Joanna Cosgrove, Contributing Editor03.04.19

In an age of sensitive ingredients, high viscosity formulas and 2-in-1 product configurations, clogged sprayers and leaky pumps can adversely impact a beauty consumer’s perception of a product and the brand behind it. That’s why dispenser designers and manufacturers are implementing design technologies and eco-conscious responsible innovations to propel the dispenser segment forward.

Bob Murphy, principal, RLM Group Ltd., Mount Kisco, NY, says that the innovation in dispensers must rise to the occasion to optimize the end-user experience. “From our vantage point, that means easier, cleaner, controlled delivery—no matter the viscosity or air sensitivity,” he says. “It means providing dispensers that prevent the product from spilling or leaking down the sides or on counters and vanities [and] maintaining the original beauty of the package by eliminating ‘gunky’ build-up at the delivery point or around the cap via a simple less expensive system than standard dispensing systems.”

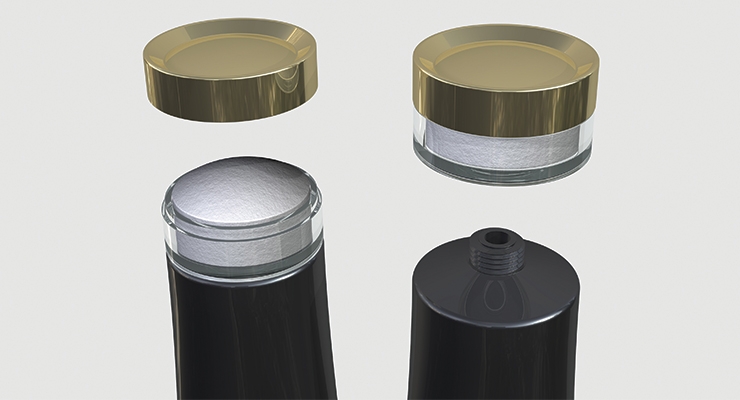

RLM Group has developed a variety of patented dispensers that address efficiency, customization and convenience. RLM InFusion Lip Gel System consists of a stock tube and closure with a sintered plastic lip tip that marries a primary formula with a secondary formula (e.g. color with oil or serum) as they pass through the tip. The company also offers a 15ml Serum Jar featuring a “saturated, stationary, porous insert” that allows for a controlled, no-drip delivery of low viscosity products.

The Glide Cap is one of RLM’s recent dispenser developments for the beauty industry. It offers brands the opportunity to deliver two complementary products (e.g. a cleanser and separate moisturizer), all in one package. The system consists of a tube that can be filled with any product brand’s wish, plus a lower viscosity companion product housed in the dual-use cap. The system does not combine the two products when squeezed. The cap includes a saturated, stationary, porous insert that dispenses the product separately, similar to the aforementioned 15ml Serum Jar.

Revlon’s dual-formula, Root Erase permanent multi-use root touch-up kit required dual-dispensing technology so the company selected an appropriately named solution from Toyo & Deutsche Aerosol GmbH, Neutraubling, Germany. According to the company’s Valerie Vail, Toyo’s executive vice president, North America, The Dual is a dual-valve canister that allows for both Revlon’s colorant and developer to be dispensed simultaneously, resulting in an easier stress-free application experience.

Forward-Thinking Designs

“Today, innovating is a necessity, almost an obligation, for cosmetics,” comments Rosa Porras Mansilla, marketing and communication manager, Virospack, Barcelona, Spain. She adds that dispensers—and in particular, droppers–require an exacting amount of precision that ratchets up the difficulty of creating a design that maximizes excitement while also being effective in form and function.

“Despite relying on market research to learn how consumers’ needs change, innovating is not easy,” she says. “We need to ensure that in addition to being an innovative and attractive concept, the new dropper dispenser is functional and high quality with maximum precision.”

Virospack’s latest work has reinvented the classic dropper curved shapes on the bulb and/or the cap. The company also reworked the push-button dropper into something more linear and customizable with the Ring Push-Button Dropper. The dropper is composed of three visible parts but fully integrated, forming a single, flat-topped unit that’s fully receptive to decoration. Its dosage capacity is higher than the other conventional push-button droppers, delivering an average of 0.65ml of formula in one push.

Bobbi Brown turned to Virospack to help convey a cosmeceutical positioning for its Remedies line, launched in 2018. The range consists of “made for me” personalized solutions for specific skin problems (e.g. improved moisture and clarity) and Virospack manufactured the line’s droppers and black injected caps for both the brand’s regular and smaller, kit-format sizes.

Virospack additionally worked with Kiehl’s on a companion kit of two of its popular facial serum treatments resized in a smaller format presentation. The daytime serum is packaged in white and the nighttime serum in black, and both packages feature a Virospack push-button dropper assembly identical to the standard sized serum assembly.

Korea-based YonWoo International/PKG Group has also unveiled a new dropper dispenser, a 10ml ampoule dropper with precise dosing and a sleek design. It’s one of three new dispenser designs from the company, which also includes the Ice Tube, 40mm diameter tube featuring a “continuously cool applicator tip” ideal for products requiring massage application, and a two-way, dual applicating system, whereby product can be applied with a sponge or rod applicator with a doe foot.

Airless Dispensing

For formulas with ingredients that can degrade if exposed to air or light, airless is the answer.

“Currently we are seeing a lot of demand for packages that provide airtightness [with the] ability to customize using various custom decoration techniques to provide a distinct look and feel in the marketplace,” says Philip Cho, country manager, SamHwa USA Inc., Hoboken, NJ. “There is much room for innovation as the market trend is currently focusing on the consumer’s ability to customize the product per skin type and aesthetic preference.”

SamHwa has launched a 20ml airless compact that dispenses 0.15CC of product when the base is depressed. Cho says the unit is completely hygienic because it separates the content space from the applicator space, and antibacterial material is applied to the applicator’s housing to keep both the applicator and the content clean.

Skincare company Dr. Jart selected a SamHwa airless, hard-cased tube package for its “hero” products. Different from standard tubes, theses tubes are fitted with a proprietary mechanism that ensures formula longevity and shelf life. Custom decoration for SKU differentiation included custom tooling (performed in-house), as well as UV coating and sparkling spray coating, metallization and silk screening.

Maximizing Eco-Responsibility

The eco-friendly, sustainable movement has transcended across the strata of consumer goods manufacturing, with “sub-zero waste” and “plastic-free” emerging as industry-shaping demands. In response, the industry is innovating with solutions that are not only manufactured with Post-Consumer Recycled (PCR) resin but are also mono-material and fully recyclable or even reusable.

“The problem with PCR and dispensers is that some of the components in dispensers such as pistons, accumulators and orifices, have extremely tight tolerances; however there are opportunities in manufacturing closures and the heads of dispensers,” says Bruce Glincman, the North Brunswick, NJ-based global sales director for HK Blossom, which operates out of a UK BRC-certified plant with a staff of 30 degreed, innovation-driven engineers.

He notes that the biggest challenge to manufacturers is finding stable sources of PCR. “PCR also has an added cost over virgin resin; once you make PCR where it becomes less expensive than resin, and have a stable source of PCR supply, manufacturers will embrace using it.”

Aptar Beauty + Home, Crystal Lake, IL, is also committed to the PCR cause, having created a solution that integrates color matching into dispensing closures comprised of qualified, 100% PCR material. The company’s grade and supply of PCR material allows them to maintain high product performance and aesthetic expectations, alongside a color matching process that yields a broad palette of custom and stock color solutions. The company’s Eatontown, NJ, facility additionally offers a broad portfolio of all plastic, recyclable airless solutions with local production for speed to market.

“Being able to produce 100% PCR closures in color with a high degree of color consistency is a major milestone in our sustainability journey,” said David Griffin, vice president of sales, Aptar Beauty + Home. “This unique capability means our customers no longer have to sacrifice brand identity as they work to achieve their sustainability goals.”

Silgan Dispensing, Richmond, VA, was an early adopter of PCR, launching PCR-based dispensing products such as dispensers, trigger sprayers and closures. “For example,” says Brinder Gill, senior manager, global beauty category development, “our SD 200 2CC personal care dispenser is now available with more than 55% of the plastic from the recycle stream, and we have launched closures made with nearly 100% PCR.”

In addition to its work with PCR, Silgan also creates dispensers that enhance the user experience. Its latest innovation is a new version of its Mark VII Max Fine Mist Sprayer called Mark VII Max Style. This new iteration features an improved user-friendly actuator that’s especially suited for products like sun care formulas that require multiple sprays. Its curved profile delivers a soft, friendly look and easy actuation even when fingers are slippery from oil or lotion.

Last year, the company also elevated its Aria cosmetic dispenser with the launch of Aria Luxe, which delivers “expectations of luxury” through sensory cues such as metallic aesthetics, a secure locking mechanism and a comfortable finger groove. Ogee Luxury Organic Skincare selected Aria Luxe for its Seeds of Youth Serum, choosing a shiny gold, fully metallic iteration of the pump.

Environmental responsibility is a movement, not a trend, says Jerry Ruud, a representative of Grateful Packaging LLC, Boonton, NJ, and U.S. sales agent for Wista Packaging of San Paulo, Brazil. “End-users are demanding that packaging companies and consumer product companies take care of our environment.”

Wista focuses on meeting the needs of brands that create clean, natural formulations using the highest possible content of renewable, sugarcane resin-based Green PE in its packaging because its carbon footprint is lower compared to petroleum-based PE.

Last September the company launched Sage, its new airless system that’s patent pending in 156 countries and primarily comprised of Green PE. Ruud bills it as one of the lightest gram-weighted airless systems in the world, and it’s beefy enough to dispense a wide range of viscosities from creams, to foundations, to lip products, to oils and even water and alcohol with precision. “Our range of valves (High Viscosity, Medium Viscosity, Low Viscosity and Super Low Viscosity) can be interchanged within a wide variety of application offerings (head styles and closures) to meet the customers’ requirements,” he says, adding that Wista’s fully vertically integration designs the systems, creates molds and manufactures products all under the same ownership and facility in Sao Paulo.

E-Commerce Reliability

E-commerce is another influencer driving innovation in dispensing solutions. E-commerce sales are projected to exceed $905 billion in the U.S. and $5.8 trillion globally by 2022 (Source: “Global Packaging Trends 2019”, Mintel). Global data also suggests non-store retail is expanding at a faster pace, with an 8% CAGR compared to store-based retailing CAGR of 4% 2012-2017 (Source: “Where consumers shop for beauty and personal care;” Jan.2019, Euromonitor).

Online shopping is certainly convenient, but it places unique rigors on packaging componentry. “Leakage and breakage can lead to a poor consumer experience [and] brands must consider that consumers will relate a poor delivery or opening experience of a product back to the brand,” comments Lisa Petersmark, vice president regional market development, personal care, Aptar Beauty + Home. “As consumers become more mobile, embrace new shopping experiences and online consumption increases, dispensing manufacturers must consider new innovations for portability that can provide secure transit without leakage or damage.”

Aptar has created dispensing solutions that can withstand the rigors of e-commerce delivery to ensure brands are creating a consistent consumer experience whether consumers are taking delivery in store or through e-commerce. The company says their Disc Top GO and Purity e-latch are the first disc top and first tube top (respectively) in the market specifically designed with e-commerce in mind.

“Each of these products features proprietary Aptar technology integrated into the component, which eliminates the need for shrink wrap, tear bands, or additional costs to bag or protect the product in transit,” Petersmark explains. “No more accidental unlocking as our integrated technologies prevent leaking whether you’re throwing the product in your gym bag or packing for your next trip.”

Disc Top GO is a three-piece design meant to appeal to multiple color schemes for maximum on-shelf differentiation. Purity e-latch features soft smooth edges and a sculpted finger recess that adds a modern, elegant look to any package.

As product varieties and formulas continue to expand, the future for dispenser innovation is vibrant and virtually limitless. As RLM’s Murphy aptly surmises, “design never sleeps.”

Ball Aerosol Packaging, Broomfield, CO, has unveiled a new 360° aerosol can shaped to give consumers a better grip while dispensing thanks to an ergonomically-shaped, hourglass design.

“The shaped area can be oriented in a way that provides the consumer with grip, a feature that comes in handy with beauty and personal care products, such as shower and cleansing foams, where slippage is a usability concern,” says Jason Galley, Ball’s global innovations director. “In short, 360° – easy to handle, no mess.”

The can has a 1-in. opening, which accommodates all standard actuators. And since the 360° can is all about custom shaping, the company says an actuator may be designed to complement the 360-degree view.