Marie Redding, Senior Editor03.04.20

Developments in tech often inspire innovation. In the beauty industry, advances in digital and 3D printing are inspiring some designers and manufacturers to develop new types of decorating processes and innovative packaging.

Digital printing, which replaces plates on a conventional printing press with electronic files, is being used by some brands on labels, cartons, tubes, flexible packaging, rigid plastic containers, and metal. The global digital printing market is on track to reach $38 billion by 2025, growing at a CAGR of 14%, according to analysts at Kenneth Research.

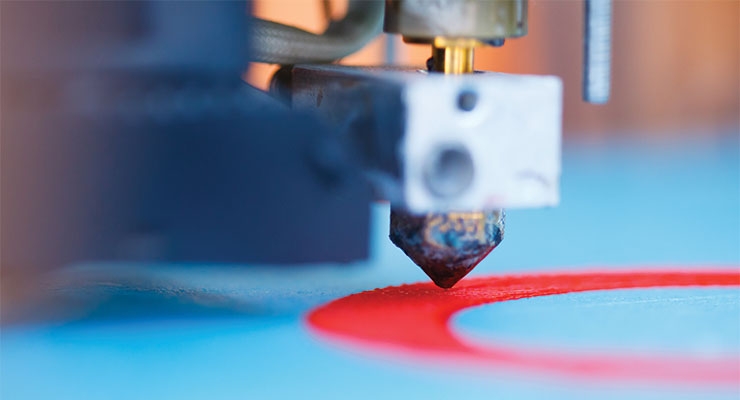

3D printing, also known as additive manufacturing, turns a digital “blueprint” into a three-dimensional object by adding material layer by layer. The global 3D printing market is projected to reach over $41 billion by 2026, registering a CAGR of 20.1% over the forecast period from 2019, according to Acumen Research and Consulting.

The beauty industry, especially fragrance brands, have been using 3D-printing technology for years for design and product development. Package designs are 3D-printed as prototypes, so changes can be made before production runs begin.

Now, Designer Parfums’ Formula 1 Collection is the first fragrance brand to 3D-print bottles that are sold to consumers. Visionary designer Ross Lovegrove designed the 3D printed works of art to mark the launch of the collection—and the three bottles feature gold-plated titanium “exoskeletons.” This spring, the brand will launch a fourth bottle that will roll out to retailers, globally, and it will be 3D-printed in technopolymeric resin. (See more about these bottles below.)

Digital Delivers Customization & Personalization Benefits

Experts agree—customization and personalization are big trends in beauty. Digital printing enables beauty brands to create customized SKUs, making it useful for limited edition products. “Digital printing is a way to experiment with imagery or messaging for different audiences. Since it is easy to change and edit designs on a digital press, this method is optimal for using variable designs and conducting market testing,” says Greg Maze, director of marketing, Neenah. “It only requires a minimal number of manual pre-press procedures, so production is expedited. This allows for quick turnaround times on short runs, such as samples and fast-selling products,” adds Maze.

Neenah offers a large variety of options in digital colors and textures for its Neenah Folding Board and Estate Label product lines. “We are continually adding more options, to accommodate demand,” says Maze.

Merav Sheffer, marketing manager, Velox, says that when a package is decorated digitally, there are strategic benefits for brands. “Customization, competitive responsiveness and supply-on-demand are just a few of the many benefits,” she says.

Velox’s breakthrough direct-to-shape digital technology allows brands, for the first time, to use digital printing for mass production—and it’s not cost-prohibitive, no matter the run length. “We are opening up a world of possibilities for converters and brand owners in terms of production agility, design flexibility, and endless business opportunities,” says Sheffer. (More about this, below.)

3D Printing for Prototyping & More

Beauty brands have long known the value of using 3D printing as a prototyping tool. “We use it to test the fit, feel, and function of a package, so then adjustments can be made,” says Nick Sicilian, packaging development director, Anomatic. “When a prototype is 3D printed, it provides an excellent approximation of weight distribution, and you are able to see how the package feels in your hand,” he says.

Anomatic also uses 3D printing for tooling. “3D modeling and printing can replace the physical tooling that would be needed to decorate samples. This greatly reduces package development time, because it can be done so quickly,” Sicilian says. “We have been able to reduce our lead times with samples and limited production quantities from six to ten weeks down to less than two weeks, due to our ability to 3D print the tooling,” he adds.

Plastube uses digital printing to decorate tubes, and the team there says that digital printing enables brands to produce pre-press samples quickly, and on-budget. “Since printing plates are not required, artwork changes can be made without high costs,” says Stéphane Beauchemin, vice president of sales & marketing, Plastube. “Digital printing is also ‘printing on demand,’ ” so there is less waste,” he adds.

Plastube offers high-resolution digital printing with low MOQs. Their “fast pack program” has a 4-week lead time.

Digital Decoration for Mass Production

Velox is pioneering the use of digital decoration for mass production, with its breakthrough digital direct-to-shape technology. Digital decoration is typically cost-prohibitive for large runs, but Velox’s industrial-grade digital decorator can deliver large quantities at full production speed, making this production method ideal for both mass production and short runs.

Sheffer says, “Our digital decoration is the only digital printing technology that is cost-effective, no matter the run length. It delivers a wide range of strategic benefits such as supply-on-demand, time-to-market, competitive agility, and of course superior decoration quality.” She adds, “We can print on the tube’s cap, not just on the body, and print around the tube, 360 degrees in vibrant colors and photo-realistic images. These are just a few examples.”

Velox also says its technology provides another benefit—it helps improve the recyclability of a tube, significantly reducing the environmental footprint of the entire decoration process. “In many cases, a brand is able to replace labels with direct-printing, and this supports the mono-material vector required for plastic recycling,” Sheffer explains. “Digital decoration at full production speed opens up a new world of operational and marketing opportunities for converters and brand owners,” she adds.

Suppliers Invest In, AND Develop New Machinery

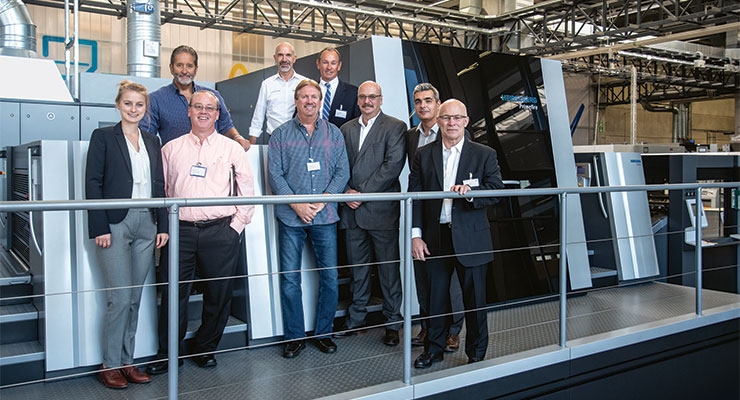

Arkay Packaging works with some of the largest companies in the beauty business, and is often recruited to print fragrance cartons. Arkay’s team is currently looking forward to installing its new Heidelberg digital press, Primefire 106, at its Roanoke plant in March. The supplier first announced the purchase of the press last fall, which it says may be a gamechanger for its beauty customers.

The Primefire 106 is the first commercially available industrial inkjet digital printing system in a 70 X 100 size, which is a 40-inch format. With the capability to offer the highest quality dpi at 1,200 X 1,200, the system has the ability to match offset print quality. It features a seven-color inkjet system, designed to reach volumes of up to 1.5 million sheets per month. All inks are water-based, low migration and environmentally sustainable, the company states.

Walter Shiels, COO, Arkay Packaging, comments, “Through the purchase of the Drupa model Heidelberg Primefire digital printing press, we enter the multicolor digital printing market. We are highly motivated to enhance, develop, and lead into the future with the newest technologies for package printing.”

Epson, which counts many suppliers among its customers, recently announced the debut of its SurePress L-6534VW, a new digital LED UV inkjet press. It boasts fast speeds of up to 164 feet per minute (fpm), which is ideal for producing high-quality labels and packaging. The easy-to-use press is designed for label converters investing in a digital label press for the first time, or looking to expand production facilities.

The press comes standard with all the functions required for label production, including a Corona Treater, white ink, digital varnish, and an additional UV curing unit. The print heads, inks, LED pinning and curing lamp units, media feeding, and control system are all developed, serviced and manufactured by Epson.

Mike Pruitt, product manager, Epson America, Inc., explains, “The SurePress L-6534VW produces high-quality prints with an amazingly wide color gamut. For packaging converters with demanding jobs, it brings together an expanded feature set, including the unique Digital Varnish and reliable automated operation. This allows converters to expand offerings and revenue opportunities to increase both productivity and profitability.”

Epson also produces equipment designed for use by Indie brands and small businesses. The company recently debuted new models in its ColorWorks C6000 series of on-demand color label printers. The 8-inch size is available now, while 4-inch models ship in April. The new models deliver high-volume color labels at up to 5 inches per second.

Andy Scherz, senior product manager, Commercial Label Printers, Epson America, Inc., says, “We have already received a tremendous response around the launch of these printers; businesses are excited to make the switch from black-only thermal transfer printing to on-demand color label printing.” These are Epson’s first printers designed as a color upgrade to black-only thermal transfer printers.

Scherz continues, “Time after time, business owners have expressed their frustrations with unused, pre-printed labels and the money wasted when label designs or requirements change. These new printers will allow companies to eliminate the need for pre-printed labels, preventing material and monetary waste. In addition, adding color to a label can improve brand recognition and process efficiency and reduce errors.”

What’s Next?

It’s an exciting time for digital technologies—especially 3D printing, as new advances are being developed and utilized by many industries, including healthcare, automotive, construction, and aerospace. This month, Urwahn Bikes, based in Germany, partnered with lightweight bike component specialist Schmolke Carbon to develop a racing bike featuring a 3D printed frame. A company called Apis Cor is a leader in advancing the use of 3D printing technology for construction and used a 3D printer with concrete to 3D-print wall structures for a two-story building, floor-by-floor, in Dubai.

Researchers from the MIT Media Lab, Harvard University’s Wyss Institute, and the Dana-Farber Cancer Institute have developed a method to 3D print objects that can control organisms, called the Hybrid Living Material fabrication platform. It has the potential to be used for medical devices with therapeutic agents, such as a wearable interface designed to customize antibiotics according to the user’s genetics. Perhaps beauty brands will next work on launching “smart” skincare—in packages that can detect what your skin needs based on your environment?

No matter what new beauty and packaging innovations arise out of new technologies, change is certain. As designer Ross Lovegrove said in a CNN documentary, “In the future, we’re going to have to get used to ideas that transform our lives—more organic more dynamic and significantly different than what we know today.”

Designer Parfums’ newest fragrance brand is Formula One, a name that refers to the highest class of auto racing sanctioned by the Fédération Internationale de l’Automobile and owned by the Formula One Group. The team at Designer Parfums enlisted world-renowned artist and industrial designer Ross Lovegrove to design the brand’s luxurious 3D-printed bottles, which are refillable—and priced at $10k.

The limited-edition collection includes three bottle designs, Agile Embrace, Fluid Symmetry, and Compact Suspension. Like sculptural works of art, the bottles are gold-plated and 3D-printed in stainless steel and titanium. The designs are organic shapes with intricate lines—and too complex to be produced using traditional manufacturing methods.

The launch marks the first time a fragrance brand is producing 3D-printed bottles to sell to the end user—and in metal. Dilesh Mehta, chairman & CEO, Designer Parfums, says, “Being the first fragrance brand to utilize 3D printing is a huge achievement.”

The collection was available with five interchangeable fragrances at the Formula 1 Etihad Airways Abu Dhabo Grand Prix last November 29th–December 1st. One-hundred more will become available this year.

Lovegrove worked with a team for two years to design and engineer the bottles, which feature geometric patterns that include sleek, curvy lines, inspired by a car’s aerodynamics. An outer exoskeleton encases an inner glass “suspended core,” not unlike how a car’s body surrounds its driver. The inner glass flask, which contains the juice, is produced by Heinz Glas.

Parag Vidyarthi, managing director, Designer Parfums, explains, “From the very first conversations we had with Ross, we were drawn to the idea of bringing 3D printing into our fragrance design. The process allows us to create stunning shapes and forms that are not achievable using any other process.” Vidyarthi continues, “The luxury pieces showcase the design possibilities from 3D printing and allow us to utilize materials such as titanium. They tell a story of F1, of advanced technology and design and have an incredible elegance and beauty.”

Next, a Premium collection will launch, which will be “the same five Haute Perfumery fragrances introduced in Abu Dhabi,” Vidyarthi says, with a technopolymer resin replacing the metal. This bottle will be produced using digital light synthesis 3D printing technology, and will retail for $250 at select retailers globally later this year.

Will custom bottles be next? “We look forward to pushing 3D printing even further in future years when we will offer consumers the ability to create their own customized designs,” says Mehta.