Joanna Cosgrove, Contributing Editor04.26.23

The shine and gleam of metal and metallized packaging can have a beckoning influence on consumers, attracting their attention and inviting them to pick up and discover a product. Brands that choose metal bottles, jars and tubes do so because they know the material conveys a visual panache and luxurious quality to consumers. It’s a similar effect with packaging that incorporates metal caps, collars and dispensers.

“The visual and the tactile attributes of metal make a real statement for beauty packaging of all kinds,” comments Damien Dossin, president & CEO, Anomatic. “The shiny metal attracts the eye. The smooth, cool-to-the-touch surface is a sensory delight. A beautiful package makes an important first impression and it extends the pleasurable experience of the beauty product to follow.”

One of Anomatic’s most recent metal projects entailed developing an all-aluminum debossed lid for a series of products by REN Clean Skincare. Recyclability was an imperative, as was reimagining a plastic-free jar lid. “The aluminum used to manufacture the lid is infinitely recyclable,” explains Dossin, noting that sustainability has always been a key component of the company’s design and manufacturing process. “Anomatic accelerated the development of this innovative all-aluminum lid that is both aesthetically pleasing (no visible thread) and recyclable.”

The two-piece jar lid features a precise thread on the inner and smooth walled outer and is assembled for a flawless look, thanks to the work of Anomatic’s engineering teams and 3D rendering capabilities which helped to enable an arduous “aluminum to glass” thread engagement. The debossed logo for REN Clean Skincare on the lid was achieved using a custom metal stamping tool design, and anodizing parameters included metal removal and proprietary additives, lining and final assembly of the two-piece all-aluminum jar lid.

The prestige look of metal packaging is also enhanced by its inherent durability.

TNT Group recently crafted a fascinating limited edition fragrance accoutrement for the new Eau de Parfum from By Far that gives new meaning to the concept of mobility when it comes to fragrance packaging.

The package features two sprayed aluminum shells and a logo-embossed zamac collar which adorn the refillable glass fragrance bottle, making it a “traveling accessory.” A weighted PP cap shell insert and POK inserts in the collar and base help ensure product integrity during travel, while a stainless-steel key unlocks the body shell for replacing the bottle or for added personalization. The body shells and caps are available in six colors and the collar comes in two finishes (gold e-coating and shiny white bronze that’s galvanized and varnished).

TNT Promo also created a VIP box and display that showcase the shells, caps and key rings, as well as a Duo box which houses two different colored shells plus two refills. The containers include several compartments and features dedicated to holding each of the accessories, and the box is said to be infinitely reusable.

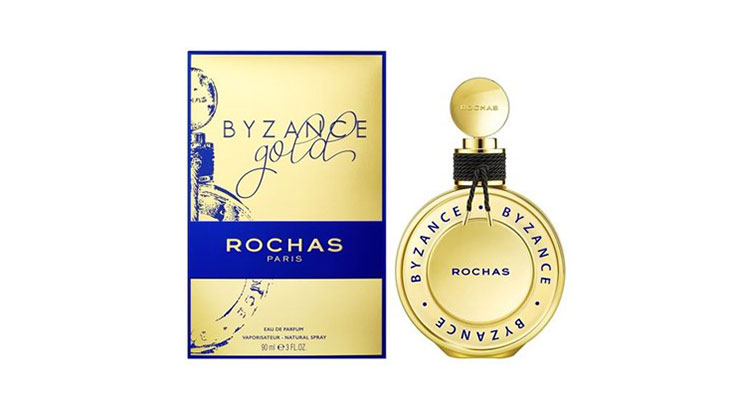

TNT Group also contributed a luxurious cap for Byzance Gold, the latest fragrance from Rochas. The zamac cap is manufactured in a single piece and fitted with a PP insert. For maximum shine, the cap is e-coated in gold and polished for maximum shine. The brand’s logo is embossed on the disc-like panel atop the cap, while the base of the cap is wound with a brass-tipped black ribbon that’s assembled mechanically and glue-free.

The cap rests on a gold metallized bottle crafted by Bormioli Luigi and is evocative of the original Byzance bottle from 1987. The entire presentation is housed in an FSC-certified cardboard box that’s coated in metallic polyester film manufactured by Edelmann.

Consumers equate metal packaging with value and luxury.

Skincare brand Augustinus Bader utilized copper-colored metal accents on the collar and cap of its high-performance skin, body and hair care product packaging and it conveys luxury and clinical quality. The clean look of the packaging also underscores the high caliber science behind the sustainably-sourced, high-potency botanicals and “bio-engineered clean actives” using in its formulations, which were inspired by 30 years of research and innovation prior to the line’s launch in 2018.“The sheer weight and feel distinguish [metal] from other raw materials [and] with a variety of finishes and textures, metal brings a variety of aesthetics to life,” comments Anthony DiMaio, CEO, Cameo Metal Products.

Cameo offers a variety of finishing techniques that can lend a glossy, matte or brushed look to metal, as well as four-color decorating and hot stamping to enhance the brilliance of the metal. For brands on a budget, the company is currently developing a new Eco-Coat one-pass coating process that eliminates multiple semi-automatic processes that increases the cost of using metal in packaging. “This eco-coat process will drive costs down and offer a variety of bright satin finishes for our customers on our complete product line,” notes DiMaio.

Deco Effects

There’s nothing like the sparkle of metal–or is there? Packaging suppliers know consumers love the look of metal and they’ve developed clever decorating processes to deliver a similarly eye-catching look.“Metal and metallic look products can be applied to non-metallic components like plastic or glass bottles and jars, and on caps, pumps, and droppers via decorative processes like plating and over-shelling, [while] aluminum components can be buff-and-lacquered or anodized to yield very high-end looks,” explains Liana Marchese, director of sales, ABA Packaging Corp.

“Aluminum, plastic, and glass components can all be decorated with metal and metallic effects via ink screening, hot stamping with metallic foils, metallization, and of course custom label applications.

ABA Packaging offers metallic effects and metal looks on almost all the primary packaging components that it sells. Marchese says the company’s most popular and innovative metal and metallic decorative effects have been used on its Envases lines of aluminum bottles and cans, and on their stock lines of high-quality glass bottles and jars. Hot-stamping, using many available stock and custom metallic effect foils, can now be successfully applied to the company’s aluminum bottles and cans in-line.

“The look of the hot-stamped printed images along with six-color offset printing and spot varnishing is astounding,” says Marchese. “Hot-stamping glass has always been technically challenging, but we are happy to offer it to our valued customers.

“Screen printing precious metals on glass can also yield attractive metal-like images. Both processes can successfully enhance the look and value of the glass products,” she continues. “Adhesive labels with hot-stamped images can also be an option to provide a luxurious metal or metallic effect on all packaging materials.”

Among Anomatic’s metallic solutions are anodizing (embossing, debossing, etc.), hot foil stamping, iridescent printing and offset flexographic printing, as well as cost-effective vacuum metallization, which deposits a thin layer of metal onto a plastic, metal or glass substrate and is well-suited for complex shapes and higher color changeovers.

“Brands today expect more from their packaging, to stand out in a crowded field, and to deliver an optimal performance,” says Anomatic’s Dossin. “We offer fully tested, fully functional packaging and a wide range of color and decoration options.”

Anomatic’s lacquering and metallization options span pearl spray, gradient effects-metallizing, matte/velvet and digital embossing in addition to regular metallization, which it performs for customers like Olay and OPI.

Sustainable Metallization

An important trend in metallized packaging is not only achieving a metal look but also hitting sustainability targets.Quadpack recently extended its sustainable decoration capabilities with full-cover hot foil stamping, which the company says delivers a high-end look with a lower environmental impact. This deco capability comes on the acquisition of decoration specialist Stefan Wicklein Kunststoffveredelung GmbH, one of only a handful of companies that provide the technique.

According to Quadpack, full cover hot foil stamping “endows packaging solutions with a glossy, premium finish through the seamless application of foil to cover a complete pack, offering a low-emission, solvent-free, more sustainable alternative to metallization” that requires less energy and no solvents.

The PET carrier foil can also be produced using PCR material and Quadpack is developing a process to recycle it.

The Tapematic PST Line system is another example of clean, modern manufacturing, where the key factors are the sustainability, efficiency and quality, according to Tony Denning, president, Tapematic USA.

“Tapematic is the only company in the market that offers a fully automated in-line system that allows countless metallization using sputtering technology and decoration solutions,” he says, adding the PST lines are cost-saving and eco-friendly, granting the highest efficiency by using significantly less varnish than traditional methods, along with the lowest power consumption with no unnecessary waste. “Very minimal floor space is required, full control of the entire process can be managed by a single operator, and the highest efficiency in UV varnish consumption is granted.”

In 2022, Tapematic improved the process of its IDM II decoration module to create different types of unique decoration on all types of packaging, including 360° hot stamping and laser engraving, giving brands more control over the aesthetics of cosmetics packaging. “Users can create countless decoration[s] in-house and apply a protective overcoating immediately on the product to increase the overall performance by preventing possible damage by manual manipulation,” Denning says. “The internalization of some of the production phase is something that interest[s] all categories of cosmetics, but in particular, products that are part of the prestige segment, those that need to have impeccable aesthetic finishes.”

Inca, an Italian producer of aluminum and plastic components, sees a huge advantage in the use of aluminum because of its 100% recyclability rate.

The company’s stamping machines allow it to shape aluminum into simple or complex forms in small or large batches. “We are fully equipped with polishing and brushing machines adapted to work on cylindrical or shaped parts,” says Stefano Parodi, CEO. “Our two anodizing lines allow us great flexibility in production and final finishing.”

The company has contributed packaging and decoration to a variety of luxury product launches, including the Valmont Luminosity skincare product line via customized aluminum caps with an embossed logo. The surface is lacquered in pink through a holographic technique, which creates changing reflections depending on the light. The company also contributed to the decoration of the Carthusia’s Linea A’mmare perfume bottles, and additionally crafted a custom-made aluminum lid for a Parfums Francis Kurkdjian candle. Most recently, Inca debuted an eco-designed, refillable, 100% recyclable aluminum travel spray prototype that is richly decorated with a honeycomb pattern to underscore the company’s expertise in “Shaping Brilliant Ideas.”

During January’s Paris Packaging Week, Eviosys presented its advancements in sustainable luxury sector metal packaging with the debut of three new manufacturing and design techniques. First, the company highlighted hot stamping with holographic effects directly on metal, which creates color reflection effects and 3D illusions on metal packaging.

Second, it spotlighted its design testing capabilities with MyTin, a new interactive catalogue that allows any customer or designer to customize Eviosys metal packaging and visualize the result instantly, expediting the decision-making process and reducing the impact of the time to market. And finally, the company showcased its micro-embossing technology in a new way that makes packaging more inclusive for blind consumers. Micro-embossed Braille indications allow visually impaired consumers to easily identify a scannable QR code that conveys necessary product information such as instructions for use, expiry date, composition, communication with an advisor, and more.

An important trend in metallized packaging is not only achieving a metal look but also hitting sustainability targets.

Unifoil is a leading innovator within the sustainable packaging sector with over 50 years’ experience in providing plastic-free metallized substrates—with exclusive surface trends that “provide maximum on-shelf impact with integrity,” according to David Peters, the company’s global product development director.

Peters says Unifoil offers sustainable product lines that best fit their customers’ needs. “Unilustre is one of our hero products that sits perfectly for the beauty, cosmetic and personal care sector. Our trends-focused customizable substrates provide the perfect bespoke solutions to the sector.”

From beautiful premium silver finishes to dramatic holographic designs, “This trend-led approach is resetting the retail environment,” says Peters. He explains, “Backed with science and innovation, Unilustre is plastic and solvent-free and fully recyclable. From a production standpoint, Unilustre uses less energy and materials to produce, providing companies with assurance that they are addressing their sustainability initiatives and significantly reducing their carbon footprint.”