Joanna Cosgrove, Contributing Editor05.29.19

Economical for brands and ultra-convenient for consumers, cosmetic and personal care tubes are projected to be valued at $2.8 billion by 2022 and represent the largest segment of the global tube packaging industry (Source: Future Market Insights).

Plastic continues to be the most popular tube material and given the ongoing focus on environmental concerns in each facet of the packaging industry, the tube sector continues to find new ways to add layers of eco-responsibility to its products and manufacturing protocols.

In April, Berry Global Group, Inc., Evansville, IN, announced Impact 2025, a sustainability strategy tasked with minimizing and optimizing product impact with 100% of packaging designed with sustainably sourced materials that are reusable, recyclable or compostable. From a performance perspective, the company has committed to reducing its greenhouse gas emissions 25% by 2025, landfill waste by 5% and energy/water consumption by 1% per year. Berry is also working on engaging its partners to end plastic waste and expand and modernize waste infrastructures to increase plastic recovery and prevent plastic loss into the environment.

“Consumers are demanding [sustainable packaging] and brands are looking for solutions which include PCR content, bio resin and recyclability,” comments Berry Plastics’ Rebecca Vara, vice president of sales, personal care. She adds that brands are also ramping up their on-pack messaging to share their sustainability assurances to consumers. “They are beginning to communicate the sustainability and recyclability of the package more so that consumers know what they are buying and how to recycle it.”

Berry recently introduced a tube with up to 100% PCR as part of its Verdant line of packaging. Vara says the laminate tube offers the same functionality and feel of a non-PCR tube, with the same decorating options. “The line includes multiple options of tubes and closures with varying PCR content to help brands reach the PCR percentage that they are looking for–from 34% up to 100%—a good, better, best menu of tubes,” she explains. “In addition to our Verdant tubes we offer a number of decorating options for our laminate and extruded tubes including soft-touch, registered embossing, flexographic printing, hot stamping—and new this year: photochromic tubes that change colors when exposed to light, and holographic tubes.”

Switzerland-based Neopac’s EcoDesign product line was also created to satisfy customer desire for more sustainable packaging materials. EcoDesign products comply with EU legislation requiring minimized environmental impact for packaging solutions and spans three types: recycled, sugar cane and PICEA.

Recycled tubes are made from a body and shoulder mixture containing up to 75% recycled, food-grade compliant polyethylene plastics. “The recycled material contains 50% PCR (post-consumer recycled)–for example, milk bottles from closed loop recycling in Western European countries, and 25% from PIR (post-industrial recycled) material from tube laminate production waste,” says Cornelia Schmid, Neopac’s head of marketing. “Sugarcane is made from renewable raw materials and offers the same characteristics and processability as fossil-based polyethylene.”

PICEA is comprised of unique and 95% renewable material in the tube body and shoulder, including 10% of spruce wood from wood waste in sawmills. PICEA meets Ecocert and Cosmos certification requirements and was recently recognized by PCD’s Sustainability Awards.

Germany-based Biana GmbH selected a silkscreened PICEA tube to house four products: a hand cream, night cream, day cream and body lotion. “Biana’s products are organic and natural, and the responsibly-sourced, sustainable PICEA tube aligned well with the brand’s elevated eco-consciousness,” says Schmid. “The natural look of the tube material supports the brand’s message.”

Optimized Dispensing

An added convenience of tube packaging is the ability to accommodate a variety of dispensing needs, whether it’s a simple, standard squeeze orifice or something that’s a little more complex.

Global Packaging Inc., La Habra, CA, has seen an increase in the inquiries from its customers for different dispensing/applicator options, according to Vinay Upsani, the company’s owner. To meet the demand, the company has extended its product line to offer scrub head, dropper head, roller ball, thick brush head, titanium and zinc alloy, thin bristle head, thick bristle head and vibrating head applicators.

Global Packaging recently supplied a tube with a titanium applicator to skincare brand NuFace for its NuFace FIX Serum, which is billed to be the first “microcurrent skin-care formula” featuring an “ionized formula infused with NuFace’s proprietary Pure Energy blend” to optimize skin.

“When applying this to eyes, lips, and forehead, the use of a cooling applicator provided by us to NuFace enhances the absorption of the serum in the skin,” Upsani says. “The tube is a [half-ounce], five-layer, co-ex sleeve [that] holds the active ingredient very well and provides a perfect barrier. The cooling titanium spot applicator head as shown in the image (left) is the ‘high-end’ applicator that supports the perfect application and absorption of serum.”

The package features one-color offset printing and exudes a high-end look thanks to a shiny silver metallized collar and matching cap.

RLM Group Ltd., Mount Kisco, NY, focuses on creating unique, efficient and cost-effective delivery systems that not only meet customer and consumer demands, but also result in a better overall package, according to Bob Murphy, principle.

“We’ve recently introduced a variety of patented solutions that are generating great interest among some of the leading cosmetic and personal care brands,” he says. “Several of these new offerings allow for the delivery of complementary products in a single package, while others allow for the clean, controlled delivery of low viscosity products from both tubes and bottles.”

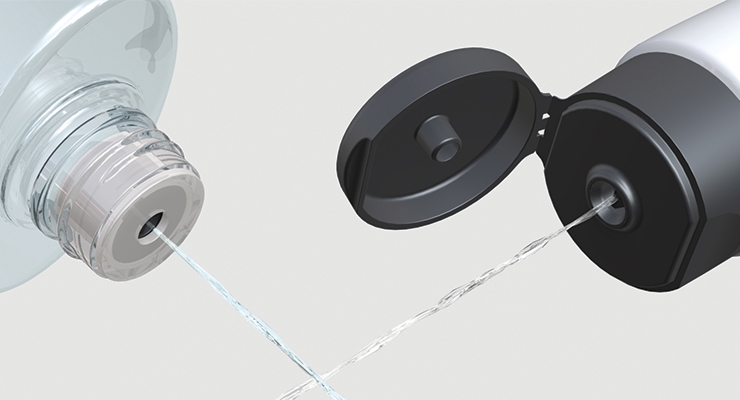

Among the new offerings is the NeatStream Tube (also available in a bottle format). The simple, low-cost system allows for clean, dripless dispensing of low viscosity products in a thin, controllable stream with pinpoint accuracy. The dispensing system is easily changed to accommodate formulas ranging from astringents to liquid makeup. Product flow is controlled by the consumer squeezing the tube (or bottle), and ceases flow immediately when the consumer releases pressure. Murphy says there is no leaking, even if the tube is laid down on its side, and the dispensing head remains clean and clog-free.

RLM Group recently helped two leading (and unnamed) cosmetic brands overcome challenges related to dispensing new products. One of the company’s customers was planning to launch a new product packaged in a tube, but learned that due to the product’s low viscosity, it wasn’t going to dispense properly, Murphy explains. Upon learning that the brand was leaning toward a more expensive package, RLM Group worked with its partners at Shenzhen Beauty Star and others to develop an alternate solution: a new, patented dispensing system that works to control the flow of a product by slowing it down before it reaches the orifice.

“As a result, we were able to provide the brand’s marketing team with an alternate system that enabled them to proceed with their original plan to launch the product in a tube, stay within the original budget, and produce the high-quality package the brand requires,” says Murphy. “Not long after, another leading brand was experiencing a similar challenge with a low-viscosity product they were gearing up to launch. Having heard about how the other brand had solved the same problem, they contacted RLM Group and soon became the second brand to use this new technology.”

Accurate dispensing was also a must-have for Living Proof as it sought a tube configuration for its dry scalp treatment product. The prestige hair care brand turned to WWP, Florham Park, NJ, where it was outfitted with a 100ml PP soft-touch tube capped by a unique dispensing system. “We were challenged to design a luxe tube with a unique delivery system that could dispense non-viscous formulas with pinpoint accuracy,” says James Farley, WWP’s executive vice president of global business. “With internal details to aid in surface tension and an elegant heavy-weight clear cap, this tube is truly one of a kind.”

Deco and Differentiation

A prime benefit of tube packaging is the inherent amount of surface area available for decoration and brand messaging—a true asset when it comes to on-shelf differentiation. Tube providers are continuing to expand the creative options available to brands so they can maximize the opportunity.

Plastube, Granby, QC, Canada, recently installed a new digital press that Steven MacPhail, vice president, sales and marketing, says is especially beneficial to brands with smaller runs. The technology delivers exacting detail and gives Plastube the ability to customize and mix a variety of effects within one production pass. It also prints at speeds 50% faster than the company’s regular offset presses and can change to another artwork without a setup, with a tap of the screen. No change of plates or cleaning inks, so jobs can be turned around in record time.

Crabtree & Evelyn took advantage of this technology to develop their new 12-item hand cream line, Cult Collection. “Each tube has a combination of a portrait-like theme and an all-over color printed to the shoulder,” MacPhail says, noting that in traditional offset print the color separation and detail required could not be achieved. “Now with these precise, pinpoint droplets of digital ink we can achieve both without affecting the colors…running at 800 dpi, which provides much greater detail than an offset at much lesser resolution.”

Crabtree & Evelyn also benefited from Plastube’s ability to print a number of color variations for each tube so that they could approve color matches, enabling Plastube to run the tube off the press within minutes. “In the past, this process of pre-press approval and moving ink colors could have taken several hours to days,” MacPhail explains. “Now we were able to achieve press-ready tubes within a few hours for twelve individual packages.”

To finish off the full effect the brand sought for their tubes, Plastube added a silkscreen varnish lay-down combined with a gold metallic ink highlight.

Flexibly serving small run customers is also on the radar for Pack-Tubes, The Woodlands, TX. Adrian Ayala, vice president sales and marketing, reports Pack-Tubes has developed the ability to manufacture custom-made laminated and plastic tubes in small batches of 300 units per design for a fully refundable flat fee against a 10k purchase order down the road. “We have recognized the need for Indie beauty brands to get custom-made tubes to launch their formulas on a small scale including startup under e-commerce platforms,” he says, adding that one of Pack-Tubes’ latest tube solutions is a high-barrier, luxury finish tube with an airless pump dispensing device. “We are offering 320 micron, MPET stiff material for a rigid laminated wall structure fully decorated over a mirror material to the beauty and personal care markets.”

The use of texture can play a distinctively tangible role in tube decorating. Viva IML Tubes, Toronto, recently launched a new velvet premium soft-touch texture tube that offers a premium feel with anti-scuff, dust-resistant and fingerprint-resistant properties.

The company worked with Unwash to develop a tube package for its latest hair conditioner. According to Bruno Lebeault, Viva’s marketing director, Americas, the final configuration is a 100% PP, D38.5 mm diameter tube. The tube’s predominantly white base color served as an understated canvas for the velvet soft-touch effect and earned Viva the 2018 Tube Council North America Best Personal Care Tube-Silver Award.

A final method of tube differentiation other than on-pack decoration is closure choice, and the options are ever-expanding.

“We do see market saturation for regular tubes with flip-top caps, especially in mass-market,” says Maria Eaton, senior account executive, Berlin Packaging, Chicago, IL. Among Berlin’s offerings are heavy acrylic caps and metallized twist-open caps. “Our prestige brand customers want to stand apart by offering tubes that create a luxurious experience for their consumers.”

Berlin helped Image Skincare select the perfect closures for the brand’s various tube packages. The pricing of their product offering ranges from a fair entry price to a premium price, depending on the system,” Eaton says. “For most of their tubes, we streamline the sizes and specs for SKU rationalization, but we modify closures or create stand-alone tubes for specific systems.”

Some of the tube and closure pairings Image Skincare chose include a silver polyfoil tube with silkscreen and hot stamp plus an acrylic twist off cap for Max Neck Lift; a glossy HDPE tube with silkscreen and hot stamp plus vacuum metallized twist open/close center dispensing cap for Vital C Water Burst; and a glossy HDPE tube with silkscreen and hot stamp plus double-walled, twist-off cap for its I Mask Firming Transformation Mask product.