Joanna Cosgrove, Contributing Editor11.04.20

Investing in a full suite of packaging can be an expensive gamble for Indie brands just entering the beauty scene. Even with a clear market vision and solid planning, high minimum order quantity packaging thresholds can make or break a fledgling company, especially if they’re in search of packaging with a bespoke aesthetic. It’s a similar situation for global brands. Limited launches and seasonal promotions warrant a cost-effective option that can be customized for maximum impact. Low minimum order quantity (MOQ) packaging sold in quantities ranging from 10 to 10,000 pieces is the solution to fill these shared niches, with an emphasis on being budget-friendly, quickly available, and flexibly customizable.

“ ‘Let’s start a cosmetic, fragrance, or personal-care brand, and buy a truckload of components right from the start,’ said no one,” jokes Mike Warford, national sales manager, ABA Packaging Corp. “The established global brands didn’t start their businesses by buying a truckload of packaging components; they were once emerging brands, too, and low MOQs with affordable price points for primary packaging components contributed to their successes.”

ABA Packaging maintains large shelf-stock inventories of packaging components that are critical for new brands and can provide custom decorating at low MOQs, including screen and hot-stamp printing, spray color and frost coatings, and custom label manufacturing and applications. In addition to the componentry, the company also provides guidance. “We understand that start-up brands need more support due to a lack of expertise and we’re here to help them as we have done for many of the large global brands before them,” Warford says.

As with most things, buying packaging in bulk is typically the best way to get a better price—and it’s usually not an option for start-ups. Warford says Indie brands and entrepreneurs often convey their frustration with trying to get reasonably priced, high-quality primary packaging components in small quantities. “It is a fact of life that high-quantity purchases generally yield better service and lower pricing,” he comments. “We’ve worked to purchase our shelf-stock packaging products in volume, and we are able to pass some of those savings on to our small customers to aid them in finding reasonably priced packaging components.”

For decorated glass bottles and jars, Warford says a purchase in the neighborhood of about 5,000 pieces seems to be the best economical starting point. ABA’s plastic bottles and tubes are generally manufactured in custom colors so MOQs and lead-times for those tend to be higher. “Depending on the item, a 10,000- to 20,000-piece MOQ for a custom in-mold colored decorated plastic bottle or jar is not unusual,” he says. “Aluminum bottles and cans are at about the same MOQ for highly decorated items—we can decorate in quantities under 5,000, however the economics are affected adversely by larger set-up costs.”

SamHwa USA maintains a broad selection of luxury and innovative low MOQ products—such as their new 15- and 30ml glass refillable airless bottles, 2-in-1 twist ampoule and 100% sustainable PCR 15- and 30ml airless bottles—because it’s an important component of cultivating relationships with brands both big and small. For example, one of SamHwa’s brand partners, AHC, started as a small company with a primary focus on the cushion compact segment. “They knew the large market potential of the cushion market in Korea and decided to launch…with a low MOQ quantity,” says Vince McCarthy, U.S. sales director, SamHwa USA, who adds that they partnered with SamHwa because as a Korea-based company, SamHwa has a distinctive, first-hand advantage in the cushion compacts sector. “On the success of that initial low MOQ compact project, they expanded their brand investment and SKUs and got noticed by and finally acquired by Unilever.”

Indie brands in particular are outstanding at recognizing industry trends and being nimble enough to leverage nuances in a changing beauty landscape. Cost is an especially critical driver in low MOQ packaging. “The balance between minimizing investment risk and maximizing marketing effect continues to change,” comments McCarthy. “As companies are able to find non-traditional marketing channels, the barriers to bringing a new product to market is lowered through a new marketing tool called SNS, which creates an opportunity to launch a brand at a lower cost.”

Changes in the distribution structure are also levying a lot of influence, which is evident right now in the wake of the pandemic. “Large retailing, selling and fulfillment need has arisen as the retail market declines and the online market opportunity increases,” McCarthy says. “E-commerce channels have given many Indies the opportunity to enter the market with a small quantity. One or two small successes online become noticeable by distributors, and these Indies can find themselves absorbed into the distribution structure of larger retail brands such as Sephora and Ulta, which is the foundation for a successful brand launch.”

On-Demand Innovation

Low MOQs allow for flexibility and speed to market but also optimize business by keeping low inventory.

“One would think that the higher price point would be the downside of it but that is usually not an issue for our customers because this also entails cost savings in other places such as warehousing, inventory, etcetera,” says Gilda Mirra Cutri, vice president of operations & business development, Coverpla Inc.

Coverpla supplies primary components for fragrance and skin care packaging with an MOQ threshold ranging from 1,000 to 2,500 pieces, depending on its inventory. New to the company’s low MOQ inventory lineup is a selection of zamac caps as well as a new array of packaging called Ecoline available in sizes ranging from 15ml all the way up to 100ml.

As reported in Beauty Packaging earlier this year, Coverpla has partnered with Luigi Bormioli on the development of the Ecoline range with the goal of reducing packaging weight and developing rechargeable, sustainable solutions that are easy to recycle.

Comprised of two bottles (50- and 100ml) and two jars called Ecojars (30- and 50ml), Ecoline delivers a 40% reduction in weight compared with the 100g of glass used for a classic 100ml bottle, for example. This sustainable approach allows an average 60% reduction in carbon dioxide emissions across the supply chain (compared with plastic or blown or pressed glass).

The Ecojars’ “CV15” neck makes them compatible with a standard screw pump solution. This specificity allows brands to perform their own filling operations and offer products that are rechargeable and 100% recyclable (because each individual part can be separated for recycling). Coverpla has also designed a specific trim for the standard pump that can be matched with any of the caps in its catalog.

At Madeline Blondman, the standard MOQ is 5,000 pieces—a number the company’s president, Randi Barron, says gives smaller brands the opportunity to have an upscale looking packaging with a smaller investment. “Our products occupy a small but necessary niche in packaging,” she says. “We offer the same low MOQ to our new customers as well as our biggest ones.”

With an average lead time of four weeks, Madeline Blondman tries to offer multiple material options so brands make choices based both on the appearance they’re looking for and on the compatibility with their products. The company also works to keep its tooling cost low. “If a small brand wants a prestige look, they can add the logo—the piece price remains the same with or without the logo, regardless of quantity,” Barron comments. “If we are creating a new logo tool, the lead time may be a bit longer for the first order [because] the logo tooling needs to be created, sampled, and approved before the new item is entered into the production schedule.”

Customizable Stock

“Stock” packaging doesn’t have to look boring or cookie cutter.

The daily challenge for Baralan, according to Robert Lopez, the company’s key account manager, is to provide high-quality stock products that conform and satisfy the ever-increasing needs for quickly personalized packaging. “Baralan’s stock inventory management on glass and accessories is studied to reduce the time-to-market, guarantee timely re-orders and allow customer requests to be adequately satisfied following market trends and unpredictable forecasts,” Lopez says, adding that Baralan’s inventory management approach allows global customers to launch smaller volumes or also limited edition promos with high-quality standards, providing flexibility especially for startups to launch their products into the market with less capital investment.

Baralan recently worked with Erin’s Faces on packaging for its five-shade range of Radiant Firming Concealer. The brand selected Baralan’s iconic and sophisticated, Claudette 8 SW glass bottle, which is characterized by a long, cylindrical shape. The set is completed with accessories including a doe foot applicator, wiper and Kura 13 white, smooth, polypropylene overcap. The MOQ threshold amount for each item was 5,000 pieces.

Lopez says his client sought a packaging solution that was both innovative and sustainable. “They were intrigued by our Claudette 8 SW glass and its versatility to be used as a skin care product,” he says. “We were able to partner with a decorator to provide low MOQ silk screening decoration for multiple SKUs with glossy white ink decoration.”

To keep its low MOQ offerings fresh, each year Baralan expands its collection to include a new standard product line, such as the latest Aphrodite line comprised of cylindrical glass bottles that emphasize “authentic beauty” and “traditional and modern elegance.” Available in four different sizes and two different neck styles (crimp and screw), the line is compatible with many accessories.

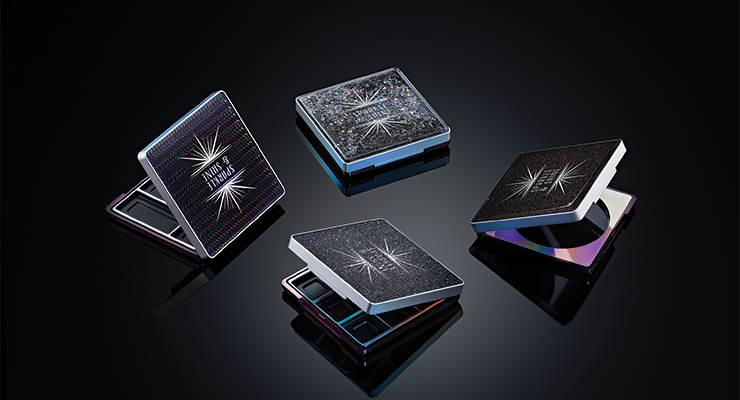

HCP Packaging focuses on the flexibility of its cohesively designed collection of stock packaging to appeal to a spectrum of needs. “For brands looking for smaller MOQs, stock packaging is an ideal solution—especially when time and budget constraints don’t stretch to custom designs,” comments Cheryl Morgan, creative marketing manager, HCP Packaging. “As well as requirements for low MOQs, both speed-to-market and budget are pivotal to brands choosing stock packaging; larger global brands have to react quickly to the accelerated market trends created by more nimble start-ups whilst smaller independent brands, in turn, cannot necessarily afford the tooling investment for custom packaging and need the more accessible MOQs and flexibility that stock packaging offers.”

Morgan says HCP has invested significantly in contemporary stock packaging designs and on-trend decoration options, which she says is a key part of HCP’s solution for low MOQ requests.

The company can quickly deliver deco aesthetics ranging from modern simplicity to extensively customized. “Indie brands are requesting quicker speed to market and also more unusual decoration to really stand out,” Morgan explains. “They are also driven by personalization and inclusivity as they are so engaged with their customer base and need products, and packaging, that reflect this.”

One option for low MOQ differentiation is digital printing, which is ideal for speed-to-market and artwork sampling and delivers highly detailed, full color designs, and can be elevated with various sprays. “Digital printing offers lower origination costs than the heat transfer labels that are often used for designs with a high level of detail and requiring four-color/CMYK printing,” Morgan explains. “For an extra special touch to give sparkle to lower production runs for compacts, glitter or shimmer screen prints can be applied beneath a clear molded dome or diamond.”

Top plate decoration is another way to add a custom touch to stock compacts and palettes. A breadth of decorative materials including textiles, printed paper, gel, and molded designs in different resins can be combined with artwork, foil and heat transfer labels to create a uniquely bespoke look.

Stocksmetic, the exclusive distributor of Premi spa for custom packaging in small quantities, was founded on the premise of offering high-quality, refined, “Made in Italy” packaging for cosmetic products, fragrances and makeup with a low MOQ that is generally around 50-100 pieces.

Federico Prestini, Stocksmetic’s managing director, said brands ranging from start-ups to multinationals can buy packaging in small and large quantities, starting from one box up to the quantity available in stock. The company has also streamlined the package creation process via its website. “[It’s] easy and requires a few simple steps: just select the bottle or jars best suited to your beauty line and match it with the available accessories by choosing among droppers, cream and spray pumps and more,” he says.

Customizing a package can be achieved with logos and graphics using Stocksmetic’s boxes, labels and a new screen printing service. “This kind of printing can be made on plastic and glass bottles and jars, in 14 different glossy shades, and three metallic ones—silver gold and bronze—starting from a minimum of 200 pieces,” he says. “The screen printing service gives the opportunity to our customers to create a highest level cosmetic line.”

For Plastube, the mission is to “Be the partner of choice for fillers and manufacturers of products packaged in tubes for small to medium size runs.” As such the company prides itself on being able to provide low MOQs through its Fast Pack program. According to Stephane Beauchemin, the company’s vice president of sales and marketing, the program enables brands to place orders with a minimum set at $2,500. “Low MOQ & four to six week delivery program is available when selecting tubes from our in-stock tube program, that includes a wide range of pre-extruded tubes in a variety of sizes and tube types such as White Coex (PE or 45% PCR) and Natural Illumifoil,” he says.

One of Plastube’s most recent brand partnerships was with Davincia, which sought a low MOQ packaging solution for its cosmetical sunscreen and face cream products. The brand ultimately selected digitally printed white coex tubes. The MOQ was 3,000 and Davincia chose nine different vessels in three different diameters. Beauchemin says the production supported the brand’s product launch and delivered on a tight timeline.