Marie Redding, Senior Editor05.01.20

A metallic finish on a package draws the consumer’s eye—enticing shoppers to touch in-store or “click” online. A heavyweight metal lipstick case, compact, or cap can elevate a product’s perception and help a brand convey “authority.”

Both metal and metalized packages feel luxurious to hold. Elegant details, such as an engraved plaque on a bottle, are often in metal. Metallic finishes on tubes, labels, and cartons can also take any product up a notch.

The use of metal is on the rise, researchers say, perhaps for the reasons mentioned above. According to Research & Markets, the metal cosmetic packaging market accounted for $4.15 billion in 2018 and is expected to reach $6.90 billion by 2027, growing at a CAGR of 5.8% during the forecast period.

Rouge Hermès, Designed by Pierre Hardy

Hermès Beauty chose metal packaging for its debut collection at Harrod's in March, Rouge Hermès. The lipstick line has 24 hues, plus three limited-edition colors that will launch twice yearly. The lipstick colors are based on 75,000 color references from Hermès archives of silk scarves, plus leather products in 900 colors.Rouge Hermès lipstick in Orange Boîte is shown -- and the bullet color matches the color of Hermès signature box, which made its debut in 1942. (Poppy Lip Shine is also shown.) The metal lipstick case is refillable and features a modern, color-block design. It is lacquered, brushed, and polished metal in black, white, and permabrass gold. The package is assembled by hand. (Scroll down to the brand's video via Instagram below to hear the team discuss the decisions behind the design.)

Pierre Hardy, creative director of Hermès jewelry and Hermès shoes, designed the packaging. He states, “I love the simplicity of pure shapes, and that colors can animate. Intuitively, to become timeless, this object had to be able to morph, remain iconic, but stay fluid, be part of a connected sequence, and perpetually recognizable—a constant yet ever-changing object.”

Most Often Requested Colors for Metals & Metallics

Suppliers agree—beauty brands are using metal and metallic materials more often. There are various ways to customize the material’s look, and several companies spoke to us about their suggestions.“Metal has a great story to tell, for a beauty brand,” says Eric Leray, vice president of sales, Anomatic. “Anodized aluminum has long been a popular luxury finish, but is growing more popular because it is a sustainable material and ideal for premiumization,” he says. Anomatic is a leader in producing anodized aluminum and metalized packaging. The company offers brands customized solutions, plus a stock line of jar systems that includes lids.

April Lytle, marketing coordinator, Kurz Transfer Products, says, “We see a resurgence of metal decoration for packaging, including clever designs with metallics used as detailed accents on a variety of substrates.”

A transfer decoration combined with embossing or debossing effects can highlight a beautiful design. “This type of effect on a package will greatly increase the perceived value of the product,” says Lytle.

“Consider using metallic components on packaging and labeling during the initial phase of the design process, to develop luxury branding from the start,” she advises.

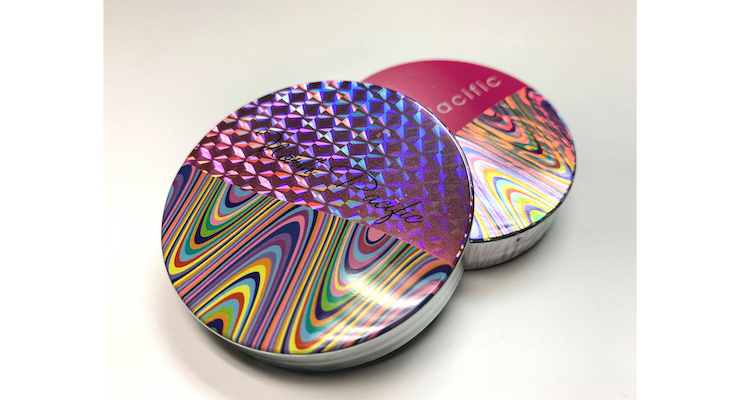

As for colors, Lytle says various shades of classic gold and silver are typically most often requested, but there is a move toward brighter jewel-tone shades. “We also see an increasing demand for our holographic and diffractive patterns,” Lytle says. “There is a rise in registered images as well—such as lens effects and surface relief technologies, as the application technology becomes available for beauty brands and the luxury goods market,” she explains.

Cornelia Schmid, head of marketing, Hoffmann Neopac, says, “We are getting many requests for plastic-free all-metal packaging, especially for cosmetic and oral-care products. Silver and gold tones are popular, but marketers are also choosing metallics that match their brand colors.”

Danielle Peebles, account manager, Metapack USA, says, “The luxury brands we work with prefer shiny gold for their metal packaging. However, we have also seen an increase in demand for rose gold, as well as matte black metal packaging.”

At North Pacific International, Oscar Gordillo, technical support, says silver is the most popular choice, with metallic gold, copper, and rose gold not too far behind.

Don Earl, president, Overnight Labels says brands often choose silver foils because they are the most reflective. Adding colors by overprinting on silver metallic is another popular option. “Brands are overprinting in bright pink, magenta, and purple, as well as more earthy tones in the bronze and copper family,” he says.

Earl suggests choosing metallic accents when a brand wants to upgrade the look of a carton or label. “Softer metallics, as well as processes that combine matte finishes with foils, are often requested lately. These printing techniques provide a high-end look, and ‘pop’—so products stand out, both on store shelves and online.”

Anthony Grinnell, CEO, Harmony Paper Company, says that since metalized papers can be printed, it’s not the color of the paper that is the key decision—but the color of the base substrate. “Deciding between gloss or matte and plain silver or holographic as a base substrate is most important to figure out first. Any color and design can be overprinted, but it is the base substrate that will determine how the printed color will look,” explains Grinnell. He gives an example saying, “A gloss silver substrate allows for shiny metallic graphics, a matte silver substrate results in dull metallic graphics, and holographics enable color shifts or patterns.”

Grinnell adds, “By far, the most prominent substrate for premium packaging right now is gloss silver. Rainbow holographic is a distant second.”

AR Metallizing’s Wendy Cross says that metallic elements are a way to elevate all types of products, especially cartons and labels. “One of the strongest trends is holographic looks,” she says. “Beauty brands are embracing both full holographic coverage and spot holography, which can give a brand a strong visual identity that sets it apart from competitors,” she adds.

Refillable Options, Luxe Caps

Metal is an ideal material for all types of refillable packaging. Hermes refillable lipstick is one example, but other beauty brands offer consumers ways to refill fragrances, compacts, palettes, and more.Metapack offers a variety of refillable options. One of their newest designs is a refillable solid perfume stick, offered as part of their standard packaging line. “We offer a range of luxury stock options in metal that are refillable, recyclable, and customizable, including travel spray pursers, solid perfume compacts, makeup compacts, and lipstick holders,” says Peebles. “Many of the items we produce are made of zamac, which is a zinc, aluminum, magnesium, and copper alloy. Zamac is beautiful and long-lasting,” she says. “Refillable packages are a much less wasteful solution,” she adds.

Metal is ideal for caps—to top off a bottle, jar, or tube. TNT Global Manufacturing produces the cap for the Byzance by Rochas fragrance. The luxurious one-piece cap is zamac, and is decorated with an embossed logo and gold e-coating.

TNT’s team developed the cap, ensuring it could be manufactured in a single piece, and custom-designed the cord. “Gold e-coating gives the cap an elegant look. The cap’s brass tips were assembled without glue. There is also a mass-dyed PP insert,” says Boris Schaefer, vice president of sales, TNT Global Manufacturing.

Anomatic offers a stock line of jar systems and lids, which are offered in both anodized aluminum and metallized options. “Speed-to-market is extremely important, and we’re able to deliver this with our stock line. Plus, our ability to metallize in the U.S. is a huge benefit,” says Leray.

Anomatic excels in metallization techniques. “Metallization offers an alternative to UV spray coatings. Companies are requesting this process more often, because it provides a high-end look. One major beauty company recently observed that upgrading their packaging helped to differentiate their product on the shelf and boosted sales,” says Leray.

Metallic Labels, Foils & More

Rather than choosing metal, many brands opt for replicating the look on plastic by using metallization techniques on caps, jars and compacts, for example. Metallic decorations are often created with hot-stamping and cold-foiling materials.“More brands are recognizing the value in choosing a metallic decoration instead of a metal package,” says NPI’s Gordillo. “One brand, for example, recently replaced an aluminum jar for an upcoming launch with a plastic jar wrapped in silver aluminum foil. A heat transfer label was chosen for the lettering, and gloss black pigment banding completed the design. This cut costs, and achieved the same look,” he explains.

Gordillo recommends using NPI’s aluminum hot-stamping foil to create a metallic look. “We recommend choosing silver or gold to decorate a cap, along with metallized foil banding on a bottle or jar,” says Gordillo. “It’s a luxurious look,” he adds.

Metallic foils often give cartons a flashy look, with strategically placed design elements. AR Metallizing provides premium finishes for cartons and blister packages with its Packle product line. “Our in-house creative team often collaborates with brands on decorating techniques, to suggest ink coverage, holographic options, and the best ways to use our metallized paperboard,” says Cross.

AR Metallizing’s Packle products were used to create a matching metallic decoration on a carton and label, shown.

Other suppliers also offer metallic materials, suggesting ways to use them. Kurz Transfer Products supplies decorators with its Luxor/Alufin products, Lightline diffraction decoration, and custom holograms. “These metallized decoration products are often used by beauty brands on both primary and secondary packaging,” says Lytle.

Lytle often suggests beauty brands use hot-stamping or cold foil transfer to achieve a prestige look. “These are an easy way to add luxury accents without the added cost of laminate board or other forms of decorative embellishments,” she says. Kurz has extensive experience in developing hot, cold, and digital transfer decorations, as well as related processing materials, tooling, and stamping equipment.

Overnight Labels’ Earl says that many beauty brands are choosing metal accents for labels as a way to keep costs down, yet still create a metal-like look. “Shrink sleeves and flexible film packaging are increasing in popularity, and look prestige when combined with advances in new foil techniques and innovative varnish textures,” he says.

Earl also notes an increasing use of glitter and holographics. “Over the past year, we have seen a big uptick in foil labels that incorporate these specialty effects,” he says. “We also see foils combined with specialty varnishes such as tactile or soft-touch,” he adds.

Eva NYC used Overnight Labels’ cold foil on a shrink sleeve to achieve a glitter effect on its can for the product, ‘Kween’ Glitter Spray, which is shown. (Product photo in slider above via Anthropologie.)

Overnight Labels offers foil options for shrink sleeves, pressure-sensitive labels and heat-sealable films. “They can be cold-foiled, hot-stamped or foil-faced substrates, depending on application or intended end result,” says Earl.

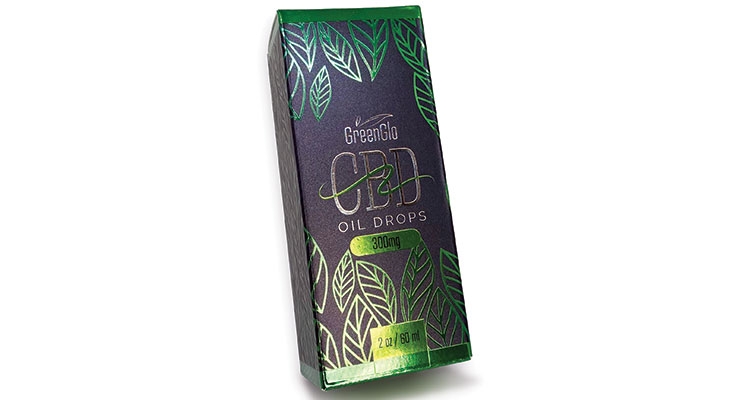

Harmony Papers’ Grinnell says beauty brands are using metallic effects on cartons at varying levels, ranging from small metallic logos to full cartons decorated with metallic foil. Harmony Papers’ metallic green foil is shown on the carton for Green Glo CBD Oil Drops. The pop of metallic color elevates its look, helping the brand to differentiate from competitors in the growing CBD market.

The company offers EcoFX metallized and holographic papers. “Unlike metal transfer, where a layer of PET is metallized and then used to transfer an aluminum layer to another substrate, EcoFX directly applies the metal layer to paper without requiring the use of plastic,” Grinnell explains. “Both metal transfer and EcoFX result in a plastic-free material,” Grinnell says.

Decorating & Machinery for Metals

Creating certain types of metallic decorations requires specific machinery—or partnering with a decorator that has specific equipment. Tapematic manufactures a PST Line, which is a fully automated system that cleans, pre-treats, applies UV base paint, metallization, UV top coat paint with in-line inspection, and in-line decoration.The line is fully automated, so there is no need to manually move parts from one process to the next and this feature allows it to be very flexible in the types of decoration it can accomplish. “We are seeing great interest in brands and decorators using our PST line to create metallic accents on plastic substrates,” says Denning. “This is when a logo is metallic, on a plastic substrate. The protective paint layer must be maintained, as it is required for the metallic portion. This can be achieved in an in-line process on our PST machine,” says Denning.

GTO is another company that specializes in machinery for decorating, offering ways to use a lamination process, metallic effects, gold and silver on glass, plastic, and leather. “Our machinery decorates irregular surfaces, and can emboss in high definition,” says Valter Scolaro, co-owner, head of R&D, GTO.

GTO’s patent-pending Tampolamina machine simplifies lamination without the use of traditional hot-stamping dies by using pad-printing. “We also have traditional hot stamping machines, but they don’t allow printing on irregular surfaces with the same level of high-definition as our Tampolamina machine,” says Scolaro. “This new machine could really change the game in terms of packaging and decoration of regular stock packaging,” he adds.

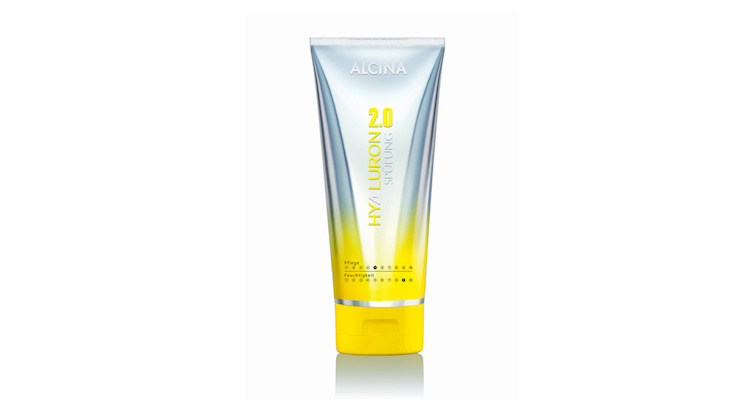

Sleek & Shiny Metallic Tubes

Metal upgrades a tube’s look, and also offers extra protection for products. “We have two solutions, in metals: One is our metallic, high-barrier Polyfoil tubes, and the other is our new SpringTube,” says Cornelia Schmid, head of marketing, Hoffmann Neopac. “Using our new decoration technology on our SpringTube, we can decorate the tube body by printing any Pantone color on a silver metallic base,” she explains.The SpringTube is by 3D Neopac, a subsidiary of Hoffman Neopac. It is specially designed to maintain its shape, and can be decorated via digital, flexo and metallic foil processes. “For product protection, an ethylene-vinyl alcohol (EVOH) barrier preserves oxygen-sensitive formulas, and helps extend the shelf life of beauty and personal care products,” says Schmid. The tube is paired with a tamper-evident, push-on flip-top cap.

Hoffmann Neopac’s new direct-to-shape digital decoration service is “DigitAll360°.” The service prints photorealistic graphics and text on the entire surface of cylindrical containers. It is available for a wide variety of substrates, including metal tubes. “It addresses the growing demand for high-quality variable printing, precision color matching, flexible batch sizes, and expedited delivery,” Schmid adds.

Customization is Key

Whether you’re choosing metal or metallics, customizing is always key—and suppliers of metal and metallic products offer lots of ways to achieve a look that is in sync with a brand’s identity. When every element of a package, from bottles and caps to cartons, are decorated to convey the same message, it tells a cohesive “brand story.” Even parts that you might think are minor details can be customized—including metal pans.Acme Cosmetic Components produces metal pans for cosmetic products, such as pressed powders and hot pours. This type of pan is typically available in two base metals—tinplate, which is steel-electroplated with tin, or an aluminum alloy, which is coated with a high-performance polymer. “We provide a high-quality pan at a low pricepoint. We’ve done a few colors this past year, including gold and opaque black, as opposed to just a clear coating,” says Mike Roughton, president and CEO, Acme Cosmetic Components.

Final Tips

No matter which type of metal packaging or metallic decoration you choose to use, it’ll elevate a brand’s image. “Investing in a metallic decoration is a way to differentiate—and convey luxury and quality,” says NPI’s Gordillo.Harmony Paper’s Grinnell adds, “Manufacturers will always try to advise brands to choose a process or material based on their investments and offerings. The fact is, every situation is unique and based on desired design aesthetics, budgets and sustainability stances.”

AR Metallizing’s Cross says, “Now, more than ever, it’s important for beauty brands to stand out with beautiful packaging—especially as there is more competition in the industry than ever before, and e-commerce and online shopping adds more rivalry. Adding or incorporating metallic looks is a great way for beauty brands to add premium, eye-catching elements to packaging.”