Joanna Cosgrove, Contributing Editor02.01.24

The global beauty industry generates 120 billion units of packaging per year that accounts for 70% of the beauty industry’s waste (Zero Waste Week, Terracycle, courtesy of PA Knowledge Limited). Beauty consumers are not only concerned, but they’re spending accordingly, with three in five customers saying environmentally or socially responsible products made up at least half of their last purchase, and two in five consumers in a lower income bracket saying they had paid a premium for sustainable/socially responsible products (IBM research, 2022, courtesy of PA Knowledge Limited).

Fortunately, sustainable alternatives to virgin plastic abound and the creativity driving the development of packaging made with these alternative materials is at an all-time high. Beyond infinitely recyclable glass and aluminum, materials originating from wood as well as waste from the ocean, sugarcane processing and even the textile industry are “new and now” for brands looking to carve out a unique look with an eco-savvy purpose.

Knoll Packaging has advanced the technical abilities of its Ecoform Molded Pulp into new opportunities for plastic-free makeup compacts with mirrors engineered to be removable to encourage recyclability. The latest iteration utilizes two snap closures to keep the compact closed and offer a seamless appearance. “We see countless opportunities for this approach, particularly with refills and single pan eye shadows, allowing for a sustainable but eye-catching design,” says the company’s Benjamin Cohen, Chief Marketing Officer.

One of the material’s unique design aspects is that it can be shaped to suit most any creation. “We spend a lot of time brainstorming and researching unique shapes that could only be possible in pulp,” he says, noting that the material is sleek, sturdy and can be color matched to suit a brand’s unique aesthetic. “We’ve started to combine pulp and board together into one single coffret, [unlocking] even more decoration and customization opportunities.”

Knoll is currently supplying molded pulp in Europe and Asia, and Cohen says each area has its own supply chain and product mixture to ethically source and produce the components. “This has also allowed for greater implementation as we can now produce a rigid box on our custom machinery in Europe, and have the pulp insert created locally too,” he comments. “We can’t underestimate the intelligence of a customer, but regardless we have to continue doing the right thing and keep eliminating plastics from the supply chains.”

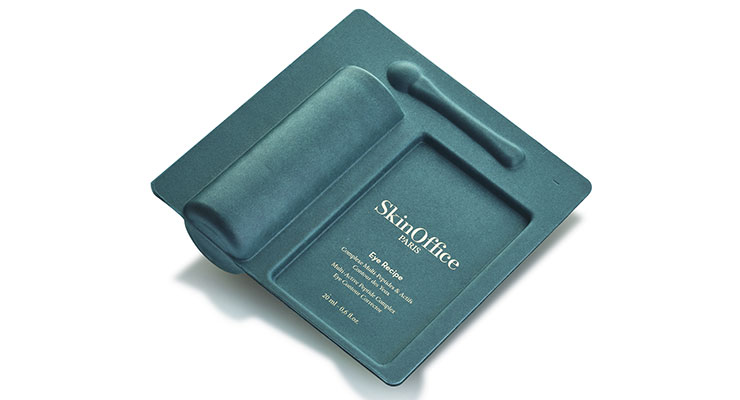

One of Knoll’s latest brand partnerships is with Skin Office which resulted in the debut of a 100% Knoll Ecoform molded pulp secondary package. The sustainable clamshell consists of Knoll’s recyclable pulp made from bamboo and bagasse fibers and features a multi-cavity molded shape with dedicated sections for the serum, tool and brochure. The pulp structure of Knoll Ecoform was color-matched to achieve the brand’s desire to echo the color of the algae complex in the product formula.

Using the same type of pulp commonly used by other paper packaging manufacturers, PulPac has pioneered the process of converting the pulp into a paper product by removing the use of water to create “Dry Molded Fibre” packaging.

“Instead of defibrating the paper fibers in water, making it into a “slurry” that is later formed into products, we use air,” explains Ann Dynehäll, PulPac’s Chief Communications Officer. “A mill separates the fibers, which are then air-laid into a dry web of loosely tangled cellulosic fibers that we form into rigid packaging.

“The dry process makes fiber-based packaging even more sustainable, as we lower both water- and energy-use, plus it speeds up production, giving higher output and better unit economics than traditional fiber-forming methods.”

Rather than commercially producing the fiber-based packaging itself, PulPac instead makes its technology available and accessible to converters by offering the technology itself, along with its know-how, specially designed machinery and network of suppliers throughout the value chain.

But how do dry molded fiber-based packages fare against moisture-containing product formulations? “For fiber-based packaging, sustainable barriers are an important nut to crack,” Dynehäll says, adding that PFAS have been the prevalent solution, but they’re being banned in more regions, and for good reason. “In some cases, a fiber-based product with a plastic liner is better than an all-plastic product [but] the end goal, however, is clear: We need to make the shift away from unnecessary plastics.”

The company’s latest machine platform, The PulPac Scala, addresses the beauty packaging market where high-quality paired with lower volumes are often the case. And Dynehäll says the Dry Molded Fibre technology is ready to be used in beauty packaging formats like perfume bottle inserts. PulPac’s partner, PA Consulting, is also working with the development of products such as bottles and blister packs but these new products aren’t quite ready for prime time just yet.

All of Paper Tube Co.’s paper is FSC-certified and uses soy-based inks for printing. Whenever the packaging requires lining or lamination, the company uses PLA, plastic-free greaseproof paper and biodegradable films.

The company’s approach got the attention of Common Heir, a personal care company with sustainability deeply rooted in its core identity. Dedicated to transforming beauty traditions with “clean, plastic-free, high-performance skincare,” Common Heir worked with Paper Tube to develop bespoke packaging for a variety of its products.

“Each of these products required unique packaging designs and material choices, all guided by our shared commitment to sustainability,” says Paper Tube’s David Molo, CPO.

For instance, Common Heir’s Serum is packaged in a 2-Piece Telescoping Tube made of textured watercolor paper and decorated with full bleed artwork printed with soy inks, foil stamping and embossing. Other products, like its Gua Sha Box, Gift Box and Candle box consist of similarly textured watercolor paper decorated in the same cohesively upscale fashion.

In response to demand for improved circularity, Eska has launched Eska Pure: a mass-colored premium solid board made from 100% recycled fibers that’s 100% circular. “Raw, and natural, it’s the natural choice for eco-lovers of luxury,” comments the company’s Sophie Greff, RDM Group Marketing Director.

“Our customers are increasingly looking for simpler solutions with fewer materials and Eska Pure is the ideal solution to match this trend.”

Eska Pure is available in five classic and subtle colors: ivory, grey, black, green and anthracite. The material is soft to the touch and Greff says it has a unique texture and facilitates crisp cut-outs and razor-sharp, 90-degree boxes for packaging that combines modernity, ecology and refinement. What makes it unique is that it can be directly printed on and is mass-colored, eliminating the need for cover paper and making it a viable option for brands in search of “naked packaging.”

“Composed of three layers, it has an optimal rigidity that allows a perfect hold and an optimal protection of the product,” Greff says. “It can also be perfectly used to design sustainable inserts and replace plastic solutions.”

Eska Pure’s fibers are sourced from the Netherlands, Germany and UK, and come mainly from printing and converting companies. “Thanks to our unique circular process, the residues from recycling are then converted into energy, which powers the whole production process of our solid board,” Greff says.

“Many brands now have sustainable packaging targets such as including specific percentages of PCR [and] major beauty retailers are also implementing sustainable packaging requirements, amplifying environmental awareness and increasing the demand for PCR,” says Seb Hofstede, Director of Packaging and Project Development at ICONS/ICS. “At the same time, consumer recycling has increased over the years, and as a result, the accessibility of PCR resins has increased, making PCR materials more readily available.”

As brands become more educated about how to assimilate the sustainability needs of consumers and the environment into their product and packaging lineup, their efforts help enhance their reputation, fostering brand loyalty while doing their part for the planet. “As a result, brands and products that are sustainable can have an advantage, especially in economic downturns when consumers may purchase less items but want to maintain their personal values,” he says.

According to Hofstede, consumers today not only prioritize packaging that’s easily recyclable but also has aesthetic appeal. “As a general rule, the higher the percentage of PCR in packaging components, the more challenging it becomes to maintain the same level of clarity and color consistency compared to products made with virgin raw materials,” he says. “When incorporating PCR into beauty packaging, it is important to also ensure the traceability and sustainability of the PCR materials. At ICONS|ICS, we collaborate with certified PCR suppliers, and we also hold an ISCC PLUS certification. This ensures brands can confidently incorporate PCR into their products knowing the materials are verifiable and traceable.”

One of the latest PCR innovations from ICONS/ICS is a patented, recyclable pump. “The 97% PP pump has a PET gasket and PE piston and valve, twist lock design, and can add up to 70% PP PCR in the actuator and collar,” Hofstede says. “The 24/410 neck size fits a wide range of plastic and glass bottles and the 0.2cc dosage makes it perfect for lotions, serums, body wash, primers and gels.”

An in-mold matte collar and actuator adds an extra element of stylish sustainability since no secondary process is required to achieve the premium matte effect.

Despite increased global efforts to curb our collective reliance on plastics, recycling organizations still aren’t a perfect solution to the problem. For instance, Claude Desmarais, Business Development Director, Northeast USA, Beauty Market, Bosk Bioproducts, wonders how recyclers work with certain plastics that can only be recycled a few times until they are no longer usable. “Can [they] be sorted from the ones that are still recyclable/usable? To my knowledge, there is no way of knowing how many times a PCR package has been recycled, used in producing PCR materials,” he says. “My guess is the recyclers are likely not recycling many PCR packages since they cannot be sure and do not want to contaminate the virgin packaging recycling stream.”

The complex plastic problem makes biodegradable materials seemingly poised to bridge the gap. Though not a packaging manufacturer, Bosk Bioproducts is a producer of the bio-resin Regen, a biobased and compostable material made from industrial carbon sources such as non-edible plant oil that’s still compatible with standard plastic product manufacturing equipment. The company is currently testing Regen bioplastics with many vendors in rigid, semi-rigid and extrusion formats for thermoforming films and laminations, targeting color cosmetic and skincare applications, given that their relatively small sized parts can easily fall through recycling line screens and go directly to landfills. Regen materials can biodegrade into industrial composting facilities in a few weeks to months, depending on a package’s wall thickness.

Pack Tech’s Ocean Waste Plastic (OWP) is packaging made with plastic from oceans and rivers in Indonesia. “Collected from boats by former fishermen, it reflects a harsh reality where traditional livelihoods tied to fishing are no longer viable,” explains Mads Kjeldgaard Oddershede, communications manager. “The pervasive presence of plastic in the ocean has compelled these fishermen to shift their focus from catching fish to retrieving plastic, as the environmental impact of plastic pollution has led to the decline and displacement of fish populations.”

During the collection process, plastic is meticulously documented with a batch number, coordinates, picture, date and collector initials. The material is then weighed at multiple checkpoints. Sorting stations register the plastic in Pack Tech’s blockchain system, and the plastic is sorted by type (PP and HDPE). Sorted plastic is then bale-pressed and sent to plastic processors, who shred, wash and melt it into OWP granulate that’s ready to be used in packaging.

The collection process—carried out by Pack Tech’s subsidiary ReSea Project—is certified by DNV, a globally recognized independent third party. Pack Tech also empowers brands to showcase the positive impact they are making through QR codes on their products. “This makes it easy for consumers to see the tangible difference that choosing a product made with OWP can make,” explains Mads Kjeldgaard Oddershede, Communications Manager.

Zenz recently chose OWP to package its Body Wash in HDPE Pantone Cool Grey bottles and PP black caps. Pack Tech overcame a minor challenge when it came to stretching the material to specifications. “It took us some weeks to find the right adjustments for the blow molding machines,” Oddershede says. “We also learned that we have to separate the waste materials from each other close to 100%, as just a little part of ‘wrong’ material in a batch of HDPE, for example, can make the blow molding process impossible.”

Seacliff Beauty Packaging’s exclusive partnership with #tide Ocean Materials has enabled the company to develop a proprietary conversion process in partnership with the Swiss Institute of Applied Sciences for an “exceptionally clean” PCR product that’s both FDA- and REACH-compliant. “#tide also provides tracking that shows the full journey through #tide’s supply chain from point of collection to delivery of material,” says SeaCliff’s Amanda Greuel, Senior Marketing Manager.

She says corporations, governments and consumers continue to demand increases in sustainable solutions. “Consumers continue to push, especially the younger, up-and-coming brands, Greuel comments. “And to help combat greenwashing, which continues to be a concern in the ocean plastic industry, Seacliff and #tide, offer a material passport using blockchain technology that physically shows the journey and certifies these resins.”

Norwex Skincare’s Renewing Eye Cream is one of Seacliff’s first projects to use Ocean Bound Plastic, supplied by #tide Ocean Material. The package is refillable, made with 30% PCR glass and utilizes #tide Ocean Bound Plastic for its caps, collars, pumps and actuators.

As the official supplier of Oceanworks At Risk Resin, Roberts recently increased its Bio Resin capabilities by developing its own from-domestic, non-diverted feedstock. Now, in addition to its existing Bio Resin tubes, the company supplies blow-molded Bio Resin containers with optional landfill composting capability.

“This year in particular has seen a very steep rise in demand,” observes Stephen Corsi, Roberts’ Vice President of Packaging Development, “however issues surrounding authenticity continue to be at the forefront.

“For example, Oceanworks resins collected from at-risk areas within 50km of the coastline are categorized Oceanbound; however, we have learned of some unscrupulous vendors offering PCR from factories within 50km of coastlines and incorrectly labeling it as Oceanbound, i.e., not actually collected from the environment,” he says. “Whether you work with Roberts or one of our competitors on an Oceanbound project, be sure to request certification that the material supplied is what it is claimed to be.”

Roberts recently used Oceanworks PP, LDPE and HDPE resins to produce 3oz tubes for Cocofloss 3oz, and in doing so, hit an industry high of 74% ocean waste PCR.

Plastube offers options for tubes that help achieve up to 50% PCR and up to 100% PCR in assembled flip top caps. Its EcoPrime PCR material is derived from standard recycling facilities and its Ocean Bound PCR material is derived from recycled materials from ocean tributaries.

Plastube uses FDA-approved PCR resins and although the quality of PCR resins is not a concern, Plastube’s Philip Rubin, Sales Representative, Strategic Accounts, says that maintaining integrity of the overall package compared to the use of virgin resins provides manufacturing challenges. “Plastube has been successful in implementing proprietary and best-in-class extrusion of its tubes to provide unparalleled quality,” he says. “The overall quality of the tube surface area and maintenance of overall tube color is not compromised using PCR resins.”

Plastube has executed a variety of personal care products in tubes that were extruded with its PCR resin, including body lotions for Dr. Teal’s and haircare products for Curlsmith and Aquage. The tubes were all custom-colored and decorated with either silk screen printing or digital printing with proprietary Plastube varnish.

Tree Free Upcycled packaging from Moquin Press is a paperboard made from bagasse, a byproduct of sugar production. This novel packaging is recyclable, compostable and biodegradable and comes in white/coated and natural/uncoated options which pair with all of the company’s premium finishes from spot UV to foils.

The company’s Juliana Lopez, Marketing Director, explains that the product comes from the fibrous material that remains after sugarcane has been crushed to release its juice. “The resulting fibers can be repurposed into paper pulp,” she says. “Normally these by-products would be burned, contaminating the air with greenhouse gases. Instead, the fibers are upcycled into paper pulp to create folding cartons of high quality.”

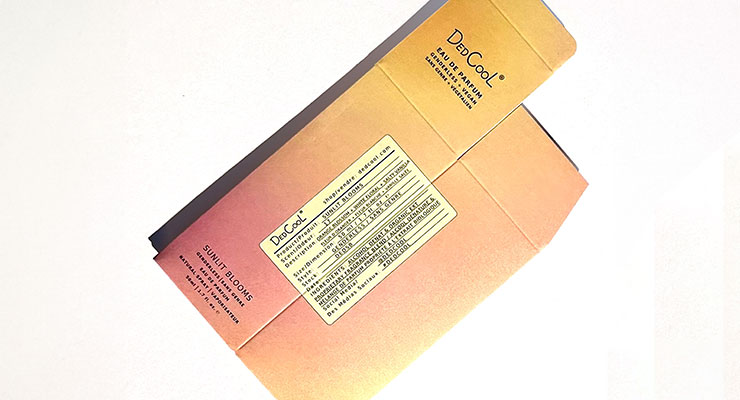

Lopez says that due to the density of the bagasse fibers, the substrate is best suited for smaller scale applications such as cosmetics, fragrances, or personal care products. The product proved to be a perfect fit for fragrance brand DedCool, a brand known for its use of high-quality ingredients that are natural, vegan and cruelty-free. The brand chose boxes made of Moquin Press’s 18pt Sugarcane C1S in which Moquin prints 4cp + soft-touch coating, which are die-cut, folded and then glued.

And finally, JSN Industries has found sugarcane-origin resin to be an excellent plastic-alternative for producing flexible packaging like tubes.

To help circumvent the potential concern surrounding how sugarcane is being harvested in recently deforested Brazilian rainforest, JSN provides a chain custody tracing the ingredients from the opposite side of the country from the rainforest.

The company’s Casey Nagel, Senior Manager of Business Development, says blended solutions consisting of several different sustainable resins in percentages defined by the customer are most currently in demand. “These resins could occur in the inner or outer sleeve, head of the tube and the tube cap [and] in all cases there are some practical limits to the amount of sustainable resin,” he says. “An individual customer may want sugarcane LDPE resin on the inside for product contact issues, HDPE PCR on the exterior and as much polypropylene PCR in the cap as possible.”

JSN’s recent “Sustainable and PCR Options” sample shows how collaborative a blended product development solution can be. The tube consists of a sugarcane inner sleeve, a PCR outer sleeve and a PCR cap.

Pujolasos is known for its sustainable work with hardwood and wood waste and its latest endeavor, Renew, turns recycled textile industry waste into beautifully bespoke fragrance bottle caps.

Renew is part of the company’s new Matsos brand, which is “committed to creating sustainable solutions through innovation, reuse and the circular economy, with the aim of promoting responsible and eco-friendly consumer behavior.”

“We started from an empirical need to recycle, to transform textile materials so that products that have already reached the end of their useful life are reintroduced into the production and consumption cycle,” says Montse Font, Marketing and Communication.

Renew’s raw materials are collected from customers with ensured traceability, then are circularly transformed by Pujolasos, giving new life to materials that would otherwise be discarded. In short, high-quality remnants like denim and other textiles, cork, wood and leather and turned into uniquely elegant, high-quality caps. The result is nothing short of luxurious.

Font says the Renew line has an inherent complexity because a product made from “waste” may not be perceived as luxurious. “However, if you produce with the best quality raw material, the waste will continue to have that quality, the raw material does not change,” he says. “We must be conscious that the true luxury will be the one that can be sustainable.”

Fortunately, sustainable alternatives to virgin plastic abound and the creativity driving the development of packaging made with these alternative materials is at an all-time high. Beyond infinitely recyclable glass and aluminum, materials originating from wood as well as waste from the ocean, sugarcane processing and even the textile industry are “new and now” for brands looking to carve out a unique look with an eco-savvy purpose.

Molded Pulp, Board & Paper

Paper, paperboard and molded pulp continue to be an effective use of the paper recycling stream.Knoll Packaging has advanced the technical abilities of its Ecoform Molded Pulp into new opportunities for plastic-free makeup compacts with mirrors engineered to be removable to encourage recyclability. The latest iteration utilizes two snap closures to keep the compact closed and offer a seamless appearance. “We see countless opportunities for this approach, particularly with refills and single pan eye shadows, allowing for a sustainable but eye-catching design,” says the company’s Benjamin Cohen, Chief Marketing Officer.

One of the material’s unique design aspects is that it can be shaped to suit most any creation. “We spend a lot of time brainstorming and researching unique shapes that could only be possible in pulp,” he says, noting that the material is sleek, sturdy and can be color matched to suit a brand’s unique aesthetic. “We’ve started to combine pulp and board together into one single coffret, [unlocking] even more decoration and customization opportunities.”

Knoll is currently supplying molded pulp in Europe and Asia, and Cohen says each area has its own supply chain and product mixture to ethically source and produce the components. “This has also allowed for greater implementation as we can now produce a rigid box on our custom machinery in Europe, and have the pulp insert created locally too,” he comments. “We can’t underestimate the intelligence of a customer, but regardless we have to continue doing the right thing and keep eliminating plastics from the supply chains.”

One of Knoll’s latest brand partnerships is with Skin Office which resulted in the debut of a 100% Knoll Ecoform molded pulp secondary package. The sustainable clamshell consists of Knoll’s recyclable pulp made from bamboo and bagasse fibers and features a multi-cavity molded shape with dedicated sections for the serum, tool and brochure. The pulp structure of Knoll Ecoform was color-matched to achieve the brand’s desire to echo the color of the algae complex in the product formula.

Using the same type of pulp commonly used by other paper packaging manufacturers, PulPac has pioneered the process of converting the pulp into a paper product by removing the use of water to create “Dry Molded Fibre” packaging.

“Instead of defibrating the paper fibers in water, making it into a “slurry” that is later formed into products, we use air,” explains Ann Dynehäll, PulPac’s Chief Communications Officer. “A mill separates the fibers, which are then air-laid into a dry web of loosely tangled cellulosic fibers that we form into rigid packaging.

“The dry process makes fiber-based packaging even more sustainable, as we lower both water- and energy-use, plus it speeds up production, giving higher output and better unit economics than traditional fiber-forming methods.”

Rather than commercially producing the fiber-based packaging itself, PulPac instead makes its technology available and accessible to converters by offering the technology itself, along with its know-how, specially designed machinery and network of suppliers throughout the value chain.

But how do dry molded fiber-based packages fare against moisture-containing product formulations? “For fiber-based packaging, sustainable barriers are an important nut to crack,” Dynehäll says, adding that PFAS have been the prevalent solution, but they’re being banned in more regions, and for good reason. “In some cases, a fiber-based product with a plastic liner is better than an all-plastic product [but] the end goal, however, is clear: We need to make the shift away from unnecessary plastics.”

The company’s latest machine platform, The PulPac Scala, addresses the beauty packaging market where high-quality paired with lower volumes are often the case. And Dynehäll says the Dry Molded Fibre technology is ready to be used in beauty packaging formats like perfume bottle inserts. PulPac’s partner, PA Consulting, is also working with the development of products such as bottles and blister packs but these new products aren’t quite ready for prime time just yet.

All of Paper Tube Co.’s paper is FSC-certified and uses soy-based inks for printing. Whenever the packaging requires lining or lamination, the company uses PLA, plastic-free greaseproof paper and biodegradable films.

The company’s approach got the attention of Common Heir, a personal care company with sustainability deeply rooted in its core identity. Dedicated to transforming beauty traditions with “clean, plastic-free, high-performance skincare,” Common Heir worked with Paper Tube to develop bespoke packaging for a variety of its products.

“Each of these products required unique packaging designs and material choices, all guided by our shared commitment to sustainability,” says Paper Tube’s David Molo, CPO.

For instance, Common Heir’s Serum is packaged in a 2-Piece Telescoping Tube made of textured watercolor paper and decorated with full bleed artwork printed with soy inks, foil stamping and embossing. Other products, like its Gua Sha Box, Gift Box and Candle box consist of similarly textured watercolor paper decorated in the same cohesively upscale fashion.

In response to demand for improved circularity, Eska has launched Eska Pure: a mass-colored premium solid board made from 100% recycled fibers that’s 100% circular. “Raw, and natural, it’s the natural choice for eco-lovers of luxury,” comments the company’s Sophie Greff, RDM Group Marketing Director.

“Our customers are increasingly looking for simpler solutions with fewer materials and Eska Pure is the ideal solution to match this trend.”

Eska Pure is available in five classic and subtle colors: ivory, grey, black, green and anthracite. The material is soft to the touch and Greff says it has a unique texture and facilitates crisp cut-outs and razor-sharp, 90-degree boxes for packaging that combines modernity, ecology and refinement. What makes it unique is that it can be directly printed on and is mass-colored, eliminating the need for cover paper and making it a viable option for brands in search of “naked packaging.”

“Composed of three layers, it has an optimal rigidity that allows a perfect hold and an optimal protection of the product,” Greff says. “It can also be perfectly used to design sustainable inserts and replace plastic solutions.”

Eska Pure’s fibers are sourced from the Netherlands, Germany and UK, and come mainly from printing and converting companies. “Thanks to our unique circular process, the residues from recycling are then converted into energy, which powers the whole production process of our solid board,” Greff says.

Alternatives to Virgin Plastic

There’s been a surge in the use of PCR in beauty packaging throughout 2023, with increased demand for a growing percentage of PCR content—and growth is expected to accelerate in 2024 and beyond.“Many brands now have sustainable packaging targets such as including specific percentages of PCR [and] major beauty retailers are also implementing sustainable packaging requirements, amplifying environmental awareness and increasing the demand for PCR,” says Seb Hofstede, Director of Packaging and Project Development at ICONS/ICS. “At the same time, consumer recycling has increased over the years, and as a result, the accessibility of PCR resins has increased, making PCR materials more readily available.”

As brands become more educated about how to assimilate the sustainability needs of consumers and the environment into their product and packaging lineup, their efforts help enhance their reputation, fostering brand loyalty while doing their part for the planet. “As a result, brands and products that are sustainable can have an advantage, especially in economic downturns when consumers may purchase less items but want to maintain their personal values,” he says.

According to Hofstede, consumers today not only prioritize packaging that’s easily recyclable but also has aesthetic appeal. “As a general rule, the higher the percentage of PCR in packaging components, the more challenging it becomes to maintain the same level of clarity and color consistency compared to products made with virgin raw materials,” he says. “When incorporating PCR into beauty packaging, it is important to also ensure the traceability and sustainability of the PCR materials. At ICONS|ICS, we collaborate with certified PCR suppliers, and we also hold an ISCC PLUS certification. This ensures brands can confidently incorporate PCR into their products knowing the materials are verifiable and traceable.”

One of the latest PCR innovations from ICONS/ICS is a patented, recyclable pump. “The 97% PP pump has a PET gasket and PE piston and valve, twist lock design, and can add up to 70% PP PCR in the actuator and collar,” Hofstede says. “The 24/410 neck size fits a wide range of plastic and glass bottles and the 0.2cc dosage makes it perfect for lotions, serums, body wash, primers and gels.”

An in-mold matte collar and actuator adds an extra element of stylish sustainability since no secondary process is required to achieve the premium matte effect.

Despite increased global efforts to curb our collective reliance on plastics, recycling organizations still aren’t a perfect solution to the problem. For instance, Claude Desmarais, Business Development Director, Northeast USA, Beauty Market, Bosk Bioproducts, wonders how recyclers work with certain plastics that can only be recycled a few times until they are no longer usable. “Can [they] be sorted from the ones that are still recyclable/usable? To my knowledge, there is no way of knowing how many times a PCR package has been recycled, used in producing PCR materials,” he says. “My guess is the recyclers are likely not recycling many PCR packages since they cannot be sure and do not want to contaminate the virgin packaging recycling stream.”

The complex plastic problem makes biodegradable materials seemingly poised to bridge the gap. Though not a packaging manufacturer, Bosk Bioproducts is a producer of the bio-resin Regen, a biobased and compostable material made from industrial carbon sources such as non-edible plant oil that’s still compatible with standard plastic product manufacturing equipment. The company is currently testing Regen bioplastics with many vendors in rigid, semi-rigid and extrusion formats for thermoforming films and laminations, targeting color cosmetic and skincare applications, given that their relatively small sized parts can easily fall through recycling line screens and go directly to landfills. Regen materials can biodegrade into industrial composting facilities in a few weeks to months, depending on a package’s wall thickness.

The Promise of Ocean Plastic

With plastic pollution in our oceans reaching epidemic status, a number of organizations have taken to the seas and waterways to reclaim and recycle this waste into something that’s not only useful, but also beautiful.Pack Tech’s Ocean Waste Plastic (OWP) is packaging made with plastic from oceans and rivers in Indonesia. “Collected from boats by former fishermen, it reflects a harsh reality where traditional livelihoods tied to fishing are no longer viable,” explains Mads Kjeldgaard Oddershede, communications manager. “The pervasive presence of plastic in the ocean has compelled these fishermen to shift their focus from catching fish to retrieving plastic, as the environmental impact of plastic pollution has led to the decline and displacement of fish populations.”

During the collection process, plastic is meticulously documented with a batch number, coordinates, picture, date and collector initials. The material is then weighed at multiple checkpoints. Sorting stations register the plastic in Pack Tech’s blockchain system, and the plastic is sorted by type (PP and HDPE). Sorted plastic is then bale-pressed and sent to plastic processors, who shred, wash and melt it into OWP granulate that’s ready to be used in packaging.

The collection process—carried out by Pack Tech’s subsidiary ReSea Project—is certified by DNV, a globally recognized independent third party. Pack Tech also empowers brands to showcase the positive impact they are making through QR codes on their products. “This makes it easy for consumers to see the tangible difference that choosing a product made with OWP can make,” explains Mads Kjeldgaard Oddershede, Communications Manager.

Zenz recently chose OWP to package its Body Wash in HDPE Pantone Cool Grey bottles and PP black caps. Pack Tech overcame a minor challenge when it came to stretching the material to specifications. “It took us some weeks to find the right adjustments for the blow molding machines,” Oddershede says. “We also learned that we have to separate the waste materials from each other close to 100%, as just a little part of ‘wrong’ material in a batch of HDPE, for example, can make the blow molding process impossible.”

Seacliff Beauty Packaging’s exclusive partnership with #tide Ocean Materials has enabled the company to develop a proprietary conversion process in partnership with the Swiss Institute of Applied Sciences for an “exceptionally clean” PCR product that’s both FDA- and REACH-compliant. “#tide also provides tracking that shows the full journey through #tide’s supply chain from point of collection to delivery of material,” says SeaCliff’s Amanda Greuel, Senior Marketing Manager.

She says corporations, governments and consumers continue to demand increases in sustainable solutions. “Consumers continue to push, especially the younger, up-and-coming brands, Greuel comments. “And to help combat greenwashing, which continues to be a concern in the ocean plastic industry, Seacliff and #tide, offer a material passport using blockchain technology that physically shows the journey and certifies these resins.”

Norwex Skincare’s Renewing Eye Cream is one of Seacliff’s first projects to use Ocean Bound Plastic, supplied by #tide Ocean Material. The package is refillable, made with 30% PCR glass and utilizes #tide Ocean Bound Plastic for its caps, collars, pumps and actuators.

As the official supplier of Oceanworks At Risk Resin, Roberts recently increased its Bio Resin capabilities by developing its own from-domestic, non-diverted feedstock. Now, in addition to its existing Bio Resin tubes, the company supplies blow-molded Bio Resin containers with optional landfill composting capability.

“This year in particular has seen a very steep rise in demand,” observes Stephen Corsi, Roberts’ Vice President of Packaging Development, “however issues surrounding authenticity continue to be at the forefront.

“For example, Oceanworks resins collected from at-risk areas within 50km of the coastline are categorized Oceanbound; however, we have learned of some unscrupulous vendors offering PCR from factories within 50km of coastlines and incorrectly labeling it as Oceanbound, i.e., not actually collected from the environment,” he says. “Whether you work with Roberts or one of our competitors on an Oceanbound project, be sure to request certification that the material supplied is what it is claimed to be.”

Roberts recently used Oceanworks PP, LDPE and HDPE resins to produce 3oz tubes for Cocofloss 3oz, and in doing so, hit an industry high of 74% ocean waste PCR.

Plastube offers options for tubes that help achieve up to 50% PCR and up to 100% PCR in assembled flip top caps. Its EcoPrime PCR material is derived from standard recycling facilities and its Ocean Bound PCR material is derived from recycled materials from ocean tributaries.

Plastube uses FDA-approved PCR resins and although the quality of PCR resins is not a concern, Plastube’s Philip Rubin, Sales Representative, Strategic Accounts, says that maintaining integrity of the overall package compared to the use of virgin resins provides manufacturing challenges. “Plastube has been successful in implementing proprietary and best-in-class extrusion of its tubes to provide unparalleled quality,” he says. “The overall quality of the tube surface area and maintenance of overall tube color is not compromised using PCR resins.”

Plastube has executed a variety of personal care products in tubes that were extruded with its PCR resin, including body lotions for Dr. Teal’s and haircare products for Curlsmith and Aquage. The tubes were all custom-colored and decorated with either silk screen printing or digital printing with proprietary Plastube varnish.

From Sugarcane to Bagasse & Resin

Sugarcane is more than just a sweet commodity; it’s also given rise to bagasse and sugarcane resin packaging materials.Tree Free Upcycled packaging from Moquin Press is a paperboard made from bagasse, a byproduct of sugar production. This novel packaging is recyclable, compostable and biodegradable and comes in white/coated and natural/uncoated options which pair with all of the company’s premium finishes from spot UV to foils.

The company’s Juliana Lopez, Marketing Director, explains that the product comes from the fibrous material that remains after sugarcane has been crushed to release its juice. “The resulting fibers can be repurposed into paper pulp,” she says. “Normally these by-products would be burned, contaminating the air with greenhouse gases. Instead, the fibers are upcycled into paper pulp to create folding cartons of high quality.”

Lopez says that due to the density of the bagasse fibers, the substrate is best suited for smaller scale applications such as cosmetics, fragrances, or personal care products. The product proved to be a perfect fit for fragrance brand DedCool, a brand known for its use of high-quality ingredients that are natural, vegan and cruelty-free. The brand chose boxes made of Moquin Press’s 18pt Sugarcane C1S in which Moquin prints 4cp + soft-touch coating, which are die-cut, folded and then glued.

And finally, JSN Industries has found sugarcane-origin resin to be an excellent plastic-alternative for producing flexible packaging like tubes.

To help circumvent the potential concern surrounding how sugarcane is being harvested in recently deforested Brazilian rainforest, JSN provides a chain custody tracing the ingredients from the opposite side of the country from the rainforest.

The company’s Casey Nagel, Senior Manager of Business Development, says blended solutions consisting of several different sustainable resins in percentages defined by the customer are most currently in demand. “These resins could occur in the inner or outer sleeve, head of the tube and the tube cap [and] in all cases there are some practical limits to the amount of sustainable resin,” he says. “An individual customer may want sugarcane LDPE resin on the inside for product contact issues, HDPE PCR on the exterior and as much polypropylene PCR in the cap as possible.”

JSN’s recent “Sustainable and PCR Options” sample shows how collaborative a blended product development solution can be. The tube consists of a sugarcane inner sleeve, a PCR outer sleeve and a PCR cap.

Pujolasos is known for its sustainable work with hardwood and wood waste and its latest endeavor, Renew, turns recycled textile industry waste into beautifully bespoke fragrance bottle caps.

Renew is part of the company’s new Matsos brand, which is “committed to creating sustainable solutions through innovation, reuse and the circular economy, with the aim of promoting responsible and eco-friendly consumer behavior.”

“We started from an empirical need to recycle, to transform textile materials so that products that have already reached the end of their useful life are reintroduced into the production and consumption cycle,” says Montse Font, Marketing and Communication.

Renew’s raw materials are collected from customers with ensured traceability, then are circularly transformed by Pujolasos, giving new life to materials that would otherwise be discarded. In short, high-quality remnants like denim and other textiles, cork, wood and leather and turned into uniquely elegant, high-quality caps. The result is nothing short of luxurious.

Font says the Renew line has an inherent complexity because a product made from “waste” may not be perceived as luxurious. “However, if you produce with the best quality raw material, the waste will continue to have that quality, the raw material does not change,” he says. “We must be conscious that the true luxury will be the one that can be sustainable.”