Marie Redding, Senior Editor12.10.19

Packaging's role is to convey a beauty brand's message. Different types of decoration and decorative effects can elevate a package and tell a brand's story. Design is the tool that marketers and designers use to accomplish this task—while working with suppliers to execute their vision.

Suppliers offer brands a multitude of ways to decorate all types of packaging—including glass, plastic, and paperboard. An innovative decorative technique can help elevate a package and influence the user's experience with the product.

Bottles, tubes, and jars can be silk-screened, hot-stamped, and metalized. Lacquering and spray-painting techniques can make glass bottles look sleek and beautiful. Statement-making decorations might feature specialized inks and coatings for plastic tubes, paperboard cartons—and more.

Color Trends

When a brand discusses decoration with a packaging supplier, color trends are often an influencing factor. Beauty brands most often stick to its signature color, experts say—except for limited edition launches, which often feature trendy looks.Pantone will announce its Color of the Year 2020 in December (Update: It is Classic Blue), and trend forecasters predict that coastal-inspired hues are likely to be popular in beauty, fashion and home furnishings.

Corals and popular pinks might soon be replaced by sea-inspired blues and greens. “Blues will take center stage…browns are inspired by dried seaweed and driftwood. We can also expect to see “sand-like whites” and cool green hues,” reveals Laurie Pressman, vice president, Pantone Color Institute.

Pantone’s Spring/Summer 2020 New York Fashion Week Color Palette includes several blues and greens—Classic Blue, Biscay Green, Faded Denim, Chive, Mosaic Blue, plus a purple, Grape Compote. The lineup also includes warmer hues—Flame Scarlet, Saffron, Orange Peel, Sunlight, Coral Pink, and Cinnamon Stick.

“Combining our desire for stability, creativity, and more spontaneous design approaches, the color palette for Spring 2020 infuses heritage and tradition with a colorful youthful update that creates strong multi-colored combinations as well as energizing and optimistic pairings,” explains Leatrice Eisemann, executive director, Pantone Color Institute.

Color can be used in combination with various types of finishes—or a clear finish can provide a tactile element. Different finishes can also change the appearance of a color, when used over ink. “Our most popular decoration processes this year have been matte and soft touch finishes, as well as clear, frosted and tinted finishes—plus, reverse-out shade identification finishes,” says Eleanor Bunting, International Cosmetic Suppliers (ICS).

Anthony Grinnell, CEO, Harmony Paper Company, says he hasn’t seen beauty brands gravitate toward a particular color palette or finish this year. “Brands seem to be maintaining their ‘look’ for the most part, but there is a push for more eco-friendly materials and that has forced somewhat of a retraction from ‘shiny’ packaging—and this is why our EcoShine product line is a game-changer,” he says. (More on this below.)

Popular Decorations

GTO Pad & Screen Printing Machines, a supplier of printing machinery (described in more detail below), has a department of inks in both its Italy and U.S. facilities, to assist its customers with matching Pantone colors or creating custom ones, and ensuring consistency.“We receive requests for a variety of different types of decorations, but we are doing more plain printing than anything else—often paired with a single laminated effect,” says Martina Gasparella Rosetti, the company’s marketing director.

Alpha Packaging’s container decorating division, Technigraph Corporation, has seen a significant increase in the number of beauty brands interested in spray-frosting bottles and jars. (More about its Eco-Frost process is below.)

“Raised inks are also often used as an innovative way to cost-effectively change the look and feel of a plastic bottle,” says Marny Bielefeldt, vice president of marketing, Alpha Packaging. “It gives an embossed effect,” she adds. “The inks can be metallic, to create a high-end effect at a fraction of the cost of custom embossing,” she adds.

The team at Takemoto says requests are coming in for matte spray-coated looks, and the supplier offers an alternative. “Our new molded frost-look finishes give plastic bottles and jars a high-end look,” says Atsko Fukada, senior director, Takemoto.

'Clean' Beauty Influences Design Trends

The 'clean' beauty trend is influencing design. As consumers gravitate toward more natural and organic cosmetic products, packaging is taking on a more natural look, suppliers say.“Last year, glossy colorful packaging was still at play with the continued popularity of Millennial Pink. This year, we have seen a major shift in finishes to more matte and earthy textures,” says ICS’ Bunting.

“Nudes have been the color of choice, ranging from creamy, chocolatey hues to sandy, rosy tones," she continues. "Clear, transparent packaging has been a leading decorative look for both plastic and glass. “Transparent shades and textures make consumers feel their packaging is more sustainable and trustworthy, while also remaining playful, youthful and tactile,” Bunting explains.

One way for a beauty brand to convey a ‘clean and natural’ image is to use soft, frosted bottles with earthy, organic colors advises Bunting. ICS recently worked with ILIA Beauty to develop the packaging for its True Skin Radiant Priming Serum and Liquid Light Serum Highlighter.

“The brand’s packaging features finishes that are the perfect example of the ‘clean beauty’ trend,” says Bunting. “ILIA’s decoration style is natural and organic. The priming serum’s bottle has a soft matte cream-colored finish. The highlighter features an earthy mink-colored pearlized pump and cap, paired with a clear frosted bottle,” she adds.

Myro's Cartons Tell a Story

Myro, a new natural deodorant brand, designed its cartons to tell a 'story' -- and convey each fragrance in its collection.Myro designed an innovative refillable deodorant case, which is plastic and comes in different colors. Refillable scented pod refills are sold separately. The refills come in cartons, decorated with a design that truly elevates the brand.

Yael Eisele, Myro’s creative director, and partner at Deerfield, a boutique agency in Brooklyn, explains, “We approached the narrative around each scent in a way that’s more typical of fine fragrance, crafting stories that people can make emotional connections to online—a format that clearly doesn’t allow for smelling product."

Eiselecontinues, "The pod boxes rely more on visuals than romance copy to tell our scent stories. Mood-inspiring snapshots on each package support the scent names.”

The cartons are printed using a 4-color-process on FSC-Certified board. “The printing is complemented with our Myro Green PMS color—a ‘happy bright’ only Pantone can achieve, and a deboss/spot varnish for emphasis, used sparingly. That detail is a splurge that takes our refill boxes from a nice box to something more candy-like,” Eisele explains.

Myro's collection is shown in the slideshow above. It includes Cabin No 5, in a green case and an image of a forest printed on the carton. The scent includes vetiver, patchouli, and geranium. Solar Flare is an orange case -- with a picture of 'dreamy' clouds.

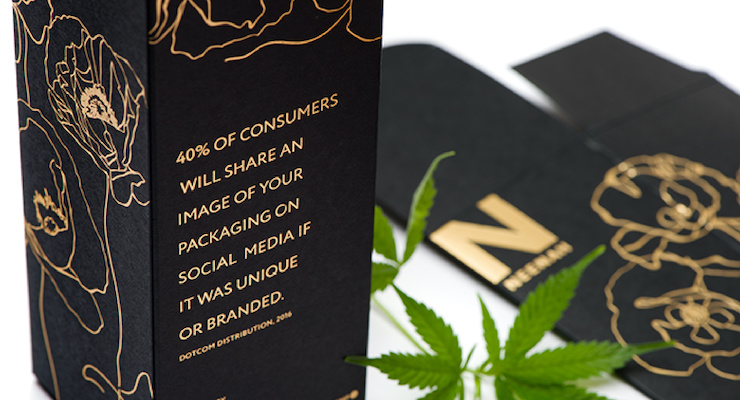

Neenah's Hemp Fiber Papers

No matter how a carton will be decorated, a decoration will often look different depending on the type of board and inks that are chosen. Certain types of board will also help tell a brand’s eco-friendly story.Neenah recently introduced new Hemp Fiber Papers into its premium folding board portfolio. The supplier offers a range of stocked options, custom capabilities, and PCW content ranging from 30% to 100%, all of which are FSC Certified.

“These premium packaging papers are engineered to provide best in class printing results while allowing our customers to design as sustainably as possible while not forgoing luxury,” said Michelle Turner, brand manager, Neenah.

Decorating a Dropper Pack

Since sustainability is a part of nearly every brand’s discussion, many brands are choosing glass bottles and jars, especially Indie skincare brands. Suppliers offer a variety of decorating options for glass.Virospack offers its metallized push-button droppers with injected central rings in different colors, paired with glass bottles decorated in various ways. Virospack decorates glass using a spray-painting process, in a range of opaque and translucent colors with shiny or matte finishes. “Our electrostatic paint facility is used for this purpose,” says Rosa Porras Mansilla, marketing communications manager, Virospack. “Our process, and water-based inks, comply with paint-industry regulations while respecting the environment,” Porros adds.

Virospack recently incorporated an aerographic spray-painting line into its facility. “This allows us to produce any special effect on glass and plastic—from color gradients to pearly finishes, using two or three coats with conventional or UV curing,” Porros explains. She continues, “The development of plasma treatments allows us to offer a greater offer of packaging decoration and metallic colored finishes to our customers, while operating in a more sustainable way.”

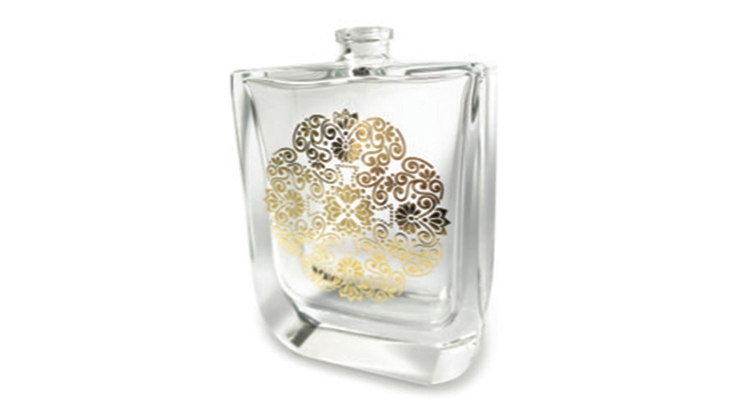

Decorating Glass

Monvera Glass Décor is another supplier that decorates glass, and its specialty is screen printing on glass bottles. “Screen-printed labels are an upscale alternative to paper and adhesive labels, for a high-end look. And design options are available that are not always easy to achieve with pressure sensitive and paper labels, such as a 360-degree full wrap,” says Caitriona An-derson, the company’s vice president.Another advantage, according to Anderson, is that Monvera’s screen-printed labels won’t rub off. “If the label is printed with ceramic inks, it is extremely durable, and won’t wear off over time,” she says. “This is a critical issue for beauty brands. It is all too common to see the text including usage instructions and ingredients rub off a package over the normal course of usage. The label and text must be able to withstand handling and product spills,” explains Anderson.

Monvera’s ceramic printing process includes a pass through its lehr oven, where the glass bottle or jar is fired at 1,100 degrees Fahrenheit. This causes the inks to fuse with the glass, enhancing durability. “It also provides the added benefit of sterilizing the glass,” says Anderson.

“The packages are packed directly from the oven. Precious metal and gold inks can be used alongside ceramic inks,” she says, adding, “There is real gold in these inks, so they are more expensive, but perfect for a luxury brand.”

Monerva decorated Reverie hair care's glass bottles, shown above, using this process.

The Right Machinery To Execute a Design

Decorating a package requires using the right type of machinery for the job and, in addition to decorating ability, the equipment a brand or supplier uses also affects lead time and budgets.Kaufman Container has a new decorating machine, and the company says it is “drastically changing the game for beauty brands.” “Our new automatic machine can handle very tight registration and is capable of 5 color screen print and 1 color hot stamp in-line,” says Richard Szoradi, vice president of operations, Kaufman Container. “I challenge our customers to design complex artwork, because I am confident in its printing capabilities,” he says.

Kaufman Container says it offers low tooling costs, short lead times, and low minimum order quantities for its brand partners. The supplier says hot-stamping is popular, with silver or gold foil, and due to its new decorating capabilities, some of its customers are adding this element to existing designs.

Tapematic offers its customers, who are typically decorators, its PST Line. “It is able to provide different types of finishes and decorating solutions, without the need for dedicated equipment. It can process both aluminum and plastic closures,” says Tony Denning, the company’s president.

In addition, Tapematic’s PST Line offers eco-friendly benefits. “It is the most eco-friendly for coating and metallization processes, as it can use up to 100% solid coatings, which means virtually zero VOCs are generated. Additionally, the power consumption of the line is the most economical in the industry,” explains Denning. “With our Spray-On-Demand paint technology, the savings in paint alone are enormous. Also, as the system is in-line, the rejects and waste are reduced to a minimum,” he adds.

GTO Pad & Screen Printing Machines has a new patent-pending machine with the capability to print a decoration that looks like hot-stamping, without using a traditional hot-foil printing pro-cess. Valter Scolaro, the company’s co-founder and R&D manager, developed the machine with the help of GTP’s engineering team.

“The main difference is the durability of the print,” explains GTO’s Rosetti. “It allows for the foil shine to be printed even on irregular surfaces, whereas traditional hot foil printing allows only for round or flat surface printing. This was created specifically because of the need of some of our clients to have durable foil-like shine and versatility of application,” she says.

GTO’s customers use its versatile machinery to decorate all types of packaging, from glass perfume bottles to wood makeup brushes and plastic tubes. The supplier’s capabilities include decorating with up to 6 colors, and laminated (foil) printing on any type of material.

“Our multiple color pad printers are capable of printing on all shapes with a 90-degree angle, front and back. “They print in multiple colors, all in one step and without the mess of inks,” adds Rosetti.

Many of GTO’s customers are cosmetic manufacturers, as well as packaging companies that provide brands with turnkey solutions, which include in-house printing services.

Shine, Glitter, Frosts & Inks That Are Recyclable

Sometimes “shiny” packaging implies the opposite of “green,” but that’s not always the case.Harmony Paper offers eco-friendly, recyclable options that feature shine and glitter. Harmony Paper’s Grinnell explains, “The vast majority of today’s decorative packaging contains plastic, which means the end product is not recyclable. Silver metallized PET is often used with paperboard, and it is just one example. Due to this—and the lack of alternatives—there are misconceptions, and the false perception that decorative, attention-grabbing packaging and eco-friendliness cannot coincide. But there are plastic-free options available, and they won’t break the bank.”

Harmony Paper has been developing alternative materials for eco-friendly packaging for two years. “Our new EcoShine line of plastic-free metallized and holographic papers not only eliminates plastic in the final product, but also does not use any plastics during manufacturing,” says Grinnell. He continues, “Unlike metal-transfer and zero-gauge options that use plastic in the manufacturing, EcoShine is completely plastic-free from start to finish—and its aesthetics are virtually indistinguishable from plastic counterparts.”

Harmony Paper has also created the first-ever 100% non-shedding glitter paper, and it is the first glitter paper that is recyclable. “It has almost 90% re-pulpability,” says Grinnell. “By using water-based glues and patented processes, Diamond Print Glitter doesn’t release glitter into the environment and allows extremely high-pulp recovery rates,” he explains.

ICS offers eco-friendly decorating options as well. “The sustainability trend continues to expand into all aspects of packaging, and decorating processes cannot be ignored,” says Bunting.

ICS offers eco-friendly based inks that don’t contain VOCs. Plus, the supplier offers its exclusive 100% Biodegradable Packaging. “It is a versatile, sustainable, natural plant-derived material sustainably grown, which we decorate using eco-friendly techniques that include printing with embossing and debossing effects,” says Bunting.

Technigraph Corp., a division of Alpha, also offers a “green” decorating option—Eco-Frost, its trademarked, environmentally-friendly UV spray frost. “It is often applied as the first step of the container decorating process. Plastic containers are conveyed down a line past a series of nozzles, where the frost is sprayed directly onto the bottle or jar, which evenly rotates as it passes the nozzles. Round bottles, as well as oblong and oval bottles, can be decorated using this process,” explains Bielefeldt. “Once the bottles have been spray-frosted, they can then be screen-printed or labeled for a dramatic decorative effect. This process provides the high-end look of etched glass without the costs of transportation and breakage,” she adds.

Technigraph’s screen-printed and spray-frosted bottles are easier to recycle than bottles that are decorated with pressure-sensitive labels or shrink sleeves, according to Bielefeldt. “The use of direct screen-printing also eliminates the materials and scrap associated with PS labels, which can often add as much as 1 gram of material to every bottle, once it is labeled or sleeved,” she says.

Decorating Plastic

Another supplier, Kurz Transfer Products, offers a new type of decorating process called IDD—Indirect Digital Decoration. “It gives plastic tubes and jars an irresistible eye-catching look,” says Allan Quimby, the company’s marketing manager.Kurz developed the technology with its subsidiary ISIMAT. The decorating process gives plastic packaging a glittering or multi-color effect with intense color, combining foil decoration with digital printing, to decorate in one step.

“It offers brands a multitude of color options, as well as custom colors and metallizing capabilities," says Quimby. "Tubes and jars can then be finished in a single pass with metallized motifs, and then coated or printed with several colors. The technology is ideal for seasonal or promotional items, which can be implemented individually and economically, since the deco is easily changed,” he explains.

Kurz also offers new holographic foils that provide superior chemical resistance without overcoating.

In terms of being “green,” Kurz says that foil and/or heat transfer decoration is a “dry decoration” process, which eliminates many harmful chemicals and processes from the manufacturing environment. In addition, its IDD technology can provide shorter runs, which reduces waste. Kurz products are also recyclable in both the plastic and paper spaces.

“In plastics, we can go through the regrind or reclaiming processes and they can be reused," says Quimby. "This cannot be done with painted or coated products today," he explains. "In the paper space, our products will break down in the pulp process. This cannot be easily achieved with other laminate films and boards," he adds.

The Future of Deco is 'Green'

Anomatic, a supplier known for its decorating expertise, especially in metallization, anodizing, and color-matching, says its team has many new eco-friendly decorating processes in development.“Sustainable packaging is top of mind for consumers and brands alike, and, as a packaging supplier, it’s something that we are laser-focused on. One of our newest innovations in development is lacquering plastic with a UV water-based system,” says Didier Teillard, technical director, Plastic Coating & Decorating, Anomatic. “This revolutionary process addresses the conversations and needs that every packaging provider is having with its customers—a need to be more eco-friendly,” he adds.

Anomatic currently uses high solid paint formulas to dramatically reduce VOCs. “Our ultimate goal is to transition this new process into our metallizing process,” says Teillard, adding, “Once our trials are complete, we’ll be able to do virtually everything we can do with the traditional thermal technology, including glitter, gradients, and more. It’s another step in the right direction for our customers, their customers and the planet.”

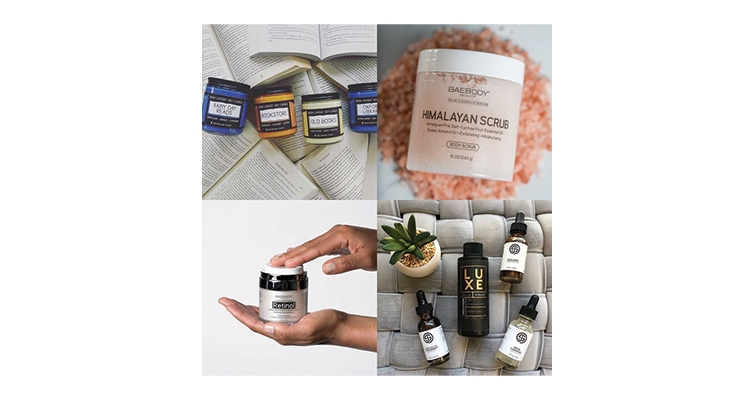

In the competitive beauty and personal care market, the look and feel of a product in a shopper’s hands and before their eyes can make or break a sale. Labels are often a customer’s initial introduction to a brand with the ability to tell a story while conveying brand identity all at once.

Steve Smith, president and founder at Wizard Labels, a specialist in e-commerce and a supplier of digitally-printed custom product labels for a variety of markets, including beauty and personal care products, stresses how product labeling is critical to a beauty brand’s success.

“A well-designed product label does a number of things. First, it informs the prospective customer about what your product is and how it benefits them,” he says. On a crowded shelf, labels can also attract attention away from competitive products. He says an eye-catching beauty label will always fare better than a drab uninteresting one.

“Another important thing to keep in mind is that a professionally designed label will usually just look better than something amateurish,” Smith says. “After all, poor design is a visual distraction and only encourages viewers to focus on the wrong things.”

Finally, a product label design frequently needs to include regulatory information in order to meet legal requirements, which may be a critical component of certain end-use segments of the beauty market.