Jamie Matusow, Editor-in-Chief02.26.24

Cosmoprof/Cosmopack, with shows around the world that represent the entire beauty industry from formula to finished product, premiered in Florida on January 23-25 at the Miami Beach Convention Center. This second U.S. venue joins its sister event that takes place every July in Las Vegas. The Miami edition aimed to reach a different area of the U.S. as well as attract visitors and suppliers from Latin America and South America.

According to Cosmoprof North America organizers, the event drew 19,000 visitors representing 113 countries, alongside an array of over 700 exhibitors from 40 countries. 56% of the Miami exhibitors were brand new to Cosmoprof. Exhibitors in the Cosmopack section accounted for about one quarter.

“The success of the first edition of Cosmoprof North America Miami is really a positive signal for the development strategy of the Cosmoprof network,” said Antonio Bruzzone, Chief Executive Officer of BolognaFiere Group. “As a global partner for business for all beauty stakeholders, our aim is to facilitate networking and commercial relationships; starting from today, we can provide our global community with two specific events dedicated to the U.S. market, enriching the global offer of our international platform.”

The general sentiment on the Cosmoprof Miami (CPM) show floor was that the event was an unquestionable success, with a “larger-than-expected” size, and companies and exhibitors that spanned the world from South America to China. Both attendees and suppliers that Beauty Packaging’s Publisher, Jay Gorga, and I spoke with, commented on the quality of visitors and the level of the leads.

There’s a focus on making packaging criteria, including recycling and refilling, more consumer-friendly. An increase in the use of mono-material packages as well as in developing easy separation strategies make recycling as easy as possible for consumers. Lots of refillable jars with pods from pop-in to screw-in were spotted, all designed with the goal of attaining consumer acceptance with a refill method that’s as easy and fast as possible—and with no breakage occurring in the process.

A number of suppliers said they were seeing increased demand for rPET. Advances in technology are making it possible to ramp up the percentages used, with compositions from 30-100%. Supply of PCR has increased and costs are slowly dropping. One supplier commented: “Customers/consumers like the idea that they’re buying a product (container) that’s made from something that’s already had commercial use.”

Aluminum packaging is now a key sustainable packaging choice, with everything from bottles and caps to tins.

We also saw numerous examples of large packaging sizes designed for “more volume in less containers,” and smaller order quantities for indie brands starting out in the market.

There was also a noticeable rise in “fast tracking packaging”—in which a brand takes a stock package, and puts their deco on it—for increased speed-to-market.

The company offers comprehensive solutions by integrating the molding, bottling, and decoration processes under one roof, “ensuring customer confidentiality and offering a one-stop-shop for all their requirements.”

Valentina Manera, marketing director of Brivaplast, explained, “Our metallic and holographic visual makeup experimentation created both a futuristic goddess in the real world, matched against their AI-generated model—a mirror game between the two worlds.”

Manera pointed to the collection’s easy-to-use flocked applicator, with a large dimension and curved shape that offers two large application surfaces for oversized formula loading. The mascara brush is made with B Brivaplast shaped fiber. This fiber design of a “b” creates a reservoir along the entire single filament which increases the loading of the formula. The shape of this flocked applicator, which is reminiscent of “a painting tool,” makes it possible to easily light up facial features like a cupid arch, the edge of the eyes and the nose. Its design ensures an extremely precise application. It is suitable for all formulas that need to be applied accurately.

The mirrored cuts on each side enable, with just one dip in the formula, to make-up the lower and upper lip by switching sides. The slanted front is ideal to define the contour of the lips and draw precise lines.

The LB30 Lip Balm Filler features a manual loading station with an angled guide that allows for easy loading and a quick-change puck mounting system that enables toolless changeovers among different sizes. The LB30 offers puck tooling that fits most lip balm brands .15-ounce 500 style tubes, including those used by Inpres, Federal, CCP, and Sapona. An on-board cap sortation station features a gravity cap track to present caps for the auto capping station and the positive cap sap station ensures caps are pressed on completely.

From formulation, development, and design to packaging and assembly, Simon said, “Seacliff provides a one-stop, full-service solution that brings brands and products to life. Our strong partnerships with formulators, researchers, and engineers ensures you have access to the most ground-breaking ingredients and technology.”

With a passion for sustainability, Simon said, “We feel that environmental consciousness is essential in the everchanging world of beauty. Sustainability has become a fundamental part of corporate responsibility and Seacliff Beauty has strived to exceed expectations by investing in research and development of environmentally friendly solutions, including initiatives such as aligning with a Swiss company called #tide Ocean Bound material that offers 100% ocean-bound plastics.

According to Cosmoprof North America organizers, the event drew 19,000 visitors representing 113 countries, alongside an array of over 700 exhibitors from 40 countries. 56% of the Miami exhibitors were brand new to Cosmoprof. Exhibitors in the Cosmopack section accounted for about one quarter.

“The success of the first edition of Cosmoprof North America Miami is really a positive signal for the development strategy of the Cosmoprof network,” said Antonio Bruzzone, Chief Executive Officer of BolognaFiere Group. “As a global partner for business for all beauty stakeholders, our aim is to facilitate networking and commercial relationships; starting from today, we can provide our global community with two specific events dedicated to the U.S. market, enriching the global offer of our international platform.”

The general sentiment on the Cosmoprof Miami (CPM) show floor was that the event was an unquestionable success, with a “larger-than-expected” size, and companies and exhibitors that spanned the world from South America to China. Both attendees and suppliers that Beauty Packaging’s Publisher, Jay Gorga, and I spoke with, commented on the quality of visitors and the level of the leads.

Trendspotting

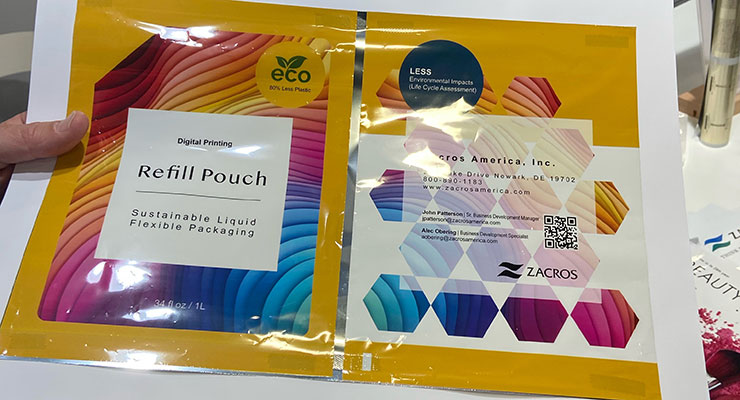

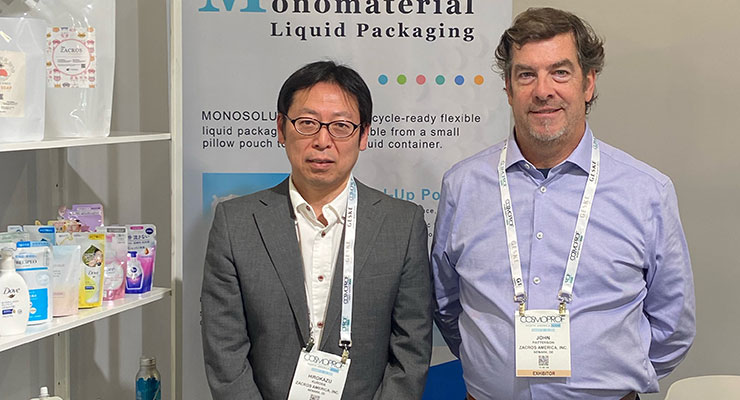

As we walked around the show and spoke with many of the suppliers exhibiting at Cosmopack (the packaging & supply chain portion of the show), we noticed a number of trends. Most notably, with sustainable packaging now pretty much a given, suppliers are advancing their solutions.There’s a focus on making packaging criteria, including recycling and refilling, more consumer-friendly. An increase in the use of mono-material packages as well as in developing easy separation strategies make recycling as easy as possible for consumers. Lots of refillable jars with pods from pop-in to screw-in were spotted, all designed with the goal of attaining consumer acceptance with a refill method that’s as easy and fast as possible—and with no breakage occurring in the process.

A number of suppliers said they were seeing increased demand for rPET. Advances in technology are making it possible to ramp up the percentages used, with compositions from 30-100%. Supply of PCR has increased and costs are slowly dropping. One supplier commented: “Customers/consumers like the idea that they’re buying a product (container) that’s made from something that’s already had commercial use.”

Aluminum packaging is now a key sustainable packaging choice, with everything from bottles and caps to tins.

We also saw numerous examples of large packaging sizes designed for “more volume in less containers,” and smaller order quantities for indie brands starting out in the market.

There was also a noticeable rise in “fast tracking packaging”—in which a brand takes a stock package, and puts their deco on it—for increased speed-to-market.

On the Show Floor at Cosmoprof & Cosmopack Miami

Following is a rundown of some of the packaging suppliers and highlights we spotted on the show floor.

ABA Packaging

In addition to a wide variety of packaging products on display, including an array of aluminum components, ABA Packaging was highlighting their new lines of aluminum disc fitments for jars. Features include: safe protection of formulas; easy manual handling and self-centering. The lids are available in a range of shapes and sizes and can be embossed or printed. They are also suitable for automatic processing when stacked.Above Aerosol Labs

Above Aerosol Labs and Pacific Bridge Pack have united as a leader in hair spray packaging. The CA-based filler can work with low MOQs. Pacific Bridge has a large inventory of aluminum cans for aerosol packaging— ”providing a supply chain solution for a shortage.”AGI Greenpac

AGI Greenpac claims to be India’s leading glassmaker, with a wide range of specialty and commercial glass—and globally, one of the largest for nail polish bottles, to fragrances to candles to spirits. Operating three state-of-the-art manufacturing plants in India, AGI caters to marquee international brands in the non-alcoholic and alcoholic, pharmaceutical, and F&B sectors. Complementing these, AGI’s specialty plant “is meticulously designed to meet the unique requirements of the cosmetics and perfumery industry, with an unwavering commitment to serving the discerning needs of the global market.”The company offers comprehensive solutions by integrating the molding, bottling, and decoration processes under one roof, “ensuring customer confidentiality and offering a one-stop-shop for all their requirements.”

Allta

One of Allta’s products of interest was their lip masque, a cream that looks like colorful ice cream in a jar.APC Packaging

For brands looking for packaging from mono-material strategies to refillable alternatives, to the sophistication of glass, integrating post-consumer recycled (PCR) materials, or opting for all-plastic solutions, APC Packaging unveiled an array of EcoReady Packaging Solutions at Cosmoprof Miami. Among the highlights were two “revolutionary” all-plastic airless pumps, the EJA and EAPP, distinguished by their innovative design that’s free from metal springs. Additionally, the BRGP showcased an elegant glass airless pump equipped with refillable and recyclable cartridges. The showcase also featured a collection of refillable jars crafted from glass, PET, and PP, each paired with recyclable inserts, alongside their new ERAJ airless jar (shown) boasting refillable and recyclable inserts.APR Packaging

At APR Packaging, John Shen, CEO, showed Beauty Packaging one of their latest smash hits: stick-on nails in a package. Shen emphasized there is no need to go to a salon—and the set, with dissolvable glue, lasts for a week.Baralan

Baralan is making refillables as attractive as possible. One example was a fragrance vial that was placed within a 3D printed filigree casing, which one would definitely want to treasure as a keepsake and continue to purchase refills.Bayport Laboratories

Bayport Laboratories, based in Houston, Texas, and founded by Angle Camacho, was on the show floor, showcasing their many formulations for skincare, hair and color, as well as turnkey. The supplier has extensive experience in product development and unique formulations, with machinery for “any product and customers’ needs.” One of their specialties is producing samples in as little as two weeks, with production in three months.Brivaplast

Brivaplast’s new Virtuality collection was created to spark imagination toward the future of makeup; “what colors and textures could be on trend in a reality of a hyper-realistic digital world where technology boosts creative power.”Valentina Manera, marketing director of Brivaplast, explained, “Our metallic and holographic visual makeup experimentation created both a futuristic goddess in the real world, matched against their AI-generated model—a mirror game between the two worlds.”

Manera pointed to the collection’s easy-to-use flocked applicator, with a large dimension and curved shape that offers two large application surfaces for oversized formula loading. The mascara brush is made with B Brivaplast shaped fiber. This fiber design of a “b” creates a reservoir along the entire single filament which increases the loading of the formula. The shape of this flocked applicator, which is reminiscent of “a painting tool,” makes it possible to easily light up facial features like a cupid arch, the edge of the eyes and the nose. Its design ensures an extremely precise application. It is suitable for all formulas that need to be applied accurately.

The mirrored cuts on each side enable, with just one dip in the formula, to make-up the lower and upper lip by switching sides. The slanted front is ideal to define the contour of the lips and draw precise lines.

Cohere Beauty

Cohere Beauty, a full-service provider, is made up of 4 partner companies and offers a combined 180 years of experience in formula incubation and manufacturing. In formulas, they produce droplets to serums to masks for hair care and skincare. Products range from mass to prestige to luxe. Tony Kirk, COO, said that turnkey has become extremely popular, and they can take a brand from ideation to process to shelf.Coverpla

An expanded selection of new in-house deco capabilities, including pad printing, silk-screening and hot stamping are now available at Coverpla—from low MOQs of 1,000. A large array of plastic caps is also available, with all manufacturing, customization and printing also done in-house. The France-based supplier is currently working on developing new molds and plastic cap assembly, also for low MOQs.Elcos

A new airless refillable glass jar at Elcos allows the consumer to just “punch in” the refillable rather than screw it in. “Just drop in and assemble,” said Michelle Joo, Vice President, who said they were in the process of getting an international patent on the jar. The idea? Make it as easy as possible for the consumer to recycle—and “they don’t have to worry about anything malfunctioning or breaking during the refill process—no broken pumps to return.”Express Tubes

Seattle, Washington—based Express Tubes was highlighting the increased amounts of PCR materials that they are now able to incorporate into their glass and plastic packaging options—in some cases, up to 100%. John Turville, General Manager, said that former high percentages of 60% were increasing thanks to expanded and new recycling methods. He explained that technology for production is catching up with demand.Fusion Packaging

At Fusion Packaging, Jessica Tarangioli President of Marketing & Turnkey, showed Beauty Packaging some of the company’s new “supersized’ packaging for skincare products, available as full families from 50- 250ml. She explained that many brands are requesting larger capacities for jars, tubes and airless. Jumbos are offered in mono-materials with a metal-less pump. With both color and skincare trends on the rise, Fusion is also branching more into color. Their Squeeze-it package is ideal for “the ultimate in fluid dispensing.”HCT by KDC/One

At CPM, David Greco, Executive Vice President Business Development at HCT by KDC/One highlighted end-to-end full turnkey solutions (designed for speed to market), and also spoke about innovative packaging, formulation, brushes, accessories and devices. Greco said the company has the largest selection of stock components. The new Nora bottle, which has soft curves, is available in a variety of sizes, including a large size for shampoos, body products, etc., which Greco said has been a trend. Interest at the show was also in refillables, such as 4-well compacts.K1 Packaging Group

Custom packaging provider K1 Packaging Group offered a “one-stop solution” for primary and secondary items, including primary structural packaging design and engineering. The company manufactures coated corrugated boxes, which are resistant to moisture and so, help in increasing the longevity of the products. They also offer molded pulp packaging.KG International

Miami-based full-service primary packaging supplier KG International offered a wide range of packaging solutions regardless of size and volume—from bottles to caps, rigid to flexible, simple to custom, clear to colored. Options include sugar cane resins for PCR, rPET (from 10%-100%).Lady Burd

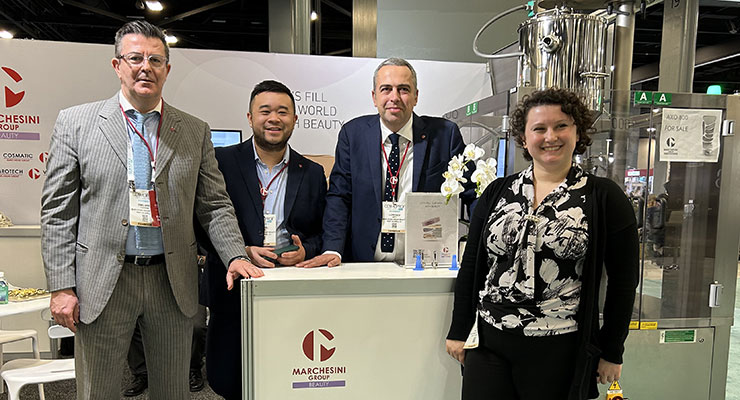

At cosmetics specialist Lady Burd, Samantha Burd told Beauty Packaging that their new line of lip oils was seeing a lot of interest. She also teased that the supplier will soon launch their first line of shampoos and conditioners.Marchesini Group Beauty

Bologna, Italy—based Marchesini Group Beauty, with North American headquarters in West Caldwell, NJ, provides modular and turnkey solutions for the processing and packaging of cosmetic products, and is in the midst of growing their beauty side of the business. Celebrating its 50th anniversary this year, the company was at CPM to showcase some of its machinery solutions. They spoke to attendees about their many custom solutions for companies of all sizes—from small indie brands to multinational corporations—including complete full lines of emulsifiers, to tube fillers to cartoning and pelletizing. According to Marchesini, they have the only equipment that can do the processing of complete lines from lipstick to creams to cleansers to nail polishes. What’s selling most right now? The answer is Cartoners.Morae Packaging

Korea-based manufacturer Morae Packaging specializes in full turnkey production for the beauty industry, manufacturing glass, plastic and molding machinery. The company headquarters are located in Mahwah, NJ. The sustainable packaging-focused supplier offers eco-friendly glass and plastic products “that meet the highest standards.” A wide range of decorative options is available, including anodizing, embossing, debossing, hot stamping and spraying.New High Glass

New High Glass, which says it takes brands “from concept to reality,” featured a wide variety of options, both stock and custom, for products from fragrance to skincare. The Miami-based company has four fulfillment warehouses around the country. A wide variety of decorative finishes are available, including spray frosting, screen printing and color spray.NF Beauty Group

NF Beauty Group displayed a wide range of cosmetic packaging in Miami, including their popular Eco Jar, a fully recyclable glass jar base and aluminum cap. Mono-material and all-aluminum recyclable options were also popular.ProSys

ProSys highlighted their LB30 Lip Balm Filler at Cosmoprof Miami. The semi-automatic hot melt filling line that fills, cools, and caps lip balm sticks created a lot of interest for its efficiency, high speed, pricing and client support. The machinery was designed and manufactured by its exclusive partner Pendergraph Machines. The semi-automatic hot melt filling line fills, cools, and caps lip balm sticks at a machine cycle rate of up to 30 per minute. Also, on display at the booth was the HL-30 labeler, which was used to place labels on the lip balm sticks being filled at the show.The LB30 Lip Balm Filler features a manual loading station with an angled guide that allows for easy loading and a quick-change puck mounting system that enables toolless changeovers among different sizes. The LB30 offers puck tooling that fits most lip balm brands .15-ounce 500 style tubes, including those used by Inpres, Federal, CCP, and Sapona. An on-board cap sortation station features a gravity cap track to present caps for the auto capping station and the positive cap sap station ensures caps are pressed on completely.

Qosmedix

At CPM, Qosmedix displayed an extensive collection of cosmetic packaging, essential hygienic applicators, beauty tools and accessories, and much more. The Long Island—based company has greatly expanded its hair supply category collection with new brushes and combs, capes, printed foils and more—many of which can be customized with brand logos. As far as their wide range of packaging, Sari Sternschein, President, “said, “It’s all about sustainability.”Seacliff Beauty

Seacliff Beauty offered numerous packaging and full-service solutions at CPM. Vonda Simon, founder and CEO, told Beauty Packaging, “Environmental consciousness is essential in the beauty industry, and Seacliff Beauty strives to exceed expectations by investing in the research and development of eco-friendly packaging solutions.”From formulation, development, and design to packaging and assembly, Simon said, “Seacliff provides a one-stop, full-service solution that brings brands and products to life. Our strong partnerships with formulators, researchers, and engineers ensures you have access to the most ground-breaking ingredients and technology.”

With a passion for sustainability, Simon said, “We feel that environmental consciousness is essential in the everchanging world of beauty. Sustainability has become a fundamental part of corporate responsibility and Seacliff Beauty has strived to exceed expectations by investing in research and development of environmentally friendly solutions, including initiatives such as aligning with a Swiss company called #tide Ocean Bound material that offers 100% ocean-bound plastics.