bright white.

Board and Paper Previews

At Luxe Pack Monaco, Mitchell Kaneff, CEO, Arkay Packaging, told Beauty Packaging that Arkay continues to seek environmentally responsible materials and was proud to announce that Arkay was awarded Gold Medal recognition due to its high EcoVadis CSR Rating. This rating includes companies that advocate sustainability, which Arkay does. At Luxe Pack, for instance, their customer gifts were made of two boards, Monadnock Kona folding box board from reclaimed coffee bean bags, with variegated fibers that convey a natural aesthetic; and Monadnock’s Astrolite folding box board, which is FSC certified, and more luxe and smooth.

Kaneff also showed us examples of their “Paint on Press” capabilities, which he said are very popular. “The technique gives gorgeous touches and brand realization far in advance of printing the actual product. It takes 2D artwork and enhances designs,” explained Kaneff. He also spoke about Arkay’s successful relationship with Switzerland-based Model Group (with whom Arkay shared a booth), noting: “Regionalization is very real and Arkay is prepared for it.”

Big Arkay news at the show: Arkay announced its purchase of the Drupa model Primefire 106, the first commercially available industrial inkjet digital printing system in the 70 x 100 (40-in.) format. According to Kaneff, the Primefire 106 has the ability to match offset print quality, giving customers the option of printing digitally or offset, based on job length. Arkay looks forward to the installation of the Primefire 106 in its Roanoke, VA plant in March 2020.

With a focus on sustainability, the Neenah booth featured the company as a holistic, custom solutions partner for all premium packaging and retail graphics needs. Known for its high precision color matching, Neenah allows global brands to present a consistent brand presence across multiple locations. Greg Maze, director of marketing, packaging and retail solutions, said, “Whether customers are purchasing products in Los Angeles or Hong Kong they expect to find brand consistency. Seeing varying shades of a signature color, or finding an unfamiliar texture on a box can weaken the customer’s trust in the product and create a questionable brand experience. Neenah’s custom matching capabilities provide brands with the certainty that their customers have come to expect.”

Neenah also emphasized a big launch in Monaco—the Neenah Folding Board Portfolio, with a focus on sustainability and a wide format. The supplier introduced its new Hemp Board

papers, which are available in a vellum finish, in three of Neenah Folding Board’s most popular shades, including a bright white, 80% PCW sheet with highly visible hemp fibers for brands that want to clearly identify the use of hemp papers in their package design. Neenah’s FSC-certified folding board papers range from 30-100% PCW content.

At Sweden-based BillerudKorsnäs, Anders Gathu, marketing manager, told Beauty Packaging that they “have entered a new era with the introduction of CrownBoard”—a new cartonboard available in white, prestige, high-gloss, for digital printing. It can be embossed, debossed, made highly textural, light weighted, even in some cases using 5-10% less paper. Gathu spoke about the “incredible textural colorful glossy effects,” and said there are also “lots of ways to save resources.”

According to Gathu, CrownBoard is so strong that it allows for substantial reduction of packaging weight. “The launch of CrownBoard gives customers new opportunities to save cost and reduce environmental impact,” said Gathu. “With the stronger board, a lower basis weight does the job.” In addition to light-weighting saving costs, less raw material is used and less energy and production resources are needed. Less transport and warehousing requirements, too. “It adds up to great savings along the entire value chain,” adds Gathu.

Cosmetics and Skincare Specialties

In front of its living green wall at Luxe Pack Monaco, SamHwa was featuring dual-formula dip tube airless bottles. They were also showcasing their continuing development in PCR and glass. For example, twist-up airless bottles are being reconfigured into more sustainable packaging such as PCR replacements.

ShyaHsin, specialists in lipstick and mascara, featured a plethora of stock and custom packaging. The company’s new chairman, Howard Clark, told Beauty Packaging that everything is produced in house in a brand-new, state-of-the-art 2-million square foot facility in Shanghai. Capabilities include metal forming, anodizing, decorating and in-house tool machining. “It’s soup-to-nuts, build-it-all production,” said Clark.

Geka presents a new collection at nearly every industry show, and Luxe Pack Monaco was no exception; in fact, here, they showed two: the Polymorph mascara collection, with an innovative packaging solution for a smart and elegant prestige mascara; and the pureOBSESSION collection, a premium collection featuring high-end components and luxury decoration finishes.

The pureOBSESSION collection includes a mascara, a lip gloss, a liquid concealer, a liquid eyeshadow as well as a multi-benefit makeup brush and a clutch.

A focus on green—punctuated with a living wall and grassy settings for several new products—instantly got the sustainability message across at Cosmogen, where new CEO Priscille Caucé, showed Beauty Packaging new developments including brushes with FSC beechwood, bamboo, and coconut handles. Additional accessories such as spatulas and massagers are also made with FSC wood. Engraved logos avoid the use of ink. Also on display, different accessories developed with varying percentages of PCR plastic, depending on what clarity a brand wishes to achieve. New brush sets without ferrules avoid aluminum with just the tuft and handle.

Maud Lelievre, key account manager, Cosmogen, showed Beauty Packaging tubes made with bio-based sugarcane—both squeeze and roll on systems. They now separate for easier recycling—you can detach the roller and recycle the applicator. Cosmogen’s Tense tube also has a removable applicator, and can be refillable too. PCR can be used in all tubes and caps—in various mixes/percentages.

Mascara remains a popular product category at HCP, according to Jackie Mantle, managing director HCP-UK, who told Beauty Packaging, “We are experiencing lots of mascara business—in the U.S. and elsewhere.” She added: “We’re also seeing more desire for regionalization capabilities.”

As far as environmentally responsible solutions, HCP is focusing on developing primary packaging that optimizes the opportunity to ‘reduce, reuse and recycle.’ The HCP Eco Lab team is using PCR and “exploring cutting-edge options such as bio-materials, as well as identifying how the rapidly evolving beauty landscape should inform the stock development program.”

Cheryl Morgan, creative marketing manager, HCP, showed Beauty Packaging an exclusive green sustainable material called EcoWood, a bi-product of the paper industry, made from FSC waste products—100% wood and vegetable waxes, of several different grades. She explained that it has undergone lots of trials, and is available in compacts to jars, and with no metal hinges.

At Axilone, beautiful custom and stock—and combinations of the two—lipsticks drew attention as always. A By Killian lipstick featured a stock item inside; for the outside, Axilone created the fashion part using just a few tools: 1 mold (just 1 tool), cap and bottom. It’s available in smaller quantities of 20,000-25,000 pieces. New elongated lipsticks for YSL featured a square bulk and cap shape; this lipstick featured 100% custom new tools for everything.

More Luxe Pack

The next edition of Luxe Pack will take place February 11-12, at the Los Angeles Convention Center, co-located with MakeUp in LosAngeles.

At this year’s Luxe Pack Monaco, BillerudKorsnäs presented the first Grand Finale winner of PIDA (Packaging Impact Design Award), an international competition arranged by BillerudKorsnäs and carried out in collaboration with leading universities and colleges in Sweden, the UK, France and Germany. For the first time an overall European winner was named in a celebration at the supplier’s stand, with four finalists present—and their packaging projects showcased.

Bois underwear was the winner, for a banana-shaped package created in an environmentally friendly way.