Marie Redding, Senior Editor04.27.21

Beauty marketers are working with packaging suppliers to use metals and metallic effects in glamorous ways—giving packaging lustrous accents, ornate details, and shimmering reflective surfaces. Metals convey luxury and have an undeniable, eye-catching appeal.

“Metallization and shine effects are associated with luxury,” says Martina Rosetti, marketing director GTO America. “They convey a sense of prestige, capturing the consumer’s attention on shelves and online,” she says.

Metals and metallics range from minimalist modern silver hues to “gilded” components in gold, bronze and rose gold. “We certainly see a continued trend for premiumization and for metal,” says Steve Rusch, vice president of marketing and business development, Anomatic.

Metal finishes can transform a wide range of packaging applications—including fragrance bottles, lipstick, makeup palettes, skincare tubes, jar caps, cartons and more. “Packaging with premium finishes and reflective properties have proven to be very successful,” says Kelley Stearman, vice president of business development, Americas, at LLFlex. “Beauty brands might use silver, gold, metallization, custom holographs, lens structures, tactile finishes and color-change effects—all to create stand-out looks,” she explains.

Metal packaging can be eco-friendly, especially since it’s made to last. “Refillable packaging represents a long-lasting trend in the beauty industry, and we manufacture beautiful metal products that are worth keeping for a long time,” according to Metapack. “We offer a large range of standard refillable packaging in zamac, including compacts, pursers, lipsticks and sticks,” says Isaure de la Noue. co-founder, Metapack.

Boris Schaefer, vice president of sales, TNT Global Manufacturing, says, “Metal remains a prized material in the world of perfume and beauty, given the preciousness that gold or silver shine brings to a product—even to the simplest cap or accessory.” However, not all metals have the same properties, Schaefer says. “For a high-end positioning, zamac is preferred,” he advises.

Aluminum is Infinitely Recyclable

Aluminum is the most preferred type of metal for packaging in terms of sustainability, some suppliers say. Steve Rusch, vice president of marketing and business development, Anomatic, says, “Aluminum is infinitely recyclable—it’s the most recycled material in the world.”When anodizing aluminum, the material’s recyclability isn’t affected. “We offer many different customizable decorating options, none of which affect the material’s sustainability,” Rusch says.

Unilever's Love, Beauty, Planet is one haircare brand choosing aluminum, for its reusable shampoo and conditioner bottles.

Anomatic recently launched a customizable stock range of all-aluminum lids paired with different types of jars. The eco-friendly line is 100% recyclable.

ABA’s Mike Warford also says that aluminum is an ideal packaging material. “Aluminium is lightweight, opaque, nearly unbreakable—and infinitely recyclable without any loss of its properties,” says Warford. “It is the ideal material for refillable products, which allow the user to keep a package long-term, resulting in less waste, reduced energy, and a reduction in raw materials.”

ABA’s Envases line of threaded neck aluminum bottles are refillable. “The threaded necks allow for re-sealing and re-use with a pump, dropper, or cap,” says Warford. “We also offer large neck openings, to ensure there are no issues,” he says. “Eco-responsibility is not just an option anymore, it is a real requirement for all beauty brands,” he adds.

ABA’s Envases line is available in capacities from 50- to 750ml, and in various shapes and profiles. The supplier’s team also has the technical expertise to adapt the openings on any of its bottles to accommodate automatic refilling caps, if necessary. “We also offer customization, including some exclusive options, such as embossing, online integrated hot stamping and special finishes,” Warford says.

Lindhardt, a supplier that also produces aluminum packaging, such as cans for beauty drinks, points out another benefit. “Aluminum is perfectly suited for recycling because it requires only 5% of the energy initially required for extraction to return to the material loop,” explains Christian Kunzelmann, sales director, Linhardt. “In Germany, around 90% of aluminum packaging is recycled and 75% of all the aluminum ever produced is still in use today,” he says.

Metal for Makeup

A metal lipstick package feels substantial to hold—and Amorepacific’s HERA Rouge Holic lipstick collection looks luxurious. Designed to resemble a “beautifully designed object,” the team says its goal was to create an iconic design. “We used the basic shapes that HERA has always used, such as circles and rectangles, to create a modern design with a beautiful harmony of straight line and curve,” says Jeanie Lee, HERA brand manager, Amorepacific. “We also tried to make it fit in hand perfectly,” she adds.Matte and gloss finishes on the package correlate with each lipstick formula, for a tactile quality that delivers a sensorial experience. “We focused on reinterpreting ‘classic’—and used saturated colors, an engraved logo, weight and other details,” explains Seoyoung Baek, HERA brand manager, Amorepacific.

Scanavo offers beauty brands a luxe packaging option for makeup—its SteelBook palette. The supplier’s patented minimalist design, the SteelBook palette features an outer tin shell, held together by an inner PP shell. “There is an additional metal plate covering the outer spine, perfect for printing a logo,” says Soren Heinrichs, sales manager, Scanavo.

It is also eco-friendly. “It’s a sustainable design certified by both EcoCert and Cosmos,” says Heinrichs, adding, “and if you add a magnet plate to the bottom of the tray, you can make it refillable.”

Scanavo also offers multiple ways to customize it. “There are numerous options for the inside construction of the trays, shapes of recesses and applicators,” says Heinrichs.

Jimmy Choo's Golden Hues—In Both Metal & Metallized Plastic

Sometimes a beauty brand will choose meta—or, some components are plastic. Decorating with a metallization process, however, can ensure that plastic will shine as much as metal does.Metal and metallized details on caps and collars enhance a bottle, while plaques and logos add “bling.” The Jimmy Choo I Want Choo fragrance bottle features both—plus, a matching carton that also glistens with a metallic deco.

The 'I Want Choo' packaging features several shiny elements. The faceted bottle is paired with a round gold spray cap with a lower fret. “It is decorated with a layer of galvanization to achieve its golden color,” explains Delphine Pommier, marketing and communications, Interparfums. “The upper ball is metallized plastic,” she adds.

The ‘JC’ logo, which is also galvanized plastic, is designed to mimic the logo on Jimmy Choo’s fashion accessories. “The logo’s grainy texture and the fret were engraved in the mold to create a harmonious look,” says Pommier.

Jimmy Choo Seduction Collection Nail Polish is a glamorous bottle, with a glistening cap that is adorned with a gold “ski-shaped” metal plaque. The cap also has a sparkling ring on its lower rim, featuring a hammered finish. TNT Global Manufacturing produced these elements.

“The hammered finish effect was achieved using a specific process after die-casting, specially developed,” explains Schaefer.

An Art Deco Look for Judith Leiber's Refillable Bottle

Judith Leiber More is More! For Him Eau de Parfum feels luxurious—and the glass bottle looks as if it’s encased in metal. The men’s fragrance is in the same innovative refillable three-chamber bottle as the women’s scent, but with a shiny, mirror-like finish in navy blue.“We were inspired by the Chrysler building in New York and its art deco heritage,” says Mike Edwards, Judith Leiber. “It’s adorned with Swarovski crystals as an ode to our design house, Judith Leiber Couture, and its sparkling Hollywood soiree clutches,” Edwards says.

The outer “case,” which is a molded polyethylene frame, is decorated using a three-stage metallizing process. “A silver substrate is added, then metallized with color and lacquered,” Edwards says. “The glass flacon refills also go through a metallization process.

We fade to clear at the base of the bottle. This process took some trials and was complex to achieve a smooth, faded look,” he explains.

Skincare Shines

Skincare brands often use metals and metallics as accents on a bottle or tube. A silver collar or cap, for example, provides an instant “upgraded” look.Cosmogen offers tubes that are ideal for skincare products, paired with removable zamac applicator caps. The caps look luxe, in gold and rose gold. The consumer keeps the applicator after the product is finished, which adds value—and can replace the product with a refill tube, which is eco-friendly.

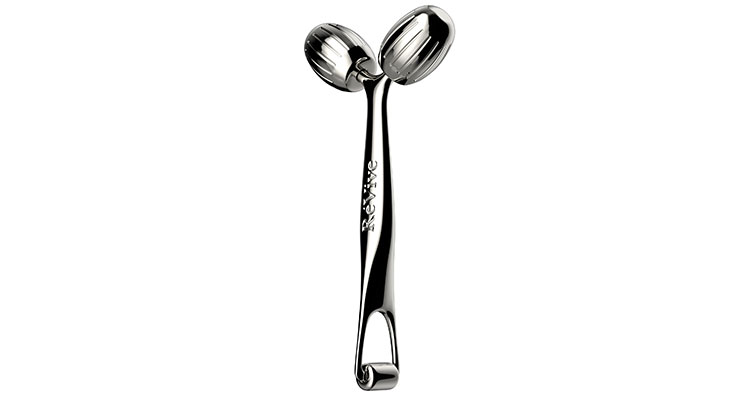

The popularity of skincare tools, including face rollers, is on the rise since the Covid-19 pandemic. There are several trendy types of rollers, including jade and rose quartz—but RéVive went for a different look with its new ReVolve Contouring Massage Roller. It is made from zamac, and looks upscale and elegant.

RéVive’s founder, Dr. Gregory Bays Brown, says, “We used zamac for our Intensité Moisturizing Lip Balm applicator, and chose it again now for our Revolve Roller because it provides a consistently cool temperature. It feels refreshing on the skin, and it also helps to minimize puffiness.”

Designed with three rotating rollers—two laser-grooved for the face, neck and décolletage, plus a smaller smooth roller for the eye area—the roller claims to help improve the look of skin for less visible puffiness and a firmer appearance.

“Zamac provides a luxe and substantial look and feel,” adds Brown. “We selected it because of its durability and anti-rust capabilities. These properties add to its shelf life, making it extensively reusable,” he explains, adding, “The metal’s natural cooling effect eliminates the need to use additional energy resources to cool the device.”

A Recycling Chain for Zamac

Zamac is a luxury material that is widely used for prestige packaging. Zamac allows for custom shapes and a high level of detail, according to TNT’s Schaefer. “Unlike metallized plastic, zamac provides a ‘cold touch’ sensation. It also adds weight, which is synonymous with quality.”Since nearly every beauty company is increasing its sustainability goals, TNT Global Manufacturing launched a zamac recycling chain. “We are working with partners and, in particular, smelters, whose demand for CSR-zamac is strong. Not only is it an eco-friendly and self-financing chain, but also more virtuous, since recycling requires limited energy resources compared to an initial production,” explains Schaefer.

Metapack's Refillable Pursers

Metapack specializes in zamac packaging, including the refillable pursers, shown. “Zamak offers many surface treatment possibilities, such as electroplating with precious metals in gold or silver. We offer a large range of standard plating colors in matte and shiny effects—or trendy vintage looks,” says Isaure de la Noue, co-founder, Metapack.Metapack’s refillable pursers are available in a range of finishes, including gold, gunmetal, rose gold, nickel-plating and black e-coating. “Personalization is necessary for beauty brands to differentiate. Different plating colors are perfect for limited editions,” says de la Noue.

Metapack also offers other techniques that will imitate a metallized effect on plastic. “This technology, similar to a transfer sticker, allows for smaller minimum order quantities, and has a shorter production lead time,” says de la Noue.

Decorating with Metallic Foils

Hot-stamping foils in metallic hues will make a package shine. “Foils can be applied to full areas, such as an entire cap and bottle, or used as banding to decorate certain areas of a cylindrical or round enclosure,” says Favian R. Guardado, marketing coordinator, North Pacific International (NPI).Beauty brands also use metallic foils for a logo, or to highlight certain words, such as a product’s key attributes, on a carton. “Foils for small text can be transferred using die-stamping techniques,” says Guardado. “For much more detailed artwork with several colors, our transfer labels are an option. They include metallic colors, and can convey a distinguished look,” he explains.

NPI offers a metallic series of hot foils. “They have passed rigorous compatibility tests, making them an excellent choice,” says Guardado.

LLFlex offers laminated and transfer metallized substrates for various packaging applications. “We offer a full range of paper and paperboard products that are uncoated and/or laminated to foil or film. Our films included metallized, holographic, rainbow, lens, and even custom holograms to achieve a metallic appearance that can then be further enhanced by our customers using inks and embossing,” says Stearman.

Hot & Cold Foil Decorating Processes

Metallic looks can be achieved through the use of traditional hot foils, or a cold foil process. Mike King, president, Eagle Systems, talks about the benefits of cold foil, explaining, “We can put down a silver foil, and then overprint in any color of the rainbow. Cold foil is innovative—it can often replace any type of hot foil decoration, in any color.” Eagle’s expertise lies in both hot and cold foil machinery.Which decorating process to choose? “For some applications, beauty brands choose hot foil due to the rich look it provides,” says King. It is a secondary process, however, and often requires more lead time and a bigger budget. “Beauty brands want that ‘bling’ and sparkle,” says King, “so cold foil usually offers a solution that won’t go over-budget.”

Hot foil has a high gloss sheen and slightly raised, 3D look. “Cold foil doesn’t have the same gloss level on some substrates—but emboss it, and you usually won’t be able to tell the difference,” King adds.

Metallic Foils & Sustainability

If you’re wondering if decorating with foils affects a package’s sustainability, it doesn’t, King says. “Both hot and cold foils are 100% recyclable,” he confirms.Confusion arises when foil decorating on a laminated board, or when foils are used to create a laminated board. “Laminated boards are often made using a plastic substrate, and this is not recyclable,” says King.

Eagle is currently funding a recycling study on foils at Western Michigan University, after its foils already passed similar tests at PIRA and Georgia Tech. “Both our hot and cold foils on boards passed the repulpability tests,” says King. Eagle will publish the full results once the recyclability testing is complete.

GTO’s Rosetti also says both hot and cold foil are eco-friendly processes. “The foil is recyclable and repulpable—on products as well as the discarded parts,” she says, adding, “but then it is up to the end user to put it in the recycle bin.”

Rosetti also says many of their prestige beauty customers are finding ways to combine luxury and sustainability. “Many achieve this by adding foil and lamination effects to sustainably made paper packaging, glass, and recycled plastics,” she says.

Another eco-friendly option is LLFlex’s Zero Gauge portfolio of Hampden Papers. “It’s an eco-friendly alternative to conventional foil and film lamination,” says Stearman. “These products are designed to meet sustainable packaging and green initiatives without sacrificing the aesthetic beauty that brilliant silver and holographic film base stocks offer,” she explains.

LLFlex’s transfer metallized Zero Gauge products have the same metallic appearance as the supplier’s laminated products, but they’re made by transferring a thin metallic layer to the base paper or paperboard substrate via a carrier film. “The carrier film is then stripped away leaving a paper substrate that is recyclable and environmentally friendly,” says Stearman.“To ensure complete sustainability, LLFlex then reuses or recycles the carrier transfer film, which is an important part of the sustainable life cycle of transfer metallized materials,” she adds.

Specialized Machinery To Create Metallized Looks

GTO’s specialized machinery creates metallized effects on packaging. Its line of made-in-Italy hot foil printing machines are designed for flat and round objects. “We have different sizes for different markets, and can customize the machines for in-line production and automation,” says Gasparella.GTO’s patented Tampolamina system combines a screen printing or pad printing technique with a hot foil application. “This means that a customer who is already using pad printing or screen printing can now offer hot foil decoration just by adding this one machine,” says Rosetti. “In addition, it can create an embossed effect,” she says.

Tapematic's Fully Automated In-line Decorating

Another system for creating metallic decorations is Tapematic’s IDM II—a fully automated in-line module for decorating substrates. “The IDM II design allows complex decoration in one continuous process, by linking and synchronizing multiple hot-stamp stations—so it’s capable of endless color and shape combinations,” says Tony Denning, president, Tapematic.The supplier’s specialized machinery also comes equipped with a serialization feature that allows any single item to be totally unique and identifiable. Plus, during a metallization process, the object being decorated is never touched by hand. “This results in a smooth production process that increases the overall performance of the line,” says Denning.

Acme Provides Essential Metal Components

Consumers might not give a second thought to the metal pans in a makeup palette, but they’re a crucial part of the package that Acme provides. “Our newest product is antimicrobial, and it is 100 percent recyclable,” says Mike Roughton, president, Acme Cosmetic Components.Acme is a world leader in stamped metal cosmetic components, and can produce custom tooling for innovative shapes.

The Future Looks Shiny & Green

Beauty brands will always gravitate toward metal and metallic effects, for eye-catching, luxe looks. Plus—it seems like the next generation of materials are designed with sustainability in mind.LLFlex’s Stearman advises, “Collaborate with a substrate expert early on in the design process because we can suggest ways to differentiate your brand. There is something truly special and memorable about a brilliant metallic package—and it can also be eco-friendly.”

GTO’s Rosetti adds, “It is clear that long-lasting, refillable packaging will be key for the future. So the key is to make things more beautiful.”