Joanna Cosgrove, Contributing Editor07.25.16

If you think stock packaging is a humdrum alternative to custom-made packaging, you’re mistaken. Stock packaging has the exciting, chameleon-like ability to adapt to whatever a product requires. In the beauty and personal care markets where speed to market is essential, stock packaging offers a variety of time- and cost-saving advantages, making it a smart alternative to custom packaging for global and niche brands alike.

One of stock packaging’s chief advantages is its cost savings benefit. “The savings in time from selection of a stock container to first delivery of the product can be up to 90 or more days,” says Lou Della Pesca, president, 3C Inc., Hawthorne, NJ. “The cost savings for custom tooling can range from a few thousand for a simple cap to $40,000 or more for a compact.”

Tooling costs are often one of the most prohibitive cost factors when starting out with a new brand or line. With stock packaging, these costs are already amortized by the packaging supplier. Jean Paul Corbeil, CEO, Corpack, Munich, Germany, says that ready-made tooling and molds not only decrease costs, but also lead times.

Walter Dwyer, president, Port Washington, NY-based Cosmopak, says that with stock packaging, there’s also less chance of encountering quality and functionality defects since the item has been made several times. “Any small issues have more than likely been resolved,” he explains.

Jackie Mantle, managing director, HCP Packaging UK Ltd., Dorset, UK, says shopping for packaging from a stock library is an important consideration, not just for complete line launches but also for “infill” of existing ranges (think limited or seasonal product editions) that have lower start up and capital investment costs and require faster speed to market.

“MOQs, long production and shipping lead times, port delays, they can all combine to eat up months between product conception and packaging delivery,” agrees Robert McDermott, director, technical sales, East Hill Industries Inc., Carrolton, TX. He adds that in-stock, on-demand packaging helps brands get their products to market quickly, often within weeks. “Stock packaging’s comparatively low minimum order quantities (often packaging can be ordered by the case-load) also helps brands large and small get to market.”

In addition to cost savings and quick turnaround, the third quality that makes stock packaging shine is its receptivity to decoration, enabling brands to develop a package that looks custom-created.

“The realm of ‘customized stock’ packaging has been visually enhanced quite a bit over the years due to the variety of surface treatments and decoration techniques available to the industry now,” comments Corbeil. “The variations in colors, effects and texture that can be applied to the packaging these days has increased immensely and thus a standard package can quickly obtain a totally different look or appeal without having to create a custom design or tooling. In other words, standard packaging can be differentiated through these techniques, creating an entirely different look without functionally changing the packaging.”

Mantle says decorating techniques can range from the simple to the complex. “Increasingly, the use of more complex added-value finishing and highly decorative effects are being specified to catch the consumer’s attention, so packs stand out on-shelf,” she says. “Techniques available include shiny or matte metallization in special colors, the use of gradient effects, 3-D water droplet technology, and pearl and tactile soft touch sprays.

In addition to offering color-matching of inks and a wide range of foils to match the brand livery, Mantle says HCP’s newly developed specialty sprays include a ‘Fireworks’ spray, which she describes as “a cacophony of color literally ‘exploding’ on the surface of the container.”

CPP Global, Asheboro, NC, has elevated the potential of plastic with Metalook, a proprietary, environmentally friendly technique that gives plastic componentry the appearance of a metal finish. “Metalook is applied both in our U.S. and China facilities, creating advantages in lead time and meeting domestic sourcing requirements with many of our customers,” says Beth Joyce, the company’s marketing director. “CPP Global recently completed a project that required multiple sizes of stock jars to be decorated with Metalook, silk screening and a UV top coat. Because of our ability to do all of these processes in house, on stock jars, it was cost- and lead-time effective for our customer.”

Brand Advantages

Stock packaging’s near limitless customizability has made it increasingly attractive to brands both large and small. Fort Lauderdale, FL-based APC Packaging works extensively with Dr. Brandt skin care, a high-end, global niche brand that is always on the lookout for unique, innovative, customizable packaging that can be personalized to fit in not only with their brand image, but that also tells the story of their products.

The latest addition to the range of packaging APC provided for the Dr. Brandt skin care company is a customized acrylic jar to house its time- reversing cream, part of the brand’s Do Not Age product line. “The story of that line is centered around dual encapsulated pearls, so to incorporate the packaging for that product into the existing product line we went with an acrylic jar from our JZ series that has a round shaped center encased in acrylic,” explains Jennie Crumpler, APC’s creative manager.

The outer portions of the acrylic jar were left clear while the inner portion was embellished with a pearly white spray, creating the effect of an encapsulated pearl. The company’s signature hot foil silver band was then applied to the center closing portion of the jar to keep it visually in line with their other products.

British beauty brand Charlotte Tilbury took advantage of HCP Packaging’s stock range of compacts, using it as a springboard for a high-end, customized look. “Charlotte Tilbury has been a stunning success story utilizing stock compacts from HCP that have been designed with high quality aluminum top plates featuring the CT logo and engraved effects to give a vintage, art-deco brand image,” comments HCP’s Mantle. “HCP has also designed customized inserts for this now iconic brand incorporating the debossed brand name and product layouts using selected standard pan sizes.”

Mantle adds that HCP specializes in the design and creation of stock packaging where one part of the component can be customized. “For example, the top plate of the flexible Radii round and square [compact] ranges can be replaced with multi-colored printed card, highly decorative metal sheets or gel technology, customizing the range in such different styles that they look uniquely individual,” she says.

Pacifica Beauty has an ongoing relationship with Viva Healthcare Packaging to produce colorful tubes for its line of Body Butters. The company uses Viva’s 8oz injection molded tubes with in mold labels and all components are manufactured and printed under the same roof in Viva’s Toronto, ON facility.

The tube is a 48.5mm in diameter and made out of 100% polypropylene number 5. “The tube is fully recyclable without having to separate any of the tube component and requires up to 35% less energy to produce,” says Viva’s Bruno Lebeault, marketing director North America.

He noted that Viva IML Tubes had a comprehensive Life Cycle Analysis (LCA) done on its IML tubes to confirm how sustainable the technology is—something that was important to Pacifica. “Pacifica…is extremely keen on communicating about the sustainability of its formulas as well as of its tubes,” he says. “The fact that both the tube and the cap are made out of the same resin making it fully recyclable, is clearly communicated on the tube for the consumer, who is paying attention to these details.”

In order to meet Pacifica’s needs, Lebeault says the company provides Viva with a forecast six months in advance to give the company time to print the totality of in-mold labels and mold in advance the flip top caps for that period of time. “When tubes are needed, tube molding is launched in record time so that Pacifica can meet its customers’ aggressive time lines as the brand enjoys tremendous growth,” he says.

Up-and-coming new beauty and skin care brand, LimeLight by Alcone, turned to 3C for a cost-effective lipstick packaging solution. The brand selected a cylindrical premium metal lipstick case with unique customizations. “They created a decoration for an area of the lipstick’s metal sleeve that has not been done before,” Della Pesca explains. “We developed and engineered a new slant tip design for the lipstick cap [and] the tooling cost to modify a current cap was far less than tooling costs for a complete custom lipstick case.”

Corpack’s Corbeil reports that the German cosmetic company Evora took advantage of Corpack’s Allegra stock packaging range for the relaunch of its color cosmetics line. “Evora used a 59mm and a 37mm mirrored compact, a lipstick, a nail lacquer, a mascara and a lipgloss from our Allegra line,” he says.

The Allegra line is comprised of SAN material, and all components are UV metallized in a special matte gold with a hot-stamped logo. “In this case we only had to color-match the pale, matte gold metallization for all components,” he says.

New Stock Debuts

Packaging providers are continuing to expand their in-stock offerings and related services thanks to the ongoing interest in stock tubes, bottles, jars and related componentry.

HCP Packaging is looking ahead to this fall’s Luxe Pack Monaco show, where it will launch a “chubby” version of its Fusion Glass Lip Gloss package. According to the company, the package displays all the desirable qualities of glass but none of the fragility. The bottle and base button are made of PETG material to provide an ultimate “glass-looking” pack and good formula compatibility. Boasting a fill capacity of 10.4ml (estimated fill of 7-8ml depending on the formula and applicator), this new HCP stock offering accommodates multiple applicator options to fit various formulas like matte and glossy lip lacquers, concealer/highlighters, brow grooming formulations and even eye color configurations.

With a nod to the interest in cushion-type formats currently all the rage in color cosmetics, Cosmopak recently added a range of 15- and 24ml cushion compacts to its stock repertoire. The sifters are available in mesh and “sun” shapes and brands can choose between either NBR or silicone. The packages are also available with or without a polyester urethane foam sponge. Initial testing has indicated that the compacts are airtight and best compatible with liquids. Testing on powdered formulations is still underway.

Smartstock is a stock packaging initiative from WhipSmart of Ronkonkoma, NY, that provides whole package solutions in keeping with the company’s reputation as a turnkey provider. “To date, most other packaging companies sell parts that the client has to validate for their end use,” says Bill Armstrong, president and CEO. “Our whole package solutions are intended to take the guesswork out of stock packaging.”

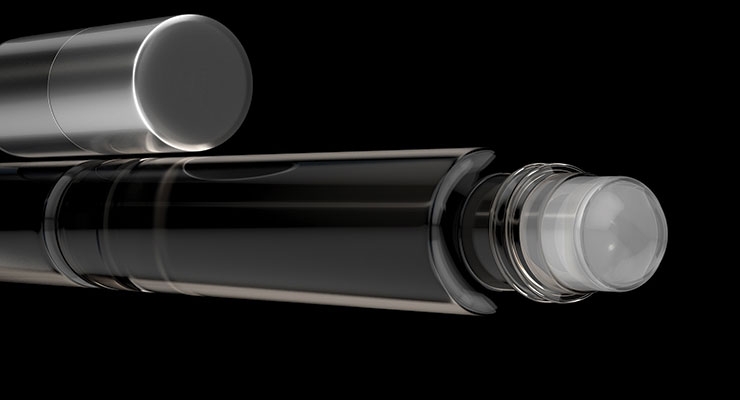

One of Smartstock’s most recent additions is the Touch Rollerball and Mist Fragrance samplers. Positioned as “complete fragrance sampling solutions,” the packages dovetail with WhipSmart’s existing stock fragrance offerings and are designed with evocative shapes, luxury weight and total versatility.

Carrolton, TX-based East Hill Industries Inc. recently added in-stock, on-demand 0.5oz and 1oz airless pump tubes to its eponymous Stock Tube Program. Developed with a cost saving and tamper evident integral pump head, “the pump tube offers a low-cost and flexible alternative to traditional airless pump packaging,” says the company’s Robert McDermott, director, technical sales. “The tubes can be printed or labelled in-house by East Hill for a quick turnaround [and are] easily and quickly filled by fillers with tube filling equipment.”

The company also grew its stock bottle range with the addition of a family of HDPE Bullet Bottles, available in 1oz, 2oz, 4oz, 8oz, 12oz, 16oz and 32oz sizes. Currently available in white, McDermott says the bottles can be paired with a multitude of cap, pump and in-house deco options to suit every requirement.

Amy Waterman, global marketing communications manager, Berry Plastics, Evansville, IN, says tactile enhancements like soft touch and embossing are also proving appealing to her company’s customers and their consumers. “Some of the stock offerings we have seen a lot of success with in the past year are: laminate tubes, bi-injection closures with a grip-like feature, jars, and new, premium decorating options that include a texture and metallizing,” she says, noting that Berry Plastics affords its customers the services of Blue Clover Studios, its full service design agency. “Our process allows our customers to take full advantage of ideation, realization, proof of concept and prototyping,” she says.

“We also provide consumer validation to ensure we’re delivering the benefit to the end-user.”

UA Packaging, Guangzhou, China, recently innovated its hot stamping process to achieve a detailed hot stamping foil decoration in one pass around a stock PP jar. “With this special hot stamping process we can add more unique and beautiful shiny foil designs all around a jar or bottle while keeping the cost low and efficiency high,” says Steven Peters, UA’s sales manager.

UA has an enormous library of more than 7,000 stock designs spanning traditional square and Boston round shapes, to ball shaped, tapered, oval and “body” shaped containers. “We recently launched a new heavy wall, 30- and 50ml PMMA jar, which should be especially attractive for high-end skin care brands,” Peters says. “With the heavy wall we get very close to emulating not only the look of glass, but also the weight of glass.”

ABA Packaging Corp., Holtsville, NY, maintains “stock from shelf” inventories of many popular packages including perfumery and treatment glass bottles, plastic and glass jars, pumps, caps, droppers, rollerballs, disc fitments and vials in its Holtsville, NY warehouse and at a number of remote locations. “Our ability to supply ‘stock from the shelf’ and ‘stock designs from existing tooling’ allows the purchaser to begin testing and design work very quickly which promotes speed to market,” says the company’s Michael Warford, director of sales. He adds that ABA is also partnered with world renowned glass manufacturers for access to a large selection of stock luxury glass perfumery bottles.

Packaging is often the first impression a brand makes on consumers at retail and stock packaging is proving to be an increasingly flexible and valuable way for brands to quickly and affordably communicate their messages.

One of stock packaging’s chief advantages is its cost savings benefit. “The savings in time from selection of a stock container to first delivery of the product can be up to 90 or more days,” says Lou Della Pesca, president, 3C Inc., Hawthorne, NJ. “The cost savings for custom tooling can range from a few thousand for a simple cap to $40,000 or more for a compact.”

Tooling costs are often one of the most prohibitive cost factors when starting out with a new brand or line. With stock packaging, these costs are already amortized by the packaging supplier. Jean Paul Corbeil, CEO, Corpack, Munich, Germany, says that ready-made tooling and molds not only decrease costs, but also lead times.

Walter Dwyer, president, Port Washington, NY-based Cosmopak, says that with stock packaging, there’s also less chance of encountering quality and functionality defects since the item has been made several times. “Any small issues have more than likely been resolved,” he explains.

Jackie Mantle, managing director, HCP Packaging UK Ltd., Dorset, UK, says shopping for packaging from a stock library is an important consideration, not just for complete line launches but also for “infill” of existing ranges (think limited or seasonal product editions) that have lower start up and capital investment costs and require faster speed to market.

“MOQs, long production and shipping lead times, port delays, they can all combine to eat up months between product conception and packaging delivery,” agrees Robert McDermott, director, technical sales, East Hill Industries Inc., Carrolton, TX. He adds that in-stock, on-demand packaging helps brands get their products to market quickly, often within weeks. “Stock packaging’s comparatively low minimum order quantities (often packaging can be ordered by the case-load) also helps brands large and small get to market.”

In addition to cost savings and quick turnaround, the third quality that makes stock packaging shine is its receptivity to decoration, enabling brands to develop a package that looks custom-created.

“The realm of ‘customized stock’ packaging has been visually enhanced quite a bit over the years due to the variety of surface treatments and decoration techniques available to the industry now,” comments Corbeil. “The variations in colors, effects and texture that can be applied to the packaging these days has increased immensely and thus a standard package can quickly obtain a totally different look or appeal without having to create a custom design or tooling. In other words, standard packaging can be differentiated through these techniques, creating an entirely different look without functionally changing the packaging.”

Mantle says decorating techniques can range from the simple to the complex. “Increasingly, the use of more complex added-value finishing and highly decorative effects are being specified to catch the consumer’s attention, so packs stand out on-shelf,” she says. “Techniques available include shiny or matte metallization in special colors, the use of gradient effects, 3-D water droplet technology, and pearl and tactile soft touch sprays.

In addition to offering color-matching of inks and a wide range of foils to match the brand livery, Mantle says HCP’s newly developed specialty sprays include a ‘Fireworks’ spray, which she describes as “a cacophony of color literally ‘exploding’ on the surface of the container.”

CPP Global, Asheboro, NC, has elevated the potential of plastic with Metalook, a proprietary, environmentally friendly technique that gives plastic componentry the appearance of a metal finish. “Metalook is applied both in our U.S. and China facilities, creating advantages in lead time and meeting domestic sourcing requirements with many of our customers,” says Beth Joyce, the company’s marketing director. “CPP Global recently completed a project that required multiple sizes of stock jars to be decorated with Metalook, silk screening and a UV top coat. Because of our ability to do all of these processes in house, on stock jars, it was cost- and lead-time effective for our customer.”

Brand Advantages

Stock packaging’s near limitless customizability has made it increasingly attractive to brands both large and small. Fort Lauderdale, FL-based APC Packaging works extensively with Dr. Brandt skin care, a high-end, global niche brand that is always on the lookout for unique, innovative, customizable packaging that can be personalized to fit in not only with their brand image, but that also tells the story of their products.

The latest addition to the range of packaging APC provided for the Dr. Brandt skin care company is a customized acrylic jar to house its time- reversing cream, part of the brand’s Do Not Age product line. “The story of that line is centered around dual encapsulated pearls, so to incorporate the packaging for that product into the existing product line we went with an acrylic jar from our JZ series that has a round shaped center encased in acrylic,” explains Jennie Crumpler, APC’s creative manager.

The outer portions of the acrylic jar were left clear while the inner portion was embellished with a pearly white spray, creating the effect of an encapsulated pearl. The company’s signature hot foil silver band was then applied to the center closing portion of the jar to keep it visually in line with their other products.

British beauty brand Charlotte Tilbury took advantage of HCP Packaging’s stock range of compacts, using it as a springboard for a high-end, customized look. “Charlotte Tilbury has been a stunning success story utilizing stock compacts from HCP that have been designed with high quality aluminum top plates featuring the CT logo and engraved effects to give a vintage, art-deco brand image,” comments HCP’s Mantle. “HCP has also designed customized inserts for this now iconic brand incorporating the debossed brand name and product layouts using selected standard pan sizes.”

Mantle adds that HCP specializes in the design and creation of stock packaging where one part of the component can be customized. “For example, the top plate of the flexible Radii round and square [compact] ranges can be replaced with multi-colored printed card, highly decorative metal sheets or gel technology, customizing the range in such different styles that they look uniquely individual,” she says.

Pacifica Beauty has an ongoing relationship with Viva Healthcare Packaging to produce colorful tubes for its line of Body Butters. The company uses Viva’s 8oz injection molded tubes with in mold labels and all components are manufactured and printed under the same roof in Viva’s Toronto, ON facility.

The tube is a 48.5mm in diameter and made out of 100% polypropylene number 5. “The tube is fully recyclable without having to separate any of the tube component and requires up to 35% less energy to produce,” says Viva’s Bruno Lebeault, marketing director North America.

He noted that Viva IML Tubes had a comprehensive Life Cycle Analysis (LCA) done on its IML tubes to confirm how sustainable the technology is—something that was important to Pacifica. “Pacifica…is extremely keen on communicating about the sustainability of its formulas as well as of its tubes,” he says. “The fact that both the tube and the cap are made out of the same resin making it fully recyclable, is clearly communicated on the tube for the consumer, who is paying attention to these details.”

In order to meet Pacifica’s needs, Lebeault says the company provides Viva with a forecast six months in advance to give the company time to print the totality of in-mold labels and mold in advance the flip top caps for that period of time. “When tubes are needed, tube molding is launched in record time so that Pacifica can meet its customers’ aggressive time lines as the brand enjoys tremendous growth,” he says.

Up-and-coming new beauty and skin care brand, LimeLight by Alcone, turned to 3C for a cost-effective lipstick packaging solution. The brand selected a cylindrical premium metal lipstick case with unique customizations. “They created a decoration for an area of the lipstick’s metal sleeve that has not been done before,” Della Pesca explains. “We developed and engineered a new slant tip design for the lipstick cap [and] the tooling cost to modify a current cap was far less than tooling costs for a complete custom lipstick case.”

Corpack’s Corbeil reports that the German cosmetic company Evora took advantage of Corpack’s Allegra stock packaging range for the relaunch of its color cosmetics line. “Evora used a 59mm and a 37mm mirrored compact, a lipstick, a nail lacquer, a mascara and a lipgloss from our Allegra line,” he says.

The Allegra line is comprised of SAN material, and all components are UV metallized in a special matte gold with a hot-stamped logo. “In this case we only had to color-match the pale, matte gold metallization for all components,” he says.

New Stock Debuts

Packaging providers are continuing to expand their in-stock offerings and related services thanks to the ongoing interest in stock tubes, bottles, jars and related componentry.

HCP Packaging is looking ahead to this fall’s Luxe Pack Monaco show, where it will launch a “chubby” version of its Fusion Glass Lip Gloss package. According to the company, the package displays all the desirable qualities of glass but none of the fragility. The bottle and base button are made of PETG material to provide an ultimate “glass-looking” pack and good formula compatibility. Boasting a fill capacity of 10.4ml (estimated fill of 7-8ml depending on the formula and applicator), this new HCP stock offering accommodates multiple applicator options to fit various formulas like matte and glossy lip lacquers, concealer/highlighters, brow grooming formulations and even eye color configurations.

With a nod to the interest in cushion-type formats currently all the rage in color cosmetics, Cosmopak recently added a range of 15- and 24ml cushion compacts to its stock repertoire. The sifters are available in mesh and “sun” shapes and brands can choose between either NBR or silicone. The packages are also available with or without a polyester urethane foam sponge. Initial testing has indicated that the compacts are airtight and best compatible with liquids. Testing on powdered formulations is still underway.

Smartstock is a stock packaging initiative from WhipSmart of Ronkonkoma, NY, that provides whole package solutions in keeping with the company’s reputation as a turnkey provider. “To date, most other packaging companies sell parts that the client has to validate for their end use,” says Bill Armstrong, president and CEO. “Our whole package solutions are intended to take the guesswork out of stock packaging.”

One of Smartstock’s most recent additions is the Touch Rollerball and Mist Fragrance samplers. Positioned as “complete fragrance sampling solutions,” the packages dovetail with WhipSmart’s existing stock fragrance offerings and are designed with evocative shapes, luxury weight and total versatility.

Carrolton, TX-based East Hill Industries Inc. recently added in-stock, on-demand 0.5oz and 1oz airless pump tubes to its eponymous Stock Tube Program. Developed with a cost saving and tamper evident integral pump head, “the pump tube offers a low-cost and flexible alternative to traditional airless pump packaging,” says the company’s Robert McDermott, director, technical sales. “The tubes can be printed or labelled in-house by East Hill for a quick turnaround [and are] easily and quickly filled by fillers with tube filling equipment.”

The company also grew its stock bottle range with the addition of a family of HDPE Bullet Bottles, available in 1oz, 2oz, 4oz, 8oz, 12oz, 16oz and 32oz sizes. Currently available in white, McDermott says the bottles can be paired with a multitude of cap, pump and in-house deco options to suit every requirement.

Amy Waterman, global marketing communications manager, Berry Plastics, Evansville, IN, says tactile enhancements like soft touch and embossing are also proving appealing to her company’s customers and their consumers. “Some of the stock offerings we have seen a lot of success with in the past year are: laminate tubes, bi-injection closures with a grip-like feature, jars, and new, premium decorating options that include a texture and metallizing,” she says, noting that Berry Plastics affords its customers the services of Blue Clover Studios, its full service design agency. “Our process allows our customers to take full advantage of ideation, realization, proof of concept and prototyping,” she says.

“We also provide consumer validation to ensure we’re delivering the benefit to the end-user.”

UA Packaging, Guangzhou, China, recently innovated its hot stamping process to achieve a detailed hot stamping foil decoration in one pass around a stock PP jar. “With this special hot stamping process we can add more unique and beautiful shiny foil designs all around a jar or bottle while keeping the cost low and efficiency high,” says Steven Peters, UA’s sales manager.

UA has an enormous library of more than 7,000 stock designs spanning traditional square and Boston round shapes, to ball shaped, tapered, oval and “body” shaped containers. “We recently launched a new heavy wall, 30- and 50ml PMMA jar, which should be especially attractive for high-end skin care brands,” Peters says. “With the heavy wall we get very close to emulating not only the look of glass, but also the weight of glass.”

ABA Packaging Corp., Holtsville, NY, maintains “stock from shelf” inventories of many popular packages including perfumery and treatment glass bottles, plastic and glass jars, pumps, caps, droppers, rollerballs, disc fitments and vials in its Holtsville, NY warehouse and at a number of remote locations. “Our ability to supply ‘stock from the shelf’ and ‘stock designs from existing tooling’ allows the purchaser to begin testing and design work very quickly which promotes speed to market,” says the company’s Michael Warford, director of sales. He adds that ABA is also partnered with world renowned glass manufacturers for access to a large selection of stock luxury glass perfumery bottles.

Packaging is often the first impression a brand makes on consumers at retail and stock packaging is proving to be an increasingly flexible and valuable way for brands to quickly and affordably communicate their messages.