Marie Redding, Senior Editor12.06.21

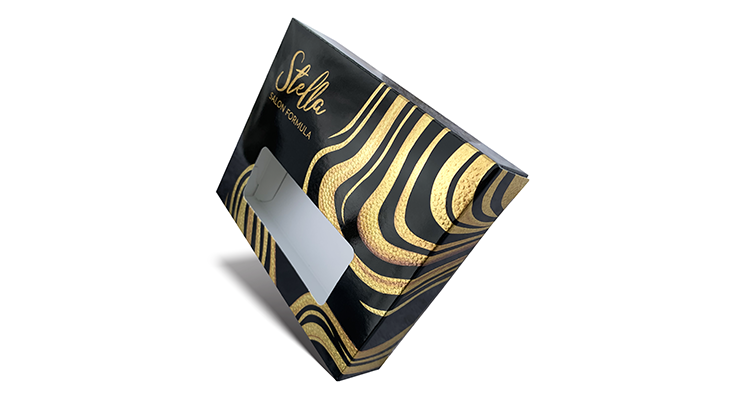

Whether it’s a bottle, jar, or carton—it’s often a decoration that elevates it, turning packages into vessels worthy of housing a prestige makeup collection or a designer fragrance. The right design, paired with a luxe decoration, can turn any ordinary container into a “beauty package.” Decorating processes require using inks, foils, colorants and more.

“After a period of time where beauty brands were reducing embellished finishes, we are seeing brands re-energize their personality on-shelf,” says David Peters, global marketing & communications manager, LLFlex. “Shine, dazzle, texture, and precision-varnish detailing is now more important than ever before,” he says.

Beauty brands have to balance glamour with sustainability, however—and packaging suppliers and decorators offer solutions. “Luxury brands now have more options for sustainable, recyclable materials that will help a package stand out without breaking budgets,” says Anthony Grinnell, CEO, Harmony Paper Company. “While many suppliers have struggled with passing official recyclability tests, there are now a handful, including Harmony Paper Company, offering certified recyclable options,” he says.

Metallic Finishes Are in Demand

Suppliers say they are hearing lots of requests from beauty brands for metallic finishes. Due to increasing demand for metallic looks that are also eco-friendly, Harmony Papers launched a new, recyclable metallized material in its EcoFX line earlier this year. “We have the ability to control not only the base material construction, but also every step of printing and conversion to ensure a package and all materials maintain their recyclability,” says Grinnell.He explains that simply choosing an eco-friendly material isn’t enough. “Brands need to be diligent in selecting certified base materials, but also in ensuring all of the other decorating processes and materials used in printing and converting won’t negate the package’s recyclability,” he explains. “For example, a rigid box can have a certified metallized paper laminated to a certified chipboard, but if the incorrect glues are used for lamination, it will fail recyclability testing,” he says.

The team at LL Flex spoke about decorating trends for packaging, and say that all types of precious metals, such as pale golds, copper and platinum finishes, are popular, especially when combined with brush metal print effects and deep embossing.

“Our metallic finish Mylar is our most popular substrate, and it’s a designer’s go-to for deep metallic shine and excellent printability,” says Peters. LLFlex’s ‘Boutique Flex,’ a trend inspired by the Art Deco era, will be popular for 2022, the company predicts. “We see lots of soft-touch textures and rich velvet prints that convey timeless luxury—in emerald greens, ruby reds, deep yellow golds and pale precious metal finishes,” says Peters.

LL Flex also sees a strong interest in its exclusive ‘ZeroGauge’ substrate, which offers a metal finish that is plastic-free. “Metallic finishes can now be sustainable, plastic-free and also provide a beautiful surface for detailed designs and print features,” Peters says. “And our fully recyclable embossed papers have seen a strong interest for packaging design inquiries for 2022,” he adds.

Another supplier, Alpha Packaging’s Technigraph, offers screen-printing processes directly on plastic bottles, jars and closures with metallic inks, and they are UV-cured and fully recyclable. “Our Antique Silver ink is great if you are interested in metallics with a unique twist,” says Marny Bielefeldt, vice president of marketing, Alpha Packaging. “The protective coating will enhance durability and shine, and the silver ink will gradually look ‘tarnished’ over time, taking on a truly unique and antique quality,” she says.

For a more traditional metallic appearance, Bielefeldt suggests its ‘Super Silver’ ink. “It’s the ultimate metallic effect for fine detail—and at 60% to 70% less costly than hot-stamping, you can use this environmentally-friendly ink on your bottles, your jars and your closures,” she advises.

Technigraph specializes in direct screen-printing of up to six ink colors on all types of packages, including uniquely-shaped plastic closures. “A brand can combine screen-printing with other decorating processes, such as spray-frosting, which can add textures or color to other parts of a bottle,” says Bielefeldt.

“Direct screen printing with UV-cured inks is more eco-friendly than pressure-sensitive labeling, because a typical label on a 12-ounce bottle weighs one to three grams. Printing directly onto the bottle reduces the weight of the finished package and eliminates the cost, transportation, and roll-stock waste associated with the pressure-sensitive labeling process,” she explains. “It’s also easier to recycle a bottle printed with UV inks than to recycle a bottle that has a label affixed to it with an adhesive,” she adds.

Solving the 'Cracking' Issue to Decorate Compacts & More

The team at Harmony Papers says that preventing cracking can sometimes be a challenge when using a metallized transfer decorating process and direct metallization technique. “This often happens on a package with a hinge, such as a compact, or on a multi-directional fold line, like a folding carton thicker than 20pt,” says Grinnell.Realizing this is a big problem, particularly for luxury brands that really need to maintain a prestigious brand aesthetic, Harmony Paper Company released a certified, recyclable, crack-proof metallized and holographic line in August.

Metallized Looks for Dropper Packs

The team at Virospack say there is a strong market demand for all types of metallized finishes for its dropper packs. “Beauty brands can choose different materials for bulbs, and use different decorating processes to create custom looks for bottles and caps, including spray-painting, hot-stamping, and metallized finishes. “We can also screen-print glass pipettes,” says Rosa Porras, marketing communication manager, Virospack.Virospack has produced dropper packs for over 65 years, and decorates them in-house. The company recently worked with Clarins to provide its classic dropper with a white bulb and metallized gold cap.

Virospack recently increased its capacity to provide metallized finishes with its new sputtering line, which decorates components with a metallic effect coating. The coating has a high abrasion resistance and high chemical resistance, according to Porras. “High-vacuum sputtering is a ‘clean’ coating technique,” Porras says. “It’s sustainable and cost-efficient, and produces a uniform coating while reducing waste,” she says. Porras explains that sputtering is a dry and low-temperature process that forms an indestructible relationship between a film and substrate. “It welds them at the molecular level,” she explains.

Virospack also offers two new types of injected plastic caps, with a glossy finish. “A glossy color can convey glamour,” says Porras. “And it is possible to be more respectful of the environment without giving up a luxurious image,” she says. “Both of our new caps and collars have a large decorative surface area, and like the bulb, can be injected in a wide variety of colors. They are made from paint-free injected PP, and the collar’s outer shell is friction-adjusted, so it doesn’t require any glue. The finish is luminous and radiant,” Porras adds. Since inks aren’t required, nor a secondary decorating process, CO2 emissions are reduced.

More Suppliers Offering All Types of Decorating Capabilities

Choosing a supplier to create the look you envision, and knowing which types of decorating processes are best for different types of packaging and materials can be a challenge. Screentech is a company known for its ability to decorate glass, and fragrance bottles are its specialty. The supplier offers spray coating, screen printing, tampo printing, hot-stamping and labeling for glass bottles and jars.“The sustainability of glass combined with our water-based and organic decorating process makes for a very environmentally friendly product,” says John Schofield, owner, VP sales & marketing, Screentech. “This combination is ideal for custom decorations for luxe brands, and a way to customize one of our stock packages,” he says. “We’re known for our ability to make a stock package look elegant,” he adds.

Beauty brands that need to print on plastic tubes, bottles, jars, or on glass often turn to Cosmetic Packaging Resources (CPR) for its in-house printing capabilities. “We use UV and solvent-based inks, as well as some eco-friendly-based inks, depending on the substrate,” says Cyndi Matthews, packaging sales manager, CPR. The company has two fully automatic and several semi-automatic printing machines.

Tapematic is known for its expertise in decorating machinery. The company recently introduced its Tapematic IDM II module. “It can be seamlessly integrated with all of the modules of the PST II Line, creating a completely automated line that allows you to achieve a variety of goals,” says Tony Denning, president, Tapematic USA.

The new module can do all of the following decorating processes: deposit a base UV varnish; metallize an entire surface with any metal material using 3D sputtering technology; decorate the side or top surface with a variable hot-stamping system; insert an additional laser decoration; add a QR code or another variable data field; and deposit a transparent UV varnish in any desired color to embellish the decoration under it for excellent chemical and mechanical resistance properties.

How Decorating Solved Covid-19 Challenges

Packaging suppliers say that the Covid-19 pandemic posed quite a few manufacturing and supply challenges. Decorating, in a way, solved some of these issues for beauty brands.“Some of the decorating trends we are seeing were born out of necessity,” says Alpha Packaging’s Bielefeldt. “Packaging components have been hard to source for the past year, so beauty brands have had to make compromises about the bottles and jars they purchased.

For example, a brand may have used a custom-colored purple jar with a matching purple lid, but the colored jar or lid may not have been available for several months. Instead, they relied on decorative effects—and used techniques such as spray frosting and full-body shrink sleeves to achieve their branded color scheme,” she explains. “We’ve also had customers spray-frost clear plastic bottles to look like frosted glass when they couldn’t get glass containers shipped from overseas,” she says.

Screentech also comments on how the Covid pandemic affected packaging, and how decorators are offering solutions. “In these days of supply chain issues, our ability to mix and blend colors in house has a tremendous advantage in getting a finished product to the market quicker,” says Schofield.

Tapematic’s Denning adds, “The past eighteen months have proven to be challenging, with many changes and limitations. Despite this, we are pleased to report our team has continued to be focused and highly dedicated to finding innovative solutions that satisfy a somewhat volatile market.”

What’s Next? Suppliers Continue to Advance Offerings

Packaging suppliers and decorators continue to innovate, and expand capabilities to offer beauty brands more options. “At Technigraph, we recently began blow-molding bottles for the beauty market at our Midwest decorating facility,” says Bielefeldt. “This reduces costs and time, dramatically, as well as the petroleum required to ship bottles from another location. We can now mold a customer’s bottle on-site and decorate it almost immediately,” she says.Virospack recently reached an agreement with IFS, a software provider, to use its IFS Cloud solution to optimize production, design, and material traceability. Efficiency can be improved using the IFS Cloud solution. It allows all products to be managed in a unified way, on a single API-based platform designed for the Cloud, which can be run anywhere.

The software also provides traceability by allowing the carbon footprint of each product to be traced, as well as the materials used. The software can help advance a brand’s environmental goals by helping to develop more sustainable products. Both companies will work together over the next 12 months to develop tools adapted to Virospack’s operation. The supplier will implement IFS’s tools this December, and will begin to use it by December 2022.

2 Beauty Brands That Use Decoration Differently

UMA Oils Are Decorated To Symbolize Luxury

UMA Oils, which just made this year’s Oprah’s Favorite Things list, uses hand-blown glass packaging for its hair oil, body oil, face serums, and candles. The packages are all “hand-decaled by an artisan,” says founder and chief executive officer Shrankhla Holecek.“We embrace technological advancements, but believe technology will never be a substitute for experience, judgment and personalized attention,” Holecek explains. “Luxury is more than a label—it’s a statement of exquisite craftsmanship, characterized by an investment of time, and an attention to detail,” she says.

The labels on the bottles and jars say ‘Uma’ and the product name. The minimal and elegant squares, with paper liners, resemble “Tiffany blue.” They are printed using a 4-color process, outlined with a gold foil stamp decoration, and topped with a super clear lamination for protection.

UMA Oils just launched a holiday gift set, with candles. “We wanted to ‘gift’ our customer the delight she expects from holding a truly indulgent product, in every aspect,” says Holecek “but without the environmentally insensitive use of ‘bells and whistles’ that quickly make their way into trash and landfills.”

The labels on the glass candle jars are stickers that are applied by hand, using a non-toxic adhesive. “We chose a two-step decorating process, and we knew this cost more, but we wanted the labels to be easily removable so the jars could live on and be reused,” says Holecek. The brand worked with a local artisan in Los Angeles to develop this decal process.

Wanting to ensure that the gold foil on the label wouldn’t affect its recyclability, or the recyclability of the cartons, Holecek says she did a lot of research. “We learned that gold foil is extremely thin, so it dissolves completely during the re-pulping process,” she says, so the packaging can be recycled without issue. “There’s lots of available literature on this,” she adds, “and our manufacturer only sources from a certified zero-waste foil producer.”

An intricate, elegant flower-and-herb design adorns the candle jars and cartons. “My sister, Bhoomika Upadhyay, an artist and fashion designer, sketched the original imprints. She was inspired by the flowers and herbs that adorn our UMA meadows in India. Then we worked with a Spanish design firm, and Vania Nedkova, to execute her vision,” says Holecek.

Originally, Holecek said the motifs were going to be part of the sticker label on both the bottles and boxes, but instead it is screen-printed. “In an unusual burst of extravagance, I decided that the motif should spread across all glass and external packaging, which considerably raised our costs and turnaround times—not to mention the extensive training we had to cover for the artisans. It definitely feels like we made the right choice, as our bottles are truly distinctive,” Holecek says.

The cartons are made from post-recycled stock. Holecek says she chose screen-printing over an offset process because it helped give the ink a “feathery” look and feel. “We also used a spot UV printing technique, which reflects quality,” she says.

MyChelle's Design Conveys Product Benefits

MyChelle’s new Hydrate Collection features hyaluronic acid, which attracts water to the skin, so it makes sense that its packaging features a light blue decoration, inspired by water. More specifically, the graphics printed on the collection’s white packaging include wavy lines, reminiscent of the sea.The design also draws the consumer’s eye to product benefits, which are highlighted in light blue—in a fun way that looks like someone went over the bottles with a highlighter. Lauren Vaughan, creative director, MyChelle, says, “We designed custom patterns for each of our benefit categories. The blue pattern was created to correlate to water and hydration.” The brand created custom-embossed dyes to print the packaging.