Joanna Cosgrove, Contributing Editor12.10.19

Speed to market is essential in the fast-paced beauty sector, but the path to retail can be risky. Contract manufacturers and turnkey service providers can help by handling some or all of the legwork, starting with product ideation and customized formulating through to providing packaging and marketing assistance. If your brand is contemplating a service provider partnership, turnkey and contract service suppliers are brimming with advice on how brands can maximize the experience.

Cliff Davis, CEO, QRS, says a critical part of the process is for brands to look inward and evaluate their internal capabilities to determine exactly what they want to tackle and what they need to farm out. “Handling a project internally requires packaging expertise, project management skills, product knowledge and a working understanding of materials management (ordering, tracking components and shrinkage, component reorder points, etc.),” he says. “As well, most brand owners prefer [to] devote the bulk of their time to the sales, marketing and distribution of products, rather than to the operational aspects.”

Brands must be honest about their own expertise as it relates to formulations, packaging, filling, secondary packaging, regulatory, creative and testing, asserts Bob Congionti, vice president of operations, Tokiwa Cosmetics America. “The less experience or exposure a company has in these areas, the more important and critical a qualified, experienced turnkey supplier becomes,” he says, advising that when reviewing potential suppliers, brands should inquire about what role and key elements they will be directly providing in the development and production process [because] the more elements or activities a supplier directly provides, the better. “Experience and longevity in the beauty industry is another critical question to ask of potential suppliers. Typically, new start-ups, due to smaller staffs, will require more services, which a qualified, full turnkey supplier is capable of providing.”

For success, it’s important that brands and contract manufacturers have a detailed, upfront plan for formulas and packaging, says Vincent Groccia, president and CEO of ColorVera Biotech Group Inc. “A realistic timeline, a confirmed budget and clear and regular communication between the parties is integral to the process,” he says.

ColorVera just completed production on a new 50 SKU color cosmetics brand for an online retailer building the brand completely from the ground up in about nine months. “First, we created the brand positioning and confirmed the SKU mix, then developed a budget and timeline [then] we provided all design direction and marketing support for the brand,” Groccia explains. “We moved quickly because of our ability to customize formulas and source both primary and secondary packaging.”

Choosing the Best Options

Brands that don’t have the knowledge or expertise in packaging, formulation, filling or product testing would benefit from a full-service, turnkey provider. All aspects of the process are covered with a simple, single point of contact, says Vonda Simon, owner, SeaCliff Beauty Packaging, a full-service turnkey supplier. “If you work separately with labs, fillers and packaging suppliers, the brand will have to have the knowledge to link all of the pieces together on their own,” she notes. “Turnkey contract manufacturers focus on taking away your team’s day-to-day complexity allowing the brand to focus on their marketing strategy and branding DNA.”

Erma Estrella, senior director of product sales/product development, HCT Group, says full-service, turnkey services like those offered by HCT Group can benefit small and large brands.

“In addition to packaging and product development, we also help guide brands through the entire development process including regulatory, quality control and logistics,” she says. “We help coordinate all collaterals from various locations all the way up to delivering the finished goods at the brand’s distribution center. Having support on all of these items can help brands streamline their launches and improve their speed to market.”

For brands not requiring complete service, contract service providers can manage aspects of a brand’s formulating, filling or packaging, depending on the need. Elizabeth Forsyth, CEO and partner at Sheencol’or USA, a turnkey beauty and personal care supplier to global and Indie brands, says many times, brands choose a turnkey supplier who has different in-house capabilities than they do. “For example, powder pressing is a messy and challenging business and requires a certain level of expertise and costly machinery,” she comments. “Many brands come to us to produce their powder formulas since we are fully equipped with semi-automatic and automatic machinery that produce a high-quality product in a fraction of the development and production time.”

Marketing assistance is another perk of some service partnerships. For instance, prior to founding CTK Cosmetics’ full-service division, Sunny Choi, CEO of CTK Cosmetics, a K-Beauty specialist, worked in marketing for worldwide brands. When she started full service at CTK, her goal was to offer tailored marketing services to brands, including concept, ingredient story, formula, design and packaging from the brand’s point of view. CTK’s latest customizable product is its Brush Pop Compact for pressed powders, bronzers or highlighters, and features a separate slot for a full-size brush. The brush slides out from the bottom of the compact, allowing for a thin overall profile while keeping the brush hygienic and the mirror clean.

The first step in a brand’s partnership journey is evaluating service providers to ensure their core competencies are a good fit.

While some providers are jacks of all trades, others specialize in certain services or market sectors. Some are also especially good at working with organic or fair-trade ingredients and sourcing eco-friendly packaging materials.

When interviewing potential turnkey partners, brands should be extra clear on the goals they have for the products they want produced and understand that there may be steps in the process that shouldn’t be overlooked. Kathie Elliot, vice president of sales, marketing and product development, Cosmetica, says contract providers can expertly manage important aspects of product development like QA/QC, regulatory, compatibility and stability testing, scale up and pilot trials. “This provides more agility, less project resources and expertise in areas that some brands may not have,” she says.

Navigating Challenges with Ingenuity

Another benefit of partnering with service providers is their seasoned ability to head off potential issues before they become major problems.

QRS, a provider of high-end fragrances, body care products, cosmetics and skincare, was approached by a company that did not have the infrastructure to launch a new fragrance brand on its own. The project spanned five different 30ml, full-sized fragrances, along with a four-fragrance gift set comprised of 7ml rollerballs. QRS delivered the full-sized products in clear glass bottles with matte black caps and pumps plus front labels and four-color process, matte finished folding cartons. The kits included four 7ml rollerball packages, each printed in two colors. The rollerballs gift set featured a windowed folding carton with four color process printing.

QRS’s Davis says it’s common to encounter challenges in the development process. In this case, there was “an aggressive budget” to adhere to, cartoning issues that were solved, and a small bottle label that the customer needed maximized for executing their design (which they also desired to be visible from the front and back of the bottle). “We determined the best approach was to use our outside labeling partner, one with expertise in similar challenges,” he says. “Partnering with the right label supplier for the project allowed the client’s desired design element to be achieved.”

PakLab recently built a line of 12 unusually durable products with a twist for an NDA-protected e-commerce retailer in less than 14 months, from concept to launch. “Our client relied on our expertise to formulate, efficacy test and design the first outer cartons to be considered ‘drone drop proof’ under the strictest guidelines for regulatory compliance, global claims and quality control,” says Alex Cripchuck, senior vice president, commercialization, PakLab.

The packaging for the “high-performance” line not only required durability, it also had to deliver a satisfying unpacking experience.

“The brand needed to build loyalty based on consumer feedback (no advertising), and packaging would have to be recyclable, contain no glass components and not be damaged in transit. Satisfying the International Safe Transit Association (ISTA) was just par for the course,” he adds.

Formula-wise, laser focus was required to ensure the products met EU Clean Label standards, as well as Ecocert and COSMOS safety and toxicity claims down to the incidentals on every ingredient, plus being able to prove efficacy on usage levels of each “silver bullet ingredient.”

At the same time, Cripchuck says, PakLab’s packaging team was designing for ultra-durability, beginning with glass-alternative componentry and ending with “drone drop proof” outer shell packaging. “Finding glass replacement options for dropper tips was challenging, so special molds had to be opened to produce these from PETG,” he comments. “Knowing that most beauty companies design outer cartons for display in brick and mortar stores where structural strength is not always the main concern, we proposed to be the first to offer unit cartons that were specifically engineered to convey the brand’s premium look, and at the same time be able to withstand the rigors of direct-to-consumer shipping.”

Agility & Adaptability

An added benefit of working with a service provider with industry expertise is their ability to stay on top of ingredient and packaging trends.

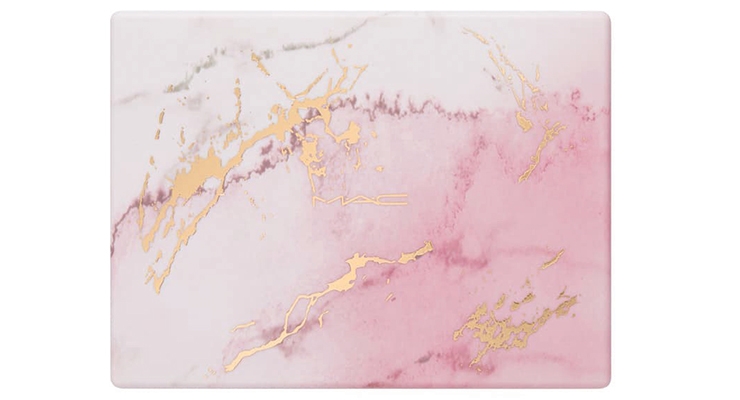

With an expertise in color cosmetics, Wormser Corporation says they take pride in adapting to market changes. As a partner of The Esteé Lauder Companies for several years, the company has assisted in the design, engineering and product launches for many Lauder brands, including customized palettes for MAC Cosmetics. “The six- and 12-well Electric Wonder palette was designed with a special water transfer label process that included a gold hot stamp foil as a second process in order to achieve a targeted appearance,” explains Scott Wormser, director of customer marketing, noting that the technical and visual quality earned MAC the Color Cosmetics Platinum award in the NJPEC Package of the Year competition.

SeaCliff Beauty worked with Jazmine Beauty, a Gen Z brand, to develop tinted moisturizers with SPF, in PE airless tubes, lip gloss/liquid lipstick trios in glass, and a trio highlighter compact in 100% PCR ABS packaging. In addition to using sustainable packaging, the brand wanted products that were clean, vegan, cruelty free, paraben and gluten free, petrolatum free, synthetic, fragrance and mineral oil free. “We also worked with this client on the branding of this line by assisting in the creation of the name of the brand, product names, brand image, secondary packaging supply and design and complete customization of packaging that we will be manufacturing for them in the near future,” says SeaCliff’s Simon.

Service partners are also able to nimbly react to industry trends. For instance, Cosmopak saw the uptick in consumer demand for clean beauty, combined with the rise of Indie brands, and two years ago made a focused offering around turnkey clean beauty and eco-friendly packaging by establishing a dedicated product development department. Syeira Simon, Cosmopak’s product development and formula innovation manager, says the department was instrumental during a recent collaboration with an Indie brand for a turnkey liquid eyeliner. The product, which converted a stock formula into a vegan- and cruelty-free version, was packaged with a striking black matte vial, cap and custom brush.

Bringing a Brand’s Story to Life

Contract and turnkey service providers are vested partners helping brands bring their beauty concepts to reality.

APR Beauty’s design team is constantly exploring and developing new innovations in packaging and formulations. “We understand each brand has different needs, but our chemists are constantly keeping themselves up to date on the latest ingredients to help each brand tell their story,” says Aliya Anand, associate vice president of marketing and product development.

“All the products we offer always have a skincare story; we want to position our custom formulations as ‘skincare with makeup benefits’ but with functionality to meet our clients’ needs.”

FusionPKG and its BeautyLab unit recently partnered with Stila to execute the formula and packaging for the global launch of Stila’s 30-shade Hide & Chic Fluid Foundation range—with just six months between concept and launch.

“The formula specifications included a lightweight, long-wearing foundation with good-for-you ingredients and a satin finish that allows for buildable coverage,” says Jessica Tarangioli, FusionPKG’s vice president of business development, noting that Stila wanted packaging that revealed the foundation’s shades. “We presented packaging design options and guided Stila to decorate our 30ml Allure bottle for a sleek look. The clear, glass-like base showcases the formula and allows for true color visibility.”

Stila’s branding hinges on a signature champagne color. FusionPKG customized the caps with UV metallization and bottles with a hot stamp to match, resulting in a polished finish with a matte champagne pump and shoulder.

Earlier this year, Cosmetic Design Group (CDG), a WWP Global Company, collaborated with Ulta Beauty and the Frida Kahlo Foundation, overcoming a tight timeline to design and develop a collection honoring the late artist, Frida Kahlo. The collection spans a 12-shade eyeshadow palette, a shadow switching pan, a four-pan brow sculpting palette, a liquid highlighter, two blush/bronzer duo powders, a face primer, three shades of nail lacquer and a signature keepsake box.

The face primer packaging presented a unique technical challenge for CDG. “As a black tube substrate with white images on top, the packaging required richness of color and bright, white artwork,” recalls Alison Kohlenstein, executive vice president, CDG.

There was no compromising on the artwork, so CDG developed a second layer of white print to avoid blurring or alterations to the artwork. “The final print on the black tube was beautiful, powerful and impactful,” Kohlenstein remarks, “just like Frida’s artwork.”

David Berkman, president and CEO, Allta International, a factory-direct turnkey supplier of color cosmetic formulas and packaging, concludes that trustworthy relationships are the foundation of all turnkey and contract manufacturing partnerships.

“The most important key is communication,” he says. “We ask the right questions, talk about benchmarks and qualities that brands want from their product, then sit back and listen to exactly what needs to be achieved. If we’re not specific, this process can get very costly.”

Cliff Davis, CEO, QRS, says a critical part of the process is for brands to look inward and evaluate their internal capabilities to determine exactly what they want to tackle and what they need to farm out. “Handling a project internally requires packaging expertise, project management skills, product knowledge and a working understanding of materials management (ordering, tracking components and shrinkage, component reorder points, etc.),” he says. “As well, most brand owners prefer [to] devote the bulk of their time to the sales, marketing and distribution of products, rather than to the operational aspects.”

Brands must be honest about their own expertise as it relates to formulations, packaging, filling, secondary packaging, regulatory, creative and testing, asserts Bob Congionti, vice president of operations, Tokiwa Cosmetics America. “The less experience or exposure a company has in these areas, the more important and critical a qualified, experienced turnkey supplier becomes,” he says, advising that when reviewing potential suppliers, brands should inquire about what role and key elements they will be directly providing in the development and production process [because] the more elements or activities a supplier directly provides, the better. “Experience and longevity in the beauty industry is another critical question to ask of potential suppliers. Typically, new start-ups, due to smaller staffs, will require more services, which a qualified, full turnkey supplier is capable of providing.”

For success, it’s important that brands and contract manufacturers have a detailed, upfront plan for formulas and packaging, says Vincent Groccia, president and CEO of ColorVera Biotech Group Inc. “A realistic timeline, a confirmed budget and clear and regular communication between the parties is integral to the process,” he says.

ColorVera just completed production on a new 50 SKU color cosmetics brand for an online retailer building the brand completely from the ground up in about nine months. “First, we created the brand positioning and confirmed the SKU mix, then developed a budget and timeline [then] we provided all design direction and marketing support for the brand,” Groccia explains. “We moved quickly because of our ability to customize formulas and source both primary and secondary packaging.”

Choosing the Best Options

Brands that don’t have the knowledge or expertise in packaging, formulation, filling or product testing would benefit from a full-service, turnkey provider. All aspects of the process are covered with a simple, single point of contact, says Vonda Simon, owner, SeaCliff Beauty Packaging, a full-service turnkey supplier. “If you work separately with labs, fillers and packaging suppliers, the brand will have to have the knowledge to link all of the pieces together on their own,” she notes. “Turnkey contract manufacturers focus on taking away your team’s day-to-day complexity allowing the brand to focus on their marketing strategy and branding DNA.”

Erma Estrella, senior director of product sales/product development, HCT Group, says full-service, turnkey services like those offered by HCT Group can benefit small and large brands.

“In addition to packaging and product development, we also help guide brands through the entire development process including regulatory, quality control and logistics,” she says. “We help coordinate all collaterals from various locations all the way up to delivering the finished goods at the brand’s distribution center. Having support on all of these items can help brands streamline their launches and improve their speed to market.”

For brands not requiring complete service, contract service providers can manage aspects of a brand’s formulating, filling or packaging, depending on the need. Elizabeth Forsyth, CEO and partner at Sheencol’or USA, a turnkey beauty and personal care supplier to global and Indie brands, says many times, brands choose a turnkey supplier who has different in-house capabilities than they do. “For example, powder pressing is a messy and challenging business and requires a certain level of expertise and costly machinery,” she comments. “Many brands come to us to produce their powder formulas since we are fully equipped with semi-automatic and automatic machinery that produce a high-quality product in a fraction of the development and production time.”

Marketing assistance is another perk of some service partnerships. For instance, prior to founding CTK Cosmetics’ full-service division, Sunny Choi, CEO of CTK Cosmetics, a K-Beauty specialist, worked in marketing for worldwide brands. When she started full service at CTK, her goal was to offer tailored marketing services to brands, including concept, ingredient story, formula, design and packaging from the brand’s point of view. CTK’s latest customizable product is its Brush Pop Compact for pressed powders, bronzers or highlighters, and features a separate slot for a full-size brush. The brush slides out from the bottom of the compact, allowing for a thin overall profile while keeping the brush hygienic and the mirror clean.

The first step in a brand’s partnership journey is evaluating service providers to ensure their core competencies are a good fit.

While some providers are jacks of all trades, others specialize in certain services or market sectors. Some are also especially good at working with organic or fair-trade ingredients and sourcing eco-friendly packaging materials.

When interviewing potential turnkey partners, brands should be extra clear on the goals they have for the products they want produced and understand that there may be steps in the process that shouldn’t be overlooked. Kathie Elliot, vice president of sales, marketing and product development, Cosmetica, says contract providers can expertly manage important aspects of product development like QA/QC, regulatory, compatibility and stability testing, scale up and pilot trials. “This provides more agility, less project resources and expertise in areas that some brands may not have,” she says.

Navigating Challenges with Ingenuity

Another benefit of partnering with service providers is their seasoned ability to head off potential issues before they become major problems.

QRS, a provider of high-end fragrances, body care products, cosmetics and skincare, was approached by a company that did not have the infrastructure to launch a new fragrance brand on its own. The project spanned five different 30ml, full-sized fragrances, along with a four-fragrance gift set comprised of 7ml rollerballs. QRS delivered the full-sized products in clear glass bottles with matte black caps and pumps plus front labels and four-color process, matte finished folding cartons. The kits included four 7ml rollerball packages, each printed in two colors. The rollerballs gift set featured a windowed folding carton with four color process printing.

QRS’s Davis says it’s common to encounter challenges in the development process. In this case, there was “an aggressive budget” to adhere to, cartoning issues that were solved, and a small bottle label that the customer needed maximized for executing their design (which they also desired to be visible from the front and back of the bottle). “We determined the best approach was to use our outside labeling partner, one with expertise in similar challenges,” he says. “Partnering with the right label supplier for the project allowed the client’s desired design element to be achieved.”

PakLab recently built a line of 12 unusually durable products with a twist for an NDA-protected e-commerce retailer in less than 14 months, from concept to launch. “Our client relied on our expertise to formulate, efficacy test and design the first outer cartons to be considered ‘drone drop proof’ under the strictest guidelines for regulatory compliance, global claims and quality control,” says Alex Cripchuck, senior vice president, commercialization, PakLab.

The packaging for the “high-performance” line not only required durability, it also had to deliver a satisfying unpacking experience.

“The brand needed to build loyalty based on consumer feedback (no advertising), and packaging would have to be recyclable, contain no glass components and not be damaged in transit. Satisfying the International Safe Transit Association (ISTA) was just par for the course,” he adds.

Formula-wise, laser focus was required to ensure the products met EU Clean Label standards, as well as Ecocert and COSMOS safety and toxicity claims down to the incidentals on every ingredient, plus being able to prove efficacy on usage levels of each “silver bullet ingredient.”

At the same time, Cripchuck says, PakLab’s packaging team was designing for ultra-durability, beginning with glass-alternative componentry and ending with “drone drop proof” outer shell packaging. “Finding glass replacement options for dropper tips was challenging, so special molds had to be opened to produce these from PETG,” he comments. “Knowing that most beauty companies design outer cartons for display in brick and mortar stores where structural strength is not always the main concern, we proposed to be the first to offer unit cartons that were specifically engineered to convey the brand’s premium look, and at the same time be able to withstand the rigors of direct-to-consumer shipping.”

Agility & Adaptability

An added benefit of working with a service provider with industry expertise is their ability to stay on top of ingredient and packaging trends.

With an expertise in color cosmetics, Wormser Corporation says they take pride in adapting to market changes. As a partner of The Esteé Lauder Companies for several years, the company has assisted in the design, engineering and product launches for many Lauder brands, including customized palettes for MAC Cosmetics. “The six- and 12-well Electric Wonder palette was designed with a special water transfer label process that included a gold hot stamp foil as a second process in order to achieve a targeted appearance,” explains Scott Wormser, director of customer marketing, noting that the technical and visual quality earned MAC the Color Cosmetics Platinum award in the NJPEC Package of the Year competition.

SeaCliff Beauty worked with Jazmine Beauty, a Gen Z brand, to develop tinted moisturizers with SPF, in PE airless tubes, lip gloss/liquid lipstick trios in glass, and a trio highlighter compact in 100% PCR ABS packaging. In addition to using sustainable packaging, the brand wanted products that were clean, vegan, cruelty free, paraben and gluten free, petrolatum free, synthetic, fragrance and mineral oil free. “We also worked with this client on the branding of this line by assisting in the creation of the name of the brand, product names, brand image, secondary packaging supply and design and complete customization of packaging that we will be manufacturing for them in the near future,” says SeaCliff’s Simon.

Service partners are also able to nimbly react to industry trends. For instance, Cosmopak saw the uptick in consumer demand for clean beauty, combined with the rise of Indie brands, and two years ago made a focused offering around turnkey clean beauty and eco-friendly packaging by establishing a dedicated product development department. Syeira Simon, Cosmopak’s product development and formula innovation manager, says the department was instrumental during a recent collaboration with an Indie brand for a turnkey liquid eyeliner. The product, which converted a stock formula into a vegan- and cruelty-free version, was packaged with a striking black matte vial, cap and custom brush.

Bringing a Brand’s Story to Life

Contract and turnkey service providers are vested partners helping brands bring their beauty concepts to reality.

APR Beauty’s design team is constantly exploring and developing new innovations in packaging and formulations. “We understand each brand has different needs, but our chemists are constantly keeping themselves up to date on the latest ingredients to help each brand tell their story,” says Aliya Anand, associate vice president of marketing and product development.

“All the products we offer always have a skincare story; we want to position our custom formulations as ‘skincare with makeup benefits’ but with functionality to meet our clients’ needs.”

FusionPKG and its BeautyLab unit recently partnered with Stila to execute the formula and packaging for the global launch of Stila’s 30-shade Hide & Chic Fluid Foundation range—with just six months between concept and launch.

“The formula specifications included a lightweight, long-wearing foundation with good-for-you ingredients and a satin finish that allows for buildable coverage,” says Jessica Tarangioli, FusionPKG’s vice president of business development, noting that Stila wanted packaging that revealed the foundation’s shades. “We presented packaging design options and guided Stila to decorate our 30ml Allure bottle for a sleek look. The clear, glass-like base showcases the formula and allows for true color visibility.”

Stila’s branding hinges on a signature champagne color. FusionPKG customized the caps with UV metallization and bottles with a hot stamp to match, resulting in a polished finish with a matte champagne pump and shoulder.

Earlier this year, Cosmetic Design Group (CDG), a WWP Global Company, collaborated with Ulta Beauty and the Frida Kahlo Foundation, overcoming a tight timeline to design and develop a collection honoring the late artist, Frida Kahlo. The collection spans a 12-shade eyeshadow palette, a shadow switching pan, a four-pan brow sculpting palette, a liquid highlighter, two blush/bronzer duo powders, a face primer, three shades of nail lacquer and a signature keepsake box.

The face primer packaging presented a unique technical challenge for CDG. “As a black tube substrate with white images on top, the packaging required richness of color and bright, white artwork,” recalls Alison Kohlenstein, executive vice president, CDG.

There was no compromising on the artwork, so CDG developed a second layer of white print to avoid blurring or alterations to the artwork. “The final print on the black tube was beautiful, powerful and impactful,” Kohlenstein remarks, “just like Frida’s artwork.”

David Berkman, president and CEO, Allta International, a factory-direct turnkey supplier of color cosmetic formulas and packaging, concludes that trustworthy relationships are the foundation of all turnkey and contract manufacturing partnerships.

“The most important key is communication,” he says. “We ask the right questions, talk about benchmarks and qualities that brands want from their product, then sit back and listen to exactly what needs to be achieved. If we’re not specific, this process can get very costly.”