Joanna Cosgrove, Contributing Editor08.26.22

Caps and closures are functional indicators of a brand’s aesthetics and often represent an important first touchpoint for consumers as they experience a fragrance, beauty or personal care formulation.

They can also be visual indicators of tamper evidence while having the capacity to dose formulas with accuracy. At a time when visual appeal, cleanliness and product security has never been more critical, cap and closure providers are heeding the call, creating fresh options with inspired designs and functional advancements.

Packaging differentiation is an important and often subtle driver that goes hand in hand with the excitement surrounding advances in beauty and personal care formulas, says Simon Silvano, project coordinator, Eurovetrocap, who’s noticed several cap and closure trends in recent years.

“While the premium/luxury segment remains attached to heavy, metallized or over-shelled closures, mass and ‘masstige’ segments are…requiring compact, recyclable and technical closures (i.e., pumps), progressively leaving aside the traditional codes of aesthetics for closures,” he says. “As far as aesthetics are concerned, there is an increasing demand for flush closures so that the packaging looks very neat and linear, [and] Covid definitely boosted the demand for dispensing caps and high dosage pumps.”

“Closure integrity is a critical aspect to all packages,” agrees Mark Bellard, president of Siloa, a supplier of caps, closures and dispensing systems for skincare and luxury fragrances. “The consumer expects it to look good, feel good and function perfectly but first and foremost it has to be product compatible and seal sufficiently well to protect the specific contents through filling, distribution, sale, travel and use.

“The cap is often a key element of the design and might help secure that first purchase,” he continues. “It’s function and aesthetic throughout the product life as part of the overall product experience, will be a factor in the re-buy decision.”

Bellard says the visual impact of caps in the beauty and personal care markets might mean a cap is the statement-making component on a stand-alone product or as part of a line in which it adds to or coordinates with the brand image. “The functional aspects are just as important today as they always were, but caps (and packages in general) are subjected to greater demands of today’s distribution system than a retail environment alone would demand,” he says.

From Design to Reality

There are many developmental phases when it comes to interpreting a brand’s closure wishes to create a solution that both elevates a package’s aesthetic and seamlessly integrates its functionality.Siloa’s Bellard says that at the heart of meeting a brand’s closure needs is detailed communication that addresses a brand’s must-haves and most desirable closure attributes, as well as the product’s intended positioning as high-end, mid-market or mass. “In that first discussion a customer will usually tell us what they want to achieve and what aspects are the most important to them,” he says. “This starting point will determine next steps--do they have a design turn-over, a concept or just the beginnings of an idea?”

In hashing out the details that follow, plenty of questions follow. “Some customers have a very clear idea of their design requirements and others are at the very beginning of the process,” he says, adding that if there’s a line of products to consider, how they all coordinate has to be a primary concern. “Siloa’s intention is to help guide the customers through this process regardless of their starting point--ultimately our job is to translate ideas and feelings into a technically engineered product that addresses their creative vision.”

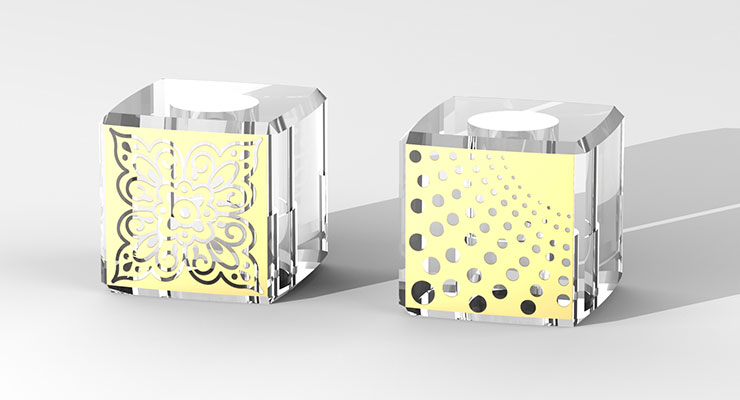

Effective caps and closures combine three critical characteristics, according to David Chen, managing director of ZheJiang B.I. Industrial Co., Ltd.: security, function and beauty. “A good closure or cap design will not only upgrade one brand but also promote their sales,” he says. “To reach this point, we are always thinking how to adopt more innovation into existing materials and industrial process.”

He points to fragrance closures, for instance. “Normally we use Surlyn materials to produce [them], but ZheJiang B.I. Industrial has developed a new technology: we add some metallic powder into [the] Surlyn, then the lid glitters like a star instead of being plain [and] transparent like [other] lids in the market,” he says, noting that the company also stamps the Surlyn for added visual interest.

Chen has observed that in the fragrance segment, there’s been a movement on the part of brands to combine several different materials to create new closure designs. The top combinations, he says, are currently Surlyn and Zamac, Surlyn and wood/bamboo, and plastic and leather. “On the other hand, for skin care lines, customers are looking for more recycled materials like PCR materials,” he comments.

ZheJiang B.I. Industrial has developed a specialty finish for its ABS caps that’s evocative of snowflakes, a product of its design and development center. Chen explains that 20% of ZheJiang B.I.’s new cap and closure developments are for skincare brands and 80% are for fragrance brands such as New Avon, Revlon and Zara. “Around 65% of our cap/closure projects are custom caps, the balance 35% are from our standard projects we call public mold, which means all [clients can use them],” he says.

Spotlight on New Closures

Despite a less than stellar economy and global supply chain issues, cap and closure suppliers have been hard at work creating wow-worthy new options spanning standards with improved eco-friendliness as well as custom projects that creatively encapsulate a brand’s ethos.TNT Global Manufacturing, a producer of high-quality metal and fully recyclable Zamak caps for perfume bottles, caters to cosmetics and makeup brands including Jimmy Choo and Sisley, recently working with Puig to co-develop three incredible new caps for the Christian Louboutin’s three-scent, Loubiworld fragrance collection. In an homage to the Middle East, TNT crafted a scarab beetle and a royal falcon, which are made of two Zamak pieces, as well as a Zamak snake.

The brand’s iconic red was syringe-applied with epoxy to embellish the e-coated orange-gold finish of the caps and each cap is finished with a shared red dyed PP insert. These caps required a complex unmolding process, precise assembly and polishing operations.

Another complex project TNT Global Manufacturing realized was the cap for The World According to Arthur, a recent addition to Penhaligon’s Family Portrait fragrance collection.

The scent and its cap pay homage to the eponymous king and warrior who was known to breath fire when enraged. The cap is made of five gold electroplated Zamak pieces produced under a precision-controlled production process spanning die-casting, unmolding and assembly. The mouth of the fire-breathing icon on the cap was a difficult and delicate technical challenge which required the addition of two Zamak parts, a detailed assembly process and manual polishing before the gold electroplating process.

On the business side, TNT Global Manufacturing expanded its production capabilities to Southern Europe to help meet the proximity and supply chain demands of brands in Asia and Europe with greater agility, responsiveness and production capacity. The company has also integrated a galvanizing and e-coating unit in Asia, that enables better quality control and efficacy. “To our knowledge we are the sole Zamak player fully vertically integrated, both in Europe and Asia,” comments Boris Schaefer, the company’s vice president of sales.

On the heels of manufacturing more than 110 million dropper units in 2021, Virospack has debuted a number of new developments and new materials which illustrate the company’s commitment to the environment as well as the commitments of its brand partners.

The company produced two dropper packages for Horace, a men’s natural grooming and personal care brand. The first, an Anti-Hair Loss Serum, features a white bulb and PP injection cap that provides precision application of the serum directly to the scalp and a precision dose of product via the glass pipette. The dropper’s “up-market” plastic collar offers a premium finish that does not require extra decoration. Its cap has an injected plastic shell and a glue-free inner cap assembled by friction fit, which makes it more sustainable.

The second dropper package, for Horace’s new Serum Salicylic 2% & Niacinamide 3% product, emphasizes easy precision dosage in a package that exudes a distinctly male vibe thanks to its premium finish in an elegant custom shade of deep blue.

“The cap with a plastic shell has a great surface that has been injected in a custom dark blue of the brand,” comments Mansilla. “It’s a more sustainable collar that offers a gloss finish by friction adjustment without needing any lacquering, or glue, removing an extra process, thus reducing CO2 emissions.”

Coverpla creates closures in Surlyn, Zamac and metal, as well as ecologically sourced wood with easier-to-recycle cork inner liners. One of its newest creations is a Surlyn marble-like cap made for fragrance brand Skylar. Coverpla’s Gilda Mirra Cutri, vice president of operations and business development, says the use of an uncommonly beautiful cap like this can go a long way toward creating a bespoke brand differentiation, whether the primary package is custom or customized stock.

“Our customer requested a clean, natural cap and the marble effect came into play because the brand wanted something organic that differed slightly from cap to cap,” says Mirra Cutri. “No two caps resemble each other because we mix the inks and like in nature, some may have pronounced marbling, some might not have any at all.”

She adds that natural-look marbling can be made in almost any color combination, and if a brand prefers more unified marbling Coverpla can deliver through the use of silk screening. And while Skylar’s marble cap was not weighted to convey a marble-like heft, Coverpla does offer weighted cap options, both in stock and in heavy Zamak, depending on the brand’s budget needs.

In July, Eurovetrocap, which caters to the skin and body care segments, launched a new version of its Tim lid, a flush style closure that pairs beautifully with the company’s best-selling Laurence 50 glass jar and was designed for recycling and environmental impact reduction. “The lid is a single PP piece and can be produced from virgin or recycled materials. It is endowed with a PP gasket as well, that guarantees the sealing of the set, but also perfect recyclability down the PP waste stream.

The Tim lid is available in shiny and mat finishes and boasts a very light weight (-30% compared to the company’s Laurence lid). “By the end of the year, we will also offer our Lip 24/410 dispensing cap in a new version,” Eurovetrocap’s Silvano adds. “The cap is usually produced in PP, making it a perfect match for PET bottles, [and] we are now working on an HDPE version of it, to be coupled with HDPE bottles, thus creating a full mono-material set, perfectly compatible with recycling channels for HDPE.”

TNT Global Manufacturing cements its commitment to a responsible circular economy

TNT Global Manufacturing cemented its commitment to a responsible and circular economy by establishing a self-funded Zamak recycling chain aimed at bringing together industrial players and major cosmetic brands and distributors.“Zamak caps are now collected at sales points of a famous French distributor [then] they are then separately sorted by Cèdre Group in France, then resold to Reazn Group, a European smelter that recycles Zamak,” Schaefer explains.

The company has also reconsidered its industrial process to minimize the consumption of raw material during the production. It also actively supports the growing demand for refillable products, producing metal caps and applicators with enhanced durability. “Rechargeability is one of the new standards of perfumes, makeup and cosmetics,” Schaefer says. “It means that packaging material and mechanism must be designed for a longer life, in parallel with the selection of sustainable material.”