Joanna Cosgrove, Contributing Editor04.27.21

Cartons are more than just a disposable secondary packaging element—they represent valuable real estate for brand messaging and deliver an additional layer of security to thwart tamper evidence. While eco-friendly efficiencies continue to evolve, paperboard providers and carton suppliers are flourishing, producing cartons that combine an improved environmental impact with the beauty and creativity expected in the cosmetic and personal care segment.

Environmentally speaking, cartons are undeniably more sustainable and it’s an attribute that consumers increasingly want. Greg Maze, director of product management, packaging at Neenah, says consumer demand for recyclable packaging remains high, citing data that “79% of people agree that recycling paper-based product of any kind is still worthwhile.” (Source: Isobar 2019 Segment Deep Dive, 2019) Brands are reacting, he says, by requesting natural-looking, responsibly-sourced packaging containing post-consumer content.

“Many companies are very interested in promoting a circular economy…aimed at eliminating waste and the continual use of resources,” he says. “Because paper can actually be recycled up to seven times, it’s an integral part of a closed-loop/circular economy and an excellent replacement for plastic where applicable.”

Maze says that while plastic has a place, Neenah is frequently approached by brands seeking to offset the use of plastic with paper alternatives. “It can be tricky because plastic is easy to mold and is inherently waterproof; people want the same things from paper,” he comments. “While paper isn’t naturally waterproof, it can be adapted to meet customers’ needs.”

With an eye on current and emerging trends, Neenah has added hemp-infused products targeting cannabis and CBD customers, matte-single and matte-double, soft-touch finish, and a deep Industrial Black color to its Folding Board line.

Neenah also took part in a cooperative partnership to produce a carton solution for Function of Beauty. The partnership included Wingate Packaging, which digitally color printed 10 different carton SKUs, and Klocke of America, a contract filler and turnkey packager that handled the carton assembly.

The Function of Beauty cartons contain dual, rigid, hair goal blister additives which enable consumers to customize shampoos and conditioners to deliver attributes like anti-frizz, curl definition, volumizing, deep conditioning, shine boost, scalp soothing, color protection, thermal protection, strengthen and lengthening properties.

“Klocke was looking for a 100% PCW board as requested by Function of Beauty with a definite concern regarding printability,” Maze explains, noting that Wingate had worked with Neenah board before and recommended the company to Klocke. “They ultimately chose PC 100 Vellum for its brightness, structure and printability, [and] it was a great fit for Function of Beauty, as they strive to maximize the number of sustainable materials used in packaging.”

“Many brands are exploring ways to reduce existing material but also remove plastic from their primary and secondary package,” says Daniella Kohler, brand owner manager, Cartonboard USA, BillerudKorsnäs. “Things like inserts and trays, or even plastic shrink wraps (for tamper evidency) are being evaluated.”

BillerudKorsnäs is considering ways carton board can support both the primary and secondary package for products like makeup compacts. “All of the big beauty brands have aggressive sustainability and carbon reduction goals to hit in the next 5 to 10 years and this innovation needs to start now,” Kohler says. “We’re seeing more interest from both brands and converters in our CrownBoard portfolio of products as it aligns really well with the packaging needs for beauty brands. Our board is made from virgin Nordic fibers, thus providing a stronger, lighter solution to brands in which a sustainable, lighter material is preferred.”

YouBodyCare recently worked with BillerudKorsnäs to develop a box designed to hold individual sachets of powder body wash. The package is comprised of CrownBoard Prestige 15.9pt. The boxes measure 10.5 x 3.2cm and feature vibrant, six-color graphics.

“The box needed a sturdy material since consumers will open and close the box multiple times to remove the individual packets of body wash powder,” remarked Kohler.

“YouBodyCare chose to print and convert on BillerudKorsnäs board because of their sustainability credentials,” says Heather Fritzsche, YouBodyCare’s founder and CEO. “Everything YouBodyCare does involves sustainable decisions including packets that supply more than one wash and a product that can be used over and over and over again to pre-mix custom scents and wash, thus saving water and plastic material as compared to traditional body wash bottles.”

Anthony Grinnell, CEO, Harmony Paper Co., says brand sustainability initiatives nixing plastics in favor of recycled paper-based products are definitely well-intentioned however there’s still a lot of room for improvement.

“There are recyclable, plastic free products in the market that are readily available and not cost preventative [however it’s hindered by] the lack of information, knowledge and testing labs with ‘real-world’ technology to accurately and correctly determine the recyclability of a paper-based product,” he comments. “Additionally, with the volume of retailers requiring or requesting recyclability testing, a substantial backlog is occurring where suppliers have to wait months to get their materials into the lab for testing.”

Harmony Paper Company recently launched a new EcoFX line of plastic-free, metallized and holographic papers characterized by a direct metallizing process that doesn’t use any plastics in manufacturing or in the final product. “We have dozens of holographic patterns which can be done in any custom colors, as well as in clear holography (no rainbow coloration), white holography (no silver), spot holography and anti-counterfeit, [in] weights ranging from 60gsm (40# text) to 3mm laminated boards,” Grinnell says.

Replacing environmentally harmful coatings is another concept that’s moved to the forefront. M C Packaging has been working with one of its large CPG clients to find an eco-friendly solution that would replace the poly coated paperboard (a plastic layer) on their folding cartons.

“The poly coating is used to from a moisture barrier protecting the product inside the cartons,” explains Marc Silverberg, president, M C Packaging Corp., which recently rolled out a new coating called Envirpro-tech, an aqueous based coating that offers a moisture barrier that’s environmentally friendly, recyclable and repulpable.

In addition to receiving FSC certification to have greater control and transparency of its supply chain, Knoll Printing & Packaging has responded to the call for less plastic by implementing its Knoll Ecoform pulp solution and its Patent-Pending KnollLuxe Premium Board Platforms. In 2021, Knoll will be producing over 2 million Knoll Ecoform pulp parts as replacements for plastic platforms.

Ben Cohen, Knoll’s creative and innovation director, says KnollLuxe Premium Board Platforms, is a newly developed recyclable and sustainable packaging solution that features all-finished edges and luxurious cavities to hold product. “The prestigious platforms can be seamlessly wrapped for decoration and has the most upscale appearance,” he explains. “Knoll Ecoform is a new plant material made from bamboo, wood and sugar cane fibers, originally utilized as a replacement for plastic platforms, but we’re thrilled to push the materials boundaries and utilize it for mono-material packaging solutions.”

“Hazen is seeing a rapid adoption of Envirofoil to replace metallized film laminated paperboard and foil laminated paperboard. John Hazen, president, Hazen, says Envirofoil is a good alternative to cold foil, as Hazen uses its carrier film multiple times before recycling it. “The printer does not have to deal with spent rolls of carrier film that are part and parcel to cold foil,” he says.

Beyond the realm of plastic, there has also been more support for transparency surrounding the origin and recyclability of paperboard products, paralleled by the improved use of recycled content.

“We are seeing an increased demand for paperboards made with post-consumer recycled (PCR) fiber or feature uncoated or textured surfaces,” says Dennis Bacchetta, director of marketing, Diamond Packaging. “We have also seen more interest in FSC-certified paperboards and inquiries on how brands can communicate these benefits through on-product labeling.”

Bacchetta says the ongoing trend toward more sustainable packaging with higher recycling rates has increased demand for paperboard and decreased demand for plastic substrates over the last several years, and it’s with that in mind that Diamond continues to place emphasis on innovation—and their sustainability-focused Greenbox initiative, which it launched in 2007.

“Paperboard is the most recyclable substrate in the market—the paper recovery rate was nearly 66% in 2019, and accounts for 65.7% of municipal solid waste (MSW) recovered for recycling in the U.S. (source: American Forest & Paper Association),” he explains. “When you consider the aesthetic, protective and sustainable properties of paperboard, it’s the natural choice for environmentally-friendly packaging.”

Doug Doroh, vice president of sales and marketing, Oliver Inc., says the focus on paper’s environmental impact is anything but static. Enhancing packaging sustainability tends to dominate client discussions, spanning everything from “right-sizing,” redesigning to reduce material and lower board caliper requirements, using stock with higher recycled content, and responsible sourcing such as FSC and SFI certified materials.

“As part of the sustainability conversation, many customers are focused on tree-free alternative paperboard,” he says, adding that this led Oliver to form an alliance with Emerald Brand, makers of paperboard produced using bagasse, the agri-waste from sugar production. “While many companies specify recycled and post-consumer waste content paperboard, we have identified a growing list of brands looking for alternatives to wood fiber-based SBS. Together with Emerald, we provide customers with a reliable and consistent supply chain of this SBS alternative.”

This effort caught the eye of the Lauren Conrad brand team, which turned to Oliver as it set out to develop a line of beauty products. Seeking to “shatter conventional thinking” with its choice of packaging materials, the brand chose paperboard made from sugarcane bagasse. “The result is no cutting down of trees, and the conversion of agro-residue into paperboard,” says Doroh. “The folding cartons have a natural organic look, with fibers visible on its surface that signals a brand focused on the environment.”

Oliver’s Doroh says the pandemic effectively heightened the carton’s traditional purpose of product protection, giving consumers a disposable barrier that protects against microbes reaching the surface of primary packaging. Oliver is currently conducting extensive testing of an antimicrobial coating targeted to provide another barrier to minimize the accumulation of microbes on the folding carton.

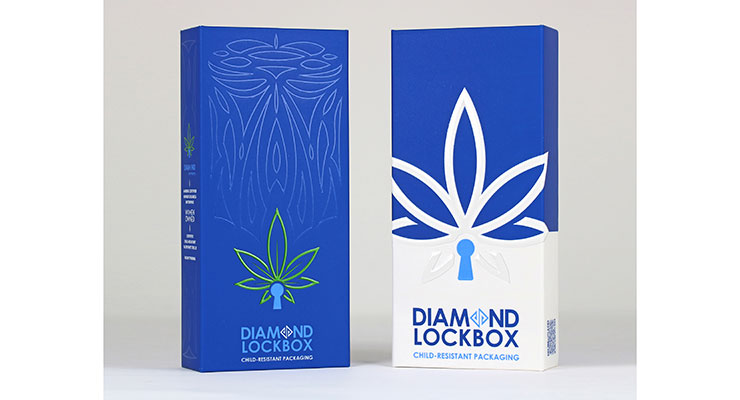

Product security is another avenue of interest. Diamond Packaging recently introduced Diamond Lockbox folding cartons, an upscale, certified child-resistant (CR) packaging solution. A combination of beauty with strength, the single and dual lock options feature finished edges and ample space for decorating and finishing, ticking the boxes for upscale and premium brands through more sustainable converting methods.

The decline of in-person, brick and mortar shopping has also created opportunities for carton innovations.

“With the lockdowns, companies were forced to pursue e-commerce at a more aggressive level,” says Neenah’s Maze. “If you’re a high-end brand and you cannot create that same gold standard service experience in the retail store, you still want to provide it to your customers at home.”

Maze says he observed a trend back to acknowledging the power of the unboxing moment. “It deterred some traditional packaging but created a whole new level of focus for many brands who adapted to the moment,” he comments. “E-commerce was gradually building anyway, but the pandemic forced brands to pivot and make advancements much faster. You still need to create brand loyalty, but more often now at the consumer’s doorstep than on the store shelf.”

To that end, Knoll has been working with its brand partners to create custom e-commerce and digitized packaging experiences that incorporate QR, NFC and AR technologies with the goal of creating at-home packaging experiences that allow customers to connect directly with the brand through various technologies.

“NFC technology, for instance, allows a device to communicate directly with the packaging through a ‘tap’,” says Knoll’s Cohen. “This allows for the customer to receive custom messaging from the brand, which could include product authentication, brand promotion and customer loyalty programs; it’s an additional and ongoing way to interact with their customers.”

BillerudKorsnäs’s Kohler points to a solid trend towards clear and impactful brand design on the secondary package. “Since Brick & Mortar suffered and e-comm grew, brands were utilizing the entire package as true brand real-estate to communicate product features and benefits,” she says.

It would seem Arkay Packaging had that trend in mind when it launched, registered and trademarked its new Paint on Press technique. The process renders any package (including those with sustainable materials) into a 3D carton that reveals all the graphic possibilities contained within a customers’ artwork. “Arkay enhances the artists’ design concept, while working to develop the most cost-effective production methodology in order to present an invaluable and unique opportunity that benefits our customers,” explains Ruth Rugoff, Arkay’s chief communications officer.

The process entails separating the art into printing and finishing layers, while at the same time developing a menu of options that are designed to enhance the completed 3D carton. Painting is done on actual production equipment, making it completely repeatable for production orders and actual finished cartons are developed with all of the options, so they can be utilized for focus groups and leadership meetings before reaching final determination. Upon completion of the process, there are frequently 25 to 50 different options created for client consideration.

The carton segment continues to be impacted by a variety of issues, and carton suppliers continue to rise to the occasion, delivering impressively innovative solutions that benefit brands and impress consumers.

With an outlook on sustainability, Allstate Paper Box, manufacturer of rigid boxes and luxury packaging, has formed a strategic partnership with Stager Packaging, a leading designer and manufacturer of bespoke transparent packaging solutions based in the United Kingdom.

As an FSC certified company, Allstate provides their customers with an array of sustainable options for setup boxes—helping their customers choose the right materials to support their sustainability initiatives. By partnering with Stager, Allstate says they now offer the best of transparent packaging made from recycled water bottle waste. “We are continually looking for ways to offer our customers packaging that is manufactured responsibly with minimal impact to the environment,” says Matthew Elias, president of Allstate Paper Box.

Environmentally speaking, cartons are undeniably more sustainable and it’s an attribute that consumers increasingly want. Greg Maze, director of product management, packaging at Neenah, says consumer demand for recyclable packaging remains high, citing data that “79% of people agree that recycling paper-based product of any kind is still worthwhile.” (Source: Isobar 2019 Segment Deep Dive, 2019) Brands are reacting, he says, by requesting natural-looking, responsibly-sourced packaging containing post-consumer content.

“Many companies are very interested in promoting a circular economy…aimed at eliminating waste and the continual use of resources,” he says. “Because paper can actually be recycled up to seven times, it’s an integral part of a closed-loop/circular economy and an excellent replacement for plastic where applicable.”

Maze says that while plastic has a place, Neenah is frequently approached by brands seeking to offset the use of plastic with paper alternatives. “It can be tricky because plastic is easy to mold and is inherently waterproof; people want the same things from paper,” he comments. “While paper isn’t naturally waterproof, it can be adapted to meet customers’ needs.”

With an eye on current and emerging trends, Neenah has added hemp-infused products targeting cannabis and CBD customers, matte-single and matte-double, soft-touch finish, and a deep Industrial Black color to its Folding Board line.

Neenah also took part in a cooperative partnership to produce a carton solution for Function of Beauty. The partnership included Wingate Packaging, which digitally color printed 10 different carton SKUs, and Klocke of America, a contract filler and turnkey packager that handled the carton assembly.

The Function of Beauty cartons contain dual, rigid, hair goal blister additives which enable consumers to customize shampoos and conditioners to deliver attributes like anti-frizz, curl definition, volumizing, deep conditioning, shine boost, scalp soothing, color protection, thermal protection, strengthen and lengthening properties.

“Klocke was looking for a 100% PCW board as requested by Function of Beauty with a definite concern regarding printability,” Maze explains, noting that Wingate had worked with Neenah board before and recommended the company to Klocke. “They ultimately chose PC 100 Vellum for its brightness, structure and printability, [and] it was a great fit for Function of Beauty, as they strive to maximize the number of sustainable materials used in packaging.”

Slashing Plastic Content

As Maze mentioned, there will always be a place for plastic packaging, however there is an overarching shift to reduce plastic in the supply chain. The challenge is finding a sweet spot in the balance.“Many brands are exploring ways to reduce existing material but also remove plastic from their primary and secondary package,” says Daniella Kohler, brand owner manager, Cartonboard USA, BillerudKorsnäs. “Things like inserts and trays, or even plastic shrink wraps (for tamper evidency) are being evaluated.”

BillerudKorsnäs is considering ways carton board can support both the primary and secondary package for products like makeup compacts. “All of the big beauty brands have aggressive sustainability and carbon reduction goals to hit in the next 5 to 10 years and this innovation needs to start now,” Kohler says. “We’re seeing more interest from both brands and converters in our CrownBoard portfolio of products as it aligns really well with the packaging needs for beauty brands. Our board is made from virgin Nordic fibers, thus providing a stronger, lighter solution to brands in which a sustainable, lighter material is preferred.”

YouBodyCare recently worked with BillerudKorsnäs to develop a box designed to hold individual sachets of powder body wash. The package is comprised of CrownBoard Prestige 15.9pt. The boxes measure 10.5 x 3.2cm and feature vibrant, six-color graphics.

“The box needed a sturdy material since consumers will open and close the box multiple times to remove the individual packets of body wash powder,” remarked Kohler.

“YouBodyCare chose to print and convert on BillerudKorsnäs board because of their sustainability credentials,” says Heather Fritzsche, YouBodyCare’s founder and CEO. “Everything YouBodyCare does involves sustainable decisions including packets that supply more than one wash and a product that can be used over and over and over again to pre-mix custom scents and wash, thus saving water and plastic material as compared to traditional body wash bottles.”

Anthony Grinnell, CEO, Harmony Paper Co., says brand sustainability initiatives nixing plastics in favor of recycled paper-based products are definitely well-intentioned however there’s still a lot of room for improvement.

“There are recyclable, plastic free products in the market that are readily available and not cost preventative [however it’s hindered by] the lack of information, knowledge and testing labs with ‘real-world’ technology to accurately and correctly determine the recyclability of a paper-based product,” he comments. “Additionally, with the volume of retailers requiring or requesting recyclability testing, a substantial backlog is occurring where suppliers have to wait months to get their materials into the lab for testing.”

Harmony Paper Company recently launched a new EcoFX line of plastic-free, metallized and holographic papers characterized by a direct metallizing process that doesn’t use any plastics in manufacturing or in the final product. “We have dozens of holographic patterns which can be done in any custom colors, as well as in clear holography (no rainbow coloration), white holography (no silver), spot holography and anti-counterfeit, [in] weights ranging from 60gsm (40# text) to 3mm laminated boards,” Grinnell says.

Replacing environmentally harmful coatings is another concept that’s moved to the forefront. M C Packaging has been working with one of its large CPG clients to find an eco-friendly solution that would replace the poly coated paperboard (a plastic layer) on their folding cartons.

“The poly coating is used to from a moisture barrier protecting the product inside the cartons,” explains Marc Silverberg, president, M C Packaging Corp., which recently rolled out a new coating called Envirpro-tech, an aqueous based coating that offers a moisture barrier that’s environmentally friendly, recyclable and repulpable.

In addition to receiving FSC certification to have greater control and transparency of its supply chain, Knoll Printing & Packaging has responded to the call for less plastic by implementing its Knoll Ecoform pulp solution and its Patent-Pending KnollLuxe Premium Board Platforms. In 2021, Knoll will be producing over 2 million Knoll Ecoform pulp parts as replacements for plastic platforms.

Ben Cohen, Knoll’s creative and innovation director, says KnollLuxe Premium Board Platforms, is a newly developed recyclable and sustainable packaging solution that features all-finished edges and luxurious cavities to hold product. “The prestigious platforms can be seamlessly wrapped for decoration and has the most upscale appearance,” he explains. “Knoll Ecoform is a new plant material made from bamboo, wood and sugar cane fibers, originally utilized as a replacement for plastic platforms, but we’re thrilled to push the materials boundaries and utilize it for mono-material packaging solutions.”

Improving Eco Impact

The big trend for Hazen Paper Company is its transfer metallizing process and product lines. Produced on Hazen’s vertically integrated manufacturing campus using hydroelectric power, Envirofoil has received Phase-2 certification from Western Michigan University, as well as USDA certification for its recyclability.“Hazen is seeing a rapid adoption of Envirofoil to replace metallized film laminated paperboard and foil laminated paperboard. John Hazen, president, Hazen, says Envirofoil is a good alternative to cold foil, as Hazen uses its carrier film multiple times before recycling it. “The printer does not have to deal with spent rolls of carrier film that are part and parcel to cold foil,” he says.

Beyond the realm of plastic, there has also been more support for transparency surrounding the origin and recyclability of paperboard products, paralleled by the improved use of recycled content.

“We are seeing an increased demand for paperboards made with post-consumer recycled (PCR) fiber or feature uncoated or textured surfaces,” says Dennis Bacchetta, director of marketing, Diamond Packaging. “We have also seen more interest in FSC-certified paperboards and inquiries on how brands can communicate these benefits through on-product labeling.”

Bacchetta says the ongoing trend toward more sustainable packaging with higher recycling rates has increased demand for paperboard and decreased demand for plastic substrates over the last several years, and it’s with that in mind that Diamond continues to place emphasis on innovation—and their sustainability-focused Greenbox initiative, which it launched in 2007.

“Paperboard is the most recyclable substrate in the market—the paper recovery rate was nearly 66% in 2019, and accounts for 65.7% of municipal solid waste (MSW) recovered for recycling in the U.S. (source: American Forest & Paper Association),” he explains. “When you consider the aesthetic, protective and sustainable properties of paperboard, it’s the natural choice for environmentally-friendly packaging.”

Doug Doroh, vice president of sales and marketing, Oliver Inc., says the focus on paper’s environmental impact is anything but static. Enhancing packaging sustainability tends to dominate client discussions, spanning everything from “right-sizing,” redesigning to reduce material and lower board caliper requirements, using stock with higher recycled content, and responsible sourcing such as FSC and SFI certified materials.

“As part of the sustainability conversation, many customers are focused on tree-free alternative paperboard,” he says, adding that this led Oliver to form an alliance with Emerald Brand, makers of paperboard produced using bagasse, the agri-waste from sugar production. “While many companies specify recycled and post-consumer waste content paperboard, we have identified a growing list of brands looking for alternatives to wood fiber-based SBS. Together with Emerald, we provide customers with a reliable and consistent supply chain of this SBS alternative.”

This effort caught the eye of the Lauren Conrad brand team, which turned to Oliver as it set out to develop a line of beauty products. Seeking to “shatter conventional thinking” with its choice of packaging materials, the brand chose paperboard made from sugarcane bagasse. “The result is no cutting down of trees, and the conversion of agro-residue into paperboard,” says Doroh. “The folding cartons have a natural organic look, with fibers visible on its surface that signals a brand focused on the environment.”

Cartons Amid Covid-19

We’re more than a year into the global pandemic and there have been some particularly fascinating developments related to using cartons to improve aspects of product integrity and the consumer/brand connection.Oliver’s Doroh says the pandemic effectively heightened the carton’s traditional purpose of product protection, giving consumers a disposable barrier that protects against microbes reaching the surface of primary packaging. Oliver is currently conducting extensive testing of an antimicrobial coating targeted to provide another barrier to minimize the accumulation of microbes on the folding carton.

Product security is another avenue of interest. Diamond Packaging recently introduced Diamond Lockbox folding cartons, an upscale, certified child-resistant (CR) packaging solution. A combination of beauty with strength, the single and dual lock options feature finished edges and ample space for decorating and finishing, ticking the boxes for upscale and premium brands through more sustainable converting methods.

The decline of in-person, brick and mortar shopping has also created opportunities for carton innovations.

“With the lockdowns, companies were forced to pursue e-commerce at a more aggressive level,” says Neenah’s Maze. “If you’re a high-end brand and you cannot create that same gold standard service experience in the retail store, you still want to provide it to your customers at home.”

Maze says he observed a trend back to acknowledging the power of the unboxing moment. “It deterred some traditional packaging but created a whole new level of focus for many brands who adapted to the moment,” he comments. “E-commerce was gradually building anyway, but the pandemic forced brands to pivot and make advancements much faster. You still need to create brand loyalty, but more often now at the consumer’s doorstep than on the store shelf.”

To that end, Knoll has been working with its brand partners to create custom e-commerce and digitized packaging experiences that incorporate QR, NFC and AR technologies with the goal of creating at-home packaging experiences that allow customers to connect directly with the brand through various technologies.

“NFC technology, for instance, allows a device to communicate directly with the packaging through a ‘tap’,” says Knoll’s Cohen. “This allows for the customer to receive custom messaging from the brand, which could include product authentication, brand promotion and customer loyalty programs; it’s an additional and ongoing way to interact with their customers.”

BillerudKorsnäs’s Kohler points to a solid trend towards clear and impactful brand design on the secondary package. “Since Brick & Mortar suffered and e-comm grew, brands were utilizing the entire package as true brand real-estate to communicate product features and benefits,” she says.

It would seem Arkay Packaging had that trend in mind when it launched, registered and trademarked its new Paint on Press technique. The process renders any package (including those with sustainable materials) into a 3D carton that reveals all the graphic possibilities contained within a customers’ artwork. “Arkay enhances the artists’ design concept, while working to develop the most cost-effective production methodology in order to present an invaluable and unique opportunity that benefits our customers,” explains Ruth Rugoff, Arkay’s chief communications officer.

The process entails separating the art into printing and finishing layers, while at the same time developing a menu of options that are designed to enhance the completed 3D carton. Painting is done on actual production equipment, making it completely repeatable for production orders and actual finished cartons are developed with all of the options, so they can be utilized for focus groups and leadership meetings before reaching final determination. Upon completion of the process, there are frequently 25 to 50 different options created for client consideration.

The carton segment continues to be impacted by a variety of issues, and carton suppliers continue to rise to the occasion, delivering impressively innovative solutions that benefit brands and impress consumers.

With an outlook on sustainability, Allstate Paper Box, manufacturer of rigid boxes and luxury packaging, has formed a strategic partnership with Stager Packaging, a leading designer and manufacturer of bespoke transparent packaging solutions based in the United Kingdom.

As an FSC certified company, Allstate provides their customers with an array of sustainable options for setup boxes—helping their customers choose the right materials to support their sustainability initiatives. By partnering with Stager, Allstate says they now offer the best of transparent packaging made from recycled water bottle waste. “We are continually looking for ways to offer our customers packaging that is manufactured responsibly with minimal impact to the environment,” says Matthew Elias, president of Allstate Paper Box.