Joanna Cosgrove, Contributing Editor12.05.16

Demand for contract services is growing by leaps and bounds. A study published by Mordor Intelligence valued the global contract packaging market at $22 billion in 2016 and projected its value to reach $39 billion by the end of 2021 (CAGR +10%). While the bulk of that dollar value is earmarked by the food, beverage and pharma segments, contract manufacturers and packagers affirm that the uptick in demand is being felt in the beauty and personal care segment, too. In recent years, beauty brands have increasingly partnered with contract service providers to fulfill their critical formulating, manufacturing and packaging needs, knowing that these allies will get the job done quickly and efficiently–which, in this market, isn’t just an asset, it’s a necessity.

Jack Rodriguez, president, JMR Development, New York, says contract service providers afford brands of all sizes the ability to enter and compete in the market quickly, without having to make the upfront investment in full development overhead. “Rather, they can use their seed money to invest in sales and market strategy and stay focused on cementing their brand narrative in the beauty space,” he says. “For larger more established brands, partnering with outside contract manufacturers and turnkey development firms gives them exposure to unique products or whole categories in which they currently don’t have a presence. And most importantly, they can do this without disrupting their internal development routine on their core products.”

Turnkey, or at-the-ready/á la carte products and services, are also great solutions for brands whose time is of the utmost essence, says Jill Manning, director of product innovation, Santa Monica, CA-based HCT Group, a full-service company that provides quality assurance and quality control services. “[Turnkey] is also a very convenient and efficient way to quickly expand a product line, cutting projected launch dates in half,” she says.

Pairing with the Right Partner

Sometimes brands need a contract packager for help with something relatively minor, like finding the right dispensing cap. Other times the job is more full service in nature. Take, for instance, a startup with a great idea, but one that needs an experienced partner with the know-how to shepherd them through the process of bringing a product to life: marrying the formula to the right package, making sure the market is sound, then getting it to market. In short, if you have a beauty-related conundrum, odds are, there’s a contract service provider with the skillset to help sort it out.

Many service providers offer a variety of convenient, one-stop options. “[When] manufacturing services are at one location, brands tend to receive far better communication and speed to market than if there are many companies in the process of creating, manufacturing, filling, and launching a product” says Melinda Wochner, chief marketing officer, CoValence, a Chandler, AZ-based service provider that specializes in formulating, manufacturing and filling. “Our clients who use different vendors for each piece of the manufacturing puzzle have found that communication and lead-times tend to be delayed which hinders their projected launch dates. Whereas, utilizing one company that can take on most, if not all, of the process will typically provide a brand with one point of contact who can help move orders through the manufacturing turnkey process with far less stress and far better lead-times and results for the brands.”

World Wide Packaging (WWP), Florham Park, NJ, takes a special interest in designing, launching and expanding beauty brands for the boutique, indie and prestige markets. “WWP links innovative formulas with the precise packaging needed to showcase the product,” says Rick Weisbrod, WWP’s executive vice president of global operations. “WWP’s team of specialists provides a comprehensive plan enabling a seamless evolution from concept to launch.”

WWP recently worked with Wander Beauty, a travel-inspired, luxury, multi-tasking makeup essentials brand, to create and fill a sleek and unique lipstick tube with an interchangeable core for its award-winning Wanderout Dual Lipstick range, which launched in March. The metal lipstick case is anodized in a rich burgundy color and hot stamped in shiny gold. What sets the package apart from typical lipstick tubes is that it’s dual-ended, giving on-the-go beauty mavens the flexibility to easily swap out a satin shade for a matte, or a neutral color for something a little bolder.

Darryl Do is a perfumer for the Delbia Do Company, a boutique manufacturer of fragrances and flavors, and contract filler in Bronx, NY. On the manufacturing side, he says companies like his are great resources for helping companies avoid making potentially harmful regulatory mistakes. “[For instance] about 10% of the brands that contact us didn’t realize that they can’t make perfumes or personal care products in their home/work space,” he says.

From a packaging perspective, Do says turnkey service options are especially great for companies that do not have an in-house purchasing agent to help sort out the intricacies of packaging componentry. “It goes beyond picking a bottle and cap option,” he says, noting that Delbia Do routinely helps customers navigate through component options such as quality, sizes, stock versus custom, etcetera. “We help our customers get their design concept into the best design option for them.”

Scaled Production Capabilities

Global brands and startups alike often have a need for small-volume manufacturing, whether it’s due to a limited budget or simply to test run a new product. This is another area where contract service providers have proven to be an ideal resource in terms of cost and time savings because many have low or no minimum buy requirements and have a broad network of packaging sources, both domestically and abroad to suit a variety of budgetary needs.

“The positive effect of this relationship would be one stop shopping and without compromising on the design of the formula or the packaging,” says Mayur Dave, president of M Plus LLC., Passaic, NJ, a contract manufacturer of liquids, gels, creams, muds and salts for hair care, skin care and bath and body.

M Plus specializes in high-end formulas using exotic oils and butters, which Dave says helps brands deliver a distinctive ingredient story. The company is currently developing a line of products for a celebrity hairdresser, using exotic oils and butters from Japan, Himalayas and the Atlas Mountains. The formulation is being developed exclusively for M Plus in Japan and mixed and filled here in its New Jersey facility.

“In the past, starting this type of line would have required a minimum of 10,000 pieces per unit and there are usually seven to nine products at the launch; by the time you’re done, your startup cost can easily climb upwards of $300,000 to $500,000,” says Dave.

“We are going to be able to develop this entire line without any minimum quantity requirements and this will enable the client to do a soft launch in many markets before placing a volume order.”

There are also times when brands experience the kind of success that requires unexpectedly quick (and stressful) production ramp-ups to meet increased demand. JMR’s Rodriguez, says fast-acting flexibility is another benefit to partnering with contract service providers.

As a specialist in custom beauty and beauty packaging development, Rodriguez says JMR appeals to brands that are “focused on disrupting a specific category that they feel may be oversaturated with stale or cookie-cutter style products.”

“This year we have executed full custom turnkey development for personal fragrance, home fragrance, bath and body, skin care and color cosmetics, but we do it on a boutique scale,” he says. “JMR remains a small outfit and we regulate our bandwidth by selecting the right client partnerships.”

One of JMR’s recent turnkey projects was for Sol De Janeiro (SDJ). A new bath and body brand, SDJ was picked up for full distribution by Sephora this year and Rodriguez says JMR successfully executed multiple SKUs under tight timelines.

“We have been with them from pretty much the beginning and primarily offer custom package design, package sourcing, custom formulating, and in most cases, supply them with complete finished goods,” he says. “When SDJ launched online for Sephora, they sold out in a day, and continue to exceed Sephora expectations. As a result, they were asked to fast track SKUs that were not on the planogram until next year.”

Rodriguez says JMR managed to quickly turn the new SKUs by using a carefully managed supply chain. “As the business continues to grow, JMR closely monitors the scalability needs of each SKU and makes adjustments to the supply chain accordingly on behalf of the client,” he says.

Innovation at the Forefront

When contract service providers focus on their core competencies, they can explore and push the bounds of innovation, investing capital in the development of new products so brands don’t have to.

Tainan City, Taiwan-based GCC Packaging Group focuses on premium beauty packaging designs and production, with a recent foray into skin care packaging. The company’s subsidiary, Grace Cosmetics, creates contract formulations.

GCC custom-develops packages utilizing a team of packaging engineers. Grace Chiu, managing director, explains that the company also actively partners and strategizes its packaging services with other co-packagers because it ultimately makes good business sense for customers. “The benefits of having this co-working relationship is time saving, firstly from my point of view, especially for new developments,” she says. “Each business provider has its own expertise. With the fundamental trust basis, more beautiful and professional ideas will be rocked out together—this is the beauty of cooperation.”

Among the company’s latest packaging innovations is Kiss Soul, a one-click makeup and lip concept that stands apart from traditional bullet lipsticks thanks to its button click mechanism. The company also has extensive expertise in palettes and compacts featuring decorative work that’s beyond standard and run of the mill. Recent launches feature an array of eye-popping decorative work, including dimensional inlay, distressed and shiny metals, domed 3-D plastic, and mother-of-pearl lacquer effects.

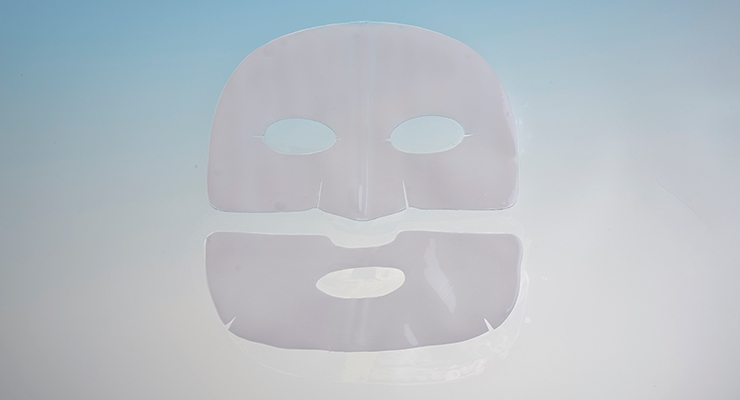

For some beauty brands, it pays to seek out suppliers of specific products and services. For instance, the popularity of Korean beauty treatments has contributed to a spike in the popularity of beauty treatment masks and convenient, pre-soaked tissue products. TaikiUSA, Montvale, NJ, is a supplier of wet tissue and mask products. The company is not only innovating to help meet the evolving diversifying demand for these products, but is also working with contract manufacturers to support the filling operation, helping to improve efficiencies for clients.

Taiki is the largest supplier of non-woven masks in Asia, producing 120 million annually. The company’s aquatic masks and gel patches come in various shapes and can be infused with custom serums. Made from biopolymer derived from seaweed carrageenan, TaikiUSA masks are environmentally friendly and biodegradable.

“For masks, Taiki is heavily involved in new product technologies,” comments Jim Perry, CEO and president, adding that the company’s latest mask advancements include an improved folding technology (which is key for optimized packaging and convenient dispensing/usage) and a new Hydrogel mask that delivers a cooling effect with increased adhesion and occlusion.

“Most of our masks are customized to meet the specific requirements/formula for each customer, but we do have the ability for filling masks in a Clean Room with preservative-free formulas.”

Innovation for Paris-based Alkos Group comes from the company’s umbrella of interconnected R&D laboratories, which produce industrialized and tailor-made “Made in France” lip and eye pencils, skin care and makeup, and perfumed soaps and stick deodorants for its beauty clients. One of the company’s best-selling innovations is the Jumbo Twist Mania, a chubby pencil format that can flexibly house lip color, eyeshadow, concealer or highlighter, and can even be augmented to accommodate airtight formulas, according to Alkos Group’s Florence Lefeuvre, group sales, marketing and communication director.

Chicago, IL-based Essentra is a global supplier specializing in cartons, labels, leaflets and tapes, as well as security solutions for anti-counterfeiting, serialization, authentication and tamper verification. The company also specializes in bespoke creative design through its new Design Hub facility, which is home to a new service that marries creative packaging design with extensive manufacturing capabilities.

“Experts can work together with brands to choose the perfect features, finishes, structures and overall visual designs,” explains the company’s Rupert Taylor, global category manager, healthcare and personal care. “Plus by working across a range of stock keeping units (SKUs), brands can be sure that all products are coherent, complement each other and are ready for sale.”

Essentra showcased the Lotus Pack, a blooming, floral-shaped carton encased in a clear acetate pyramid, at this year’s Luxe Pack Monaco. The elegant box was not only developed at Essentra’s Design Hub, it also showcases a wide range of the company’s capabilities including hot and cold foiling, varnishing, embossing, soft-touch finishing, “Holosense” holographic effects, tamper evident labels and peelable labels. Taylor says the product has generated interest because brands are increasingly seeking packaging that incorporates both innovative trend-led design and security features.

“In addition to ensuring products [are] more aligned with brand values, [turnkey] partnerships provide customers with the confidence that they can just deal with one supplier for most of the products that they need,” Taylor says. “By having fewer but stronger relationships with manufacturers, beauty brands can concentrate on working more intimately with the manufacturer, creating the perfect packaging solution for their products.”

Jack Rodriguez, president, JMR Development, New York, says contract service providers afford brands of all sizes the ability to enter and compete in the market quickly, without having to make the upfront investment in full development overhead. “Rather, they can use their seed money to invest in sales and market strategy and stay focused on cementing their brand narrative in the beauty space,” he says. “For larger more established brands, partnering with outside contract manufacturers and turnkey development firms gives them exposure to unique products or whole categories in which they currently don’t have a presence. And most importantly, they can do this without disrupting their internal development routine on their core products.”

Turnkey, or at-the-ready/á la carte products and services, are also great solutions for brands whose time is of the utmost essence, says Jill Manning, director of product innovation, Santa Monica, CA-based HCT Group, a full-service company that provides quality assurance and quality control services. “[Turnkey] is also a very convenient and efficient way to quickly expand a product line, cutting projected launch dates in half,” she says.

Pairing with the Right Partner

Sometimes brands need a contract packager for help with something relatively minor, like finding the right dispensing cap. Other times the job is more full service in nature. Take, for instance, a startup with a great idea, but one that needs an experienced partner with the know-how to shepherd them through the process of bringing a product to life: marrying the formula to the right package, making sure the market is sound, then getting it to market. In short, if you have a beauty-related conundrum, odds are, there’s a contract service provider with the skillset to help sort it out.

Many service providers offer a variety of convenient, one-stop options. “[When] manufacturing services are at one location, brands tend to receive far better communication and speed to market than if there are many companies in the process of creating, manufacturing, filling, and launching a product” says Melinda Wochner, chief marketing officer, CoValence, a Chandler, AZ-based service provider that specializes in formulating, manufacturing and filling. “Our clients who use different vendors for each piece of the manufacturing puzzle have found that communication and lead-times tend to be delayed which hinders their projected launch dates. Whereas, utilizing one company that can take on most, if not all, of the process will typically provide a brand with one point of contact who can help move orders through the manufacturing turnkey process with far less stress and far better lead-times and results for the brands.”

World Wide Packaging (WWP), Florham Park, NJ, takes a special interest in designing, launching and expanding beauty brands for the boutique, indie and prestige markets. “WWP links innovative formulas with the precise packaging needed to showcase the product,” says Rick Weisbrod, WWP’s executive vice president of global operations. “WWP’s team of specialists provides a comprehensive plan enabling a seamless evolution from concept to launch.”

WWP recently worked with Wander Beauty, a travel-inspired, luxury, multi-tasking makeup essentials brand, to create and fill a sleek and unique lipstick tube with an interchangeable core for its award-winning Wanderout Dual Lipstick range, which launched in March. The metal lipstick case is anodized in a rich burgundy color and hot stamped in shiny gold. What sets the package apart from typical lipstick tubes is that it’s dual-ended, giving on-the-go beauty mavens the flexibility to easily swap out a satin shade for a matte, or a neutral color for something a little bolder.

Darryl Do is a perfumer for the Delbia Do Company, a boutique manufacturer of fragrances and flavors, and contract filler in Bronx, NY. On the manufacturing side, he says companies like his are great resources for helping companies avoid making potentially harmful regulatory mistakes. “[For instance] about 10% of the brands that contact us didn’t realize that they can’t make perfumes or personal care products in their home/work space,” he says.

From a packaging perspective, Do says turnkey service options are especially great for companies that do not have an in-house purchasing agent to help sort out the intricacies of packaging componentry. “It goes beyond picking a bottle and cap option,” he says, noting that Delbia Do routinely helps customers navigate through component options such as quality, sizes, stock versus custom, etcetera. “We help our customers get their design concept into the best design option for them.”

Scaled Production Capabilities

Global brands and startups alike often have a need for small-volume manufacturing, whether it’s due to a limited budget or simply to test run a new product. This is another area where contract service providers have proven to be an ideal resource in terms of cost and time savings because many have low or no minimum buy requirements and have a broad network of packaging sources, both domestically and abroad to suit a variety of budgetary needs.

“The positive effect of this relationship would be one stop shopping and without compromising on the design of the formula or the packaging,” says Mayur Dave, president of M Plus LLC., Passaic, NJ, a contract manufacturer of liquids, gels, creams, muds and salts for hair care, skin care and bath and body.

M Plus specializes in high-end formulas using exotic oils and butters, which Dave says helps brands deliver a distinctive ingredient story. The company is currently developing a line of products for a celebrity hairdresser, using exotic oils and butters from Japan, Himalayas and the Atlas Mountains. The formulation is being developed exclusively for M Plus in Japan and mixed and filled here in its New Jersey facility.

“In the past, starting this type of line would have required a minimum of 10,000 pieces per unit and there are usually seven to nine products at the launch; by the time you’re done, your startup cost can easily climb upwards of $300,000 to $500,000,” says Dave.

“We are going to be able to develop this entire line without any minimum quantity requirements and this will enable the client to do a soft launch in many markets before placing a volume order.”

There are also times when brands experience the kind of success that requires unexpectedly quick (and stressful) production ramp-ups to meet increased demand. JMR’s Rodriguez, says fast-acting flexibility is another benefit to partnering with contract service providers.

As a specialist in custom beauty and beauty packaging development, Rodriguez says JMR appeals to brands that are “focused on disrupting a specific category that they feel may be oversaturated with stale or cookie-cutter style products.”

“This year we have executed full custom turnkey development for personal fragrance, home fragrance, bath and body, skin care and color cosmetics, but we do it on a boutique scale,” he says. “JMR remains a small outfit and we regulate our bandwidth by selecting the right client partnerships.”

One of JMR’s recent turnkey projects was for Sol De Janeiro (SDJ). A new bath and body brand, SDJ was picked up for full distribution by Sephora this year and Rodriguez says JMR successfully executed multiple SKUs under tight timelines.

“We have been with them from pretty much the beginning and primarily offer custom package design, package sourcing, custom formulating, and in most cases, supply them with complete finished goods,” he says. “When SDJ launched online for Sephora, they sold out in a day, and continue to exceed Sephora expectations. As a result, they were asked to fast track SKUs that were not on the planogram until next year.”

Rodriguez says JMR managed to quickly turn the new SKUs by using a carefully managed supply chain. “As the business continues to grow, JMR closely monitors the scalability needs of each SKU and makes adjustments to the supply chain accordingly on behalf of the client,” he says.

Innovation at the Forefront

When contract service providers focus on their core competencies, they can explore and push the bounds of innovation, investing capital in the development of new products so brands don’t have to.

Tainan City, Taiwan-based GCC Packaging Group focuses on premium beauty packaging designs and production, with a recent foray into skin care packaging. The company’s subsidiary, Grace Cosmetics, creates contract formulations.

GCC custom-develops packages utilizing a team of packaging engineers. Grace Chiu, managing director, explains that the company also actively partners and strategizes its packaging services with other co-packagers because it ultimately makes good business sense for customers. “The benefits of having this co-working relationship is time saving, firstly from my point of view, especially for new developments,” she says. “Each business provider has its own expertise. With the fundamental trust basis, more beautiful and professional ideas will be rocked out together—this is the beauty of cooperation.”

Among the company’s latest packaging innovations is Kiss Soul, a one-click makeup and lip concept that stands apart from traditional bullet lipsticks thanks to its button click mechanism. The company also has extensive expertise in palettes and compacts featuring decorative work that’s beyond standard and run of the mill. Recent launches feature an array of eye-popping decorative work, including dimensional inlay, distressed and shiny metals, domed 3-D plastic, and mother-of-pearl lacquer effects.

For some beauty brands, it pays to seek out suppliers of specific products and services. For instance, the popularity of Korean beauty treatments has contributed to a spike in the popularity of beauty treatment masks and convenient, pre-soaked tissue products. TaikiUSA, Montvale, NJ, is a supplier of wet tissue and mask products. The company is not only innovating to help meet the evolving diversifying demand for these products, but is also working with contract manufacturers to support the filling operation, helping to improve efficiencies for clients.

Taiki is the largest supplier of non-woven masks in Asia, producing 120 million annually. The company’s aquatic masks and gel patches come in various shapes and can be infused with custom serums. Made from biopolymer derived from seaweed carrageenan, TaikiUSA masks are environmentally friendly and biodegradable.

“For masks, Taiki is heavily involved in new product technologies,” comments Jim Perry, CEO and president, adding that the company’s latest mask advancements include an improved folding technology (which is key for optimized packaging and convenient dispensing/usage) and a new Hydrogel mask that delivers a cooling effect with increased adhesion and occlusion.

“Most of our masks are customized to meet the specific requirements/formula for each customer, but we do have the ability for filling masks in a Clean Room with preservative-free formulas.”

Innovation for Paris-based Alkos Group comes from the company’s umbrella of interconnected R&D laboratories, which produce industrialized and tailor-made “Made in France” lip and eye pencils, skin care and makeup, and perfumed soaps and stick deodorants for its beauty clients. One of the company’s best-selling innovations is the Jumbo Twist Mania, a chubby pencil format that can flexibly house lip color, eyeshadow, concealer or highlighter, and can even be augmented to accommodate airtight formulas, according to Alkos Group’s Florence Lefeuvre, group sales, marketing and communication director.

Chicago, IL-based Essentra is a global supplier specializing in cartons, labels, leaflets and tapes, as well as security solutions for anti-counterfeiting, serialization, authentication and tamper verification. The company also specializes in bespoke creative design through its new Design Hub facility, which is home to a new service that marries creative packaging design with extensive manufacturing capabilities.

“Experts can work together with brands to choose the perfect features, finishes, structures and overall visual designs,” explains the company’s Rupert Taylor, global category manager, healthcare and personal care. “Plus by working across a range of stock keeping units (SKUs), brands can be sure that all products are coherent, complement each other and are ready for sale.”

Essentra showcased the Lotus Pack, a blooming, floral-shaped carton encased in a clear acetate pyramid, at this year’s Luxe Pack Monaco. The elegant box was not only developed at Essentra’s Design Hub, it also showcases a wide range of the company’s capabilities including hot and cold foiling, varnishing, embossing, soft-touch finishing, “Holosense” holographic effects, tamper evident labels and peelable labels. Taylor says the product has generated interest because brands are increasingly seeking packaging that incorporates both innovative trend-led design and security features.

“In addition to ensuring products [are] more aligned with brand values, [turnkey] partnerships provide customers with the confidence that they can just deal with one supplier for most of the products that they need,” Taylor says. “By having fewer but stronger relationships with manufacturers, beauty brands can concentrate on working more intimately with the manufacturer, creating the perfect packaging solution for their products.”