Joanna Cosgrove, Contributing Editor08.23.23

Full-sized beauty, skincare and fragrance products can be a significant investment. Trial-sized configurations give consumers an important experiential “taste” to ensure color cosmetics and skincare formulations work for their skin type, and fragrances meld with their body chemistry. Unit and multi-dose configurations have also proven to be convenient options for on-the-go consumers who may not want to tote a full-sized product to the gym or along on their travels.

The global market for multi-industry single-dose packaging was valued at $66.2 billion in 2022 and is expected to exceed $112.1 billion by 2031 (+6.8% CAGR), according to a recent report from Transparency Market Research Inc. The leading factors behind this growth include the increasing demand for hygienic products, and will be propelled by a collective penchant for recyclable and sustainable packaging like glass vials, biodegradable and paper-based packaging.

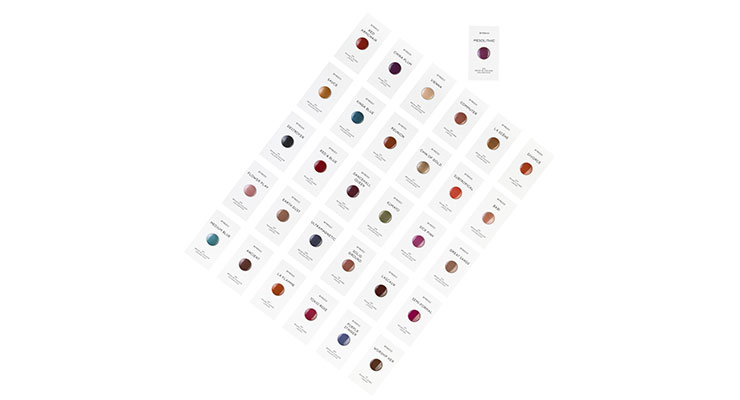

Beauty, skincare and fragrance brands continue to embrace the power of sample packaging to get their products into the hands of consumers. Lady Gaga’s Haus Labs recently launched a direct-to-consumer, at-home Discovery Set of its bestselling Triclone Skin Tech Foundation, which is sold in 51 shades across six color families. Discovery Sets are curated sets for each shade family and include three deluxe samples plus a shade finder tool, so consumers can experience the skincare-infused, medium coverage foundation and find their ideal match while avoiding the hassle of returns.

Discovery Sets are available exclusively on the Haus Labs website, and feature QR codes that link consumers directly to purchase the shade match of their choosing and to learn more. The consumer has 21 days to purchase a full-size foundation or they will be charged $12 plus tax for the Discovery Set at the end of the trial period.

Whether it’s #perfumelovers on Instagram or #perfumetok on TikTok, every social media platform has a collective of fragrance devotees that are helping to drive the buzz around trying new fragrances.

In June, Coty’s Marc Jacobs brand debuted an ultra-convenient, unit-dose take on three iterations of its iconic Daisy fragrance range with the launch of Daisy Drops, a portable tin filled with 30 single use capsules of either original Daisy, Daisy Eau So Fresh or Daisy Love Drops. Each sustainable, white aluminum tin is decorated with a playful ring of signature Daisy icons. The user simply squeezes the capsule to apply the alcohol-free, gel-like fragrance wherever they like. The company says the gels were crafted to ensure longevity.

In July, the Scentbird fragrance subscription company announced a collaboration with UK fragrance brand Jo Malone that makes its fragrances available for the first time on a subscription service company.

According to a representative for Scentbird, six different Jo Malone fragrances will be available in 8ml bottles with atomizers, which dispense about 120 sprays each. A discovery set will also be available and Scentbird subscribers will be able to purchase the full-size bottle if they end up liking their sample.

Samplex also contributed to the scent discovery movement, working with Stradivarious, a clothing company that’s part of Inditex group, owner of retail brands such as Zara, Pull & Bear, Massimo Dutti, Bershka, Oysho and Zara Home, to produce samples for their men’s and women’s fragrance ranges.

Jim McNeil, Samplex CEO and co-founder, says the brand worked with a Samplex distributor in France to customize a Realfrag Card perfume sample for six of its scents. RealFrag features a label that can be lifted, sniffed and resealed repeatedly for multiple uses. The company also opted to include QR codes to give consumers easy access to the brand’s web page to buy the scents.

“The sample was very useful,” McNeil says, “because on each online sale of clothes, the card was used to make a cross sampling campaign presenting the fragrances to the consumers enabling them to try each one of them and make an online order, raising their sales.”

Samplex offers similarly slim and portable formats for color cosmetics. Shadowear and Lipwear each hold five applications of eye shadow or lipstick in a pack that’s as small and thin as a credit card.

Arcade Beauty recently worked with Estée Lauder’s Tom Ford brand to produce a deluxe mini of Tom Ford’s Traceless Soft Matte Primer. The product is housed in a 4ml glass bottle, which Sephora retails for $35.

“The brand utilized our turnkey filling machine to fill multiple products across the same glass bottle,” Jagut says. “By using a label instead of direct printing on the glass, we were able to reduce lead times and decrease costs due to larger volume manufacturing of the blank glass in our New Jersey glass facility.”

Jagut adds that the brand chose an elevated sample to match their premium brand, allowing the customer to not only see the shade through the bottle as well as have multiple applications. Due to Arcade Beauty’s vertical manufacturing process, the glass was produced, filled and labeled in an expedited manner to help with speed to market.

Also worth noting are the strides Arcade Beauty is making in its quest for improved eco-friendliness. Its blister technology is now available with a 76% paper composition, making it a suitable solution for makeup and skincare formulas. “We are also very close to launching our BeautiPod technology using more than 90% of paper,” adds the company’s Larry Berman, senior vice president sales, North America. “We implemented an internal roadmap to extend paper base (and also mono-material) to all our existing technologies. Our eco design objective for 2023 is to reach 100% of products ready for recyclability or recyclable and to over 75% of our products integrating recycled or certified materials—and our plan is on track.”

Carded tubular glass vials have long been an industry standard for fragrance sampling and SGD Pharma has channeled the momentum of increased interest in mini kits and discovery sets into the development of a new range of mini tubular glass vials for fragrance samplers.

The company’s mini sampler glass vials, produced in SGD India, are currently available in three sizes: 1.5-, 2- and 2.6ml. For faster customization of the glass vials, SGD Pharma Beauty & Care offers a library of 19 ceramic silk screen Pantone colors to choose from for online printing.

“Produced in type 1 glass, the vials are highly resistant and have exemplary quality control based on pharma manufacturing protocols,” comments Sheherazade Chamlou, vice president of sales, beauty Americas, SGD Pharma. “Lightweight and small, the sampler vials appeal to consumers looking to easily carry their fragrances with them.”

SGD Pharma recently announced a future collaboration with Corning Incorporated to invest in a new tubing plant, which the company says will further secure its supply chain in tubing for pharma and cosmetic use. This alliance will combine Corning’s state-of-the-art tubing skills with SGD Pharma’s glass-converting expertise to manufacture Type I borosilicate glass tubing in India by Q4 2024.

Virospack, which also specializes in tubular glass as well as cosmetic dropper packs, produces class 1 tube glass that’s strong and light with excellent transparency and compatibility for use with delicate cosmetic formulations such as serums, oils, fragrances and color cosmetics.

“Tubular glass vials are a non-porous material, meaning it does not chemically interact with the cosmetic formulation, preventing incompatibility and the migration of unwanted substances, helping preserve the product’s quality over time,” explains Verena Fiori Ferreira, the company’s marketing director. “The smooth finish of a tubular glass vial makes it ideal for customization. This is a great advantage for new brands in the market, through several decoration processes, as the color spray painting—standard or custom—creates effects such as frosted, opaque, opalescent, degrade, semitransparent, pearly, metallization and hot stamping.”

Neopac is a specialist in travel-sized tube packaging. The company produces tubes ranging from 1-30ml in different material options such as Polyfoil tubes with aluminum barrier and different nozzles and applicators; EcoDesign tubes with materials such as PICEA, sugarcane, recycled PCR tubes; and mono-material Polyfoil MMB tubes with a variety of applicators and closures.

Among the company’s most recent developments related to its sample/unit dose tubes are its “long soft nozzle” tubes and “child resistant tubes” for 1-5ml content. Cornelia Schmid, Neopac’s head of marketing, says the long soft nozzle is ideal for gum, scalp or ear/eye treatment applications, while the child-resistant tubes are perfect for concentrates in skin or hair treatment or even for nutricosmetics combined with a dropper insert.

Neopac is currently working on mono-material structures also for mini tubes. “Given the mesh sizes of the recycling plants, every packaging below 2-5cm size is still hard to sort in the EU or U.S. recycling plants,” Schmid says.

With the environmental pressure on brands, retailers and packaging professionals, JP Packaging LLC is taking what Doug Rofheart, senior sales executive, calls “an easier path forward” in the flexible packaging space. “Flexible packaging requires less energy to manufacture and transport, which reduces greenhouse gas emissions and fossil fuel usage as well as using less water in the manufacturing process and has a much higher product to package ratio,” he says.

Single-use products ensure optimum protection of fragile formulas, reducing reliance on preservatives, says Aude de Livonniere, CEO of Livcer, a producer of thermoformed unit dose packaging for viscous and non-viscous liquids, powders and heat-cast lipstick, foundations and balms. And thermoformed unit dose products are “nomadic” because they’re lightweight, compact and perfectly suited for travel.

In addition to its Livstick “beauty match” product tester for in-store trials, Livcer has been working to develop new ecologically responsible samples made from paper that are suitable for makeup products containing very little water, such as lipstick, blush or eyeshadow.

“Brands are looking to produce intelligently, avoiding product waste, using less cardboard for their sales pitches, while preserving maximum product safety [and] we have invested in production tools to meet this demand,” de Livonniere comments. She goes on to note that the company has also developed a blister pack printed entirely in photo quality, eliminating the need for a card to contain the sample because all of the consumer information can be printed on the blister itself.

JP Packaging produces sachets, towelettes, pads, thermoformed blisters, tubes, jars, bottles and peel and reseal pad pouches in its Chester, NY, facility that’s FDA registered for cosmetics and OTC drugs, and is also USDA Organic Certified. One of the company’s latest developments is its recent acquisition of Toll Pack, a producer of customized flexible packaging solutions, which gives JP additional horsepower to produce die-cut shaped sachets.

With sustainability continuing to be one of the biggest issues influencing the product sampling corridor, the trend seems to be focused on the amount of flexible packaging (or plastic in general) that ends up in the environment as waste, says Evan Arnold, vice president, business development, Glenroy Inc.

“It’s our job as a flexible packaging producer to continue to educate the general public not only on the full environmental benefits of flexible packaging for sampling, unit dose and/or travel-sized beauty, personal care and fragrance products, but also when, where and how they can recycle the empty packets so they don’t end up in the general waste stream,” he says.

Glenroy’s decades of experience with engineering and manufacturing high-barrier flexible packaging structures for cosmetics and personal care products included a recent investment in new printing and plate mounting equipment that “elevates the visual quality of its printed high-barrier film laminations.” Arnold says the company is additionally pushing the boundaries of flexible packaging to find ways to make it more sustainable.

“This includes driving our focus toward mono-material structures that use the same type of material (typically polyethylene) for each layer, so it has the potential to be recyclable,” he says, noting that his team is also working to increase the amount and quality of PCR material that goes into its film laminations. “This offers another avenue for recycled flexible packaging to remain out of the waste stream and drive a truly circular economy.”

In addition to addressing the environmental implications of single-use packaging through packaging innovation and industry involvement, Glenroy also participates in consumer education, investing in research and packaging Life Cycle Assessments to create messaging, sales content, social media content, and other educational tools that can be used to educate brands, consumers and the general public on the overall benefits of flexible packaging. “We’ve found that using flexible packaging leads to water savings, reduced fossil fuel use, and lower greenhouse gas emissions,” Arnold says. “Education on sustainability has to go beyond simply recycling, and these additional elements complete that picture.”

The global market for multi-industry single-dose packaging was valued at $66.2 billion in 2022 and is expected to exceed $112.1 billion by 2031 (+6.8% CAGR), according to a recent report from Transparency Market Research Inc. The leading factors behind this growth include the increasing demand for hygienic products, and will be propelled by a collective penchant for recyclable and sustainable packaging like glass vials, biodegradable and paper-based packaging.

Beauty, skincare and fragrance brands continue to embrace the power of sample packaging to get their products into the hands of consumers. Lady Gaga’s Haus Labs recently launched a direct-to-consumer, at-home Discovery Set of its bestselling Triclone Skin Tech Foundation, which is sold in 51 shades across six color families. Discovery Sets are curated sets for each shade family and include three deluxe samples plus a shade finder tool, so consumers can experience the skincare-infused, medium coverage foundation and find their ideal match while avoiding the hassle of returns.

Discovery Sets are available exclusively on the Haus Labs website, and feature QR codes that link consumers directly to purchase the shade match of their choosing and to learn more. The consumer has 21 days to purchase a full-size foundation or they will be charged $12 plus tax for the Discovery Set at the end of the trial period.

Whether it’s #perfumelovers on Instagram or #perfumetok on TikTok, every social media platform has a collective of fragrance devotees that are helping to drive the buzz around trying new fragrances.

In June, Coty’s Marc Jacobs brand debuted an ultra-convenient, unit-dose take on three iterations of its iconic Daisy fragrance range with the launch of Daisy Drops, a portable tin filled with 30 single use capsules of either original Daisy, Daisy Eau So Fresh or Daisy Love Drops. Each sustainable, white aluminum tin is decorated with a playful ring of signature Daisy icons. The user simply squeezes the capsule to apply the alcohol-free, gel-like fragrance wherever they like. The company says the gels were crafted to ensure longevity.

In July, the Scentbird fragrance subscription company announced a collaboration with UK fragrance brand Jo Malone that makes its fragrances available for the first time on a subscription service company.

According to a representative for Scentbird, six different Jo Malone fragrances will be available in 8ml bottles with atomizers, which dispense about 120 sprays each. A discovery set will also be available and Scentbird subscribers will be able to purchase the full-size bottle if they end up liking their sample.

Samplex also contributed to the scent discovery movement, working with Stradivarious, a clothing company that’s part of Inditex group, owner of retail brands such as Zara, Pull & Bear, Massimo Dutti, Bershka, Oysho and Zara Home, to produce samples for their men’s and women’s fragrance ranges.

Jim McNeil, Samplex CEO and co-founder, says the brand worked with a Samplex distributor in France to customize a Realfrag Card perfume sample for six of its scents. RealFrag features a label that can be lifted, sniffed and resealed repeatedly for multiple uses. The company also opted to include QR codes to give consumers easy access to the brand’s web page to buy the scents.

“The sample was very useful,” McNeil says, “because on each online sale of clothes, the card was used to make a cross sampling campaign presenting the fragrances to the consumers enabling them to try each one of them and make an online order, raising their sales.”

Samplex offers similarly slim and portable formats for color cosmetics. Shadowear and Lipwear each hold five applications of eye shadow or lipstick in a pack that’s as small and thin as a credit card.

Premium Glass Advantages

Arcade Beauty’s Candice Jagut, vice president of marketing, innovation and retail, reports seeing a large demand for fragrance discovery sets, as consumers are willing to pay to try multiple fragrances before committing to a full-size fragrance. She also notes that in addition to single-use samples, there’s a big trend toward the premiumization of sampling, especially in glass.Arcade Beauty recently worked with Estée Lauder’s Tom Ford brand to produce a deluxe mini of Tom Ford’s Traceless Soft Matte Primer. The product is housed in a 4ml glass bottle, which Sephora retails for $35.

“The brand utilized our turnkey filling machine to fill multiple products across the same glass bottle,” Jagut says. “By using a label instead of direct printing on the glass, we were able to reduce lead times and decrease costs due to larger volume manufacturing of the blank glass in our New Jersey glass facility.”

Jagut adds that the brand chose an elevated sample to match their premium brand, allowing the customer to not only see the shade through the bottle as well as have multiple applications. Due to Arcade Beauty’s vertical manufacturing process, the glass was produced, filled and labeled in an expedited manner to help with speed to market.

Also worth noting are the strides Arcade Beauty is making in its quest for improved eco-friendliness. Its blister technology is now available with a 76% paper composition, making it a suitable solution for makeup and skincare formulas. “We are also very close to launching our BeautiPod technology using more than 90% of paper,” adds the company’s Larry Berman, senior vice president sales, North America. “We implemented an internal roadmap to extend paper base (and also mono-material) to all our existing technologies. Our eco design objective for 2023 is to reach 100% of products ready for recyclability or recyclable and to over 75% of our products integrating recycled or certified materials—and our plan is on track.”

Carded tubular glass vials have long been an industry standard for fragrance sampling and SGD Pharma has channeled the momentum of increased interest in mini kits and discovery sets into the development of a new range of mini tubular glass vials for fragrance samplers.

The company’s mini sampler glass vials, produced in SGD India, are currently available in three sizes: 1.5-, 2- and 2.6ml. For faster customization of the glass vials, SGD Pharma Beauty & Care offers a library of 19 ceramic silk screen Pantone colors to choose from for online printing.

“Produced in type 1 glass, the vials are highly resistant and have exemplary quality control based on pharma manufacturing protocols,” comments Sheherazade Chamlou, vice president of sales, beauty Americas, SGD Pharma. “Lightweight and small, the sampler vials appeal to consumers looking to easily carry their fragrances with them.”

SGD Pharma recently announced a future collaboration with Corning Incorporated to invest in a new tubing plant, which the company says will further secure its supply chain in tubing for pharma and cosmetic use. This alliance will combine Corning’s state-of-the-art tubing skills with SGD Pharma’s glass-converting expertise to manufacture Type I borosilicate glass tubing in India by Q4 2024.

Virospack, which also specializes in tubular glass as well as cosmetic dropper packs, produces class 1 tube glass that’s strong and light with excellent transparency and compatibility for use with delicate cosmetic formulations such as serums, oils, fragrances and color cosmetics.

“Tubular glass vials are a non-porous material, meaning it does not chemically interact with the cosmetic formulation, preventing incompatibility and the migration of unwanted substances, helping preserve the product’s quality over time,” explains Verena Fiori Ferreira, the company’s marketing director. “The smooth finish of a tubular glass vial makes it ideal for customization. This is a great advantage for new brands in the market, through several decoration processes, as the color spray painting—standard or custom—creates effects such as frosted, opaque, opalescent, degrade, semitransparent, pearly, metallization and hot stamping.”

Flexible and Eco-Friendly

Flexible tubes and pouches represent a super convenient way for consumers to take a small amount of product with them wherever they go.Neopac is a specialist in travel-sized tube packaging. The company produces tubes ranging from 1-30ml in different material options such as Polyfoil tubes with aluminum barrier and different nozzles and applicators; EcoDesign tubes with materials such as PICEA, sugarcane, recycled PCR tubes; and mono-material Polyfoil MMB tubes with a variety of applicators and closures.

Among the company’s most recent developments related to its sample/unit dose tubes are its “long soft nozzle” tubes and “child resistant tubes” for 1-5ml content. Cornelia Schmid, Neopac’s head of marketing, says the long soft nozzle is ideal for gum, scalp or ear/eye treatment applications, while the child-resistant tubes are perfect for concentrates in skin or hair treatment or even for nutricosmetics combined with a dropper insert.

Neopac is currently working on mono-material structures also for mini tubes. “Given the mesh sizes of the recycling plants, every packaging below 2-5cm size is still hard to sort in the EU or U.S. recycling plants,” Schmid says.

With the environmental pressure on brands, retailers and packaging professionals, JP Packaging LLC is taking what Doug Rofheart, senior sales executive, calls “an easier path forward” in the flexible packaging space. “Flexible packaging requires less energy to manufacture and transport, which reduces greenhouse gas emissions and fossil fuel usage as well as using less water in the manufacturing process and has a much higher product to package ratio,” he says.

Single-use products ensure optimum protection of fragile formulas, reducing reliance on preservatives, says Aude de Livonniere, CEO of Livcer, a producer of thermoformed unit dose packaging for viscous and non-viscous liquids, powders and heat-cast lipstick, foundations and balms. And thermoformed unit dose products are “nomadic” because they’re lightweight, compact and perfectly suited for travel.

In addition to its Livstick “beauty match” product tester for in-store trials, Livcer has been working to develop new ecologically responsible samples made from paper that are suitable for makeup products containing very little water, such as lipstick, blush or eyeshadow.

“Brands are looking to produce intelligently, avoiding product waste, using less cardboard for their sales pitches, while preserving maximum product safety [and] we have invested in production tools to meet this demand,” de Livonniere comments. She goes on to note that the company has also developed a blister pack printed entirely in photo quality, eliminating the need for a card to contain the sample because all of the consumer information can be printed on the blister itself.

JP Packaging produces sachets, towelettes, pads, thermoformed blisters, tubes, jars, bottles and peel and reseal pad pouches in its Chester, NY, facility that’s FDA registered for cosmetics and OTC drugs, and is also USDA Organic Certified. One of the company’s latest developments is its recent acquisition of Toll Pack, a producer of customized flexible packaging solutions, which gives JP additional horsepower to produce die-cut shaped sachets.

With sustainability continuing to be one of the biggest issues influencing the product sampling corridor, the trend seems to be focused on the amount of flexible packaging (or plastic in general) that ends up in the environment as waste, says Evan Arnold, vice president, business development, Glenroy Inc.

“It’s our job as a flexible packaging producer to continue to educate the general public not only on the full environmental benefits of flexible packaging for sampling, unit dose and/or travel-sized beauty, personal care and fragrance products, but also when, where and how they can recycle the empty packets so they don’t end up in the general waste stream,” he says.

Glenroy’s decades of experience with engineering and manufacturing high-barrier flexible packaging structures for cosmetics and personal care products included a recent investment in new printing and plate mounting equipment that “elevates the visual quality of its printed high-barrier film laminations.” Arnold says the company is additionally pushing the boundaries of flexible packaging to find ways to make it more sustainable.

“This includes driving our focus toward mono-material structures that use the same type of material (typically polyethylene) for each layer, so it has the potential to be recyclable,” he says, noting that his team is also working to increase the amount and quality of PCR material that goes into its film laminations. “This offers another avenue for recycled flexible packaging to remain out of the waste stream and drive a truly circular economy.”

In addition to addressing the environmental implications of single-use packaging through packaging innovation and industry involvement, Glenroy also participates in consumer education, investing in research and packaging Life Cycle Assessments to create messaging, sales content, social media content, and other educational tools that can be used to educate brands, consumers and the general public on the overall benefits of flexible packaging. “We’ve found that using flexible packaging leads to water savings, reduced fossil fuel use, and lower greenhouse gas emissions,” Arnold says. “Education on sustainability has to go beyond simply recycling, and these additional elements complete that picture.”