Jamie Matusow, Editor-in-chief03.16.16

A recent study from Priority Metrics Group shows that service attributes are more important than product characteristics in driving purchases of packaging containers, materials, equipment and supplies. Packaging buyers identified the most important factors as responsiveness, communication, customer service and accessibility—even higher than innovation.

Why is innovation no longer the No. 1 priority? To determine the answer, Jamie Matusow, Beauty Packaging’s editor-in-chief, spoke with Anthony DeMarco, executive vice president, HCT Group, which has a number of beauty brand customers they have served for decades. What has been key to these long-term relationships? DeMarco says: Responsiveness, communication, customer service and accessibility. Innovation is the icing on the cake.

Jamie Matusow: How did HCT Group get started in the cosmetics packaging industry, and how has the company evolved?

Anthony DeMarco: HCT was launched in London in 1992 by founder Chris Thorpe. His first customer was the UK’s popular pharmacy brand Boots. But it was the iconic MAC brand that changed everything for HCT. Chris Thorpe is fond of saying he personally designed the MAC line years ago when he convinced the owners to make their products stand out by changing the packaging. He persuaded the two owners of MAC to bring their makeup innovation to their packaging. Designing a hinged pot, in a gun metal color was the changing point that put HCT on the map as the leader in innovative packaging.

Today, HCT is a global business with offices in New York, New Jersey, Santa Monica, London, Paris, Hong Kong and Shanghai. We design, develop and produce for brands including Estée Lauder, MAC, Bobbi Brown, Urban Decay, NARS, Laura Mercier, Givenchy, Avon and Sephora—among many others.

The company has grown to include manufacturing in Asia that encompasses three plastic injection factories, one metal casting and stamping facility, an electroplating facility, a brush factory, two fill and assembly facilities and a partner airless pump factory. While the company has grown tremendously, it has always remained relevant to its customers’ needs.

JM: When it comes to service, what makes HCT stand out as a packaging supplier? What has been the secret to keeping a customer happy all this time?

AD: There is no one secret. It’s a combination of innovation, quality, attention to detail and knowing your customer. One would automatically think HCT is strong in innovations. Yes, this is true, but it’s not enough. It’s about knowing your client. It’s about every experience being unique, because every client is unique. We bring ideas and formulas that complement their brand.

JM: How does the customer influence the supplier? And vice versa? Can you give me an example or two?

AD: Every brand has a distinctive DNA. Being able to take that DNA and help create a unique package or a full turnkey solution is a challenge that motivates us every day at HCT. We are capable of translating global trends into viable and long-lasting products for our customers.

For example, NARS is famous for their minimalist packaging, so we always keep that in mind when working with the brand. On the other end of the spectrum, brands like Urban Decay strive for flamboyant innovations.

JM: How does HCT work with its clients on these partnerships?

AD: Many strong partnerships have been forged over the years due to the trust we’ve earned from our clients. They know that we are fully vested in delivering the best products possible. Our commitment to their success equates to our success.

We build partnerships with our customers, helping them take their brands to the next level by giving them the ability to compete through innovation.

The partnerships that have been forged over the years are priceless. Take MAC for example. Chris Thorpe was dealing with the original founders of MAC (Frank and Frank), and to this day we work very closely with the brand.

JM: What qualities does HCT pride itself on when creating packaging for brands?

AD: Innovation. HCT uses that word a lot, but it’s the cornerstone of our philosophy. At HCT we are passionate about innovation and bringing it to our customers.

When creating packages from scratch for a brand, such as holiday palettes for Bobbi Brown or Laura Mercier, we must make sure to capture the true essence of the brand. We make sure that every detail, no matter how minor, captures and complements the brand image.

JM: Are most packaging launches custom? How does stock fit in?

AD: HCT is unique in that we are always creating innovative designs, yet we have one of the most extensive stock libraries of components in the industry.

Today, many clients are looking for shorter lead times and quicker to market launches. Stock tools are used for many new launches. Simply through changing the color of the components and adding new graphics, you’ve now customized the stock package.

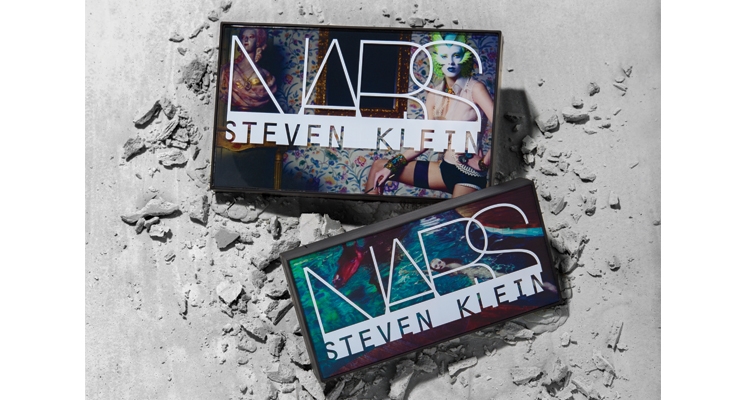

Take the NARS palettes, for instance. We use the same palette footprint, but by changing the artwork on the cover plaque, a new look is created for each season. For the recent NARS Steven Klein collection, we employed a unique process to achieve the high-resolution photos. Using a special resin for the plaque, we used a front adhesive heat transfer label on the back of the plaque to achieve a high-quality photographic 3D effect.

JM: What are some of the most innovative packaging ideas you’ve created for brands over the years?

AD: There have been many. Three memorable ones come to mind—they launched several years ago and are still going strong.

Our patented Cooling Tip Technology® has had numerous iterations to keep it fresh and exciting, from metal tips, to ceramic tips and now gel tips.

Another unique innovation that comes to mind is the Bobbi Brown eye shadow and blush customizable mono compacts and palettes. Launched eight years ago and still popular, the compacts were developed so that the consumer can pop out the godets from their single shade compacts into a larger palette to customize their own face palette. Therefore, each palette is unique and custom to the consumer’s likes.

Another innovation is our pro powder eye shadow pot. This unique mess free component features a cleverly designed inner cone that ensures just the right amount of loose powder is picked up by the bristles of the built-in brush. The design also reduces the risk of product spillage, making this component ideal for on-the-go makeup application.

What’s better than supplying an innovative package to a client? It’s providing an innovative package with a unique formula, as a full turnkey component. We did just that with our partner Laura Mercier. We used the pro powder unit with an in-house loose powder formula filled at our partner factory, supporting Laura Mercier’s Fairy Dust program.

JM: What is most important to brands today as far as packaging?

AD: Jamie, I agree with Priority Metrics Group, it’s all about responsiveness, communication, customer service and accessibility, in addition to having the right price and excellent quality.

The industry is moving at such a fast pace with quick-to-market launches that you need to be on top of your game. Clients have their plates full and are juggling multiple programs at one time; they need to partner with a supplier that complements their sense of urgency.

So to be just a quality molder is not good enough. You need to know your client, you need to be responsive and you need to be proactive. At HCT, we pride ourselves on providing excellent service.

Although innovation has always been the blood that runs through our veins, it’s not enough. With many of our key clients—or as I prefer to call them, our partners—we provide around-the-clock service. What I mean by that is that we tackle a development with a team approach. Our partners have direct access to our designers, engineers, project managers—and of course, their lead salesperson.

Why is innovation no longer the No. 1 priority? To determine the answer, Jamie Matusow, Beauty Packaging’s editor-in-chief, spoke with Anthony DeMarco, executive vice president, HCT Group, which has a number of beauty brand customers they have served for decades. What has been key to these long-term relationships? DeMarco says: Responsiveness, communication, customer service and accessibility. Innovation is the icing on the cake.

Jamie Matusow: How did HCT Group get started in the cosmetics packaging industry, and how has the company evolved?

Anthony DeMarco, executive vice president, HCT Group

Today, HCT is a global business with offices in New York, New Jersey, Santa Monica, London, Paris, Hong Kong and Shanghai. We design, develop and produce for brands including Estée Lauder, MAC, Bobbi Brown, Urban Decay, NARS, Laura Mercier, Givenchy, Avon and Sephora—among many others.

The company has grown to include manufacturing in Asia that encompasses three plastic injection factories, one metal casting and stamping facility, an electroplating facility, a brush factory, two fill and assembly facilities and a partner airless pump factory. While the company has grown tremendously, it has always remained relevant to its customers’ needs.

JM: When it comes to service, what makes HCT stand out as a packaging supplier? What has been the secret to keeping a customer happy all this time?

AD: There is no one secret. It’s a combination of innovation, quality, attention to detail and knowing your customer. One would automatically think HCT is strong in innovations. Yes, this is true, but it’s not enough. It’s about knowing your client. It’s about every experience being unique, because every client is unique. We bring ideas and formulas that complement their brand.

JM: How does the customer influence the supplier? And vice versa? Can you give me an example or two?

AD: Every brand has a distinctive DNA. Being able to take that DNA and help create a unique package or a full turnkey solution is a challenge that motivates us every day at HCT. We are capable of translating global trends into viable and long-lasting products for our customers.

For example, NARS is famous for their minimalist packaging, so we always keep that in mind when working with the brand. On the other end of the spectrum, brands like Urban Decay strive for flamboyant innovations.

JM: How does HCT work with its clients on these partnerships?

AD: Many strong partnerships have been forged over the years due to the trust we’ve earned from our clients. They know that we are fully vested in delivering the best products possible. Our commitment to their success equates to our success.

We build partnerships with our customers, helping them take their brands to the next level by giving them the ability to compete through innovation.

The partnerships that have been forged over the years are priceless. Take MAC for example. Chris Thorpe was dealing with the original founders of MAC (Frank and Frank), and to this day we work very closely with the brand.

JM: What qualities does HCT pride itself on when creating packaging for brands?

AD: Innovation. HCT uses that word a lot, but it’s the cornerstone of our philosophy. At HCT we are passionate about innovation and bringing it to our customers.

When creating packages from scratch for a brand, such as holiday palettes for Bobbi Brown or Laura Mercier, we must make sure to capture the true essence of the brand. We make sure that every detail, no matter how minor, captures and complements the brand image.

JM: Are most packaging launches custom? How does stock fit in?

AD: HCT is unique in that we are always creating innovative designs, yet we have one of the most extensive stock libraries of components in the industry.

Today, many clients are looking for shorter lead times and quicker to market launches. Stock tools are used for many new launches. Simply through changing the color of the components and adding new graphics, you’ve now customized the stock package.

Take the NARS palettes, for instance. We use the same palette footprint, but by changing the artwork on the cover plaque, a new look is created for each season. For the recent NARS Steven Klein collection, we employed a unique process to achieve the high-resolution photos. Using a special resin for the plaque, we used a front adhesive heat transfer label on the back of the plaque to achieve a high-quality photographic 3D effect.

JM: What are some of the most innovative packaging ideas you’ve created for brands over the years?

AD: There have been many. Three memorable ones come to mind—they launched several years ago and are still going strong.

Our patented Cooling Tip Technology® has had numerous iterations to keep it fresh and exciting, from metal tips, to ceramic tips and now gel tips.

Another unique innovation that comes to mind is the Bobbi Brown eye shadow and blush customizable mono compacts and palettes. Launched eight years ago and still popular, the compacts were developed so that the consumer can pop out the godets from their single shade compacts into a larger palette to customize their own face palette. Therefore, each palette is unique and custom to the consumer’s likes.

Another innovation is our pro powder eye shadow pot. This unique mess free component features a cleverly designed inner cone that ensures just the right amount of loose powder is picked up by the bristles of the built-in brush. The design also reduces the risk of product spillage, making this component ideal for on-the-go makeup application.

What’s better than supplying an innovative package to a client? It’s providing an innovative package with a unique formula, as a full turnkey component. We did just that with our partner Laura Mercier. We used the pro powder unit with an in-house loose powder formula filled at our partner factory, supporting Laura Mercier’s Fairy Dust program.

JM: What is most important to brands today as far as packaging?

AD: Jamie, I agree with Priority Metrics Group, it’s all about responsiveness, communication, customer service and accessibility, in addition to having the right price and excellent quality.

The industry is moving at such a fast pace with quick-to-market launches that you need to be on top of your game. Clients have their plates full and are juggling multiple programs at one time; they need to partner with a supplier that complements their sense of urgency.

So to be just a quality molder is not good enough. You need to know your client, you need to be responsive and you need to be proactive. At HCT, we pride ourselves on providing excellent service.

Although innovation has always been the blood that runs through our veins, it’s not enough. With many of our key clients—or as I prefer to call them, our partners—we provide around-the-clock service. What I mean by that is that we tackle a development with a team approach. Our partners have direct access to our designers, engineers, project managers—and of course, their lead salesperson.