Joanna Cosgrove, Contributing Editor01.26.18

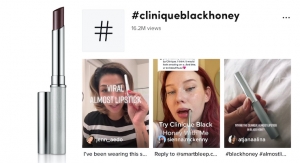

Social media has wielded an enormous effect on the lip color and eye makeup markets thanks in large part to “influencers” across platforms like Instagram, Snapchat and You Tube who give consumers insights into makeup trends and brands by engaging followers with their first-hand product reviews and experiences.

According to Cheryl Morgan, creative marketing manager, located in HCP Packaging’s UK office, the fast pace of new product ideation has similarly influenced the packaging industry. “This means having a broad and versatile stock offering that can be easily and quickly adapted to suit different brands, with options for customization through bottle-to-cap combination, mascara and lip applicators, but also added value decoration,” she says. “This also means continually investing in new pack designs to anticipate the upcoming trends to provide a packaging solution to tie in with the next big thing.”

From HCP’s vantage point, the lip color segment has experienced the most vibrant recent growth, with a proliferation of new colors, finishes, and application methods, and an especially strong interest in stock packaging. Morgan says HCP has adapted its stock offering, launching more than 30 new, quick-to-market-friendly stock options in 2017. “We have brought a strong focus to mini lipsticks with several new launches and also liquid lipsticks, which are presented in lip gloss packs,” she says, noting that the company has also invested in a variety of silhouettes to encourage brand differentiation. “The choice of pack profile, functionality and decoration should come together to achieve the correct visual indicators for the brand and also offer something new and effective to a consumer that is faced with an increasingly saturated marketplace.”

On Point Lip Color Packaging

Darren Eade, vice president of sales, Kemas, headquartered in Jakarta, Indonesia, slots lipstick products into four categories: luxury, masstige, mass and liquid. “A luxury component will typically consist of a higher degree of decoration, sometimes metal fashion parts (opposed to plastic) and a mechanism that has been produced with much tighter tolerances and control than normal, thus creating a smooth and luxurious swivel function,” he says. “Masstige and mass are typically determined by the degree of secondary decoration that has been applied, weights added, etcetera, [while] liquid has been a relatively newer trend whereby the formula is in liquid form rather than the traditional bullet.”

Many of Kemas’ projects are custom; however, the company offers a large range of stock traditional and liquid lipstick components. “To accompany the fashion parts, we offer a selection of mechanisms that are either supported or unsupported, based on diameter requirements,” Eade says. “Some brands like to develop their own unique profile with 100% customization, which would include the fashion parts. When stock components are being utilized, we would typically color match and apply the artwork unique to that brand, thus providing a unique appearance.”

While classic square or round lipstick cases remain bestsellers, Lou Della Pesca, president, 3C Inc., Hawthorne, NJ, says lipstick packages with unusual visual interest are a great way to grab consumer interest. To this end, 3C added a sharper-edged, square design to its lipstick packaging library for customers seeking an updated look, along with metal overshells and metallized cases which impart a higher-end look to a standard case.

3C’s range of lipstick cases features convenient magnetic closures. “A simple placement of the cap over the sleeve of the base and the magnetic force properly closes the cap down onto the base,” Della Pesca says. “The decoration of multi-colors available in silk screen, hot stamp and transfer label has added to the value of the case.”

Another hot trend in lip color packaging is displaying the actual formula shade through the packaging. Adrian Hook, vice president sales USA, Brivaplast Group, Torrance, CA, says it hinges on resin with superior clarity. “Our heavy walled ranges of our injection molded liquid lip vials are ideal for this purpose,” he says. To that end, Brivaplast has industrialized a new manufacturing process, using Injection Blow Molding (IBM) technology to produce a polygonal, clear vial in PETG, with a 3mm thick wall.

Lip color formulas have evolved too, adding additional tangents to new package development to protect novel formulations and enhance the application experience. “In the past, there was a clear division between lipstick, lip balm and lip gloss; liquid lipsticks have become more popular over the past few years and combine the glide of lip gloss but the wear, coverage and pigmentation of lipstick,” comments Sonia Cerato, makeup category manager, Quadpack, which is headquartered in Catalonia, Spain. “The lip powder trend from Korea, for example, uses the color in the pack with an incorporated sponge tip for application.”

Quadpack offers a range of sticks and lip gloss packs and formats, and its latest launches include a Dual Slim Jumbo option that features an integrated applicator and an elegant slim profile, as well as an Airtight Lipstick extension of its Q-Line range, a cylindrical design constructed to support softer lipstick formulations with long-lasting claims. “Airtightness keeps the product from drying out, while its construction is made of compatible materials,” Cerato says. “The use of ABS in the base and cap makes it ideal for silicone- and isododecane-based formulas [and] the A-shell comes in either metal or plastic. Isododecane in particular needs a resistant material like ABS, while hermetic seals keep these products fresh and moist.”

In addition to traditional packaging and decorating, Quadpack is also fluent in the development of bespoke products out of unconventional materials via the Technotraf wood factory aspect of its manufacturing division. What’s more, the company recently implemented a company-wide CSR strategy with the long-term goal of developing lipsticks using sustainable materials and lubricant- and POM-free mechanisms, and Cerato says the first launch will be a lubricant-free lipstick mechanism that’s in the final stages of development.

The company’s forward-thinking initiative was likely attractive to New Zealand brand Karen Murrell, whose lip color products are free from animal cruelty and harmful chemicals. The brand’s latest lip colors, launched in May, are housed in a palette developed by Quadpack. The palette lid features a vibrant floral design applied using matte black silkscreen and copper metallization processes. The mirrored interior has a base insert for the double-sided brush, which features anodized metal parts color-matched to the tray.

Capergnanica, Italy-based Lumson produces a range of standard and custom lipstick packages with quintessential Italian panache, in different materials and finishes characterized by deco technologies including screen printing, hot stamping, tampo printing, offset, spraying, metallization and digital printing.

The company also offers an environmentally-conscious range of lipstick packaging. “You can choose your green lipstick, either in PLA, which is biodegradable, compostable and its raw material derives 100% from annually renewable vegetal sources, or in PP, for an eco-friendly and recyclable lipstick,” says Federica Bonaldi, Lumson’s marketing manager. “Our lipsticks division, with two production sites located in North Italy, have injection molding, assembly and decoration machines, [and are] able to produce more than 35 million lipsticks per year.”

Brand-Forward Details

Long-term and short-term on-package decoration continues to be an important focus for lip color and mascara packages.

“Beauty brands are launching more and more limited editions and collections, often featuring their [brand] ambassador or a seasonal theme,” says Charlotte Wastyn, Albéa Tips Studio product manager. “Brands need ranges with short lifespans to be noticed at first glance and our state-of-the-art decoration techniques can make that happen. Iridescent, holographic or photo-like effects are especially popular.”

To develop innovations that give consumers a real benefit, Albéa operates expertise hubs it calls Centers of Excellence. The primary hub is located in Bottanuco, Italy, and houses the Albéa Tips Studio center, the company’s center for the invention, development and manufacturing of market-valued applicators for lips, eyes and face. In June, Albéa opened a U.S.-based Center of Excellence in Morristown, TN. “Customers can fine-tune their developments on-site [and] we can produce prototypes on industrial machines for them to test and adjust the design accordingly,” says Wastyn. “We cover every technology from wire and plastic brushes to finishing and packaging so the customer can go home at the end of the day with the definitive brush that brings their project to life.”

In 2017, Albéa helped Givenchy devise a unique brush for its Perfecto Base mascara that combines traditional and rigid nylon fibers with soft cotton fibers that both helps separate the lashes and improves the application experience. “The Mixed Fiber technology can mix two or three fiber types together before making a brush,” explains Wastyn. “Different materials like nylon or co-extruded fibers each have their own characteristics. By combining them from the start we can offer product standout and a range of makeup effects.”

China-based EFA Packaging recently worked with makeup brand BOB to develop its BOB Silk 3D Mascara and EFA’s Baoxia Zhuang, sales director, says the brand wanted its packaging to emulate the unique attributes of the formula.

“We associate the features of ‘unlimited lengthening and volumizing’ with silk characteristics so that we use the design of the silkworm in the package appearance,” she says, adding that the streamlined, injection-blown PETG tube has a soft feel and was awarded a patent for its novelty. “With injection white as a base color, we applied metallization in red and blue,” she explains. “Laser engraving streamlines and visually enhances the middle part of the package and creates a strong contrast to capture user attention. The red-white mascara package expresses its unlimited extension on eyelash lengthening while the blue-white mascara shows its perfect performance on lash volumizing.

Brivaplast supplied its packaging prowess to a complex mascara package for Italian beauty brand Collistar, which launched a new mascara in April. Brivaplast’s Hook says the PET base features three decorative treatments: a gold metallization, black silk-screened print and a UV finish. A two-piece cap showcases the brand’s name embossed in gold, and also includes a gold metal embossed overcap with the logo. An oriented closure ensures a perfect alignment between the brand name of the cap and the black silk screening.

Geka GmbH, Bechhofen, Germany offers a standard Block Building System, which allows brands to combine different components like caps, bottles and applicators to create completely unique packages. “Our laboratory ensures that the interplay between the formula, packaging and brush always works perfectly well,” says Julia Böhnlein, head of marketing. “We [also] offer numerous decoration technologies like hot foil printing, silk screen printing, pad printing, heat transfer foils, metallization, lacquering, sleeves [and] laser decoration to make each product unique.”

Precision Applicators

Applicators are the unsung heroes of lip and mascara packaging, responsible for optimum application, and for mascara to deliver on promises of volumizing, lengthening and lash separating.

“A good applicator is one that offers the perfect mix between the brush, the wiping system, the pack and the formula,” explains Albéa’s Wastyn. “[It] delivers the desired makeup effect through the formula it applies. Every beauty brand wants a makeup effect, whether volume, length or curve, and multiple formula-wiper-applicator combinations can achieve those results.”

“Ultimately, the performance of any lip or mascara product is the perfect interplay of different components, some of which are invisible for the consumer,” says Geka’s Böhnlein. “In the case of mascara, consumers usually do not notice the wiper as it is hidden within the bottle, but it plays a very important role to create perfect application results as it delivers the perfect amount of mascara formulation on the brush.”

The closing system is another nearly invisible feature, but fulfills a functional role, especially when it can be heard by the consumer. Geka’s click-close gives consumers auditory confirmation a mascara or lip gloss is closed without having to specially orient the cap onto the base to ensure the product is closed. In the final closed position, the pack is impermeable to liquids and is air-tight.

To ensure each of its lip color and mascara packages is as functional as it is beautiful, HCP works closely with their customers to match the perfect applicator to liquid lipstick and mascara formulas to achieve the desired makeup claim, whether the solution is custom developed or customized from stock. HCP’s acquisition of Rusi, a leading European packager of, among other things, mascara and lip color packaging, has brought with it a portfolio of stylish new stock options.

“Applicator shape, material, flock adhesive, flock length and density are all selected for optimum product performance,” Morgan explains. “The HCP-RUSI patented double flocking technology for lip applicators has a combination of shorter and longer flock to catch even more formula while also giving a super soft feel during application.”

HCP’s mascara brush library affords brands the opportunity for additional customization. Options include twisted-wire brushes from both the U.S. and Germany, as well as micro-injection plastic brushes and rubber wipers from France. “Micro-precision plastic brushes offer a real wow-factor in terms of brush architecture as well as delivering a desired makeup look,” Morgan exclaims. “The brushes can be color matched to the brand’s choice, which can be extremely eye-catching for point of sale imagery.”

Sephora has launched Sephora Collection #LIPSTORIES, a new range of long-lasting lipsticks featuring a new, highly pigmented formula spanning 40 shades in cream, matte and metal finishes. Each shade’s packaging whimsically features an image of a place, experience or object that brings the shade to life.

“Sephora Collection is all about making beauty uncomplicated for our clients, and always wants to be building a personal and emotional connection to our brand and products with them,” comments Beth Hayes, vice president for Sephora Collection. “We know they love high-quality products at a smart price point that they can play with or be inspired by to tell a story about themselves. With that, we created Sephora Collection #LIPSTORIES, a new inspirational collection…that encourages our one-of-a-kind clientele to tell their unique story, as inspired by the colorful shade range and unique packaging.”

The lipsticks launched in December and retail for $8 each.

According to Cheryl Morgan, creative marketing manager, located in HCP Packaging’s UK office, the fast pace of new product ideation has similarly influenced the packaging industry. “This means having a broad and versatile stock offering that can be easily and quickly adapted to suit different brands, with options for customization through bottle-to-cap combination, mascara and lip applicators, but also added value decoration,” she says. “This also means continually investing in new pack designs to anticipate the upcoming trends to provide a packaging solution to tie in with the next big thing.”

From HCP’s vantage point, the lip color segment has experienced the most vibrant recent growth, with a proliferation of new colors, finishes, and application methods, and an especially strong interest in stock packaging. Morgan says HCP has adapted its stock offering, launching more than 30 new, quick-to-market-friendly stock options in 2017. “We have brought a strong focus to mini lipsticks with several new launches and also liquid lipsticks, which are presented in lip gloss packs,” she says, noting that the company has also invested in a variety of silhouettes to encourage brand differentiation. “The choice of pack profile, functionality and decoration should come together to achieve the correct visual indicators for the brand and also offer something new and effective to a consumer that is faced with an increasingly saturated marketplace.”

On Point Lip Color Packaging

Darren Eade, vice president of sales, Kemas, headquartered in Jakarta, Indonesia, slots lipstick products into four categories: luxury, masstige, mass and liquid. “A luxury component will typically consist of a higher degree of decoration, sometimes metal fashion parts (opposed to plastic) and a mechanism that has been produced with much tighter tolerances and control than normal, thus creating a smooth and luxurious swivel function,” he says. “Masstige and mass are typically determined by the degree of secondary decoration that has been applied, weights added, etcetera, [while] liquid has been a relatively newer trend whereby the formula is in liquid form rather than the traditional bullet.”

Many of Kemas’ projects are custom; however, the company offers a large range of stock traditional and liquid lipstick components. “To accompany the fashion parts, we offer a selection of mechanisms that are either supported or unsupported, based on diameter requirements,” Eade says. “Some brands like to develop their own unique profile with 100% customization, which would include the fashion parts. When stock components are being utilized, we would typically color match and apply the artwork unique to that brand, thus providing a unique appearance.”

While classic square or round lipstick cases remain bestsellers, Lou Della Pesca, president, 3C Inc., Hawthorne, NJ, says lipstick packages with unusual visual interest are a great way to grab consumer interest. To this end, 3C added a sharper-edged, square design to its lipstick packaging library for customers seeking an updated look, along with metal overshells and metallized cases which impart a higher-end look to a standard case.

3C’s range of lipstick cases features convenient magnetic closures. “A simple placement of the cap over the sleeve of the base and the magnetic force properly closes the cap down onto the base,” Della Pesca says. “The decoration of multi-colors available in silk screen, hot stamp and transfer label has added to the value of the case.”

Another hot trend in lip color packaging is displaying the actual formula shade through the packaging. Adrian Hook, vice president sales USA, Brivaplast Group, Torrance, CA, says it hinges on resin with superior clarity. “Our heavy walled ranges of our injection molded liquid lip vials are ideal for this purpose,” he says. To that end, Brivaplast has industrialized a new manufacturing process, using Injection Blow Molding (IBM) technology to produce a polygonal, clear vial in PETG, with a 3mm thick wall.

Lip color formulas have evolved too, adding additional tangents to new package development to protect novel formulations and enhance the application experience. “In the past, there was a clear division between lipstick, lip balm and lip gloss; liquid lipsticks have become more popular over the past few years and combine the glide of lip gloss but the wear, coverage and pigmentation of lipstick,” comments Sonia Cerato, makeup category manager, Quadpack, which is headquartered in Catalonia, Spain. “The lip powder trend from Korea, for example, uses the color in the pack with an incorporated sponge tip for application.”

Quadpack offers a range of sticks and lip gloss packs and formats, and its latest launches include a Dual Slim Jumbo option that features an integrated applicator and an elegant slim profile, as well as an Airtight Lipstick extension of its Q-Line range, a cylindrical design constructed to support softer lipstick formulations with long-lasting claims. “Airtightness keeps the product from drying out, while its construction is made of compatible materials,” Cerato says. “The use of ABS in the base and cap makes it ideal for silicone- and isododecane-based formulas [and] the A-shell comes in either metal or plastic. Isododecane in particular needs a resistant material like ABS, while hermetic seals keep these products fresh and moist.”

In addition to traditional packaging and decorating, Quadpack is also fluent in the development of bespoke products out of unconventional materials via the Technotraf wood factory aspect of its manufacturing division. What’s more, the company recently implemented a company-wide CSR strategy with the long-term goal of developing lipsticks using sustainable materials and lubricant- and POM-free mechanisms, and Cerato says the first launch will be a lubricant-free lipstick mechanism that’s in the final stages of development.

The company’s forward-thinking initiative was likely attractive to New Zealand brand Karen Murrell, whose lip color products are free from animal cruelty and harmful chemicals. The brand’s latest lip colors, launched in May, are housed in a palette developed by Quadpack. The palette lid features a vibrant floral design applied using matte black silkscreen and copper metallization processes. The mirrored interior has a base insert for the double-sided brush, which features anodized metal parts color-matched to the tray.

Capergnanica, Italy-based Lumson produces a range of standard and custom lipstick packages with quintessential Italian panache, in different materials and finishes characterized by deco technologies including screen printing, hot stamping, tampo printing, offset, spraying, metallization and digital printing.

The company also offers an environmentally-conscious range of lipstick packaging. “You can choose your green lipstick, either in PLA, which is biodegradable, compostable and its raw material derives 100% from annually renewable vegetal sources, or in PP, for an eco-friendly and recyclable lipstick,” says Federica Bonaldi, Lumson’s marketing manager. “Our lipsticks division, with two production sites located in North Italy, have injection molding, assembly and decoration machines, [and are] able to produce more than 35 million lipsticks per year.”

Brand-Forward Details

Long-term and short-term on-package decoration continues to be an important focus for lip color and mascara packages.

“Beauty brands are launching more and more limited editions and collections, often featuring their [brand] ambassador or a seasonal theme,” says Charlotte Wastyn, Albéa Tips Studio product manager. “Brands need ranges with short lifespans to be noticed at first glance and our state-of-the-art decoration techniques can make that happen. Iridescent, holographic or photo-like effects are especially popular.”

To develop innovations that give consumers a real benefit, Albéa operates expertise hubs it calls Centers of Excellence. The primary hub is located in Bottanuco, Italy, and houses the Albéa Tips Studio center, the company’s center for the invention, development and manufacturing of market-valued applicators for lips, eyes and face. In June, Albéa opened a U.S.-based Center of Excellence in Morristown, TN. “Customers can fine-tune their developments on-site [and] we can produce prototypes on industrial machines for them to test and adjust the design accordingly,” says Wastyn. “We cover every technology from wire and plastic brushes to finishing and packaging so the customer can go home at the end of the day with the definitive brush that brings their project to life.”

In 2017, Albéa helped Givenchy devise a unique brush for its Perfecto Base mascara that combines traditional and rigid nylon fibers with soft cotton fibers that both helps separate the lashes and improves the application experience. “The Mixed Fiber technology can mix two or three fiber types together before making a brush,” explains Wastyn. “Different materials like nylon or co-extruded fibers each have their own characteristics. By combining them from the start we can offer product standout and a range of makeup effects.”

China-based EFA Packaging recently worked with makeup brand BOB to develop its BOB Silk 3D Mascara and EFA’s Baoxia Zhuang, sales director, says the brand wanted its packaging to emulate the unique attributes of the formula.

“We associate the features of ‘unlimited lengthening and volumizing’ with silk characteristics so that we use the design of the silkworm in the package appearance,” she says, adding that the streamlined, injection-blown PETG tube has a soft feel and was awarded a patent for its novelty. “With injection white as a base color, we applied metallization in red and blue,” she explains. “Laser engraving streamlines and visually enhances the middle part of the package and creates a strong contrast to capture user attention. The red-white mascara package expresses its unlimited extension on eyelash lengthening while the blue-white mascara shows its perfect performance on lash volumizing.

Brivaplast supplied its packaging prowess to a complex mascara package for Italian beauty brand Collistar, which launched a new mascara in April. Brivaplast’s Hook says the PET base features three decorative treatments: a gold metallization, black silk-screened print and a UV finish. A two-piece cap showcases the brand’s name embossed in gold, and also includes a gold metal embossed overcap with the logo. An oriented closure ensures a perfect alignment between the brand name of the cap and the black silk screening.

Geka GmbH, Bechhofen, Germany offers a standard Block Building System, which allows brands to combine different components like caps, bottles and applicators to create completely unique packages. “Our laboratory ensures that the interplay between the formula, packaging and brush always works perfectly well,” says Julia Böhnlein, head of marketing. “We [also] offer numerous decoration technologies like hot foil printing, silk screen printing, pad printing, heat transfer foils, metallization, lacquering, sleeves [and] laser decoration to make each product unique.”

Precision Applicators

Applicators are the unsung heroes of lip and mascara packaging, responsible for optimum application, and for mascara to deliver on promises of volumizing, lengthening and lash separating.

“A good applicator is one that offers the perfect mix between the brush, the wiping system, the pack and the formula,” explains Albéa’s Wastyn. “[It] delivers the desired makeup effect through the formula it applies. Every beauty brand wants a makeup effect, whether volume, length or curve, and multiple formula-wiper-applicator combinations can achieve those results.”

“Ultimately, the performance of any lip or mascara product is the perfect interplay of different components, some of which are invisible for the consumer,” says Geka’s Böhnlein. “In the case of mascara, consumers usually do not notice the wiper as it is hidden within the bottle, but it plays a very important role to create perfect application results as it delivers the perfect amount of mascara formulation on the brush.”

The closing system is another nearly invisible feature, but fulfills a functional role, especially when it can be heard by the consumer. Geka’s click-close gives consumers auditory confirmation a mascara or lip gloss is closed without having to specially orient the cap onto the base to ensure the product is closed. In the final closed position, the pack is impermeable to liquids and is air-tight.

To ensure each of its lip color and mascara packages is as functional as it is beautiful, HCP works closely with their customers to match the perfect applicator to liquid lipstick and mascara formulas to achieve the desired makeup claim, whether the solution is custom developed or customized from stock. HCP’s acquisition of Rusi, a leading European packager of, among other things, mascara and lip color packaging, has brought with it a portfolio of stylish new stock options.

“Applicator shape, material, flock adhesive, flock length and density are all selected for optimum product performance,” Morgan explains. “The HCP-RUSI patented double flocking technology for lip applicators has a combination of shorter and longer flock to catch even more formula while also giving a super soft feel during application.”

HCP’s mascara brush library affords brands the opportunity for additional customization. Options include twisted-wire brushes from both the U.S. and Germany, as well as micro-injection plastic brushes and rubber wipers from France. “Micro-precision plastic brushes offer a real wow-factor in terms of brush architecture as well as delivering a desired makeup look,” Morgan exclaims. “The brushes can be color matched to the brand’s choice, which can be extremely eye-catching for point of sale imagery.”

Sephora has launched Sephora Collection #LIPSTORIES, a new range of long-lasting lipsticks featuring a new, highly pigmented formula spanning 40 shades in cream, matte and metal finishes. Each shade’s packaging whimsically features an image of a place, experience or object that brings the shade to life.

“Sephora Collection is all about making beauty uncomplicated for our clients, and always wants to be building a personal and emotional connection to our brand and products with them,” comments Beth Hayes, vice president for Sephora Collection. “We know they love high-quality products at a smart price point that they can play with or be inspired by to tell a story about themselves. With that, we created Sephora Collection #LIPSTORIES, a new inspirational collection…that encourages our one-of-a-kind clientele to tell their unique story, as inspired by the colorful shade range and unique packaging.”

The lipsticks launched in December and retail for $8 each.