Joanna Cosgrove, Contributing Editor02.01.23

Molded pulp, paper and ocean-bound plastic packaging materials are taking the phrase “reduce, reuse, recycle” to new heights thanks to their collective focus on making the most of waste and maximizing renewable resources.

According to Ocean Conservancy, a science-based conservation organization, 11 million metric tons of plastic finds its way into the world’s oceans each year—and that’s on top of the estimated 200 million metric tons that currently circulate in marine environments. Collecting and processing the plastic that pollutes our oceans is an arduous undertaking, but the end result is directly contributing to innovation in plastic recycling and manufacturing.

Some brands across the CPG spectrum are swapping out traditional plastic primary and secondary packaging for suppliers’ paper and pulp alternatives. One example is Envirotray, a sustainable paper replacement for plastic vacuum-formed trays that’s produced by General Fibre. According to Jonathan Tarantino, General Fibre’s vice president of sales, innovations like Envirotray have been widely accepted by the beauty and cosmetic industry, and have helped remove more than 200 tons of plastic from the waste stream.

Continued growth in this sector is on the way. For instance, according to a Markets and Markets report on Molded Pulp Packaging Market by Source Type, the molded pulp packaging market size is projected to grow from $3.5 billion in 2019 to reach $4.4 billion by 2024 (+4.4% CAGR) driven in large part by the use of molded packaging in the food sector.

Roberts Beauty has invested in all material types of Oceanworks resin, and says it conducts rigorous performance testing to ensure uncompromised quality. Corso says the onus is on packaging suppliers like Roberts Beauty to learn, understand and account for the challenges in using ocean-based materials. “Cost can certainly be a factor, but our job as packaging experts is to understand the performance and batch variance complexities when compared to virgin plastic,” she says. “We’ve dedicated our engineering and innovation teams to be able to design with this in mind while making modifications where needed in traditional molding processes to achieve maximum success.”

Earlier this year, Roberts Beauty helped Quo Beauty match its vegan and cruelty-free philosophy with Oceanworks resin packaging solutions, producing a palette (100% Oceanworks), brik stiks (45%), bottles and lipstick package for the brand’s Big Planet, Big Love collection of color cosmetics, hair, makeup accessories, nail color and jewelry products.

WWP Beauty is in the process of launching new ocean plastic components after having developed the first-to-market Ocean Plastic 70% tube made from resin from its partners at Oceanworks. The tube bears the Oceanworks Guarantee, indicating that the resin was ethically sourced with a transparent supply chain (chain of custody can be tracked from collection to manufacturing) while also meeting strict quality, pricing and lead time requirements.

Michael Tognetti, WWP Beauty’s senior director, global sustainability and sourcing, explains that the Ocean Plastic tube is a mono-material PCR PE with flip-top closure and luxurious soft-touch matte finish, making it the ideal tube for eco-conscious skincare, personal care and color cosmetic products.

“[The] Ocean Plastic Tube features an eco-smart design, where the tube closure is integrated into the sleeve,” says Tognetti. “It uses 12% less plastic and 77% less CO2e emissions per piece than a standard tube. Being a mono-material tube construction, it also simplifies the recycling process and contributes to a more circular economy.”

International Cosmetic Suppliers Ltd. (ICS) launched its sustainably sourced HDPE Ocean Plastic tubes in the 4th quarter of 2021 and Tara Stein, vice president of sales and business development, reports demand has continued to grow throughout 2022. “ICS Ocean Plastic tubes are unique as the recycled HDPE is produced from post-use plastic pulled from the maritime industry, such as fishing nets, ropes and trawls,” she explains. “REACH and Proposition 65 compliant, the tubes are available in 13mm diameter to 50mm diameter.”

For best results, ICS recommends Ocean Plastic multi-layer tubes with up to 50% Ocean Plastic HDPE in the outer layer and virgin PE inner layer. And just like virgin plastic tubes, ICS Ocean Plastic Tubes can have a variety of printing and finish options, such as offset print, silkscreen and hot stamp and glossy, matte and soft touch finishes.

ICS recently partnered with Biossance to develop tubes for their consciously created Squalane + Enzyme Sugar Body Scrubs in 200- and 60ml sizes. “The planet-friendly packaging includes ICS HDPE Ocean Plastic in the outer layer of the tube, decorated with both silkscreen and hot stamp printing,” Stein says. “The formulation is microbead-free with dissolving natural sugar exfoliators that help to eliminate environmental accumulation.” For an added sustainable element, the injection pearlized cap is made with PP PCR.

SeaCliff Beauty doubled down on its commitment to transition the beauty industry standard towards using sustainable materials, greener formulation processes and responsible packaging solutions by forging an exclusive partnership with #tide Ocean Material® and introducing 100% Ocean-Bound Plastic packaging to the beauty industry. “#tide Ocean Material is an award-winning resource made from 100% ocean-bound plastic and compounded with renewable energy,” explains Amanda Deak, senior marketing manager, SeaCliff Beauty. “Ocean-bound plastic is collected, sorted, shredded into flakes, and washed.

“It’s processed regionally to reduce CO2-emissions and transportation, allowing the material to live a second life as packaging [and] every batch of #tide Ocean Material has a unique QR code material passport, making its journey fully traceable from the end-product back to its collection point.”

Final PET, PP, HDPE and LDPE outputs are fully customizable and can be used for skincare, cosmetic and hair care product packaging, and can be fully recycled depending on the plastic type.

Deak says one of #tide’s assets is the full control it has over its supply chain, from the sourcing up until the moment SeaCliff Beauty takes over the material. “Being in control allows us to have unmatched traceability on our materials, which is of utmost importance, as transparency is the best way to counter skepticism and allegations of greenwashing while also providing the most straightforward path to building trust with our customers and their end-users,” she says.

“It’s a readily and locally available abundant material that is sustainable, scalable, and low-cost,” she says. “In addition, fiber or paper is one of the most recycled materials in the world and, if misplaced, fiber biodegrades.”

PulPac is working to establish Dry Molded Fiber as the next global standard for sustainable packaging. “We are replacing single-use plastics with circular fiber solutions [and] by 2025 we aim to have replaced one million tons of plastic,” Dynehall says, explaining that the company is not a converter, rather, it builds partnerships throughout the value chain and shares its technology, know-how and IP with packaging converters globally.

One way it does that is by offering The PulPac Highway Application Program, a range of standardized and commercially validated applications ready for production by their licensees. “These products have a climate impact that is only a small fraction compared to single-use plastic cutlery (~15%),” Dynehall says. “Cutlery, trays, and lids are first out but additional Highway Applications will follow.”

The company, in collaboration with Hebert Group, MCC Verstraete and Pages Group, is in the process of commercializing Molded Fiber Labeling for Dry Molded Fiber products—taking a lead in sustainable fiber-based packaging with high-quality decoration. PulPac is also currently working with beauty brands to bring Dry Molded Fiber solutions to the sector.

In December, Knoll Packaging launched patent-pending 100% Knoll Ecoform molded pulp compacts that are magnet-free and fully customizable.

Knoll Ecoform is a plant material made from bamboo, wood and sugar cane fibers that’s certified recyclable in the paper recycling stream and can be molded, cut to order and color matched. The new 100% molded pulp compacts are the product of more than a year of R&D, and feature a smooth, luxury feel and finish. They can be customized with embossing and stamping or added FSC paper mask for additional decoration. According to Knoll, the most groundbreaking element of the design is its magnet-free closure and removable mirror.

“The configurations are limitless, and the material can be color matched to align with a brand’s DNA,” says Benjamin Cohen, the company’s creative and innovation director. “Knoll Ecoform has become one of the most in-demand materials at Knoll, and this latest innovation has the possibility to transform the makeup sector into a more sustainable future.”

While the application opportunities for molded pulp are practically limitless, Cohen says one challenge continues to be decoration. “Brands are looking for the effects of four-color process and recyclable mylar [and] this has driven innovation to mix paper with molded pulp elements,” he says, noting Knoll’s launch of an original design that features FSC paper on the exterior and molded pulp on the interior. “The exterior allows for full customization of papers and decoration, while the interior pulp creates a dramatic and secure display for the product. The double-hinged opening is designed to incite an emotional experience while opening the box to reveal the product inside.”

Daniella Kohler, brand owner manager, Cartonboard USA, Billerud USA LLC, says certifications like FSC and recyclable symbols are very popular in the cosmetics and beauty industry, as is stronger, lighter paperboard, “which is a more sustainable option for brands.”

Billerud sources all of its fiber from responsibly managed, FSC-certified forests in Sweden. Its pulp is currently made in its mills in Sweden, and is transitioning to domestic production in the U.S., having undertaken the process of rebuilding a paper machine in North America for production to begin in 2026. Kohler says the machine will be located in the Upper Peninsula of Michigan and will be rebuilt as a sustainable, modern multi-ply carton board machine.

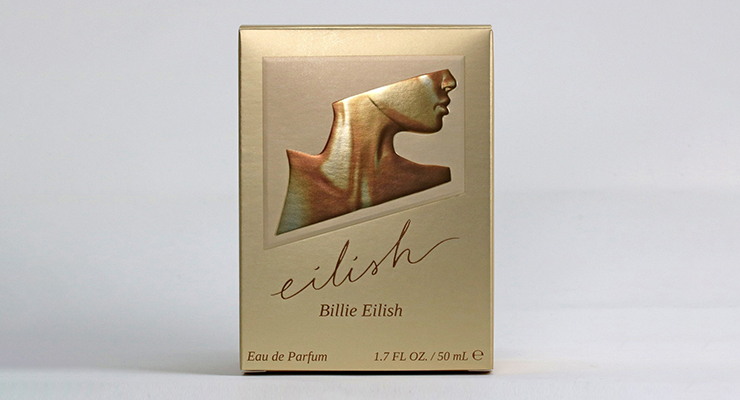

One of Billerud’s most recent beauty collaborations was for Billie Eilish Fragrance. The company produced a secondary paperboard packaging with Environfoil, a sustainable foiling method which is recyclable as paper created at Hazen Paper. The package was printed at Diamond Packaging on Billerud 17.9 CrownBoard Prestige. “The package used deep gold and foiling and superior print quality was achieved,” Kohler says. “It was important for the Billie Eilish brand to use sustainable material and printing methods.”

Albert Paper Products is also committed to upgrading its equipment and facility to accommodate its expanding product line, as well as its commitment to working with customers to achieve their sustainability initiatives in the short and long term.

The company’s Mark Kenah, vice-president, says Albert Paper Products continually works to improve its responsible manufacturing practices, which include recycling and separating scrap, and reducing waste by more efficient sheet layouts married to its raw material inventory.

Its 2023 investment is already underway and entails upgrading its corrugated machinery to keep up with customers’ demands for the manufacturing of RSCs (shippers), cell dividers, pads and e-commerce work. “By June 2023, we look to have an additional 30,000 square feet of manufacturing space… [giving] us close to 90,000 square feet of manufacturing space,” Kenah says.

The company, which has been a certified vendor for Chanel for over 20 years, sources a majority of its raw materials domestically and its Package Development department works closely with each customer to achieve individual sustainability goals while using a variety of FSC certified material. “Our FSC certification confirms to our customers our commitment to adhering to the rules of forestry and being a partner with our competitors in helping the environment with our Chain of Custody certification all while producing an affordable, quality box,” says Kenah.

For Neenah, a key focus has been on mastering the production of a premium, bright white folding board made with 100% post-consumer waste. According to the company’s Gary Bernstein, senior director of sales, packaging and sustainable solutions, NEENAH Folding board, which is used by premium brands around the globe, is engineered for packaging performance, enabling brands to create elegant, sophisticated folding cartons with a distinctive, uncoated look and feel.

One of Neenah’s latest brand collaborations is Grove Collaborative’s “Peach Not Plastic” Shampoo and Conditioner Bars. The brand’s 100% plastic free shampoo and conditioner bars are made with 100% natural fragrance and packaged in colorfully printed 100% post-consumer Neenah Folding Board.

According to Ocean Conservancy, a science-based conservation organization, 11 million metric tons of plastic finds its way into the world’s oceans each year—and that’s on top of the estimated 200 million metric tons that currently circulate in marine environments. Collecting and processing the plastic that pollutes our oceans is an arduous undertaking, but the end result is directly contributing to innovation in plastic recycling and manufacturing.

Some brands across the CPG spectrum are swapping out traditional plastic primary and secondary packaging for suppliers’ paper and pulp alternatives. One example is Envirotray, a sustainable paper replacement for plastic vacuum-formed trays that’s produced by General Fibre. According to Jonathan Tarantino, General Fibre’s vice president of sales, innovations like Envirotray have been widely accepted by the beauty and cosmetic industry, and have helped remove more than 200 tons of plastic from the waste stream.

Continued growth in this sector is on the way. For instance, according to a Markets and Markets report on Molded Pulp Packaging Market by Source Type, the molded pulp packaging market size is projected to grow from $3.5 billion in 2019 to reach $4.4 billion by 2024 (+4.4% CAGR) driven in large part by the use of molded packaging in the food sector.

The Potential of Ocean-Based Plastics

Demand for post-consumer recycled content is on the rise, and plastic packaging providers are increasingly looking to ocean-bound plastic material as a ripe PCR opportunity. “Brands and consumers alike gravitate toward ocean plastic as a way of retrieving mismanaged waste that is actively littering our planet and giving that debris new life,” says Kristen Corso, vice president of marketing, Roberts Beauty, which offers Oceanworks reclaimed, ocean-bound plastic-based packaging solutions. “When we know that a product was on its way to defacing our ocean environments, it appeals to individual conscience by evoking a feeling of contribution, which is a connection you don’t get if the source of your recycled plastic is unknown.”Roberts Beauty has invested in all material types of Oceanworks resin, and says it conducts rigorous performance testing to ensure uncompromised quality. Corso says the onus is on packaging suppliers like Roberts Beauty to learn, understand and account for the challenges in using ocean-based materials. “Cost can certainly be a factor, but our job as packaging experts is to understand the performance and batch variance complexities when compared to virgin plastic,” she says. “We’ve dedicated our engineering and innovation teams to be able to design with this in mind while making modifications where needed in traditional molding processes to achieve maximum success.”

Earlier this year, Roberts Beauty helped Quo Beauty match its vegan and cruelty-free philosophy with Oceanworks resin packaging solutions, producing a palette (100% Oceanworks), brik stiks (45%), bottles and lipstick package for the brand’s Big Planet, Big Love collection of color cosmetics, hair, makeup accessories, nail color and jewelry products.

WWP Beauty is in the process of launching new ocean plastic components after having developed the first-to-market Ocean Plastic 70% tube made from resin from its partners at Oceanworks. The tube bears the Oceanworks Guarantee, indicating that the resin was ethically sourced with a transparent supply chain (chain of custody can be tracked from collection to manufacturing) while also meeting strict quality, pricing and lead time requirements.

Michael Tognetti, WWP Beauty’s senior director, global sustainability and sourcing, explains that the Ocean Plastic tube is a mono-material PCR PE with flip-top closure and luxurious soft-touch matte finish, making it the ideal tube for eco-conscious skincare, personal care and color cosmetic products.

“[The] Ocean Plastic Tube features an eco-smart design, where the tube closure is integrated into the sleeve,” says Tognetti. “It uses 12% less plastic and 77% less CO2e emissions per piece than a standard tube. Being a mono-material tube construction, it also simplifies the recycling process and contributes to a more circular economy.”

International Cosmetic Suppliers Ltd. (ICS) launched its sustainably sourced HDPE Ocean Plastic tubes in the 4th quarter of 2021 and Tara Stein, vice president of sales and business development, reports demand has continued to grow throughout 2022. “ICS Ocean Plastic tubes are unique as the recycled HDPE is produced from post-use plastic pulled from the maritime industry, such as fishing nets, ropes and trawls,” she explains. “REACH and Proposition 65 compliant, the tubes are available in 13mm diameter to 50mm diameter.”

For best results, ICS recommends Ocean Plastic multi-layer tubes with up to 50% Ocean Plastic HDPE in the outer layer and virgin PE inner layer. And just like virgin plastic tubes, ICS Ocean Plastic Tubes can have a variety of printing and finish options, such as offset print, silkscreen and hot stamp and glossy, matte and soft touch finishes.

ICS recently partnered with Biossance to develop tubes for their consciously created Squalane + Enzyme Sugar Body Scrubs in 200- and 60ml sizes. “The planet-friendly packaging includes ICS HDPE Ocean Plastic in the outer layer of the tube, decorated with both silkscreen and hot stamp printing,” Stein says. “The formulation is microbead-free with dissolving natural sugar exfoliators that help to eliminate environmental accumulation.” For an added sustainable element, the injection pearlized cap is made with PP PCR.

SeaCliff Beauty doubled down on its commitment to transition the beauty industry standard towards using sustainable materials, greener formulation processes and responsible packaging solutions by forging an exclusive partnership with #tide Ocean Material® and introducing 100% Ocean-Bound Plastic packaging to the beauty industry. “#tide Ocean Material is an award-winning resource made from 100% ocean-bound plastic and compounded with renewable energy,” explains Amanda Deak, senior marketing manager, SeaCliff Beauty. “Ocean-bound plastic is collected, sorted, shredded into flakes, and washed.

“It’s processed regionally to reduce CO2-emissions and transportation, allowing the material to live a second life as packaging [and] every batch of #tide Ocean Material has a unique QR code material passport, making its journey fully traceable from the end-product back to its collection point.”

Final PET, PP, HDPE and LDPE outputs are fully customizable and can be used for skincare, cosmetic and hair care product packaging, and can be fully recycled depending on the plastic type.

Deak says one of #tide’s assets is the full control it has over its supply chain, from the sourcing up until the moment SeaCliff Beauty takes over the material. “Being in control allows us to have unmatched traceability on our materials, which is of utmost importance, as transparency is the best way to counter skepticism and allegations of greenwashing while also providing the most straightforward path to building trust with our customers and their end-users,” she says.

Multi-Purposed Molded Pulp

When looking at replacing the massive amounts of single-use plastics, fiber has the upper hand, asserts Ann Dynehall, chief communications officer, PulPac.“It’s a readily and locally available abundant material that is sustainable, scalable, and low-cost,” she says. “In addition, fiber or paper is one of the most recycled materials in the world and, if misplaced, fiber biodegrades.”

PulPac is working to establish Dry Molded Fiber as the next global standard for sustainable packaging. “We are replacing single-use plastics with circular fiber solutions [and] by 2025 we aim to have replaced one million tons of plastic,” Dynehall says, explaining that the company is not a converter, rather, it builds partnerships throughout the value chain and shares its technology, know-how and IP with packaging converters globally.

One way it does that is by offering The PulPac Highway Application Program, a range of standardized and commercially validated applications ready for production by their licensees. “These products have a climate impact that is only a small fraction compared to single-use plastic cutlery (~15%),” Dynehall says. “Cutlery, trays, and lids are first out but additional Highway Applications will follow.”

The company, in collaboration with Hebert Group, MCC Verstraete and Pages Group, is in the process of commercializing Molded Fiber Labeling for Dry Molded Fiber products—taking a lead in sustainable fiber-based packaging with high-quality decoration. PulPac is also currently working with beauty brands to bring Dry Molded Fiber solutions to the sector.

In December, Knoll Packaging launched patent-pending 100% Knoll Ecoform molded pulp compacts that are magnet-free and fully customizable.

Knoll Ecoform is a plant material made from bamboo, wood and sugar cane fibers that’s certified recyclable in the paper recycling stream and can be molded, cut to order and color matched. The new 100% molded pulp compacts are the product of more than a year of R&D, and feature a smooth, luxury feel and finish. They can be customized with embossing and stamping or added FSC paper mask for additional decoration. According to Knoll, the most groundbreaking element of the design is its magnet-free closure and removable mirror.

“The configurations are limitless, and the material can be color matched to align with a brand’s DNA,” says Benjamin Cohen, the company’s creative and innovation director. “Knoll Ecoform has become one of the most in-demand materials at Knoll, and this latest innovation has the possibility to transform the makeup sector into a more sustainable future.”

While the application opportunities for molded pulp are practically limitless, Cohen says one challenge continues to be decoration. “Brands are looking for the effects of four-color process and recyclable mylar [and] this has driven innovation to mix paper with molded pulp elements,” he says, noting Knoll’s launch of an original design that features FSC paper on the exterior and molded pulp on the interior. “The exterior allows for full customization of papers and decoration, while the interior pulp creates a dramatic and secure display for the product. The double-hinged opening is designed to incite an emotional experience while opening the box to reveal the product inside.”

Improving the Practicality of Paper

Paper has long been the packaging material of choice for secondary and tertiary cartons. The focus now is on sustainable material sourcing.Daniella Kohler, brand owner manager, Cartonboard USA, Billerud USA LLC, says certifications like FSC and recyclable symbols are very popular in the cosmetics and beauty industry, as is stronger, lighter paperboard, “which is a more sustainable option for brands.”

Billerud sources all of its fiber from responsibly managed, FSC-certified forests in Sweden. Its pulp is currently made in its mills in Sweden, and is transitioning to domestic production in the U.S., having undertaken the process of rebuilding a paper machine in North America for production to begin in 2026. Kohler says the machine will be located in the Upper Peninsula of Michigan and will be rebuilt as a sustainable, modern multi-ply carton board machine.

One of Billerud’s most recent beauty collaborations was for Billie Eilish Fragrance. The company produced a secondary paperboard packaging with Environfoil, a sustainable foiling method which is recyclable as paper created at Hazen Paper. The package was printed at Diamond Packaging on Billerud 17.9 CrownBoard Prestige. “The package used deep gold and foiling and superior print quality was achieved,” Kohler says. “It was important for the Billie Eilish brand to use sustainable material and printing methods.”

Albert Paper Products is also committed to upgrading its equipment and facility to accommodate its expanding product line, as well as its commitment to working with customers to achieve their sustainability initiatives in the short and long term.

The company’s Mark Kenah, vice-president, says Albert Paper Products continually works to improve its responsible manufacturing practices, which include recycling and separating scrap, and reducing waste by more efficient sheet layouts married to its raw material inventory.

Its 2023 investment is already underway and entails upgrading its corrugated machinery to keep up with customers’ demands for the manufacturing of RSCs (shippers), cell dividers, pads and e-commerce work. “By June 2023, we look to have an additional 30,000 square feet of manufacturing space… [giving] us close to 90,000 square feet of manufacturing space,” Kenah says.

The company, which has been a certified vendor for Chanel for over 20 years, sources a majority of its raw materials domestically and its Package Development department works closely with each customer to achieve individual sustainability goals while using a variety of FSC certified material. “Our FSC certification confirms to our customers our commitment to adhering to the rules of forestry and being a partner with our competitors in helping the environment with our Chain of Custody certification all while producing an affordable, quality box,” says Kenah.

For Neenah, a key focus has been on mastering the production of a premium, bright white folding board made with 100% post-consumer waste. According to the company’s Gary Bernstein, senior director of sales, packaging and sustainable solutions, NEENAH Folding board, which is used by premium brands around the globe, is engineered for packaging performance, enabling brands to create elegant, sophisticated folding cartons with a distinctive, uncoated look and feel.

One of Neenah’s latest brand collaborations is Grove Collaborative’s “Peach Not Plastic” Shampoo and Conditioner Bars. The brand’s 100% plastic free shampoo and conditioner bars are made with 100% natural fragrance and packaged in colorfully printed 100% post-consumer Neenah Folding Board.