Jamie Matusow, Editor-in-Chief07.24.20

In a recent video interview with Bryce Rutter, PhD and founder of Metaphase, “worldwide specialists in hand-intensive products,” he speaks with Beauty Packaging about why hygiene, touchpoints, “handleability” and carton coatings are some of the factors brands need to keep in mind when developing tools and packaging.

He wonders whether future cartons may have to teach the consumer where to grip, how to open, walk the person through opening the box for safety—and perhaps even provide a “rethink” on how to open the package. Will we be seeing a flurry of hygienic coatings for cartons and papers? What about coatings and inks that don’t necessarily react well to products’ ingredients—or handling? Another possibility, says Rutter: “Grab Me Here” touchpoints to guide consumers when coming in contact with a carton.

No doubt about it: Especially in light of Covid-19, how we interact with things around us has changed—and the impact on the user experience may be profound. Not only in terms of hygiene, but also as far as protection, ease-of-use and sustainability.

In this unprecedented time of elevated online shopping, cartons may be on the front lines more than ever before. As always, their No. 1 function is to protect the products that lie within—but they are also relied on to keep contents clean and safe, as well as deliver a brand message and experience for the consumer who reaches for and opens the box. Whether in-store or online—from shipping cartons to showy cartons and setup boxes—carton perceptions are now at an all-time high.

Sustainability Tops the List

In addition to safety and image, cartons are increasingly telling a strong sustainability story. With a growing number of the world’s consumers, brands and governments focusing attention on eco-responsible packaging, producers of paperboard and cartons have rallied to meet the challenges. All the carton and cartonboard suppliers Beauty Packaging spoke with for this article offered sustainable solutions, and most offer specializations in this area.

Ben Cohen, creative and innovation director, Knoll Packaging, says, “Cosmetics secondary packaging always combined the function of protection and aesthetics (both brands and product codes) in a box. Each of our sets tells a story and is unique, but now brands are focusing on the sustainability of the package.”

At nearly 100 years old, third-generation family-owned Arkay Packaging combines sustainability with luxury. Mitchell Kaneff, chairman/CEO, says Arkay’s specialty “is creating unparalleled value for prestige cosmetics and pharmaceutical brands by providing creative, profitable, and eco-friendly solutions.”

Kaneff says Arkay is “at the crossroad of innovation and excellence, as we continue our strong commitment to fostering an ecologically aware culture, while utilizing environmentally friendly products—such as Monadnock Astrolite and Kona boards—to dramatically reduce our impact on the environment.” Arkay is affiliated with—and certified by—Sustainable Forestry Initiative, Community Energy, and Forest Stewardship Council. Additionally, says Kaneff, “We have achieved CarbonNeutral status and are the recipient of the Gold Recognition Level from EcoVadis, all of which sends a clear message to our customers, employees, and associates that Arkay attaches great importance to sustainability currently—and into the future.”

At Neenah, Irene Richard, senior product manager, Neenah Folding Board and Cover Materials, tells Beauty Packaging, “Bottom line, Neenah’s specialty is lifting each brand through differentiating on shelf. We do this in a variety of ways such as color, texture, recycled fibers, alternative fibers and a variety of environmental certifications.” She says sustainable and “natural-looking” options are high on brands’ priority lists for folding cartons and box wraps for both the beauty industry and the CBD industry.

Hemp-infused Neenah Folding Board products were the first in the market, says Richard. “We want to provide those brands that either market directly into the cannabis/CBD category or that desire the natural look provided by the infusion of hemp fiber, with new, innovative options.”

BillerudKorsnäs manufactures a range of sustainable cartonboard products used for luxury packaging. According to Daniella Kohler, business development manager USA, Cartonboard, BillerudKorsnäs, “Brands continue to be driven by sustainability and carbon reduction. They are looking to reduce plastic and find innovative ways to structurally house their products in a more sustainable, simple way.” She says, “Recycling is still a key focus for brands, and paper (cartonboard) is very recyclable.”

Molded fiber has also increased in usage. Golden Arrow has specialized in manufacturing “high-cosmetic” molded fiber as a sustainable packaging solution for more than 10 years. Solutions include rigid and folding carton boxes, “cutting-edge packaging design,” printing, manufacturing and logistics.

Marianna Cilauro, director of sales and marketing at Golden Arrow, says, “An emerging trend is that clients are becoming more and more interested in the possibility of implementing 100% recycled paper in their packaging, as well as seeking ways to adapt FSC paper to be more environmentally conscious. It’s undeniable that the use of paper material-based packaging has increased.”

Golden Arrow recently designed sustainable packaging for the Eighteen-B brand. Cilauro says, “Together we designed a container made entirely of molded fiber, which enhanced their packaging to become truly recyclable and compostable.” At first, Cilauro says the design structure missed “the smooth and cohesive vision that the client had in mind. “But,” she says, “we were committed to providing our client with a quality product that reflected their brand while also offering true sustainability and smooth assembly. By providing an additional level of quality control, our molded fiber package design met our client’s practical needs and their design vision.”

Knoll Packaging offers pulp-based packaging solutions. Cohen says Knoll has worked primarily in board and paper for 35 years and has seen brands move back toward these materials.

“Over the past two to three years we’ve been working to eliminate plastic from our supply chain and have seen an overall reduction in the material in our category.” These packages have been adapted to be re-designed with Knoll Ecoform, the supplier’s pulp-based material, board and wood, many of which were implemented this year.

Cohen explains: “Our company operates on an eco-design approach by offering alternative materials and by driving sustainability through to our luxury brands. This includes rethinking packages to eliminate plastic and decrease CO2, as well as redesigning to increase recyclability.”

Eska started in 1879 as a rigid paperboard manufacturer, and Anton Meindl, strategic sales director-luxury/beauty packaging, tells Beauty Packaging, “From the start, we were the first in the world to use only recycled materials in our unique production process to create our premium, exceptional quality packaging with zero-low waste.” He says Eska is currently seeing “a huge push” for sustainability and the use of recycled materials for rigid boxes. With respect to this, Eska offers both.

Eska’s brand of premium rigid board is dedicated to “highly sustainable luxury packaging solutions.” As architects of identity materials, Meindl says they take a full spectrum view of the creation and development process. “We approach innovators who dare to move things forward, and we partner with brands to expand the boundaries of sustainable packaging. Available in various solid colors, Eska board is usually converted to decorative rigid boxes and can be used for color cosmetics, fragrances, skincare products and liquor.”

With more than 250 years of experience, and facilities in Ohio, New York, and Virginia, Oliver specializes in custom folding cartons, marketing collateral, labels and fulfillment. Doug Doroh, VP of sales and marketing, says with its state-of-the-art technology and an emphasis on sustainability, “Oliver is a one-stop-solution for all printing and packaging needs.”

Moving Away from Non-Sustainable Plastics

Packaging solutions that are both innovative and sustainable are the emphasis at Diamond Packaging, according to Dennis Bacchetta, director of marketing. He says, “The biggest trend we have seen with folding cartons is a move away from mylar and plastics toward paperboards. The use of PCW boards and uncoated boards is getting popular again.”

Allstate/Staeger’s specialty is secondary packaging with a spotlight on rigid setup boxes, which are a “classic presentation for gift sets and fragrance packaging,” says Howard Greenberg, director of sales, Allstate Paper Box Company. Greenberg tells Beauty Packaging, “We have noticed some customers moving away from mylar paper stock and looking for more environmentally friendly options. All of our suppliers have been focusing on recyclability and sustainability in their product lines in reaction to the demands of the end users.”

McLean Packaging specializes in the domestic manufacturing of folding cartons, rigid set boxes, vacuum forms, and corrugated packaging from concept to completion. With three manufacturing facilities, which combined, total nearly half a million square feet, McLean provides custom packaging solutions for the beauty and personal care sectors.

As far as the sustainability movement, Jeff Besnick, VP, Mclean, says they have seen brands explore the elimination of plastic—including plastic vacuum forms that protect and display products in folding cartons and set boxes. He says there are also trends to reduce the amount of metallic effects used on the secondary packaging.

“We have seen brands address the topic of sustainability in different ways,” says Besnick. “Some are working to eliminate plastic in their secondary packaging by removing windows, dustcovers, and plastic vacuum forms while, alternatively, we have also seen brands use post-consumer-recycled plastic rather than eliminating plastic completely. Some have eliminated Mylar and/or implemented regulations on how much of the package can have metallic details like hot stamping or cold foil.

As a secondary packaging vendor, McLean is sourcing, testing, and promoting sustainable options, covering everything from raw materials to finished goods. One of McLean’s common practices is to collect any chipboard waste from manufacturing and return it to the board vendor to be reprocessed and made into new board. “On the finished good end,” says Besnick, “we are FSC and SFI certified allowing brands that use this material to print the certification logo on their package and promote their own sustainability efforts.”

McLean has also recently committed to sourcing 100% renewable energy for all three of their manufacturing facilities in NJ and PA.

Earlier this year, HLP Klearfold changed the face of plastic cartons with the introduction of RPET100 100% PCR PET folding cartons. They have now received third-party certification by SCS Global, which allows their customers to label their RPET100 cartons with SCS Global’s Kingfisher 100% PCR logo.

The feedstock for RPET100 cartons comes from materials (water and soda bottles) that have completed their original purpose and have been diverted from landfills for re-use. RPET100 cartons require fewer fossil fuel resources and less energy to produce, and their increased consumption of PRC waste helps to drive the growth of the PET recycling infrastructure.

Pat McGee, vice president, marketing, says HLP is able to make RPET100 cartons because “We first manufacture the 100% PCR box-grade PET substrate on our in-house, box-grade PET extruders. To ensure that there is no meaningful sacrifice in substrate and carton quality or performance, we also meticulously and locally source our PET waste feedstocks.”

Meeting Brands’ Goals

The demand for sustainable solutions continues to take shape and, in some ways, has been bolstered by the Covid-19 pandemic. The preference has generated an uptick with supplier innovation.

Kohler, of BillerudKorsnäs, says they are seeing an even stronger move toward plastic and material reduction, as well as more awareness toward product recyclability. “With the increase in consumption, consumers are seeing more packaging in their homes and trash and recycle bins are fuller. Consumers are faced with additional decisions on whether a package can be recycled, waste can be composted and materials can be re-used. Covid-19 has impacted these practices for more conscious decision making.”

Kohler says many brands have aggressive sustainability and carbon reduction goals which they are trying to achieve in the next few years. As paperboard manufacturing is very energy intensive, she suggests that to help meet these goals, brands should look to mills that use efficient biofuel technology rather than intensive fossil fuel technology. BillerudKorsnäs also offers structural design services that focus on material reduction. “We produce board which is stronger, at lighter weights and calipers and enables brands to reduce the amount of material needed for their package,” says Kohler. BillerudKorsnäs also provides carbon emission comparisons for the current package and proposed lighter weight package. “Brands have the opportunity to evaluate and compare our materials as a more sustainable choice,” explains Kohler.

“The most common tasks we receive are to replace a plastic insert with a fiber-based insert,” says Kohler.

BillerudKorsnäs recently switched out the plastic insert for a nail polish gift set to a sustainable paper insert using BillerudKorsnäs paperboard.

“It’s always a challenge to develop a highly functioning insert that fits the product securely,” says Kohler. “If there is slight movement of the product, it will shake, leak and cause damage to both the product and the insert during transport. We were faced with developing customized spaces where the product fit but also made it possible to easily take the product out of the package and replace it for display or storage. It ended up being a real balancing act.”

Fiber-based inserts are delivered flat and do not take up as much space as plastic trays during transport. They can also be easily recycled which Kohler says offers advantage over plastic trays and uses more sustainable material. “Our challenge was to make the insert easy to produce and align with the filling process,” says Kohler.

At Diamond Packaging, Bacchetta says brands’ interest in sustainability has increased demand for packaging with improved environmental attributes such as folding cartons, since most are manufactured with recyclable or recycled paperboard. “Paperboard is the most recyclable substrate in the market,” says Bacchetta. “In fact, the paper recovery rate was 66.2% in 2019 (AF&PA), and accounts for 65.7% of packaging materials recovered for recycling in the U.S.(EPA). Diamond introduced its greenbox initiative in 2007 for a comprehensive approach to packaging that minimizes environmental impact throughout the supply chain.

Today, Diamond’s folding cartons are designed utilizing recyclable or recycled paperboards (many FSC-certified), and manufactured using 100% clean, renewable wind energy, in a Zero Waste to Landfill (ZWL) facility.

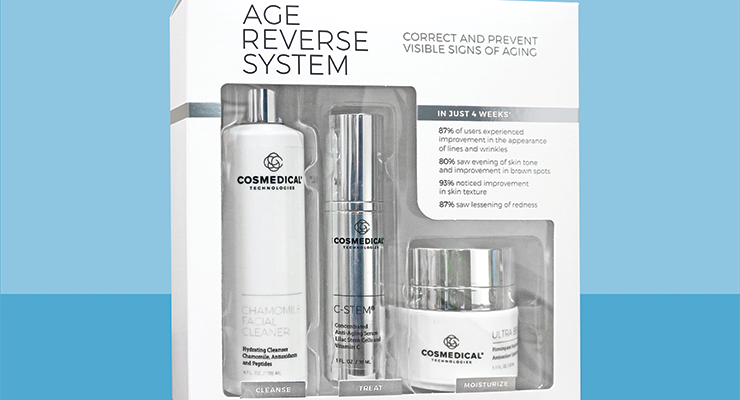

CosMedical Technologies turned to Diamond for an innovative kit package that conveyed the premium positioning of their clinically tested, medical grade products. Age Reverse System is a skincare regimen specifically formulated to correct and prevent visible signs of aging and increase luminosity. The folding cartons were converted utilizing WestRock Tango .020 SBS paperboard, cold foiled, and offset printed with PMS gray and dense black inks, in-line with DiamondTouch soft touch coating. The folding cartons utilized recyclable paperboard, and were manufactured using 100% clean, renewable wind energy in a Zero Waste to Landfill (ZWL) facility.

Golden Arrow’s Cilauro says, “We support demand for sustainability with a packaging solution firmly rooted in our use of the material of molded fiber. Our molded fiber is a blend of renewable resources of bamboo and bagasse (sugarcane fiber), but we don’t stop there; all the processes and energy that we use and maintain all have sustainable factors, including our commitment to zero emissions.”

At Oliver, Doroh tells Beauty Packaging, “We are focused on ways to minimize our environmental impact and are continually looking for ways to provide sustainable options. As an EPA Certified Green Partner, we invest in energy efficient equipment, offset our energy usage with renewable energy, use vegetable-based printing inks and zero VOC inks and coatings. In addition, we use paper made from well-managed forests. We also offer tree-free and post-consumer recycled content board options.”

Eska’s Meindl says brands want to show that they are socially involved. “For Eska,” says Meindl, sustainability is both in our DNA and in our products. We offer a high-quality, recycled board, which is manufactured in a facility that has one of the smallest carbon footprints in the industry.”

“Sustainability is at the forefront of everyone’s packaging decisions,” says Allstate’s Greenberg. “Our chipboard and paper-based rigid boxes are an excellent option for sustainability. With our FSC certification, there is an abundance of choices for our clients.” For customers looking for something transparent that is environmentally friendly, Allstate recently partnered with Stager Packaging based in the UK. They offer bespoke transparent packaging made of recycled PET from reclaimed water bottles.

A Graphic Edge

Whether purchasing online or in a brick-and-mortar retailer, an eye-catching carton often serves as the first communication tool between product and consumer, so it’s important to make a statement, whether subtle or bold.

At Knoll, Cohen tells Beauty Packaging: “Packaging should still make consumers dream and at the same time be reusable and/or recyclable. Covid-19 has accelerated consumers’ consciousness that they have to protect their environment and that health is the most important thing. In our category (secondary packaging) consumers now look for virtuous packs which combine aesthetics, protection—and that are environmentally friendly.”

From jaw-dropping gorgeous to simple and clean, brands have distinct views when it comes to carton design and decorative techniques.

Oliver’s Rolón says, “Packaging design and on-pack visuals have become more minimalistic. Brands are looking for ways to simplify designs for quicker turn times.”

For instance, Oliver recently developed a sustainable, minimalistic carton for their customer, Costa Brazil. Rolón explains, “We were able to package two glass bottles without using a vac tray and instead, used a hidden e-flute inside the insert for stability and protection. Creating a design to hold heavy products without plastic was the biggest challenge. The angled design, which holds the products, is very unique and creates a really interesting visual.”

It was exactly what the brand wanted. Michele Levy, co-founder of Costa Brazil, says, “We at Costa Brazil are consistently striving to find the best most eco-beneficial materials for our product and brand. Oliver Inc. has provided sustainable paper products we know we can trust.”

While some brands like to simplify their deco, others go for more vibrant or colorful graphic effects.

Arkay offers a wide array of graphic possibilities from simple to elegant. Kaneff explains, “Arkay’s unique Paint on Press is a step-by-step, trademarked process we use to reveal all of the true graphic possibilities contained within our customers’ art—enhancing the artists’ design concept, while working to develop the most cost-effective production methodology to create gorgeous results.”

In a circular economy approach, Eska has created Eska Jeans, which Meindl describes as “a new, eco-responsible solid board, 100% biodegradable, unique and innovative, made from recycled paper and denim fibers.” Eska Jeans was the overall winner of the 2019 Green Award of Édition Spéciale by Luxe Pack in Paris.

Eska will soon launch a new concept of the supplier’s “Naked Box.” Meindl explains, “It’s a solid-colored box, which eliminates the paper wrap around it. This will represent another, real sustainable innovation for the beauty market.”

Looking Ahead

Has Covid-19 initiated any changes in carton design and/or materials used? Such as creating or using more hygienic or contact-related materials? Will consumers look at cartons differently in the future?

Protection and sustainability seem sure to remain key factors in development.

“While Covid-19 has absolutely changed the world as we know it, it has not deterred the call for sustainable materials such as corrugated and paper materials in packaging,” according to Golden Arrow’s Cilauro.

“The need for folding cartons will continue to be important for brands post Covid,” says Oliver’s Doroh. “Folding cartons provide a secondary barrier to protect a brand’s product. Many consumers will view this additional barrier as a safer solution versus product without a folding carton.”

Meindl, of Eska, tells Beauty Packaging: “I think hygienic/contact-related issues and sustainability go hand in hand moving forward. Customers will want something they can dispose of after use instead of holding on to and reusing. But they also don’t want that package to affect the environment in a negative way.”

While brand customers have not specifically been asking them about more hygienic materials, BillerudKorsnäs’s Kohler, says secondary package itself has taken on a new role, acting as a safe delivery vehicle for consumer products. “We, as consumers, may be using gloves and wipes and spray, but want to know more than ever that our products have not been tampered with. Recent technical advances in paperboard manufacturing have led to much higher levels of tear resistance which can help boost safety perceptions.”

Kaneff says Arkay is grateful to have remained strong and productive through these challenging times, and also understands that the current climate may demand necessary accommodations. “To that end,” says Kaneff, “we are doing an analysis of utilizing anti-bacterial coatings and its effectiveness. I have faith that consumers will continue to enjoy beautiful and relevant packaging way into the future.”

Present an item that’s novel and beautiful—and purchasers will cherish it as a keepsake—not to mention, share on social.

Knoll Packaging, manufacturer and specialist of rigid beauty secondary packaging, produced two Advent calendars for brands with this goal in mind.

The solar Advent calendar for the Acqua di Parma brand (above) is shaped like a hatbox. It unfolds in four parts revealing compartments in which miniatures of fragrances Colonia or Blu Mediterraneo or products for the body or face are nestled. The design agency Chic came up with this unique advent calendar design and the young illustrator Italian Gio Pastori, known for his paper collages, created the playful luminous decor.

The execution of this new horizontal construction was extremely complex, in particular the manual assembly and adjustment of the various parts together to allow the box to deploy and create a continuous decor on both sides of the box. With its rigid and strong construction and perfect finishing, the Aqua Di Parma advent is intended to be kept and reused by the consumer.

The MAC Holiday Advent Calendar 2019 posed many challenges in production, including the engineering of 24 individual cartons, which included products from lipsticks to eyeshadows. The folding cartons are encased in a show-stopper, iconic star-shaped package, which any consumer is sure to keep for years to come.

He wonders whether future cartons may have to teach the consumer where to grip, how to open, walk the person through opening the box for safety—and perhaps even provide a “rethink” on how to open the package. Will we be seeing a flurry of hygienic coatings for cartons and papers? What about coatings and inks that don’t necessarily react well to products’ ingredients—or handling? Another possibility, says Rutter: “Grab Me Here” touchpoints to guide consumers when coming in contact with a carton.

No doubt about it: Especially in light of Covid-19, how we interact with things around us has changed—and the impact on the user experience may be profound. Not only in terms of hygiene, but also as far as protection, ease-of-use and sustainability.

In this unprecedented time of elevated online shopping, cartons may be on the front lines more than ever before. As always, their No. 1 function is to protect the products that lie within—but they are also relied on to keep contents clean and safe, as well as deliver a brand message and experience for the consumer who reaches for and opens the box. Whether in-store or online—from shipping cartons to showy cartons and setup boxes—carton perceptions are now at an all-time high.

Sustainability Tops the List

In addition to safety and image, cartons are increasingly telling a strong sustainability story. With a growing number of the world’s consumers, brands and governments focusing attention on eco-responsible packaging, producers of paperboard and cartons have rallied to meet the challenges. All the carton and cartonboard suppliers Beauty Packaging spoke with for this article offered sustainable solutions, and most offer specializations in this area.

Ben Cohen, creative and innovation director, Knoll Packaging, says, “Cosmetics secondary packaging always combined the function of protection and aesthetics (both brands and product codes) in a box. Each of our sets tells a story and is unique, but now brands are focusing on the sustainability of the package.”

At nearly 100 years old, third-generation family-owned Arkay Packaging combines sustainability with luxury. Mitchell Kaneff, chairman/CEO, says Arkay’s specialty “is creating unparalleled value for prestige cosmetics and pharmaceutical brands by providing creative, profitable, and eco-friendly solutions.”

Kaneff says Arkay is “at the crossroad of innovation and excellence, as we continue our strong commitment to fostering an ecologically aware culture, while utilizing environmentally friendly products—such as Monadnock Astrolite and Kona boards—to dramatically reduce our impact on the environment.” Arkay is affiliated with—and certified by—Sustainable Forestry Initiative, Community Energy, and Forest Stewardship Council. Additionally, says Kaneff, “We have achieved CarbonNeutral status and are the recipient of the Gold Recognition Level from EcoVadis, all of which sends a clear message to our customers, employees, and associates that Arkay attaches great importance to sustainability currently—and into the future.”

At Neenah, Irene Richard, senior product manager, Neenah Folding Board and Cover Materials, tells Beauty Packaging, “Bottom line, Neenah’s specialty is lifting each brand through differentiating on shelf. We do this in a variety of ways such as color, texture, recycled fibers, alternative fibers and a variety of environmental certifications.” She says sustainable and “natural-looking” options are high on brands’ priority lists for folding cartons and box wraps for both the beauty industry and the CBD industry.

Hemp-infused Neenah Folding Board products were the first in the market, says Richard. “We want to provide those brands that either market directly into the cannabis/CBD category or that desire the natural look provided by the infusion of hemp fiber, with new, innovative options.”

BillerudKorsnäs manufactures a range of sustainable cartonboard products used for luxury packaging. According to Daniella Kohler, business development manager USA, Cartonboard, BillerudKorsnäs, “Brands continue to be driven by sustainability and carbon reduction. They are looking to reduce plastic and find innovative ways to structurally house their products in a more sustainable, simple way.” She says, “Recycling is still a key focus for brands, and paper (cartonboard) is very recyclable.”

Molded fiber has also increased in usage. Golden Arrow has specialized in manufacturing “high-cosmetic” molded fiber as a sustainable packaging solution for more than 10 years. Solutions include rigid and folding carton boxes, “cutting-edge packaging design,” printing, manufacturing and logistics.

Marianna Cilauro, director of sales and marketing at Golden Arrow, says, “An emerging trend is that clients are becoming more and more interested in the possibility of implementing 100% recycled paper in their packaging, as well as seeking ways to adapt FSC paper to be more environmentally conscious. It’s undeniable that the use of paper material-based packaging has increased.”

Golden Arrow recently designed sustainable packaging for the Eighteen-B brand. Cilauro says, “Together we designed a container made entirely of molded fiber, which enhanced their packaging to become truly recyclable and compostable.” At first, Cilauro says the design structure missed “the smooth and cohesive vision that the client had in mind. “But,” she says, “we were committed to providing our client with a quality product that reflected their brand while also offering true sustainability and smooth assembly. By providing an additional level of quality control, our molded fiber package design met our client’s practical needs and their design vision.”

Knoll Packaging offers pulp-based packaging solutions. Cohen says Knoll has worked primarily in board and paper for 35 years and has seen brands move back toward these materials.

“Over the past two to three years we’ve been working to eliminate plastic from our supply chain and have seen an overall reduction in the material in our category.” These packages have been adapted to be re-designed with Knoll Ecoform, the supplier’s pulp-based material, board and wood, many of which were implemented this year.

Cohen explains: “Our company operates on an eco-design approach by offering alternative materials and by driving sustainability through to our luxury brands. This includes rethinking packages to eliminate plastic and decrease CO2, as well as redesigning to increase recyclability.”

Eska started in 1879 as a rigid paperboard manufacturer, and Anton Meindl, strategic sales director-luxury/beauty packaging, tells Beauty Packaging, “From the start, we were the first in the world to use only recycled materials in our unique production process to create our premium, exceptional quality packaging with zero-low waste.” He says Eska is currently seeing “a huge push” for sustainability and the use of recycled materials for rigid boxes. With respect to this, Eska offers both.

Eska’s brand of premium rigid board is dedicated to “highly sustainable luxury packaging solutions.” As architects of identity materials, Meindl says they take a full spectrum view of the creation and development process. “We approach innovators who dare to move things forward, and we partner with brands to expand the boundaries of sustainable packaging. Available in various solid colors, Eska board is usually converted to decorative rigid boxes and can be used for color cosmetics, fragrances, skincare products and liquor.”

With more than 250 years of experience, and facilities in Ohio, New York, and Virginia, Oliver specializes in custom folding cartons, marketing collateral, labels and fulfillment. Doug Doroh, VP of sales and marketing, says with its state-of-the-art technology and an emphasis on sustainability, “Oliver is a one-stop-solution for all printing and packaging needs.”

Moving Away from Non-Sustainable Plastics

Packaging solutions that are both innovative and sustainable are the emphasis at Diamond Packaging, according to Dennis Bacchetta, director of marketing. He says, “The biggest trend we have seen with folding cartons is a move away from mylar and plastics toward paperboards. The use of PCW boards and uncoated boards is getting popular again.”

Allstate/Staeger’s specialty is secondary packaging with a spotlight on rigid setup boxes, which are a “classic presentation for gift sets and fragrance packaging,” says Howard Greenberg, director of sales, Allstate Paper Box Company. Greenberg tells Beauty Packaging, “We have noticed some customers moving away from mylar paper stock and looking for more environmentally friendly options. All of our suppliers have been focusing on recyclability and sustainability in their product lines in reaction to the demands of the end users.”

McLean Packaging specializes in the domestic manufacturing of folding cartons, rigid set boxes, vacuum forms, and corrugated packaging from concept to completion. With three manufacturing facilities, which combined, total nearly half a million square feet, McLean provides custom packaging solutions for the beauty and personal care sectors.

As far as the sustainability movement, Jeff Besnick, VP, Mclean, says they have seen brands explore the elimination of plastic—including plastic vacuum forms that protect and display products in folding cartons and set boxes. He says there are also trends to reduce the amount of metallic effects used on the secondary packaging.

“We have seen brands address the topic of sustainability in different ways,” says Besnick. “Some are working to eliminate plastic in their secondary packaging by removing windows, dustcovers, and plastic vacuum forms while, alternatively, we have also seen brands use post-consumer-recycled plastic rather than eliminating plastic completely. Some have eliminated Mylar and/or implemented regulations on how much of the package can have metallic details like hot stamping or cold foil.

As a secondary packaging vendor, McLean is sourcing, testing, and promoting sustainable options, covering everything from raw materials to finished goods. One of McLean’s common practices is to collect any chipboard waste from manufacturing and return it to the board vendor to be reprocessed and made into new board. “On the finished good end,” says Besnick, “we are FSC and SFI certified allowing brands that use this material to print the certification logo on their package and promote their own sustainability efforts.”

McLean has also recently committed to sourcing 100% renewable energy for all three of their manufacturing facilities in NJ and PA.

Earlier this year, HLP Klearfold changed the face of plastic cartons with the introduction of RPET100 100% PCR PET folding cartons. They have now received third-party certification by SCS Global, which allows their customers to label their RPET100 cartons with SCS Global’s Kingfisher 100% PCR logo.

The feedstock for RPET100 cartons comes from materials (water and soda bottles) that have completed their original purpose and have been diverted from landfills for re-use. RPET100 cartons require fewer fossil fuel resources and less energy to produce, and their increased consumption of PRC waste helps to drive the growth of the PET recycling infrastructure.

Pat McGee, vice president, marketing, says HLP is able to make RPET100 cartons because “We first manufacture the 100% PCR box-grade PET substrate on our in-house, box-grade PET extruders. To ensure that there is no meaningful sacrifice in substrate and carton quality or performance, we also meticulously and locally source our PET waste feedstocks.”

Meeting Brands’ Goals

The demand for sustainable solutions continues to take shape and, in some ways, has been bolstered by the Covid-19 pandemic. The preference has generated an uptick with supplier innovation.

Kohler, of BillerudKorsnäs, says they are seeing an even stronger move toward plastic and material reduction, as well as more awareness toward product recyclability. “With the increase in consumption, consumers are seeing more packaging in their homes and trash and recycle bins are fuller. Consumers are faced with additional decisions on whether a package can be recycled, waste can be composted and materials can be re-used. Covid-19 has impacted these practices for more conscious decision making.”

Kohler says many brands have aggressive sustainability and carbon reduction goals which they are trying to achieve in the next few years. As paperboard manufacturing is very energy intensive, she suggests that to help meet these goals, brands should look to mills that use efficient biofuel technology rather than intensive fossil fuel technology. BillerudKorsnäs also offers structural design services that focus on material reduction. “We produce board which is stronger, at lighter weights and calipers and enables brands to reduce the amount of material needed for their package,” says Kohler. BillerudKorsnäs also provides carbon emission comparisons for the current package and proposed lighter weight package. “Brands have the opportunity to evaluate and compare our materials as a more sustainable choice,” explains Kohler.

“The most common tasks we receive are to replace a plastic insert with a fiber-based insert,” says Kohler.

BillerudKorsnäs recently switched out the plastic insert for a nail polish gift set to a sustainable paper insert using BillerudKorsnäs paperboard.

“It’s always a challenge to develop a highly functioning insert that fits the product securely,” says Kohler. “If there is slight movement of the product, it will shake, leak and cause damage to both the product and the insert during transport. We were faced with developing customized spaces where the product fit but also made it possible to easily take the product out of the package and replace it for display or storage. It ended up being a real balancing act.”

Fiber-based inserts are delivered flat and do not take up as much space as plastic trays during transport. They can also be easily recycled which Kohler says offers advantage over plastic trays and uses more sustainable material. “Our challenge was to make the insert easy to produce and align with the filling process,” says Kohler.

At Diamond Packaging, Bacchetta says brands’ interest in sustainability has increased demand for packaging with improved environmental attributes such as folding cartons, since most are manufactured with recyclable or recycled paperboard. “Paperboard is the most recyclable substrate in the market,” says Bacchetta. “In fact, the paper recovery rate was 66.2% in 2019 (AF&PA), and accounts for 65.7% of packaging materials recovered for recycling in the U.S.(EPA). Diamond introduced its greenbox initiative in 2007 for a comprehensive approach to packaging that minimizes environmental impact throughout the supply chain.

Today, Diamond’s folding cartons are designed utilizing recyclable or recycled paperboards (many FSC-certified), and manufactured using 100% clean, renewable wind energy, in a Zero Waste to Landfill (ZWL) facility.

CosMedical Technologies turned to Diamond for an innovative kit package that conveyed the premium positioning of their clinically tested, medical grade products. Age Reverse System is a skincare regimen specifically formulated to correct and prevent visible signs of aging and increase luminosity. The folding cartons were converted utilizing WestRock Tango .020 SBS paperboard, cold foiled, and offset printed with PMS gray and dense black inks, in-line with DiamondTouch soft touch coating. The folding cartons utilized recyclable paperboard, and were manufactured using 100% clean, renewable wind energy in a Zero Waste to Landfill (ZWL) facility.

Golden Arrow’s Cilauro says, “We support demand for sustainability with a packaging solution firmly rooted in our use of the material of molded fiber. Our molded fiber is a blend of renewable resources of bamboo and bagasse (sugarcane fiber), but we don’t stop there; all the processes and energy that we use and maintain all have sustainable factors, including our commitment to zero emissions.”

At Oliver, Doroh tells Beauty Packaging, “We are focused on ways to minimize our environmental impact and are continually looking for ways to provide sustainable options. As an EPA Certified Green Partner, we invest in energy efficient equipment, offset our energy usage with renewable energy, use vegetable-based printing inks and zero VOC inks and coatings. In addition, we use paper made from well-managed forests. We also offer tree-free and post-consumer recycled content board options.”

Eska’s Meindl says brands want to show that they are socially involved. “For Eska,” says Meindl, sustainability is both in our DNA and in our products. We offer a high-quality, recycled board, which is manufactured in a facility that has one of the smallest carbon footprints in the industry.”

“Sustainability is at the forefront of everyone’s packaging decisions,” says Allstate’s Greenberg. “Our chipboard and paper-based rigid boxes are an excellent option for sustainability. With our FSC certification, there is an abundance of choices for our clients.” For customers looking for something transparent that is environmentally friendly, Allstate recently partnered with Stager Packaging based in the UK. They offer bespoke transparent packaging made of recycled PET from reclaimed water bottles.

A Graphic Edge

Whether purchasing online or in a brick-and-mortar retailer, an eye-catching carton often serves as the first communication tool between product and consumer, so it’s important to make a statement, whether subtle or bold.

At Knoll, Cohen tells Beauty Packaging: “Packaging should still make consumers dream and at the same time be reusable and/or recyclable. Covid-19 has accelerated consumers’ consciousness that they have to protect their environment and that health is the most important thing. In our category (secondary packaging) consumers now look for virtuous packs which combine aesthetics, protection—and that are environmentally friendly.”

From jaw-dropping gorgeous to simple and clean, brands have distinct views when it comes to carton design and decorative techniques.

Oliver’s Rolón says, “Packaging design and on-pack visuals have become more minimalistic. Brands are looking for ways to simplify designs for quicker turn times.”

For instance, Oliver recently developed a sustainable, minimalistic carton for their customer, Costa Brazil. Rolón explains, “We were able to package two glass bottles without using a vac tray and instead, used a hidden e-flute inside the insert for stability and protection. Creating a design to hold heavy products without plastic was the biggest challenge. The angled design, which holds the products, is very unique and creates a really interesting visual.”

It was exactly what the brand wanted. Michele Levy, co-founder of Costa Brazil, says, “We at Costa Brazil are consistently striving to find the best most eco-beneficial materials for our product and brand. Oliver Inc. has provided sustainable paper products we know we can trust.”

While some brands like to simplify their deco, others go for more vibrant or colorful graphic effects.

Arkay offers a wide array of graphic possibilities from simple to elegant. Kaneff explains, “Arkay’s unique Paint on Press is a step-by-step, trademarked process we use to reveal all of the true graphic possibilities contained within our customers’ art—enhancing the artists’ design concept, while working to develop the most cost-effective production methodology to create gorgeous results.”

In a circular economy approach, Eska has created Eska Jeans, which Meindl describes as “a new, eco-responsible solid board, 100% biodegradable, unique and innovative, made from recycled paper and denim fibers.” Eska Jeans was the overall winner of the 2019 Green Award of Édition Spéciale by Luxe Pack in Paris.

Eska will soon launch a new concept of the supplier’s “Naked Box.” Meindl explains, “It’s a solid-colored box, which eliminates the paper wrap around it. This will represent another, real sustainable innovation for the beauty market.”

Looking Ahead

Has Covid-19 initiated any changes in carton design and/or materials used? Such as creating or using more hygienic or contact-related materials? Will consumers look at cartons differently in the future?

Protection and sustainability seem sure to remain key factors in development.

“While Covid-19 has absolutely changed the world as we know it, it has not deterred the call for sustainable materials such as corrugated and paper materials in packaging,” according to Golden Arrow’s Cilauro.

“The need for folding cartons will continue to be important for brands post Covid,” says Oliver’s Doroh. “Folding cartons provide a secondary barrier to protect a brand’s product. Many consumers will view this additional barrier as a safer solution versus product without a folding carton.”

Meindl, of Eska, tells Beauty Packaging: “I think hygienic/contact-related issues and sustainability go hand in hand moving forward. Customers will want something they can dispose of after use instead of holding on to and reusing. But they also don’t want that package to affect the environment in a negative way.”

While brand customers have not specifically been asking them about more hygienic materials, BillerudKorsnäs’s Kohler, says secondary package itself has taken on a new role, acting as a safe delivery vehicle for consumer products. “We, as consumers, may be using gloves and wipes and spray, but want to know more than ever that our products have not been tampered with. Recent technical advances in paperboard manufacturing have led to much higher levels of tear resistance which can help boost safety perceptions.”

Kaneff says Arkay is grateful to have remained strong and productive through these challenging times, and also understands that the current climate may demand necessary accommodations. “To that end,” says Kaneff, “we are doing an analysis of utilizing anti-bacterial coatings and its effectiveness. I have faith that consumers will continue to enjoy beautiful and relevant packaging way into the future.”

Present an item that’s novel and beautiful—and purchasers will cherish it as a keepsake—not to mention, share on social.

Knoll Packaging, manufacturer and specialist of rigid beauty secondary packaging, produced two Advent calendars for brands with this goal in mind.

The solar Advent calendar for the Acqua di Parma brand (above) is shaped like a hatbox. It unfolds in four parts revealing compartments in which miniatures of fragrances Colonia or Blu Mediterraneo or products for the body or face are nestled. The design agency Chic came up with this unique advent calendar design and the young illustrator Italian Gio Pastori, known for his paper collages, created the playful luminous decor.

The execution of this new horizontal construction was extremely complex, in particular the manual assembly and adjustment of the various parts together to allow the box to deploy and create a continuous decor on both sides of the box. With its rigid and strong construction and perfect finishing, the Aqua Di Parma advent is intended to be kept and reused by the consumer.

The MAC Holiday Advent Calendar 2019 posed many challenges in production, including the engineering of 24 individual cartons, which included products from lipsticks to eyeshadows. The folding cartons are encased in a show-stopper, iconic star-shaped package, which any consumer is sure to keep for years to come.