Jamie Matusow, Editor-in-Chief12.06.21

While Innovative Packaging can be defined in numerous ways, from unique gestures to dual features to eye-popping decorative techniques, today the term is almost inextricably entwined with sustainability claims.

The mandate for sustainable packaging in the beauty industry (and elsewhere) is rising dramatically, and the curve shows no sign of waning. Driven primarily by eco-conscious consumers and legislation from countries facing mounting waste and climate degradation, packaging for beauty products has come under increased scrutiny. Industry suppliers are leading the sustainable solutions revolution by innovating with options including new materials, new formats, and new additives that help speed end-of-life disposal processes—all while keeping an eye on shelf- and Instagram appeal.

At Kemas, a manufacturer of high-end color cosmetics and skin care packaging, Darren Eade, vice president of sales, confirms a pivotal emphasis from “uniqueness” to sustainability-based innovation. He tells Beauty Packaging: “Innovation in 2021 has certainly been all about sustainability.” This can come in the form of design, resin and material choices. “The industry seems to be looking beyond those ‘truly unique’ design concepts and focusing more on reaching their sustainability goals and objectives,” says Eade.

In general, Eade says beauty brands have been requesting refillable concepts, and the ‘less is more’ approach has been trending with the brands. He acknowledges: “Decoration has and always will be critical in the innovation process; however, decoration that meets recycling objectives is increasing in trend and trying to find the right balance between cost and feasibility will be critical with new innovation.”

Tara Cary, segment market manager, Cosmetic Packaging, Eastman Specialty Plastics confirms that sustainability is top of mind for brands. She tells Beauty Packaging, “The biggest ask from beauty brands that we have seen recently is to retain the ability to create truly beautiful, iconic packaging in a sustainable format.” She says recycled content, recyclability, and refill options are all in huge demand these days with “an emphasis on sustainability without compromise.” As we return to more travel, Cary says they are also seeing an increased emphasis on the importance of a sustainable design for travel-sized packages.

Overall, this immense challenge to reduce waste is opening up a surge of new partnerships and opportunities within the cosmetic industry, but there are also many questions that remain to be answered—and billions in sales at stake.

Market Demands

According to new research from B2B firm Markets and Markets, the size of the global cosmetic packaging market is projected to grow from $49.4 billion in 2020 to $60.9 billion by 2025, at a CAGR of 4.03% from 2020 to 2025. Key to growth, say analysts, is an increase in packaging innovations, and a boost in the demand for cosmetics from “the youth population.”The report also states, “Factors such as high demand from cosmetic brands for innovative, attractive and sustainable packaging across the globe are driving the demand for cosmetic packaging.” In fact, Markets and Markets says the industry “is working toward creating more environmentally friendly packaging options that can take the cosmetics market to a whole new level.”

Sustainable Partnerships

To surmount the vast hurdles involved, brands and suppliers—particularly in the Prestige sector—are collaborating to bring sustainable change to the cosmetic packaging industry as a whole. The research firm ResearchandMarkets found: “The current trend toward pursuing sustainable practices is not merely nice, it is becoming the new norm. Private and public organizations working together to speed up the environmental change, in keeping with market expectations, open up vast opportunities.Recently, five of our Top 20 brands announced they are developing an industry-wide environmental impact assessment and scoring system for cosmetics products. The goal is “to co-design an approach that is brand-agnostic, and which provides consumers with clear, transparent and comparable environmental impact information, based on a common science-based methodology.”

They are inviting other cosmetic companies to join them in this venture.

The Estée Lauder Companies (ELC) is one global brand marketer that has invested in supplier partnerships and in bringing innovation and sustainable materials to prestige packaging.

Al Iannuzzi, vice president sustainability, global corporate citizenship & sustainability, The Estée Lauder Companies, tells Beauty Packaging, “At The Estée Lauder Companies, we have an opportunity to help prestige beauty define what packaging sustainability should be by searching for materials that meet consumer expectations, while delivering on our luxury offerings and providing a high-quality experience.”

For instance, he says that Origins, a brand in ELC’s portfolio, “became the first in prestige beauty to utilize advanced recycled resin in tube pack format wherein the recycling technology used delivers high-performance plastics akin to a virgin material with no compromise to aesthetics or quality.” He says such initiatives are furthering the brand’s efforts to ensure that at least 80% of its packaging by weight is recyclable, refillable, reusable, recycled or recoverable by 2023. “By approaching packaging improvements with a spirit of innovation and collaboration, we believe we can advance solutions for the personal care and cosmetics industry at large while achieving our packaging sustainability goals,” explains Iannuzzi.

A New Slant on Innovation

Rather than focusing on a unique design or application method, Kemas’s focus has also shifted toward sustainable materials. Their most recent innovation revolves around the use of a material called LIMEX—and particularly “materials that have the ability to create a full circular economy,” says Eade.LIMEX is a new material—currently being used in Japan for the food industry, says Eade. Kemas launched a partnership with TBM (Japan) for the material that is made up of 50-60% limestone, and which is touted as greatly reducing carbon emissions during the resin procurement and incineration phase. According to Eade, “This new revolutionary material not only dramatically cuts down on carbon emissions, but is 100% recyclable. LIMEX can be made into paper or plastic parts and LIMEX paper can be recycled back into LIMEX resin, which is a game changer for the environment and the future of plastics,” he explains.

Makeup Gestures, Refillables & Creativity

New gestures have long signified packaging innovation and commanded attention in the Beauty industry, and the buzz around this type of development still holds true.WWP Beauty recently ramped up their initial makeup innovations with launches that they say represent the packaging trends they are seeing around new gestures. “Both of these launches are 2.0 launches of items we previously launched with more material, size and deco options,” explains Musa Dias, CMO, WWP Beauty.

Two of WWP Beauty’s latest packages that offer new gestures and ways of dispensing and applying product include their ColorVue Lipstick and Side Effect Dropper.

The ColorVue Lipstick features an award-winning design that was given the silver Beauty Award in the 2021 Pentawards. It features a patented revolve and reveal R2 mechanism, and a mono-material and sustainable design that uses 12% less plastic and reduces GHG emissions by up to 85% per piece.

The Side Effect Dropper is a universal package that can be used for color cosmetics, skin care and haircare products with an elevated side button, dispensing the product in a new way. “This easy to apply, convenient design is available in multiple sizes (15- and 30ml) and can be made with different sustainable materials including glass and PCR content,” says Dias.

Refillables for Keeps

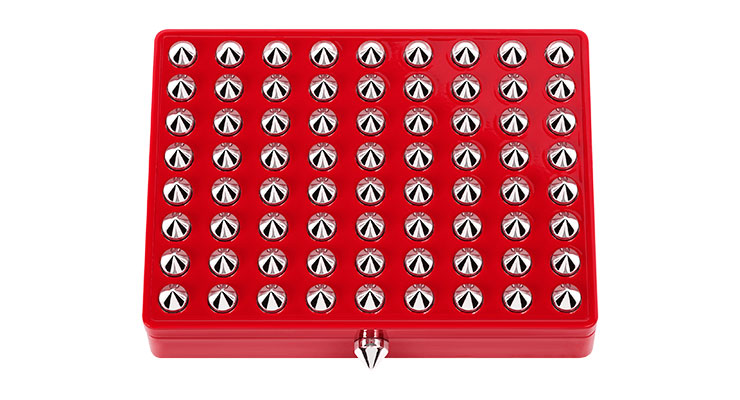

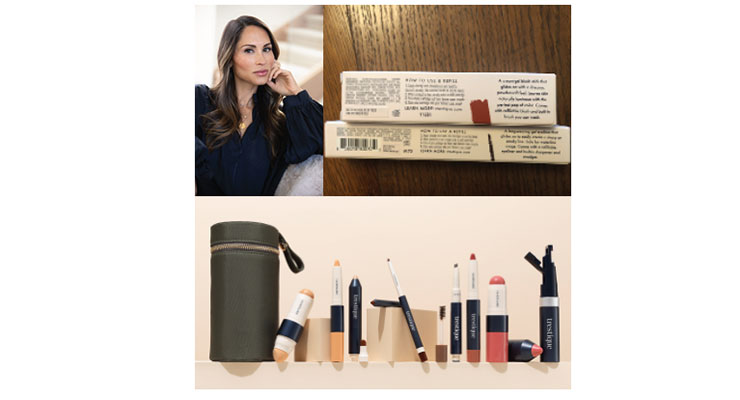

One innovative way in which suppliers and brands—particularly prestige brands—are developing refillables, is by creating an accessory-like “keepsake,” which the consumer holds on to for a long period of time, and replaces the contents when needed. In this vein, TNT Global Manufacturing created Louboutin’s luxurious, magnetic, refillable makeup case, adorned with the iconic Christian Louboutin silver spikes. Available in black or red, it also incorporates the codes of the brand’s famous, easily recognizable sole. A metallic key enables the user to extract and replace the color palette.Trestique is a beauty brand that launched six years ago, focused on “extraordinary quality, innovative packaging and unfussy routines,” according to co-founder Jenn Kapahi. At the time, she and co-partner Jack Bensason relied on their industry experience to create an original cruelty-free makeup line, made in Italy and delivered in 2-in-1 makeup crayons. Due to customer demand, the partners evolved the brand to be more sustainable, and have now created 100% reusable and refillable products “made from the highest level of recycled material that technology allows.”

From the formulas to the packaging, everything was developed through “a lens of sustainability—from sourcing and materials to manufacturing and packaging,” says Kapahi. In September 2021, despite the challenges caused by Covid and supply chain issues, Trestique introduced what they call “the most sustainable color cosmetics line” to the market. The new, clean and sustainable collection features multi-tasking, mess-free, refillable stick makeup in everything from mascara to lip color, and is described as the first 100% refillable zero-waste beauty system, according to the Carbonfund.org Foundation.

“Our packaging has the highest levels of post-consumer and post-industrial recycled materials that technology allows,” says Kapahi. She explains that they have reduced the amount of virgin plastic they use in their packaging by more than 90%, and that Trestique products are made with an average of 86% recycled materials (“the highest in the beauty industry”). All products are carbon-neutral.

The brand also uses FSC-certified paper and soy-based ink for all cartons and consumer mailers, and the paper comes from responsibly-managed forests that provide environmental, social and economic benefits to their communities and is 100% recyclable. Each makeup bag is made from a single recycled plastic bottle.

Bormioli Luigi also saw refillables as an opportunity for creativity in makeup—expanding their expertise in glass componentry, primarily for specialty fragrance, into new jar solutions for cosmetics and skin care, and innovating with semi-standard designs for lipstick, lipgloss and mascara. Thanks to partnerships with plastic injection specialists like Italian company Pibiplast, the group is presenting a full-pack offer, with complementary components.

New packaging offers include a refillable case for lipstick. Designed to be both beautiful and sustainable, the case offers a choice of systems to hold it in place, made from plastic or metal. This allows the consumer to renew the inner insert containing the bulk when finished, or to change shades at will, keeping the outer pack.

And in skin care, Bormioli Luigi’s “Le Rechargeable” jar design features a removable insert that the consumer can buy separately in store and replace with a simple gesture. This patented concept has a specific design in which a plastic ring guarantees its safety and holds it in place. The supplier says this sustainable packaging solution “is suitable for high-end developments designed to last.”

Luxe and Pulp-able

Chanel, often regarded as the epitome of luxury, has been making great strides with sustainable cosmetic packaging. Their most recent innovative pack is proof that luxe and sustainable can meet—and pulp packaging can be chic and beautiful.To celebrate the 100th anniversary of its iconic N°5 perfume, Chanel partnered with Knoll Printing & Packaging to reinvent its packaging with a 100% Knoll Ecoform pulp clamshell. The material was chosen for its sustainable materials, design qualities, and ability to be perfectly formed to recreate the N°5 perfume bottle.

Jeremy Cohen, president & CEO, Knoll Printing & Packaging, said, “The mono-material Knoll Ecoform pulp packaging for Chanel is a first-of-its kind for the luxury packaging industry. This project, which took over 18 months to develop, is not only an engineering feat, but also redefines the benchmark for sustainable luxury packaging. Chanel trusted our global team at Knoll to bring this vision to life, and it has completely disrupted the market. We anticipate our customers will follow in these footsteps as we continue to push the whole industry forward to achieve this new standard of sustainable packaging.”

Chanel’s sleek and all-white Knoll Ecoform clamshell is made of FSC-certified bamboo and bagasse (waste from sugarcane). The package is also biodegradable and recyclable in the paper & board recycling stream. “Behind the purity and perfection of this design lies a high degree of complexity of both development and engineering to bring this unique shape to life,” says Jeremy Cohen.

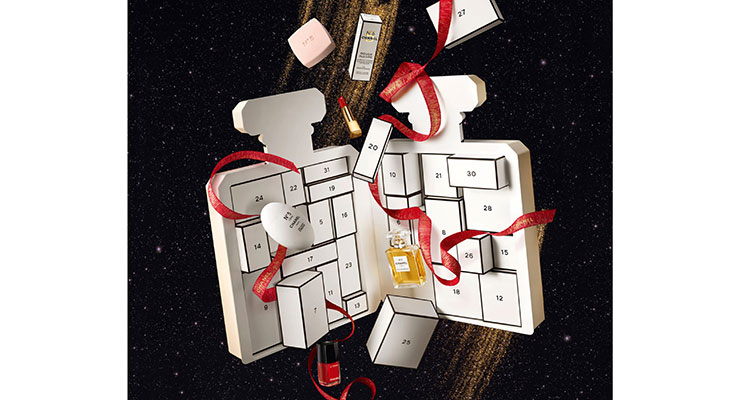

In what could be the most covetable gift of the season, Chanel partnered with Knoll on its first advent calendar, newly launched for 2021. Its debut, 27-strong product offering, pays homage to Gabrielle Chanel’s iconic Nº5 fragrance, with skus housed in a giant white and black Nº5 bottle. It contains some of the brand’s most desired beauty products, from Chanel’s Longwear Nail Colour to a Nº5 Bath Soap and Body Cream, in addition to jewelry and decorative items.

The exterior of the exquisite and sustainable calendar is 100% Knoll Ecoform pulp, which contains 27 individual folding cartons. “It is a first-of-its-kind for advents and an extraordinary use of the pulp material,” says Ben Cohen, creative and innovation director, Knoll Printing & Packaging. The calendar retails for about 700 euro.

In yet another sustainable packaging advance for Chanel, the luxe brand recently introduced a bio-based fragrance cap for all of the 125ml bottles in its Les Eaux De Chanel collection. The cap, developed in partnership with Sulapac, is made out of 91% bio-based materials obtained from renewable resources and FSC certified wood chips. It was the first dual project for the two companies since Chanel invested in Sulapac in 2018. According to Sulapac, it took at least 48 attempts to reach the final product.

Paper Solutions

Paper has long been a choice for sustainable packaging, and innovative ways for its usage continue to evolve.Gary Bernstein, senior sales director packaging & sustainable solutions, at Neenah, agrees that “All eyes are focused on sustainability.” He says, “Innovation comes into play when brands begin looking at ways to replace non-recyclable materials, reduce the amount of waste, as well as design a package that has a sustainable aesthetic.” In addition to these changes, Bernstein says there is also pressure in the market to become more transparent.

“Consumers want to know about the origin and the life cycle of the materials being used, as well as how to properly recycle them. And feel-good, honest sustainability messaging on the package not only adds to that desired aesthetic, but is expected by today’s savvy consumer.”

Bernstein says Neenah is now having lots of conversations around the wholistic customer journey—using materials beyond just the packaging that not only meet a brand’s sustainability goals, but communicate the brand’s values. “For packaging,” he says, “we see many brands trending toward a natural aesthetic—using uncoated board with minimal decoration—to match the values and concerns of the consumer. For example, a tactile, slightly rough, uncoated surface is viewed as luxe, and it subconsciously communicates a brand’s priorities. Our recent conversations tend to be around high PCW content, elevated unboxing for the growing e-commerce channel, and customization.”

Paper is now making its way into the market as an innovative sampling solution for Aveda.

As part of Aveda’s commitment “to implement cutting-edge innovations and follow design-for-recyclability principles,” the vegan beauty brand has just announced “an industry-first achievement.” Through a new partnership with Xela Pack, Aveda will launch the prestige beauty category’s “first-ever paper-based, locally recyclable sachet.”

Edmond Irizarry, Aveda’s executive director, Global Package Development, said, “At Aveda, we understand the relevance of sampling our products in a sustainable way: in-line with our mission, and without compromise on product quality or consumer experience. I am extremely proud of our three-year development partnership with Xela Pack to deliver this breakthrough sampling innovation. We look forward to expanding this technology to other markets, brands and categories in the near future.”

The patent-pending Envirotray is a product that General Fibre has been working on for many years. According to Jay Tarantino, vice president sales, the Envirotray is a paper solution to plastic vacuum forms and other single-use plastic items that customers are looking to replace with a sustainable paper solution. Recently, with the pressure to reduce plastic waste in packaging, General Fibre has seen a strong demand for the Envirotray.

“A lot of our current clients have moved toward our solution as it is recyclable and biodegradable—and FSC material options are available,” explains Tarantino. What’s more, the Envirotray is manufactured in General Fibre’s manufacturing facility in New Hyde Park, NY. General Fibre carries a large array of colors to choose from for the Envirotray, and Tarantino says the solution is “in line from a cost standpoint as well.”

Working Toward 'A New End of Life'

Many suppliers and brands are also engaging in conversations about how packaging can “move toward a circular economy.”Eastman Specialty Plastics’ Cary, says, “Over the past few years, sustainability has become an essential component of packaging design in the beauty industry.” She says the trick is to achieve this without creating undesirable compromises in aesthetics or performance. “We work across the value chain with clients early in the design phase of their projects to help bring new options to the table. Increasingly, we are asked to provide solutions that enable a circular economy for beauty packaging. So, if a brand needs a solution for the beginning of life of a package or the end of life, or both, we find ways to balance the properties to accomplish this.” She adds that taking a holistic look at the way a product is intended to be used from cradle to grave helps Eastman to create solutions that “delight consumers and satisfy their needs for responsible packaging.”

As an example, Cary cites Medicos Beauty, which recently unveiled new additions to their Minelia range of packaging featuring Eastman Cristal One Renew. Powered by Eastman’s molecular recycling technology, this new resin enables the Minelia packaging to meet three key sustainability criteria: certified recycled content (the recycled content is achieved by allocating the recycled waste plastic to Eastman Renew resins using a mass balance process certified by ISCC), recyclability in the PET stream, and reusability.

“It provides the same transparency and thick-wall processing capabilities as Eastman’s traditional co-polyesters,” says Cary, “while also maintaining the resin identification code 1(RIC1) designation for recyclability, and the durability needed for refillable and reusable packaging.”

Packaging additives are also increasingly coming into play as solutions for packaging waste.

CO II Packaging now produces folding cartons and printed materials with Biolithe. “This creates consumer confidence in your brand’s environmental responsibility,” says Joe Cicci, president emeritus, CO II Packaging, “as Biolithe is a patented clear coating, versatile additive that reduces excessive emissions of methane, a critical greenhouse gas from landfilled paper and packaging.”

Biolithe was engineered with all-natural products and is printed in line, says Cicci. “Now our customers can truly fight global warming while building an ‘earth friendly’ brand with our Biolithe additive. Biolithe, also in conjunction with direct metal transfer lamination, can make an environmentally friendly foil package having no film carrier and reduced greenhouse methane gas. The printed seal on your carton ‘Treated with Biolithe’ validates its end of life performance.”

The Korean cosmetics company “Siita” says it transformed itself into the world’s first zero-waste company. Siita has designed all of its products with biodegradable technology and says it has “succeeded in completely decomposing and composting the products using its own system.” The company completely stopped producing plastic products this year.

In the future, finished and empty products from Siita will be converted to compost at Siita’s facilities to be provided to the local farmers and communities. This will completely decompose the product to eliminate the generation of any waste—which the brand says is evaluated as “a valuable achievement in the modern society where the environmental issues are escalating worldwide.”

In-Dispense-able

Airopack, known for its VOC free air-operated dispenser, is launching what it says is the world’s first air-pressurized dispenser made of recycled PET. While Airopack’s rPET has initially been launched with North Face for a laundry spray, Sherri Ruffini, Airopack’s senior strategic director of sales, says Airopack packaging can be used for a variety of formulas.Formulas include, but are not limited to, facial refreshing spray, tanning spray, spray foundation, skin care, facial cleansers, body lotions, shampoo, conditioner, hair gels/waxes/pomades etc. “Airopack’s unique innovation is offered in spray, cream/high viscous, paste, and foaming pump/valve options,” explains Ruffini.

“The global need for reducing the CO2 footprint is accelerating and an increasing number of brand owners are seeking alternative dispensing solutions. Our new rPET Airopack is our next step towards a full recyclable dispenser. More sustainable without compromising in performance and quality,” says Roland Jonkhoff, Airopack’s CEO.

The rPET Airopack offers the same features and benefits as the standard Airopack: It uses pure air instead of (chemical) propellants, is fully transparent, can be used for a wide variety of applications and delivers a consistent dispense flow from start to finish with a 98% evacuation rate. And with its container made of 100% post-consumer recycled PET, the rPET Airopack offers brand owners a further solution toward more sustainable packaging.

Deco Delight

Fabulous decoration will always be a lure in the prestige beauty market.RéVive’s first-ever ArtJar, created for its “powerful, perfecting” Moisturizing Renewal Cream Nightly Retexturizer, is a limited-edition collector’s item created in partnership with world-renowned Brooklyn, NY artist Mike Perry, and reflects his artistic interpretation of RéVive.

According to Dr. Gregory Brown, founder of RéVive, “The visual arts have always been a passion of mine; in fact, I view plastic surgery and even RéVive as art forms and both are highly creative. I am so excited to have a new twist on our annual ArtBox this year with the introduction of ArtJar designed by Mike Perry. “ He says, “Mike has done an excellent job of capturing the happiness and efficacy of RéVive with his use of multiple organic spheres and concentric patterns of renewal, the true essence of RéVive.”

Producing the packaging was not a simple process. The jar is glass, and the secondary is a rigid set box made out of grey board wrapped with white paper stock. The jar was printed using sublimation print technique. Sublimation print was selected because of its ability to print edge to edge (full coverage print on the jar), as well as for its color vibrancy. The end print used for the jar was selected based on testing various parts of the Mike Perry artwork and seeing which combinations of colors from the artwork resonated most with the brand, and created a cohesive look between the jar and the secondary box.

Looking Ahead

What does the future hold? Here are some thoughts from some of the suppliers and brands interviewed for this article.Joe Cicci of CO II Packaging anticipates the most innovation will be in eliminating certain forms of plastic. He says, “Cosmetics packaging always used shiny foil substrates creating attractive eye-catching appeal and seductive impulse buying. Today the trend is to eliminate film, windows, vac forms or any other forms of plastic.

The challenge is to keep the graphic appeal and eye-catching qualities, but make the package environmentally friendly so the brands can achieve their validity of responsible packaging.” He adds: “As sustainable materials develop, suppliers have to be creative incorporating them into the packaging both primary and secondary. Package graphics still need to seduce the potential buyer when they see it on the shelf.”

At Eastman Specialty Plastics, Tara Cary, acknowledges: “Sustainability is becoming more of an imperative in the beauty industry. Our research tells us that consumers see the most sustainable packaging as containing recycled content and being easily recyclable. We are also seeing a push for refillable and reusable options. I would expect to see considerable innovation around designing for recyclability over the next few years.”

Neenah’s Gary Bernstein, predicts two major areas of change—“first, making the brand experience consistent throughout whatever path the customer takes. Carefully considering things like how a package is boxed for shipping, as well as every touchpoint of the retail experience.

Second—it’s all about plastic replacement and/or reduction. What alternatives are there to plastic trays and product protection? Will consumers consider refillable containers? What alternative substrates are there for sampling?”

Michael Rutchik, creative director of the OLIKA brand, says, “Innovation moving forward means finding the best way to make the refill into the product so that durable dispensers can easily be reused over and over. (See more from Rutchik here.)

Kemas’s Eaves foresees the most innovation in the future of cosmetics packaging in recyclability, new resin materials and “materials that have much less impact on a brand’s carbon footprint.”

Questions and Challenges Remain

While great progress has been made in innovative and sustainable packaging—from mass market to prestige—bottles and tubes, to refillables—much depends on consumer habits and perception. Will eco-conscious beauty customers recognize these efforts?

Will they be willing to pay the premium for products made from recycled materials‚ or opt for innovative refillables that can be used again and again? The results are anyone’s guess—but there’s certainty that the industry continues to move in this direction. Stay tuned!

Beauty Packaging asked Michael Rutchik, creative director of OLIKA, about his views on innovative and sustainable packaging designs.

Jamie Matusow: What characteristics most define “innovative packaging” in today’s beauty world?

Michael Rutchik: Innovation moving forward means finding the best way to make the refill into the product so that durable dispensers can easily be reused over and over.

Perhaps one of the best ways to innovate is to no longer sell products in durable packaging, rather we shift to sell the durable dispensers empty and the customer will not throw them away. Instead, consumers will refill the dispensers with the product. We’ve seen brands doing this in the cleaning products space and we can see it taking off in beauty.

Developing a frictionless way for the consumer to participate in the closed loop of packaging materials is necessary. A brand must make it as easy as possible to return the package over throwing it away.

JM: What are beauty brands looking for when they request an innovative package?

MR: Brands want a true collaboration between themselves and the consumer to keep all waste out of the system. One doesn’t work without the other.

An added bonus of a return packaging program is that it provides an opportunity to connect with retail customers and even offer a credit program for returned packaging.

JM: You’ve created packaging for multiple beauty brands—where do you get your inspiration—and how do you begin the process?

MR: To begin, I let the client tell me what they want the consumer to experience, and then try to create that experience through both the package and the product design. This includes not only exploring designs but also materials.

There is increased awareness that recycling is not very effective, even when consumers carefully separate out their empty packages. Accordingly, part of the consumer experience must be to participate in a more sustainable way forward. However, this doesn’t have to mean requiring them to perform additional work.

See more from Rutchik here.