Sustainability is not new for L’Oréal. The world’s largest cosmetic company has been on a sustainable packaging path since 2007, and has achieved many lofty goals to-date.

From partnering on the first groundbreaking paper-and-plastic tubes for cosmetics, to recycling plastics, to creating a refillable perfume system, packaging innovation continues to be a high priority.

Here, Brice André, Global VP Sustainable Packaging and Development for L’Oréal Group, provides Beauty Packaging’s Jamie Matusow with an update, a look at future targets—and the reasons why he believes in ‘the multiplier effect.’

Click through the slider above for photos.

Jamie Matusow: What general cosmetic packaging trends are you observing?

Brice André: In the beauty market, packaging is a direct reflection of major industry trends. Today, designs are infused with tech innovations like QR codes providing insights into a product’s ingredients, their origin or recommended usage.They are increasingly customized to meet consumers’ individual desires, and they have become more eco-conscious. A growing number of beauty products are made from recycled or recyclable materials, and I see a large offering of refillable designs. You even encounter formats like shampoo bars, where packaging has been practically eliminated.

JM: What are some of L’Oréal’s innovative or inspirational sustainable accomplishments to date?

BA: Sustainable packaging design is not new for L’Oréal: It has been a priority for the last 15 years. We have had an eco-design approach to packaging development since 2007.Five years ago, our packaging, research and sustainability teams deployed a sustainable product optimization tool measuring the environmental and social impact of our products. Our goal was to ensure that new product launches have a better footprint than the prior generation.

Fourteen sustainability criteria were included and applied to the whole of the product life cycle, from raw material extraction, to packaging and formula production, to how consumers use it and, finally, what happens after use.

This holistic approach spanning the entire value chain allowed us to improve the environmental profile of 96% of our products.

Today, we are proud that 21% of all the plastic used worldwide by L’Oréal is from recycled sources, or that 100% of the cardboard used in our products is FSC or PEPFC certified. Delivering these improvements reinforced our conviction that we can go further, that it is possible to significantly lower our impact, with the ambition to accelerate towards a circular economy operating within planetary boundaries.

In addition to collective group level commitment, we rely strongly on the power of innovation to deliver our vision for more sustainable packaging designs. In 2020, we launched the first generation of tubes made from a combination of paper and plastic.

This breakthrough allowed us to reduce the amount of plastic used by our Garnier and La Roche-Posay brands by 49% and 45% respectively. In 2021, Vichy and Biotherm also adopted this format.

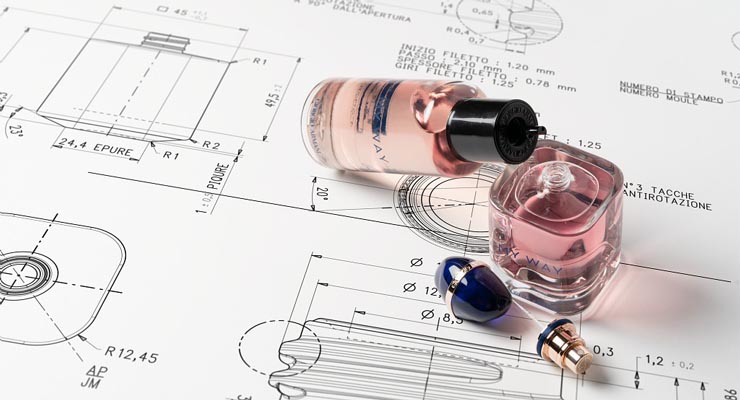

In a similar effort to reduce the quantity of material in our packaging, we created a refillable perfume system for Armani-My Way. (It is shown in the slider above, cick through the photos.)

It consists of a 50ml bottle and a 150ml refill. The combination of the two allowed a 55% reduction in glass use, a 64% reduction in plastic use, a 75% reduction in metal use, and 32% reduction in cardboard use compared to four 50ml bottles.

The glass of the perfume bottle is recyclable, and so is the refill bottle. Product innovations like these are an invitation for our consumers to experiment with more circular beauty gestures.

JM: Can you discuss future plans for L’Oréal as the leader in the sustainable packaging area?

BA: In 2020, we launched L’Oréal for the Future, a ten-year sustainability roadmap reflecting our ambition to take greater responsibility by further transforming ourselves to ensure that our activities stay within the limits of what the planet can withstand according to environmental science.For us in packaging, this means a new set of bold objectives:

- By 2025, 100% of our plastic packaging will be refillable, reusable, recyclable or compostable.

- By 2030, we will eliminate virgin fossil fuel plastic and will only use plastic coming from recycled or bio-based sources.

- By 2030, we will reduce the packaging intensity of our products by 20% vs. 2019.

To deliver on these goals, we will double down on our “3Rs” strategy:

- We will reduce the quantity of our packagings by redesigning them, resizing them and reusing them.

- We will replace materials with alternatives with a lessened environmental impact.

- We will design even more recyclable packaging and actively contribute to the development of a circular economy.

We want to continue leaning into existing partnerships and our extended ecosystem to deliver accelerated collective transformation at scale.

We try to do this in several ways. Sometimes we form a partnership with the goal of co-developing a specific innovation. This is what we did with Carbios to create the first cosmetic bottle made from recycled plastic thanks to an enzymatic technology.

Similarly with companies like Loop and Purecycle, we are experimenting with advanced recycling methods.

We also believe in the multiplier effect that comes from working with other actors of the beauty industry—it is the reason why we launched the EcoBeautyScore Consortium with 36 partners to develop a common environmental impact scoring system for our products.

L’Oréal also set up a fund dedicated to investing in circular economy solutions with the potential to scale up. Fifty million Euros will be allocated by L’Oréal to this Circularity Investment Fund by 2025.

JM: What are some ‘best packaging strategies’ for beauty brands and suppliers—and consumers (acceptance of new habits, etc)?

BA: We want to empower our consumers to make eco-conscious choices, from product formulation to packaging design. A perfect example of this is the shampoo line developed by our Garnier brand. It comes in solid form, and is wrapped in certified cardboard.Responsible packaging design is also an opportunity to radically rethink the user experience, at home or when shopping. With Life Plankton Elixir Blue Fountain, Biotherm innovated a fountain allowing our consumers to refill their serum bottle in store. The fountain opens up promising avenues for innovation.

It should contribute to a broader adoption of responsible packaging designs and ways of consuming.

More About Brice André

Brice André is the Global Vice President of Sustainable Packaging and Development for L’Oréal Group.

Brice André joined L’Oréal in 1999, and has held various positions within the Group’s Operations, including packaging-formula compatibility qualification, product development, manufacturing supply chain, product innovation.

He led the implementation of the Group’s sustainability program ‘L’Oréal for the Future.’ Since March 2021, he is in charge of the Sustainability Packaging & Development team at Group level.

Read More

L'Oreal 3D Bioprints Skin Tissue

L'Oreal Tests Shampoo Bottle Made from Carbon Emissions