Jamie Matusow, Editor-in-Chief12.10.19

The term “Innovative Packaging” has become increasingly more complex and subject to interpretation. No longer can a product be defined as innovative simply according to its look and function—or even its uniqueness or novelty in the marketplace. Today’s standout beauty products must evoke emotional connections through packaging innovation—and be immediately clear as to how they will be meaningful, practical and problem-solving.

It’s in large part a shift from the “disruptive” innovation mindset that has dominated the design industry for 15 years, to thinking about creating “solutions-based” innovation, according to David Luttenberger, global packaging director, Mintel.

The difference, explains Luttenberger, is consumers may find a package on shelf and understand that it is different. “But,” he cautions, “if they don’t understand why it is different, and more importantly, what that difference means to them personally, then it truly is a disruption—a disruption to their shopping experience, their use experience, and possibly their repeat purchase experience. Conversely, if a consumer finds a package on shelf that they not only see as being different—but they understand what that difference means to them—then it has become a solution.”

A practical emotional connection might be one based on how easy or intuitive it is to use, or the package size. A rational emotional connection might be one based on price. The irrational emotional connection is based on want or desire, versus need.

Luttenberger explains, “When a brand can evoke one, or even multiple of these emotional connections through packaging innovation, then they have created a solution-based innovation, versus simply creating a disruption of a shopper or consumer’s shopping or use experience.”

Anisa International’s chief product officer, Sarina Godin thinks similarly, defining innovation as something novel and unique whether it be a product, package, process or way to reach the consumer. She says, “It’s about finding a different approach that would be relevant to the consumer and make a difference in their lives.”

Thomas Chun, project engineer, packaging innovation, HCT Group, looks at innovation as anything that’s different from what currently exists in the market, such as the application gesture, the design of the packaging or the formula texture. But, he says customers are getting more “innovation-specific” in their requests. Chun explains, “Three trends that our customers are constantly asking for as far as new innovations in the packaging space are sustainability, Instagram-ability, and easy customization. We have expanded our offerings in all of these categories.” (See specifics from HCT Group below.)

Having a new gesture—once viewed as the ‘holy grail’ of innovation, must today have substance and benefits behind it.

Shiseido’s Jess Abrams, executive director, product development, Global Makeup Center of Excellence & Shiseido Makeup, says, “There is a fine line between being innovative versus gimmicky, so this becomes a consideration for prestige and luxury brands.

New gestures are an important part of package innovation, but they need to be intuitive enough without requiring extensive education, and they must provide consumer appeal and convenience.”

The same holds true at Milk Makeup, which was recently included on CEW’s list of Indie65 brands that range from $1 million to $1 billion in size; Milk was named in the $20 million to $50 million category.

“Today,” says Rhonda Wehbe, senior packaging engineer, Milk Makeup, “innovations in packaging have come to mean so many different things I don’t know where to begin.

From a design standpoint, I really like seeing innovations in gesture. For example, I was given a mascara with a cap that pops open, which was more interesting than the traditional threaded cap, and so much fun to fidget with. It was a lot more impactful and interactive than design innovations in say, deco.”

Wehbe says Milk Makeup’s concept of innovation has evolved over the years. “Historically, innovation for us has been about social change and how we use and think about makeup. When we first launched, our brand ethos was about freedom of expression and ease of use. This idea led to the development of an entirely brush-free makeup line.

Every product could be applied directly to your face and blended with your fingers. To accomplish this, we had to think of innovative formats and delivery systems for makeup and skincare. One of the things we ended up making was the world’s first solid serum: our Watermelon Serum Stick.” Milk’s solid skincare items—Matcha Cleanser, Matcha Toner, Watermelon Serum, and Cooling Water—were new formats in their product categories.

Brands, suppliers and consumers can each have different ideas about the nature of innovation—from marketability to the user experience. The key is finding the balance.

Kristen Corso, director of marketing and product development, Roberts Beauty, tells Beauty Packaging, the term innovative packaging can have different meanings to the different parties involved. She says, “Disruptive can go so far as to expect a totally different application action from the consumer, and different can be as simple as changes in shape. The supply side often takes complex approaches to innovation that aren’t easily understood or natural to the consumer.” She says high expectations are placed on suppliers to constantly have new innovations and this can create an environment of overcomplication as well as oversimplification.

The magic is to find the balance, says Corso. “To the brand, innovation can take many forms—it can be in the primary package, formula performance, secondary package or even the product story. The brand has a broader canvas in which to express innovation—while depending on the nature of the supplier, the innovation is typically limited by their areas of manufacturing strengths. To the consumer, innovation represents newness and trend, it’s evoking a feeling that makes a product seem unique.”

Thrown into the balance is the necessity for speed-to-market.

Kevin Jean, lead, creative innovation, at WWP, says, “To the supplier, material functionality and increased speed to market are key. On the supplier side we’re always challenging ourselves to develop products that function flawlessly and are beautiful—at a faster speed than our competitors. Brands focus on marketability—they are looking for ideas that can easily be marketed to their customer, so finding the balance between functionality and the brand DNA is extremely important.” When it ultimately comes to the consumer, Jean says the user experience is critical. “The customer is constantly looking for a new experience. it’s the act of the hunt and discovery that really gets the customer excited.”

At Asquan, Rebecca Goswell, creative director says, “Beauty packaging has to work harder than ever these days to satisfy many different market criteria. Packs have to communicate in a striking fashion, catching the all-seeing eye on Instagram feeds as a priority over visibility in online and physical stores.”

In addition, Goswell says, “The rise of influencer brands who are pragmatic decision makers, creatively nimble, and digitally native has created an increasing need for fast-paced design and development as well as accelerating whole societal shifts (such as embracing sustainability and gender fluidity) at a pace that is unprecedented.”

Goswell describes Asquan’s latest launch, Semi Circle, as “a minimal yet dramatic shift away from the norm, with multiple decoration possibilities and a striking aesthetic that lends itself perfectly to social media.”

Still, while Instagram-ability remains a top tenet of product development, Abrams says, at Shiseido, “Packaging aesthetics are always top of mind, regardless of social media.

The sustainability movement provides a new challenge for developers, as there is a consumer focus on reducing excess packaging, so prestige brands must balance the luxury experience with a reduction in waste.”

Environmental Responsibility Takes New Priority

With 2025 rapidly approaching—the year that many brands and suppliers have pledged for objectives regarding environmentally responsible packaging, innovations in materials, practices and packaging structures are taking a dominant position on the innovation front.

When asked how environmental responsibility has influenced innovation in the beauty and personal care (BPC) space, Mintel’s Luttenberger replies: “How has it not?”

He says consumers today are demanding that brands, big corporations, and even packaging suppliers be more responsible across the board. Further, Luttenberger says, “Without a doubt, Mintel sees the impact of the challenges currently associated with plastics impacting package innovation in the BPC space.”

For many BPC brands, product format and ingredients require plastic packaging, notes Luttenberger. However, he says, “with this material being the focus of consumers’ environmental ire, brands need to be open about addressing plastic use on pack. Those niche brands and products that can make plastic-free packaging claims are shining a harsh and critical light on brands that cannot.” However, he notes that small changes, such as light-weighting, using mono-material structures or giving those with dissimilar material components the ability to be separated for proper recycling, or even portfolio expansion to include refill pouches, tubes, and jars, can enable brands to adopt a “plastic reduction” stance.

“Creating responsible and sustainable material source stories can mitigate concern over plastic use,” says Luttenberger. He adds, “This points directly to an unparalleled opportunity for the BPC industry globally to step up, make changes, and most importantly, help educate consumers on what is the right thing for them to do when it comes to acting more responsibly once they are done with the product.”

Luttenberger advises brands to not only innovate around packaging to address negative perceptions, but to also communicate directly with consumers. He says, “On-pack copy can communicate how the brand is reducing the environmental impact of its plastic use. Innovation in how brands communicate—to include ‘connected packaging’ experiences—those which use apps, QR codes, AR/VR, etc.—will be as important to connecting emotionally with consumers as will be the environmental aspect of innovation.”

A focus on environmentally responsible packaging has caused the industry to rethink all phases of development—and opened the door to further innovation.

The sustainability movement has become a major trend [that’s here to stay], says Abrams, , therefore providing new criteria for innovation. She says at Shiseido, they are seeing this through applications of new resins, processes, and engineering details that are both visible and invisible to the consumer. “There is a strong focus throughout the industry on improving the integrity of these new and recycled materials, along with refining the aesthetics,” adds Abrams. Major trends include packages with Post-Consumer Recycled content, FSC certifications and reduced plastic content.

At Golden Arrow, which specializes in using molded fibers for primary and secondary packaging, Jake Snethen, packaging development manager, believes, “Sustainability has significantly changed what it means to innovate—environmental stewardship and corporate responsibility requires all of us to dig deep. Creating novelty products or improving what exists just isn’t enough. Innovation, especially in sustainability, calls us to do our part to protect our environment and our future generations by changing the way we think about packaging.”

Sustainability is a cornerstone at Golden Arrow, one that has been woven into their innovation process, according to Snethen. As consumers have become increasingly educated and aware of environmental issues, he says, “We are seeing massive strides in sustainability that have spread far and wide among beauty/fragrance/personal care packaging to meet environmental, social and governance goals. Our understanding that certain kinds of materials and processes are harmful to the planet not only motivates the industry and our search for more responsible alternatives, but it improves the health of the environment as a whole.”

Sustainability has been a strong influencer for innovation at HCT Group, where Chun says, “Sustainability has influenced innovation by introducing a new set of design requirements that packaging needs to comply with, whether it be the use of PCR material, or recyclability. To meet the demands of the industry, we have launched our sustainable packaging initiative called the Eco Modern Approach, where we are trying to educate our customers about different ways to approach sustainability, such as recyclable packaging, use of post-consumer recycled materials, bio-sourced materials, or even refillable packages.

HCT Group has launched an entire packaging program (HCT EMA, Eco Modern Approach) dedicated to sustainable packaging innovations, whether it’s through designs that have been optimized for recycling, components made from PCR and bio-sourced materials or refillable options. Some of their most recent innovations in this program include a line of mono-material components made from 100% PET including Eco Lipstick, Eco Lip Gloss, EMA Palette and Vero Compact. Because they are made out of only one material they are very simple to recycle after use in the existing waste stream. “This program is dedicated to creating a sustainable option or options for every category/product in the beauty space,” explains Chun.

The influence has also been a great innovation kickstarter at WWP, where Jean, says, “The demand for more sustainable packaging options has pushed us to look at alternate materials, reusable packaging designs and refillable options.”

At Metapack, de La Noue, says, “Nowadays, sustainability is at the heart of innovation. Brands are looking for new gestures, recyclable materials and refillable packaging. Metapack has conducted our own investigation to verify the recyclability of zamac and we can say loud and clear that zamac is 100% recyclable.” She says they have also created a range of stock models made of zamac that are refillable, such as pursers, compacts, perfume stick containers and lipstick containers.

From the brand point of view, at Milk Makeup, Wehbe says, “Sustainability should be everyone’s driving force behind innovation today.”

Corso, at Roberts Beauty, proclaims, “Sustainability has absolutely influenced innovation. We don’t even have a conversation about innovation anymore without talking about sustainability.”

HLP Klearfold has also focused considerable attention in this direction. Because many consumer products marketers and retailers have established packaging sustainability goals that include the use of plastic packaging that contains up to 100% post-consumer recycled (PCR) content, the company came up with a solution. Patrick McGee, vice president, marketing, says: “So that these companies can continue to receive the marketing and merchandizing benefits of Klearfold plastic folding cartons, while still satisfying their sustainable packaging goals, HLP Klearfold has introduced our new Klearfold RPET100 premium-quality plastic folding cartons, made with 100% (PCR) content.”

McGee explains, “We are able to produce high-quality Klearfold RPET100 cartons, in addition to the 30% PCR content cartons that we’ve been producing for the last 10 years, because of the vertical integration program that we undertook at that time. Having our own custom extruders that are designed to make premium-quality, box-grade plastics exclusively, combined with carefully and locally sourced post-consumer PET waste (water and soda bottle flake), enables us to produce box-grade RPET with 100% PCR, with no meaningful sacrifice in quality or performance, and without compromising the high marketing appeal of Klearfold cartons.”

Asquan Group’s Goswell says: “In accordance with this dynamic sea change, our view of innovation is no longer purely a matter of new shape, function or material…but has to now take into account significantly more far-reaching criteria that affect the future of our planet.”

She says, “Sustainability is ingrained within everything we do and think about at Asquan. We absolutely subscribe and adhere to our customers’ desire for PCR, single polymer packs, disassembly and refillable systems and our SS21 innovation deck reflects this determination to reduce the use of virgin plastic and subscribe to a circular economy in the short to mid-term.”

Presently, Asquan is working to offer a 100% PCR ABS cap as an alternative to virgin ABS and says it is their aim to introduce this option to as many of their new stock components “as is technically possible, moving forward.”

FusionPKG offers a vast assortment of stock packages with infinite options of materials, finishes, decoration, applicators and shapes to allow brands to pivot quickly. To provide options for brands seeking a more sustainable path, Alexander Kwapis, executive director of product design + development, FusionPKG, says they are innovating in this category: “Sustainability continues to sweep the industry. Many brands are evaluating their sustainable position in the market. We offer a variety of solutions including glass bottles and jars, PP bottles and jars, refillable packaging and threaded connections on pumps for easy disassembly and recycling.”

Gary Korba, chief officer of operations and innovation at MG New York, sums up the current complicated situation in the beauty world, noting, “With all companies working toward a goal of 2025… the greatest challenge is cost and how to make the package that is both sustainable and upscale.”

Innovation Through Customization

One way to make a sustainable—or any—package look upscale is through innovative customization of custom or stock items—an ever-growing trend in Beauty.

At MG New York, Korba says graphics will continue to help brands differentiate, and provide easy customization. They have purchased both 3D printing equipment and a cold stamping and spot varnish machine in order “to create new deco treatment and to meet the desire for faster turnaround from concept to delivery.”

For example, striking holiday compacts from MG New York elevate deco with 4-color printing on holographic foil, heavy multilevel embossing and 3D raised printing in white for the Bobbi Brown logo.

Customization also encompasses the usage of a product. Anisa International’s Godin says, “Consumers want the ability to customize products/routines and often don’t use the same products each day. Depending on how their skin is behaving, the time of the month, the day of the week, the activities they have planned for the day, their beauty routine will change and consumers want the ability to easily customize their needs.” She adds: “Consumers are also more focused than ever around sustainability and how what they’re using impacts the world around them. New materials are being launched to replace plastics and formulas are being launched to eliminate the need for water.”

Anisa International recently launched their Liquid Drops brush collection for both skincare and makeup. These brushes have recessed silicone reservoirs that allow the consumer to custom blend their beauty routine right in their product applicator. Whether you’re applying skincare and want to blend your moisturizer with your anti-aging treatment and luminizer, or you’re applying makeup and want to blend two shades of foundation with a SPF, the blends are in the hands of the consumer,” says Godin.

Easy customization is a specialty at HCT Group. Chun says, “We have adjusted some of our most popular stock components to include small changes, such as a recess in the lid for deco plaques, or the option to completely customize the platform on an existing palette like our Block Magnetic Palettes, so that our customers can make quick and easy customizations to create a package that is more on brand with their existing brand aesthetic.”

Innovation Through Dispensing

How a consumer uses a product can be a major draw for purchase—and re-purchase, and brands and suppliers are always looking for easy, effective and satisfying dispensers and gestures.

Mintel’s Luttenberger says product efficacy/freshness and how package innovation can facilitate both, will continue to be front and center. One of the best examples Mintel has identified recently is Kiehl’s Pure Vitality Skin Renewing Cream. This jar is topped with an innovative dispensing material that enables the consumer to “push” droplets of the product from the container, while still maintaining the remaining product’s full efficacy.

The formula is certified “Silver” by the Cradle to Cradle institute, based on an evaluation of the product’s material health, material reutilization, renewable energy and carbon management, water stewardship and social fairness. The certification acts as a guarantee that the products and materials have been developed to respect human and environmental health, designed for future use cycles, and utilize clean energy and water throughout the supply chain.

At Shiseido, Abrams says their recently launched Synchro Skin Self-Refreshing Foundation bottle and pump “was a huge development.” The pump is assembled with a snap feature (required for the twist-lock mechanism), however, there is an override so that it can be disassembled for recycling the glass. Abrams says, “We always design our packaging around the ideal dispensing of the formula. While we often use glass for our foundations, we also take into account how and where the product will be used by the consumer.”

Shiseido’s Gail Boyé, SVP product development, Global Makeup Center of Excellence, explains: “The vision was a pump that didn’t look like a traditional pump, that would surprise and delight the consumer. The concept was executed through a collaboration between the New York-based engineering and development teams and our package design team in Tokyo, led by designer Mao Komai. Careful consideration was made to ensure this innovative actuator remained consistent with our brand codes, with a technical design that could be successfully executed.”

The Shiseido pump is a great example of “behind-the-scenes” innovation that’s not immediately visible to the consumer. It also features a complicated decorative technique and an advanced engineering process, according to Ludovic LeCaro, SVP operations, product development, Shiseido.

LeCaro says, “The pump was designed with a juxtaposition of textures and finishes along with an on/off functionality with sensory click feedback. The decoration process is quite interesting as this component utilizes a combination of matte spray, pad-printing for the red line and a debossed design in mold for Shiseido’s signature camellia logo on the top of the actuator. The extended nozzle was engineered to dispense the perfect amount of formula paired with the pump engine size.” He adds: “Consumers don’t always realize the engineering and the thought process behind a simple artistic object like a pump packaging. For example, the pump collar was engineered to not only meet Komai’s vision, but also provide this decorative band around the bottle to hide the pump snapping features onto the bottle neck. This collar ultimately created a seamless transition between the rotating pump and the beautiful glass bottle.”

Hana Innovation has designed and created a 2ml refillable click pen. Renaud Baker, general manager for Hana Innovation America, says it has “three main and substantial differences from the myriad of click pens currently on the market.” The click pen is airless and is dosage—meaning that, with each click of the button, a defined and consistent dosage is dispensed—no free flow of product. Because the pen is in an airless design, Baker says high-viscosity products and formulations that are sensitive to air can be used. In addition, the refillable click pen meets sustainability criteria as it is designed with a cartridge that, once empty, can be replaced with a new, full cartridge instead of replacing the entire package.

Virospack recently introduced a first-of-its-kind dropper with a massager tip, designed for precise applications for low viscosity formulas. The dropper has a bulb system inside, whose PP pipette ends in a drop-shaped tip made of metal (“a completely harmless and dermatologically tested material”), which provides an instant cooling effect to skin. Not only does it provide a pleasant refreshing sensation, but according to Virospack’s marketing & communication manager, Rosa Porras Mansilla, “It increases the effectiveness of the product for its decongestant effect and blood activation for better penetration and absorption of the formula.” The metallic dropper is available in a classic or pushbutton design—and can be decorated in a variety of ways.

A patent pending dual-neck vial at Siloa Inc., allows two dispensing systems supporting a single product—and aims for customer feedback for further development. In the case of fragrance, it allows the consumer to roll-on or spritz. It’s also been designed to be refillable and it can be offered in a variable size range. Mark Bellard, president, says, “Having been able to execute a concept, we then look at other applications for it. When the idea is introduced to the market, the customers will usually have ideas that make the product better or give it wider and different possibilities.”

Beauty to Go

Along with industry trends including innovative and sustainable packaging, customization and speed-to-market, comes consumers’ love of products that can be easily accessed and used “on the-go” to accommodate their busy work-life schedules.

In this vein, FusionPKG’s Kwapis says, “Multitasking packages continue to trend. Busy lifestyles and an increasing demand for convenience led us to develop our Top Secret compact, a patent-pending compact that makes applying on the go easy and chic.” The innovative design includes a cover that transforms into a slim, premium brush for a modern, sleek look and unique user experience. It’s available in multiple shapes, each designed so you can swiftly slide the brush out, apply product and snap it back into place effortlessly. The design also protects the brush’s bristles from formula residue when not in use.

WWP’s Jean also sees the athleisure trend infiltrating the cosmetic world in a big way, with customers looking for packaging that can endure the rigors of a workout, or fit comfortably in a gym short or travel pouch. In addition, he points out that gender-neutral packaging continues to grow as well. “We’re seeing a new crowd entering the cosmetic world for the first time so having an innovation that can address many demographics is crucial for us to stay fresh,” says Jean. To satisfy these demands, WWP recently produced Lululemon’s self-care line of multifunctional products that are designed to be used before and after workouts. The collection is packaged in dual layer, soft-touch tubes decorated with silk screen and a spot varnish, in “gender-neutral white and red colors.”

In the quest for on-the-go innovation in the fragrance market—the ability to apply and wear scent anytime, anywhere—several new solutions-based innovative gestures/packages have emerged.

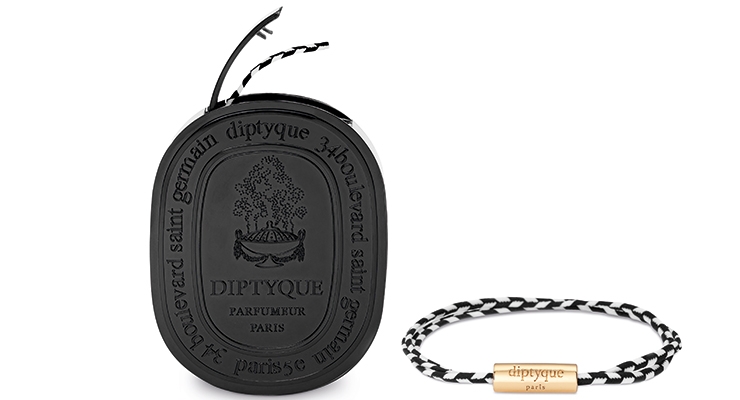

At Metapack, de La Noue points to the Diptyque scented ribbon dispenser as a good illustration. “This concept is totally unique,” says de La Noue, “as it is the first scented ribbon dispenser made by a perfume brand.” She explains, “Diptyque came to us in order to find a technical solution with very short timing. We ended up with a dispenser, 100% made in France. It combines three parts made of Zylar and two parts made of PP. The blade and weight are made of steel. The manual assembly has been done by a workshop employing disabled persons, so in addition to being an innovative project, this item also highlights CSR.”

Texen Beauty Partners recently developed a “perfumed paintbrush” for Mugler (Angel, Aura and Alien). This “beauty-to-go” product offers a new gesture in fragrance application—and is also part of the supplier’s “green range,” as it is refillable. Filled with 8ml of fragrance, it allows easy application thanks to its push-button delivery system: a single click delivers the perfect dose of fragrance to whatever part of the body the wearer desires. Its applicator brush is designed with white synthetic bristles, but it could also be developed in other materials, for example with a flocked or silicone tip, in the future. For Mugler, the pack was developed in aluminum in three different anodized shades using a particularly complex industrial process, then screen-printed in black or white depending on the product.

A Look at the Future of Innovative Packaging

Between solutions-based innovation, environmentally responsible packaging, on-the-go demand, dispensing distinctions and a goal of Instagram-ability success, suppliers and brands have a lot on their plate in trying to capture consumer attention. Where could all these efforts lead? What types of packages can we expect to see?

HCT Group’s Chun, says, “In the future, we expect to see more and more pushes for sustainable packaging. This push has been passed down from consumers to manufacturers over the years. At every level of the supply chain, suppliers are trying to innovate so we expect to see future packaging developed using new sustainable materials and more sustainable manufacturing processes.”

Roberts’ Corso agrees, saying, she foresees less disposables and more durable/reusable packaging. “Currently, many packaging items use multiple resin types which prevents them from successfully entering the recycling stream. Corso says, “I expect to see more single resin recyclables entering the market.”

At WWP, Jean says, “We’re seeing more dual-use packaging making a big splash and sustainable offerings are on everyone’s mind. We’re also starting to see the blurred lines of color cosmetics and skincare which we’re closely watching.”

Anisa’s Godin says, “For sustainability we will see several new materials launch that can replace plastics and we’ll probably see more options to create refill programs. For customization, we’ll probably see more components that allow the consumer to customize their beauty routine.”

At Metapack, de La Noue, says, “Definitely future packaging will have to be sustainable and made with recyclable and recycled materials.”

Wehbe, of Milk MakeUp, also looks at materials as a future trend. “I hope to continue to see greater strides in polymer science. From what I’ve learned so far, it seems that even if you make your package with recyclable material, it often gets sorted out of the recycling stream anyway due to size or decoration. Additionally, brands often have to sacrifice design and profit margin in order to choose an environmentally sustainable resin. Because of this, the thing I would like to see most is how to master making post-consumer recycled resin more functional and affordable, and/or making new resins compostable. I see more and more bioplastics and cleaner PCR every year. Luckily, until these materials become mainstream, we have programs like Terracycle to ethically dispose of all the goods that can’t be recycled traditionally.”

From mono materials to refillables to recyclables to customization—perhaps there has never been a more promising and opportune time for creativity and innovation in the beauty industry.

It’s in large part a shift from the “disruptive” innovation mindset that has dominated the design industry for 15 years, to thinking about creating “solutions-based” innovation, according to David Luttenberger, global packaging director, Mintel.

The difference, explains Luttenberger, is consumers may find a package on shelf and understand that it is different. “But,” he cautions, “if they don’t understand why it is different, and more importantly, what that difference means to them personally, then it truly is a disruption—a disruption to their shopping experience, their use experience, and possibly their repeat purchase experience. Conversely, if a consumer finds a package on shelf that they not only see as being different—but they understand what that difference means to them—then it has become a solution.”

A practical emotional connection might be one based on how easy or intuitive it is to use, or the package size. A rational emotional connection might be one based on price. The irrational emotional connection is based on want or desire, versus need.

Luttenberger explains, “When a brand can evoke one, or even multiple of these emotional connections through packaging innovation, then they have created a solution-based innovation, versus simply creating a disruption of a shopper or consumer’s shopping or use experience.”

Anisa International’s chief product officer, Sarina Godin thinks similarly, defining innovation as something novel and unique whether it be a product, package, process or way to reach the consumer. She says, “It’s about finding a different approach that would be relevant to the consumer and make a difference in their lives.”

Thomas Chun, project engineer, packaging innovation, HCT Group, looks at innovation as anything that’s different from what currently exists in the market, such as the application gesture, the design of the packaging or the formula texture. But, he says customers are getting more “innovation-specific” in their requests. Chun explains, “Three trends that our customers are constantly asking for as far as new innovations in the packaging space are sustainability, Instagram-ability, and easy customization. We have expanded our offerings in all of these categories.” (See specifics from HCT Group below.)

Having a new gesture—once viewed as the ‘holy grail’ of innovation, must today have substance and benefits behind it.

Shiseido’s Jess Abrams, executive director, product development, Global Makeup Center of Excellence & Shiseido Makeup, says, “There is a fine line between being innovative versus gimmicky, so this becomes a consideration for prestige and luxury brands.

New gestures are an important part of package innovation, but they need to be intuitive enough without requiring extensive education, and they must provide consumer appeal and convenience.”

The same holds true at Milk Makeup, which was recently included on CEW’s list of Indie65 brands that range from $1 million to $1 billion in size; Milk was named in the $20 million to $50 million category.

“Today,” says Rhonda Wehbe, senior packaging engineer, Milk Makeup, “innovations in packaging have come to mean so many different things I don’t know where to begin.

From a design standpoint, I really like seeing innovations in gesture. For example, I was given a mascara with a cap that pops open, which was more interesting than the traditional threaded cap, and so much fun to fidget with. It was a lot more impactful and interactive than design innovations in say, deco.”

Wehbe says Milk Makeup’s concept of innovation has evolved over the years. “Historically, innovation for us has been about social change and how we use and think about makeup. When we first launched, our brand ethos was about freedom of expression and ease of use. This idea led to the development of an entirely brush-free makeup line.

Every product could be applied directly to your face and blended with your fingers. To accomplish this, we had to think of innovative formats and delivery systems for makeup and skincare. One of the things we ended up making was the world’s first solid serum: our Watermelon Serum Stick.” Milk’s solid skincare items—Matcha Cleanser, Matcha Toner, Watermelon Serum, and Cooling Water—were new formats in their product categories.

Brands, suppliers and consumers can each have different ideas about the nature of innovation—from marketability to the user experience. The key is finding the balance.

Kristen Corso, director of marketing and product development, Roberts Beauty, tells Beauty Packaging, the term innovative packaging can have different meanings to the different parties involved. She says, “Disruptive can go so far as to expect a totally different application action from the consumer, and different can be as simple as changes in shape. The supply side often takes complex approaches to innovation that aren’t easily understood or natural to the consumer.” She says high expectations are placed on suppliers to constantly have new innovations and this can create an environment of overcomplication as well as oversimplification.

The magic is to find the balance, says Corso. “To the brand, innovation can take many forms—it can be in the primary package, formula performance, secondary package or even the product story. The brand has a broader canvas in which to express innovation—while depending on the nature of the supplier, the innovation is typically limited by their areas of manufacturing strengths. To the consumer, innovation represents newness and trend, it’s evoking a feeling that makes a product seem unique.”

Thrown into the balance is the necessity for speed-to-market.

Kevin Jean, lead, creative innovation, at WWP, says, “To the supplier, material functionality and increased speed to market are key. On the supplier side we’re always challenging ourselves to develop products that function flawlessly and are beautiful—at a faster speed than our competitors. Brands focus on marketability—they are looking for ideas that can easily be marketed to their customer, so finding the balance between functionality and the brand DNA is extremely important.” When it ultimately comes to the consumer, Jean says the user experience is critical. “The customer is constantly looking for a new experience. it’s the act of the hunt and discovery that really gets the customer excited.”

At Asquan, Rebecca Goswell, creative director says, “Beauty packaging has to work harder than ever these days to satisfy many different market criteria. Packs have to communicate in a striking fashion, catching the all-seeing eye on Instagram feeds as a priority over visibility in online and physical stores.”

In addition, Goswell says, “The rise of influencer brands who are pragmatic decision makers, creatively nimble, and digitally native has created an increasing need for fast-paced design and development as well as accelerating whole societal shifts (such as embracing sustainability and gender fluidity) at a pace that is unprecedented.”

Goswell describes Asquan’s latest launch, Semi Circle, as “a minimal yet dramatic shift away from the norm, with multiple decoration possibilities and a striking aesthetic that lends itself perfectly to social media.”

Still, while Instagram-ability remains a top tenet of product development, Abrams says, at Shiseido, “Packaging aesthetics are always top of mind, regardless of social media.

The sustainability movement provides a new challenge for developers, as there is a consumer focus on reducing excess packaging, so prestige brands must balance the luxury experience with a reduction in waste.”

Environmental Responsibility Takes New Priority

With 2025 rapidly approaching—the year that many brands and suppliers have pledged for objectives regarding environmentally responsible packaging, innovations in materials, practices and packaging structures are taking a dominant position on the innovation front.

When asked how environmental responsibility has influenced innovation in the beauty and personal care (BPC) space, Mintel’s Luttenberger replies: “How has it not?”

He says consumers today are demanding that brands, big corporations, and even packaging suppliers be more responsible across the board. Further, Luttenberger says, “Without a doubt, Mintel sees the impact of the challenges currently associated with plastics impacting package innovation in the BPC space.”

For many BPC brands, product format and ingredients require plastic packaging, notes Luttenberger. However, he says, “with this material being the focus of consumers’ environmental ire, brands need to be open about addressing plastic use on pack. Those niche brands and products that can make plastic-free packaging claims are shining a harsh and critical light on brands that cannot.” However, he notes that small changes, such as light-weighting, using mono-material structures or giving those with dissimilar material components the ability to be separated for proper recycling, or even portfolio expansion to include refill pouches, tubes, and jars, can enable brands to adopt a “plastic reduction” stance.

“Creating responsible and sustainable material source stories can mitigate concern over plastic use,” says Luttenberger. He adds, “This points directly to an unparalleled opportunity for the BPC industry globally to step up, make changes, and most importantly, help educate consumers on what is the right thing for them to do when it comes to acting more responsibly once they are done with the product.”

Luttenberger advises brands to not only innovate around packaging to address negative perceptions, but to also communicate directly with consumers. He says, “On-pack copy can communicate how the brand is reducing the environmental impact of its plastic use. Innovation in how brands communicate—to include ‘connected packaging’ experiences—those which use apps, QR codes, AR/VR, etc.—will be as important to connecting emotionally with consumers as will be the environmental aspect of innovation.”

A focus on environmentally responsible packaging has caused the industry to rethink all phases of development—and opened the door to further innovation.

The sustainability movement has become a major trend [that’s here to stay], says Abrams, , therefore providing new criteria for innovation. She says at Shiseido, they are seeing this through applications of new resins, processes, and engineering details that are both visible and invisible to the consumer. “There is a strong focus throughout the industry on improving the integrity of these new and recycled materials, along with refining the aesthetics,” adds Abrams. Major trends include packages with Post-Consumer Recycled content, FSC certifications and reduced plastic content.

At Golden Arrow, which specializes in using molded fibers for primary and secondary packaging, Jake Snethen, packaging development manager, believes, “Sustainability has significantly changed what it means to innovate—environmental stewardship and corporate responsibility requires all of us to dig deep. Creating novelty products or improving what exists just isn’t enough. Innovation, especially in sustainability, calls us to do our part to protect our environment and our future generations by changing the way we think about packaging.”

Sustainability is a cornerstone at Golden Arrow, one that has been woven into their innovation process, according to Snethen. As consumers have become increasingly educated and aware of environmental issues, he says, “We are seeing massive strides in sustainability that have spread far and wide among beauty/fragrance/personal care packaging to meet environmental, social and governance goals. Our understanding that certain kinds of materials and processes are harmful to the planet not only motivates the industry and our search for more responsible alternatives, but it improves the health of the environment as a whole.”

Sustainability has been a strong influencer for innovation at HCT Group, where Chun says, “Sustainability has influenced innovation by introducing a new set of design requirements that packaging needs to comply with, whether it be the use of PCR material, or recyclability. To meet the demands of the industry, we have launched our sustainable packaging initiative called the Eco Modern Approach, where we are trying to educate our customers about different ways to approach sustainability, such as recyclable packaging, use of post-consumer recycled materials, bio-sourced materials, or even refillable packages.

HCT Group has launched an entire packaging program (HCT EMA, Eco Modern Approach) dedicated to sustainable packaging innovations, whether it’s through designs that have been optimized for recycling, components made from PCR and bio-sourced materials or refillable options. Some of their most recent innovations in this program include a line of mono-material components made from 100% PET including Eco Lipstick, Eco Lip Gloss, EMA Palette and Vero Compact. Because they are made out of only one material they are very simple to recycle after use in the existing waste stream. “This program is dedicated to creating a sustainable option or options for every category/product in the beauty space,” explains Chun.

The influence has also been a great innovation kickstarter at WWP, where Jean, says, “The demand for more sustainable packaging options has pushed us to look at alternate materials, reusable packaging designs and refillable options.”

At Metapack, de La Noue, says, “Nowadays, sustainability is at the heart of innovation. Brands are looking for new gestures, recyclable materials and refillable packaging. Metapack has conducted our own investigation to verify the recyclability of zamac and we can say loud and clear that zamac is 100% recyclable.” She says they have also created a range of stock models made of zamac that are refillable, such as pursers, compacts, perfume stick containers and lipstick containers.

From the brand point of view, at Milk Makeup, Wehbe says, “Sustainability should be everyone’s driving force behind innovation today.”

Corso, at Roberts Beauty, proclaims, “Sustainability has absolutely influenced innovation. We don’t even have a conversation about innovation anymore without talking about sustainability.”

HLP Klearfold has also focused considerable attention in this direction. Because many consumer products marketers and retailers have established packaging sustainability goals that include the use of plastic packaging that contains up to 100% post-consumer recycled (PCR) content, the company came up with a solution. Patrick McGee, vice president, marketing, says: “So that these companies can continue to receive the marketing and merchandizing benefits of Klearfold plastic folding cartons, while still satisfying their sustainable packaging goals, HLP Klearfold has introduced our new Klearfold RPET100 premium-quality plastic folding cartons, made with 100% (PCR) content.”

McGee explains, “We are able to produce high-quality Klearfold RPET100 cartons, in addition to the 30% PCR content cartons that we’ve been producing for the last 10 years, because of the vertical integration program that we undertook at that time. Having our own custom extruders that are designed to make premium-quality, box-grade plastics exclusively, combined with carefully and locally sourced post-consumer PET waste (water and soda bottle flake), enables us to produce box-grade RPET with 100% PCR, with no meaningful sacrifice in quality or performance, and without compromising the high marketing appeal of Klearfold cartons.”

Asquan Group’s Goswell says: “In accordance with this dynamic sea change, our view of innovation is no longer purely a matter of new shape, function or material…but has to now take into account significantly more far-reaching criteria that affect the future of our planet.”

She says, “Sustainability is ingrained within everything we do and think about at Asquan. We absolutely subscribe and adhere to our customers’ desire for PCR, single polymer packs, disassembly and refillable systems and our SS21 innovation deck reflects this determination to reduce the use of virgin plastic and subscribe to a circular economy in the short to mid-term.”

Presently, Asquan is working to offer a 100% PCR ABS cap as an alternative to virgin ABS and says it is their aim to introduce this option to as many of their new stock components “as is technically possible, moving forward.”

FusionPKG offers a vast assortment of stock packages with infinite options of materials, finishes, decoration, applicators and shapes to allow brands to pivot quickly. To provide options for brands seeking a more sustainable path, Alexander Kwapis, executive director of product design + development, FusionPKG, says they are innovating in this category: “Sustainability continues to sweep the industry. Many brands are evaluating their sustainable position in the market. We offer a variety of solutions including glass bottles and jars, PP bottles and jars, refillable packaging and threaded connections on pumps for easy disassembly and recycling.”

Gary Korba, chief officer of operations and innovation at MG New York, sums up the current complicated situation in the beauty world, noting, “With all companies working toward a goal of 2025… the greatest challenge is cost and how to make the package that is both sustainable and upscale.”

Innovation Through Customization

One way to make a sustainable—or any—package look upscale is through innovative customization of custom or stock items—an ever-growing trend in Beauty.

At MG New York, Korba says graphics will continue to help brands differentiate, and provide easy customization. They have purchased both 3D printing equipment and a cold stamping and spot varnish machine in order “to create new deco treatment and to meet the desire for faster turnaround from concept to delivery.”

For example, striking holiday compacts from MG New York elevate deco with 4-color printing on holographic foil, heavy multilevel embossing and 3D raised printing in white for the Bobbi Brown logo.

Customization also encompasses the usage of a product. Anisa International’s Godin says, “Consumers want the ability to customize products/routines and often don’t use the same products each day. Depending on how their skin is behaving, the time of the month, the day of the week, the activities they have planned for the day, their beauty routine will change and consumers want the ability to easily customize their needs.” She adds: “Consumers are also more focused than ever around sustainability and how what they’re using impacts the world around them. New materials are being launched to replace plastics and formulas are being launched to eliminate the need for water.”

Anisa International recently launched their Liquid Drops brush collection for both skincare and makeup. These brushes have recessed silicone reservoirs that allow the consumer to custom blend their beauty routine right in their product applicator. Whether you’re applying skincare and want to blend your moisturizer with your anti-aging treatment and luminizer, or you’re applying makeup and want to blend two shades of foundation with a SPF, the blends are in the hands of the consumer,” says Godin.

Easy customization is a specialty at HCT Group. Chun says, “We have adjusted some of our most popular stock components to include small changes, such as a recess in the lid for deco plaques, or the option to completely customize the platform on an existing palette like our Block Magnetic Palettes, so that our customers can make quick and easy customizations to create a package that is more on brand with their existing brand aesthetic.”

Innovation Through Dispensing

How a consumer uses a product can be a major draw for purchase—and re-purchase, and brands and suppliers are always looking for easy, effective and satisfying dispensers and gestures.

Mintel’s Luttenberger says product efficacy/freshness and how package innovation can facilitate both, will continue to be front and center. One of the best examples Mintel has identified recently is Kiehl’s Pure Vitality Skin Renewing Cream. This jar is topped with an innovative dispensing material that enables the consumer to “push” droplets of the product from the container, while still maintaining the remaining product’s full efficacy.

The formula is certified “Silver” by the Cradle to Cradle institute, based on an evaluation of the product’s material health, material reutilization, renewable energy and carbon management, water stewardship and social fairness. The certification acts as a guarantee that the products and materials have been developed to respect human and environmental health, designed for future use cycles, and utilize clean energy and water throughout the supply chain.

At Shiseido, Abrams says their recently launched Synchro Skin Self-Refreshing Foundation bottle and pump “was a huge development.” The pump is assembled with a snap feature (required for the twist-lock mechanism), however, there is an override so that it can be disassembled for recycling the glass. Abrams says, “We always design our packaging around the ideal dispensing of the formula. While we often use glass for our foundations, we also take into account how and where the product will be used by the consumer.”

Shiseido’s Gail Boyé, SVP product development, Global Makeup Center of Excellence, explains: “The vision was a pump that didn’t look like a traditional pump, that would surprise and delight the consumer. The concept was executed through a collaboration between the New York-based engineering and development teams and our package design team in Tokyo, led by designer Mao Komai. Careful consideration was made to ensure this innovative actuator remained consistent with our brand codes, with a technical design that could be successfully executed.”

The Shiseido pump is a great example of “behind-the-scenes” innovation that’s not immediately visible to the consumer. It also features a complicated decorative technique and an advanced engineering process, according to Ludovic LeCaro, SVP operations, product development, Shiseido.

LeCaro says, “The pump was designed with a juxtaposition of textures and finishes along with an on/off functionality with sensory click feedback. The decoration process is quite interesting as this component utilizes a combination of matte spray, pad-printing for the red line and a debossed design in mold for Shiseido’s signature camellia logo on the top of the actuator. The extended nozzle was engineered to dispense the perfect amount of formula paired with the pump engine size.” He adds: “Consumers don’t always realize the engineering and the thought process behind a simple artistic object like a pump packaging. For example, the pump collar was engineered to not only meet Komai’s vision, but also provide this decorative band around the bottle to hide the pump snapping features onto the bottle neck. This collar ultimately created a seamless transition between the rotating pump and the beautiful glass bottle.”

Hana Innovation has designed and created a 2ml refillable click pen. Renaud Baker, general manager for Hana Innovation America, says it has “three main and substantial differences from the myriad of click pens currently on the market.” The click pen is airless and is dosage—meaning that, with each click of the button, a defined and consistent dosage is dispensed—no free flow of product. Because the pen is in an airless design, Baker says high-viscosity products and formulations that are sensitive to air can be used. In addition, the refillable click pen meets sustainability criteria as it is designed with a cartridge that, once empty, can be replaced with a new, full cartridge instead of replacing the entire package.

Virospack recently introduced a first-of-its-kind dropper with a massager tip, designed for precise applications for low viscosity formulas. The dropper has a bulb system inside, whose PP pipette ends in a drop-shaped tip made of metal (“a completely harmless and dermatologically tested material”), which provides an instant cooling effect to skin. Not only does it provide a pleasant refreshing sensation, but according to Virospack’s marketing & communication manager, Rosa Porras Mansilla, “It increases the effectiveness of the product for its decongestant effect and blood activation for better penetration and absorption of the formula.” The metallic dropper is available in a classic or pushbutton design—and can be decorated in a variety of ways.

A patent pending dual-neck vial at Siloa Inc., allows two dispensing systems supporting a single product—and aims for customer feedback for further development. In the case of fragrance, it allows the consumer to roll-on or spritz. It’s also been designed to be refillable and it can be offered in a variable size range. Mark Bellard, president, says, “Having been able to execute a concept, we then look at other applications for it. When the idea is introduced to the market, the customers will usually have ideas that make the product better or give it wider and different possibilities.”

Beauty to Go

Along with industry trends including innovative and sustainable packaging, customization and speed-to-market, comes consumers’ love of products that can be easily accessed and used “on the-go” to accommodate their busy work-life schedules.

In this vein, FusionPKG’s Kwapis says, “Multitasking packages continue to trend. Busy lifestyles and an increasing demand for convenience led us to develop our Top Secret compact, a patent-pending compact that makes applying on the go easy and chic.” The innovative design includes a cover that transforms into a slim, premium brush for a modern, sleek look and unique user experience. It’s available in multiple shapes, each designed so you can swiftly slide the brush out, apply product and snap it back into place effortlessly. The design also protects the brush’s bristles from formula residue when not in use.

WWP’s Jean also sees the athleisure trend infiltrating the cosmetic world in a big way, with customers looking for packaging that can endure the rigors of a workout, or fit comfortably in a gym short or travel pouch. In addition, he points out that gender-neutral packaging continues to grow as well. “We’re seeing a new crowd entering the cosmetic world for the first time so having an innovation that can address many demographics is crucial for us to stay fresh,” says Jean. To satisfy these demands, WWP recently produced Lululemon’s self-care line of multifunctional products that are designed to be used before and after workouts. The collection is packaged in dual layer, soft-touch tubes decorated with silk screen and a spot varnish, in “gender-neutral white and red colors.”

In the quest for on-the-go innovation in the fragrance market—the ability to apply and wear scent anytime, anywhere—several new solutions-based innovative gestures/packages have emerged.

At Metapack, de La Noue points to the Diptyque scented ribbon dispenser as a good illustration. “This concept is totally unique,” says de La Noue, “as it is the first scented ribbon dispenser made by a perfume brand.” She explains, “Diptyque came to us in order to find a technical solution with very short timing. We ended up with a dispenser, 100% made in France. It combines three parts made of Zylar and two parts made of PP. The blade and weight are made of steel. The manual assembly has been done by a workshop employing disabled persons, so in addition to being an innovative project, this item also highlights CSR.”

Texen Beauty Partners recently developed a “perfumed paintbrush” for Mugler (Angel, Aura and Alien). This “beauty-to-go” product offers a new gesture in fragrance application—and is also part of the supplier’s “green range,” as it is refillable. Filled with 8ml of fragrance, it allows easy application thanks to its push-button delivery system: a single click delivers the perfect dose of fragrance to whatever part of the body the wearer desires. Its applicator brush is designed with white synthetic bristles, but it could also be developed in other materials, for example with a flocked or silicone tip, in the future. For Mugler, the pack was developed in aluminum in three different anodized shades using a particularly complex industrial process, then screen-printed in black or white depending on the product.

A Look at the Future of Innovative Packaging

Between solutions-based innovation, environmentally responsible packaging, on-the-go demand, dispensing distinctions and a goal of Instagram-ability success, suppliers and brands have a lot on their plate in trying to capture consumer attention. Where could all these efforts lead? What types of packages can we expect to see?

HCT Group’s Chun, says, “In the future, we expect to see more and more pushes for sustainable packaging. This push has been passed down from consumers to manufacturers over the years. At every level of the supply chain, suppliers are trying to innovate so we expect to see future packaging developed using new sustainable materials and more sustainable manufacturing processes.”

Roberts’ Corso agrees, saying, she foresees less disposables and more durable/reusable packaging. “Currently, many packaging items use multiple resin types which prevents them from successfully entering the recycling stream. Corso says, “I expect to see more single resin recyclables entering the market.”

At WWP, Jean says, “We’re seeing more dual-use packaging making a big splash and sustainable offerings are on everyone’s mind. We’re also starting to see the blurred lines of color cosmetics and skincare which we’re closely watching.”

Anisa’s Godin says, “For sustainability we will see several new materials launch that can replace plastics and we’ll probably see more options to create refill programs. For customization, we’ll probably see more components that allow the consumer to customize their beauty routine.”

At Metapack, de La Noue, says, “Definitely future packaging will have to be sustainable and made with recyclable and recycled materials.”

Wehbe, of Milk MakeUp, also looks at materials as a future trend. “I hope to continue to see greater strides in polymer science. From what I’ve learned so far, it seems that even if you make your package with recyclable material, it often gets sorted out of the recycling stream anyway due to size or decoration. Additionally, brands often have to sacrifice design and profit margin in order to choose an environmentally sustainable resin. Because of this, the thing I would like to see most is how to master making post-consumer recycled resin more functional and affordable, and/or making new resins compostable. I see more and more bioplastics and cleaner PCR every year. Luckily, until these materials become mainstream, we have programs like Terracycle to ethically dispose of all the goods that can’t be recycled traditionally.”

From mono materials to refillables to recyclables to customization—perhaps there has never been a more promising and opportune time for creativity and innovation in the beauty industry.