Beauty Packaging Staff03.02.20

Lindal Group has launched a new platform that helps products reach the market more quickly.

Officially unveiled at ADF Paris in January, the Mini Engine Platform incorporates new actuator designs made from Post-Consumer Resin (PCR), a material produced using recycled plastic waste. The patent-pending technology works by separating a one-piece actuator into two elements: an outer body made from 100% PCR and an internal ‘Mini Engine’ which produces optimum spray performance. Existing manufacturing technology can be re-utilized to produce the platform, making adoption simple and economical.

Kashif Choudhry, LINDAL Group Marketing Manager, said: “Sustainability is obviously very important to our customers, and thanks to the Mini Engine’s credentials, businesses can make a positive environmental difference.”

Flexible and Smart

Not only is the MiniEngine Platform sustainable, but once it is adopted into the industry, it will enable products to be brought to market more quickly. Only the outer body tooling equipment and simple customization of assembly lines is required to implement the platform, reducing both product development time and costs. Additionally, product stability and spray performance testing can begin straight away, without the need to finalize the product design. Once the Mini Engine is validated, repeat testing is not required.

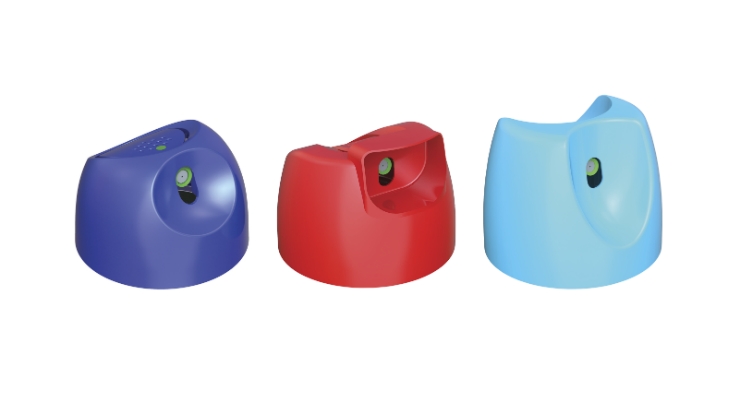

The actuator’s outer body can be adapted for standard can diameters ranging from 35 to 65 millimeters and larger, with several different colors and stock designs available. If more bespoke specifications are required, customer specific designs can be created.

Officially unveiled at ADF Paris in January, the Mini Engine Platform incorporates new actuator designs made from Post-Consumer Resin (PCR), a material produced using recycled plastic waste. The patent-pending technology works by separating a one-piece actuator into two elements: an outer body made from 100% PCR and an internal ‘Mini Engine’ which produces optimum spray performance. Existing manufacturing technology can be re-utilized to produce the platform, making adoption simple and economical.

Kashif Choudhry, LINDAL Group Marketing Manager, said: “Sustainability is obviously very important to our customers, and thanks to the Mini Engine’s credentials, businesses can make a positive environmental difference.”

Flexible and Smart

Not only is the MiniEngine Platform sustainable, but once it is adopted into the industry, it will enable products to be brought to market more quickly. Only the outer body tooling equipment and simple customization of assembly lines is required to implement the platform, reducing both product development time and costs. Additionally, product stability and spray performance testing can begin straight away, without the need to finalize the product design. Once the Mini Engine is validated, repeat testing is not required.

The actuator’s outer body can be adapted for standard can diameters ranging from 35 to 65 millimeters and larger, with several different colors and stock designs available. If more bespoke specifications are required, customer specific designs can be created.