Jamie Matusow, Editor-in-Chief12.07.22

At the 34th edition of Luxe Pack Monaco, the prevailing message was clear: Sustainable innovation was top of mind among the 450 exhibitors and the 9,430 visitors—up 20% compared to 2021 and 5% compared to 2019.

The majority of those in attendance at the creative packaging show represented the premium cosmetics category, and all were excited to be in Monaco and pursuing beauty brand partnerships.

See the slider above for photos from the show—and the following first-hand report, live from the show, along with insights from the beauty packaging suppliers we visited.

Live from Luxe Pack Monaco 2022: Show Report

While talk of energy crises, raw material costs, inflation and difficult supply chains frequently entered the conversation, the crowd at Monaco's Grimaldi Center was generally upbeat about the future.As the pressure mounts with the approach of sustainable packaging mandates, suppliers are focusing on revamping their solutions. Top on the list for many suppliers I spoke with included e-commerce ready packaging; recyclable-ready packaging, refillables, easy disassembly—and regional manufacturing to ease supply chain issues.

As usual, many attendees were looking to further educate themselves on packaging options in the premium industry. Fabienne Germond, director of Luxe Pack Monaco, said the annual trade show “is an exceptional network that boosts partner relationships between exhibitors and brands. She said, “Luxe Pack’s role is also to provide an informed perspective on the innovations and developments of all materials in terms of eco-responsibility, since this issue is at the heart of the strategy of all suppliers and principals, regardless of the industry sector.”

Glass Packaging

Glass is one material that continues to gain brand support (despite current energy woes), and is always an important contingent of Luxe Pack Monaco offerings. This year was no exception with packaging offerings from fragrance to cosmetics and haircare.Here, too, additional strides have been made in what is considered by many to be the most sustainable material. There was a noticeable increase in large size bottles for glass—even for shower use. Glass airless also stood out as a popular option.

Glass Airless Packaging

Innovation at Baralan revolved around sustainability. In its new ecological materials collection, the Italian company is using organic scraps from coffee and rice to manufacture caps. Luca Maggio, area manager, Central and Eastern Europe at Baralan also showed Beauty Packaging their easy-to-disassemble airless system in glass, which he said is “the biggest innovation of 2022.”Everything can be recycled other than the pump. Unlike other airless systems, Maggio said Baralan’s airless packaging has no internal plastic container, making it the first airless system in which the filled product is directly in contact with its glass container.

Berlin Packaging/Premi Industries was showcasing a new version of their glass airless jar, which features a frontal irrigation instead of a top shot. Available in 30- and 50ml, it is also refillable. The consumer can easily change the plastic tub inside with up to 20 refills, which maximizes the use of the pump. The airless bottle can be easily separated with the engine being the only thing that has to go in the trash.

With foamers growing in popularity, as they require less water, Andrea Ucchino, design and marketing manager of Berlin Packaging, showed Beauty Packaging “the first premium foamer bottle in the market, in glass,” which can be used for premium hair and body care products. It can be refilled from an attractive flexible package or aluminum, sugarcane or PCR/PP bottle. Premi is also entering more into the Home/Wellness categories with products such as diffusers and “on-shelf” beauty items—for “works of art in the bathroom.”

According to Emanuele Mazzei, chief executive officer & executive vice president of global business at Lumson USA, the Italian-based company is the “original glass airless pioneer,” and is now bringing new luxury to airless, expanding their core business with the intro of “super-luxury glass airless.” To this end, he said Luxe Pack was the ideal event to start proposing a new super-luxury evolution of Tag airless, shaped in two new designs (round and square) where the thickness of the glass bottle enhances the beauty of the product.

In addition, Lumson’s rechargeable glass jars and “the ultimate XPAPER, airless paper packaging,” really caught the attention of many visitors. Mazzei says these products are sustainable through both the materials and the concept of packaging itself. “We think of the product from the end-user perspective,” he explained.

Glass Packaging for Fragrance and Skincare

There's a trend toward 'glassification.' One supplier, Coverpla, showcased a wide range of glass bottles, jars and caps for fragrance and skincare—also adding larger sizes including the recently developed 100ml Firenze bottle. Coverpla's SONI and GALA ranges have new additions: 50ml for SONI and 100ml screw neck CV15 for GALA 100ml. The 100ml is offered with a screw neck for easy disassembly.Bruno Diepois, president of Coverpla, told Beauty Packaging they had also developed and produced two new zamac caps internally: Jules and Jim. The Wally cap, developed for LPM, features a Surlyn insert and an aluminum outer. A variety of wood caps, including small screw-ons, were also among the supplier's new products.

As always, Bormioli Luigi displayed beautiful fragrance bottles from recent European and U.S. launches. On display from the U.S. were some striking new custom tooled bottles. Most notable was the limited-edition custom Victoria’s Secret Bombshell Celebration featuring a wavy in-mold embossing. The Italian-based glassmaker is now producing larger sizes in 100- and 250ml—in classic and square shapes for full body lines. They also now do safe-coating so the glass is shatterproof.

Another more sobering conversation with Jennifer Duffy, VP of sales and Stephanie White, sales manager—both of Bormioli USA Perfumery Division—revolved around the rising cost of energy and extended lead-times as there is a surge in consumer demand which is saturating their capacity. Bormioli is working to free some capacity by utilizing their plant in Spain, where some new machinery is set to arrive in 2023.

B.I. Industrial was highlighting its new “super modern” glass factory in China, described as the largest, most modern quality factory in the world. They are in fact building their own entire industrial park to offer full glass services, including deco, galvanization, fire and hand polishing, injection molding for plastic caps and more. Production is estimated at 200 million glass bottles a year—“and with a 6-week delivery time, as China has no energy problems,” according to B.I.’s European representative Jorg Schmacher.

Glass and Metal for Fragrance

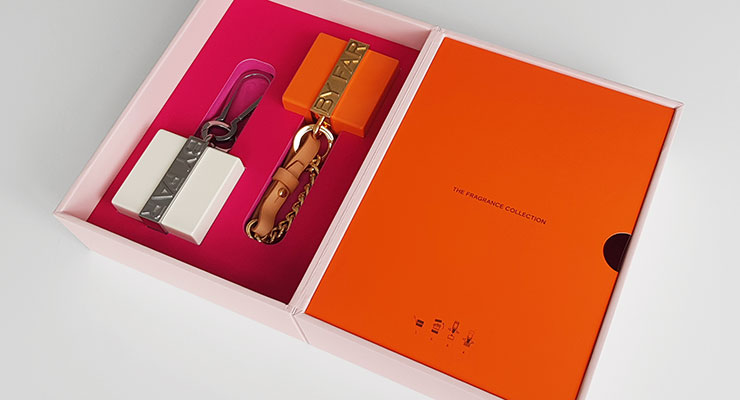

At TNT Global Manufacturing, Boris Schaefer showed Beauty Packaging one of their newest and striking fragrance packaging projects, for which they also produced the show-stopping limited edition promotional package as well, through TNT Promo.Schaefer says the By Far Daydream refillable Eau de Parfum collection is comprised of two sprayed aluminum shells and a zamac collar on the bottle. There is also an embossed logo.

Schaefer explained that the POK collar liner and the POK base shell liner were essential to ensure the hold of the bottle, which Vogue featured as a fashionable travelling accessory. The fragrance package contains a clip so the consumer can attach it to a purse. The liner of the weighted cap shell is in PP. A stainless steel key allows the opening of the body shell to replace the bottle or for a new personalization.

For customization, the body shells and caps are available in 6 colors and the collar in 2 finishes: gold coating and shiny white bronze galvanization + varnish. According to Schaefer, the 4 elements are delivered separately “for great flexibility in packaging supply management.”

The Paris-based SGD Pharma division, based in China and focused on its Beauty and Care division, participated in Luxe Pack Monaco for the first time in this year’s edition. The Beauty division of SGD Pharma is a leader for premium glass packaging for cosmetics in the APAC zone. Sheherazade Chamlou, vice president of sales, Beauty Americas, based in New York, explained that the company has served the Asia Pacific market for more than 20 years via its state-of-the art facility in Zhanjiang, China, and is now investing in growing its sales in the U.S.

SGD Pharma applies its “French know-how” to stock and custom designs for both pharma and cosmetic markets. The company offers creative R&D with a wide range of innovative decoration techniques. For instance, SGD Pharma’s “Constellations” range of stock glass cosmetic packaging is available to brands globally in multiple shapes and suitable for a variety of beauty products, including skincare and nutraceuticals.

Chamlou pointed to the introduction of one of their latest beauty innovations—the new Eclipse refillable glass jar solution—as the company’s pioneering sustainable glass packaging product aimed at the global cosmetics and beauty market. It is based on the success of the range in APAC markets where it is designed and manufactured.

The unique product consists of a glass jar, replaceable inner cup, and cap lid. Ideal for use in skincare, the Eclipse glass jar and lid consists of a unique patented twist-and-lock system. Eclipse is available as a one-piece packaging solution for brands, “offering consumers an effortless replacement and recycling experience while playing its part to minimize environmental impact.” According to Chamlou, the clean facility in Zhanjiang is increasing its beauty capacity to serve its clients worldwide.

Metal Packaging

Envases, based in Spain—and distributed exclusively in the U.S. by ABA Packaging—offered a wide range of aluminum packaging, which continues to grow in appeal due both to its sustainability and attractive appearance.Endika Albinarrate, sales manager of Envases, told Beauty Packaging that they had invested in inline hot stamping and silkscreen printing, and are the first aluminum manufacturer to do both in-house. Spot varnish can be used for haptic effects, logos can be in relief and Braille print is also offered.

New shapes include an extra flat effect on the shoulder, “so it can mimic plastic and glass bottles.” Albinarrate told Beauty Packaging that in addition to end-products, refills in aluminum are also getting very popular, not only in skincare and fragrance, but also in liquors & spirits.

Metals and More

Metal packaging shone at applicator specialist Cosmogen, with innovation in metal 3D printing for applicator tips. Priscille Allais-Caucé, CEO, Cosmogen told Beauty Packaging, this capability “mixes technical innovation with consumer innovation”—as “it can be any shape you want.” It holds a reservoir of formulation so even after wiping the applicator, there’s some left so you can dispense or smooth on lip or face.Allais-Caucé described the 3D metal printing as a “breakthrough,” saying that a brand can now customize anything without additional cost. Development is still in the concept stage. They have also found ways to remove the amount of plastic used in the applicators, and to replace it with glass (stem and tube).

Different textures of tips allow for the feel of the product on skin; dual-purpose tips allow you to smooth and scrub with the same tip. Brands can also now add their logo to the sustainable, rechargeable tips. Allais-Caucé also mentioned that the company “takes sustainability for granted from development and design on.”

Advances in Cosmogen technology now allow for precise aluminum tips to be produced with a gold finish, for an even more premium look. In addition, they are removable and rechargeable.

Dropper Packaging

At dropper specialist Virospack, the unsteady state of the industry was also under discussion, although the team noted that conditions are better in Spain than in other countries. While Spain has less energy woes, Joanna Milne, Virospack's key account manager, told Beauty Packaging that “metal lead times are running 40 weeks—and some suppliers have 2023 booked for metal availability.”A few components for anodization come from Ukraine and Eastern Europe. Virospack has the capabilities to replace metals with metallization, painting and deco. They are also using plasma rather than gas flaming in some processes. Still, the team says, “Sustainability is a complex issue and affects everything from design to marketing.”

Mixed-Materials

“With such a rapidly changing packaging landscape, including soon-to-be-banned ABS in Europe,” Denis Maurin, global president of sales and innovation, HCT by kdc/one, told Beauty Packaging, “Brands and suppliers must adapt quickly.”Maurin explained some of the global supplier’s latest innovations in sustainable packaging options. A mascara in a glass bottle can be cleaned, the stem can be removed and the aluminum cap can be recycled. HCT by kdc/one is also engaging in a partnership with Pumpart and distributing Tubeasy—a tube with a pouch—so that it works as an airless system—a tube without a pump, and with easy evacuation. The pack is also mono-material PE, making it technically recyclable, and has a 98% evacuation rate.”

At ShyaHsin, the emphasis was on developing custom tools “to create vision,” according to Phillip Cho, global vice president-global key account management. The cosmetic industry supplier, which offers design services as well as packaging, is considered the go-to source in China, said Cho. Owned by Blackstone, ShyaHsin is becoming more regional globally. Cho says they also do turnkey manufacturing and have partnered with some formulators that work with their applicators. The company’s ultimate goal, says Cho “is to help customers find the right solution.” Jenny Staab, global director of design & development, ShyaHsin, told Beauty Packaging that they are seeing lots of growth in the brow category.

Cheryl Bisset, senior VP, sales NA, told Beauty Packaging HCP is focusing on sustainable packaging, including the launch of a fully aluminum mono-material lipstick.

The design of HCP's the Harmony Luxe Lipstick allows the pack to be placed into single-stream recycling and also offers the opportunity to use recycled aluminum for outer parts. The aluminum can be anodized in a wide range of colors or decorated with embossed, debossed designs. HCP has also recently launched beautiful refillable trimline lipsticks in both round and square shapes.

As part of HCP’s growing skincare portfolio, the Affinity Airless Pump is offered as a full pack solution with bottles or tubes, and is ideal for “a premium experience.” This pump system enables 360-degree application, fast priming and controlled dosing for an enhanced user-experience. The patented disc-valve engine upgrades the dispensing performance for highly viscous formulas.

These airless packs are easily portable and convenient for use on-the-go. Tubes or bottles can be molded opaque, tinted or transparent for effective shade ID, and can be customized with HCP’s extensive decoration options.

The focus at Quadpack was on “completely restructuring their entire product line for sustainability.” Isabelle de Maistre, head of Quadpack’s Perfumery Division, highlighted recyclables and refillable mono-material plant sticks with PCR content, mono-material lip products with four different heads—and more.

“We’re trying to tick all the boxes for brands.” Still, she says, “Brand education is key as far as the two main focuses of recyclability and refillability.” The supplier has also enlarged its range of Woodacity components, now with refillable wood caps without plastic liners inside, and expanded key product lines. According to de Maistre, “Brands are buying and making sure every single component is in line with the [sustainability] message, not just the formula.”

At Albéa, Sonia Huneau, communications manager, told Beauty Packaging that they are moving towards the Ellen Macarthur Foundation’s goal of 2025, when all products will be 100% refillable, reusable or recyclable.

On top of these goals, the global packaging supplier is “continuously reducing the amount of virgin plastic used” including PCRs, reducing mono-materials and expanding paper-based solutions. It is also moving towards a 50% paper bottle. The paper in the bottle is now available in white and kraft, and can include an enhanced decoration. Albéa also offers easy-fill jars, in which the inside is simply inserted or removed. A complete PP powder container, very thin and light, without metal hinges, is available in one piece. It is refillable and recyclable. However, one problem persists on the road to 2025, says Huneau: “We need standards.”

The Bakic Group, a second-generation family-run German business with global reach, offers standard packaging and a wide range of customer-specific solutions many of which are manufactured in-house. They offered a number of interesting packages at Luxe Pack Monaco.

For instance, the Naomi Mesh powder compact has a conical shape and reflects “premium quality and high-end class at the same time.” The loose powder compacts are available with an innovative mesh sifter system that precisely doses the perfect amount of loose powder. This mesh can be combined with a custom structured silicone layer that adds unique designs to the sifter structure.

Bakic calls its Sophia Reuse Jar “an evolution in sustainability and usability,” and says it is one of a kind because “it not only offers a rechargeable cartridge after the product has been used, but gives the convenience that the cap of the cartridge can be replaced as well.” All components can be decorated and varnished extensively.

Mono-Material Packaging

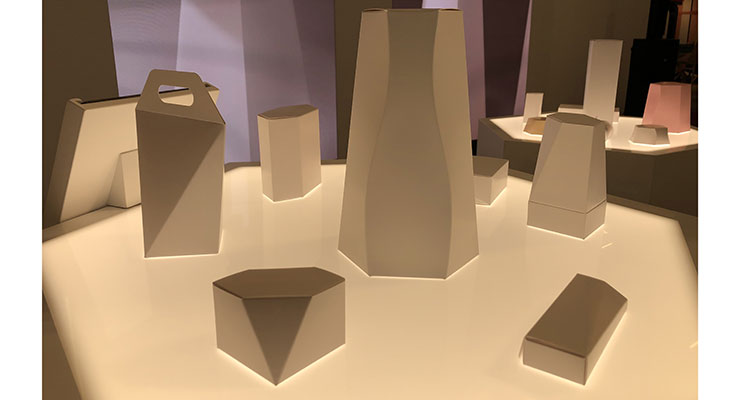

Cloud Beauty, based in Taiwan, offered innovative sustainable solutions for mono-material packaging—upcycled oyster shells and upcycled eggshells, calling the new material “ecocalcium.” Peter Wu, Cloud Beauty, told Beauty Packaging that the eco-material reduces 30-50% plastic. In addition to providing customers with the material, they also arrange marketing. Wu said he works with many suppliers around the world.Paper and Board

At Luxe Pack Monaco, the 100-year-old, third-generation folding carton company, Arkay, once again shared a booth with their European partner, Model Group, a 2022 EcoVadis Gold-awarded family-owned carton company based in Switzerland. Mitchell Kaneff, Arkay’s CEO, discussed some of their latest technologies with Beauty Packaging, while exhibiting carton samples they had produced for several brands including Estée Lauder, Elizabeth Arden, NEST, and Necessaire.One ongoing trend Kaneff noted was to display a visual on the carton of the product within, which served to relay the integrity of the brand to the consumer.

Kaneff mentioned that Arkay is providing customers with what they need – despite inflation, the increase in materials costs, supply chain delays, and the fact that many printing plates are made in Ukraine – due to having anticipated these issues and “beefed up our new materials inventory,” including Envy boards.

Kaneff added that Arkay was also utilizing new technology, which will detect any production flaws in the company’s continual effort to get to zero defects. “Ultimately,” said Kaneff, “We want to focus on partner innovation and early collaboration to ensure a smooth process and a beautiful and creative end-product.”

Daniella Kohler, brand owner manager, BillerudKorsnäs, shared the exciting news that the Swedish-based paper company would soon re-launch as Billerud, incorporating all global divisions under one name. In addition, the company will soon become a domestic supplier due to its recent acquisition of Verso Corp, a leading U.S. coated paper supplier with facilities in northern Michigan. According to Kohler, Billerud strives to increase their domestic footprint and strategic growth plan, “as their cartonboard is lighter, stronger and 100% recyclable.” Production in the Michigan facilities will begin in 2025.

Recyclable Plastics

At Berry Global, the supplier’s Recyclable 2cc Dispenser, was front and center. The new lock-up dispenser is “recyclable, suitable for e-commerce applications and can handle products with all types of viscosities.”According to global product management leader Jonathan Pitt, Berry Global is one of the first packaging manufacturers to develop a recyclable lock-up 2cc dispenser. The new Berry Wave2cc, a product of the company’s B Circular range, meets market demands for a more sustainable version of the pump format that is used for personal care products including liquid soaps, body lotions, shampoos and conditioners.

The 2cc size is the first launch in Berry’s new all-plastic, fully recyclable Wave dispenser platform, with 3cc, 4cc and 0.25ml versions to be launched in the future. Pitt says the company expects to invest over $100 million in the coming years in manufacturing capabilities throughout its global operations in order to provide localized supply “to meet the identified demand from both national and international customers.”

The Berry Wave2cc has earned a RecyClass A rating when paired with a PET bottle. Thanks to its 100% polyolefin composition and no metal parts, it is fully recyclable where appropriate facilities exist. The dispenser solution will be available containing up to 50% FDA approved post-consumer recycled (PCR) material through Berry Global’s CleanStream recycling technology. In addition, the Wave2cc features an innovative lightweight design utilizing only eight components, in contrast to the 12-14 components typically used in similar dispenser solutions.

Looking Ahead

As always, Luxe Pack Monaco was a comprehensive capsule of the latest creative packaging in the global cosmetics and fragrance industry—especially with the event’s longstanding commitment to sustainability. Even the Grimaldi Center, itself, is a “green building.” Access the full visitor report at Luxe Pack Monaco's website.The next Luxe Pack will be held February 16-17 in Los Angeles, CA; co-located with MakeUp in LosAngeles.